Hydraulic press: operating principle and purpose

A hydraulic press is a tool that is designed for processing materials and various parts under pressure. The equipment is driven by liquid under high pressure.

The hydraulic press is based on Pascal's law. The device has two cylinders or chambers. In one, smaller one, the liquid is brought to a state of high pressure and transferred through a special channel or pipeline into a large working chamber, in which the incoming liquid forms a force on the piston and is transferred to the workpiece using an actuator. An important condition for operating the press is the installation of a stop , which does not allow the workpiece or part to move under the action of the working piston. Various oils are used as liquids.

As a rule, in modern industrial hydraulic presses the location of the working chamber is usually vertical , but it can also be horizontal. Taking into account its purpose and the type of materials being processed, this device develops forces from tens to thousands of tons of pressure. The press is often used in metalworking for forging, stamping, bending and straightening, extruding pipes and profiles, as well as for packaging, briquetting, pressing of various materials, manufacturing wood chips, plastic, rubber products and in many other fields of activity.

Why is a press needed in a home workshop?

At home, a low-power hydraulic press can be an indispensable assistant during car repairs and other types of work.

To press out a silent block or bearing and press a new one in its place, you do not need to turn to a car service for help and pay a lot of money. Using a press, you can make straightening with your own hands, bend a metal blank, firmly glue two parts together under pressure, compress cans, plastic bottles, cardboard or paper, squeeze out moisture or oil. Purchasing a factory-made press will cost a considerable amount. But you can make this tool yourself , spending only on the required materials. Moreover, it is possible to make a device that is adapted and adapted to specific needs, taking into account the necessary tasks. Since a homemade hydraulic press will in any case need a certain place, if you don’t have a workshop, you can install it in the garage.

Results

In this article, I demonstrated both simple and complex exercises for the abdominal muscles, most of which even beginners can perform. These exercises are more than enough to work on your stomach. You can include them in your training program and perform them both before training as a warm-up and at the end. I recommend doing abdominal exercises when you work on the upper muscle groups (chest, back, arms, shoulders). When doing legs, you don’t have to put any stress on your stomach.

A detailed analysis of the functions of the abdominal muscles and its biomechanics makes training the abdominal muscles clear and technical. There are many abdominal exercises besides those given in this article. By understanding how the abdominal muscles work, you can choose exercises of varying difficulty to suit your physical level. That is why in this article I analyzed the anatomical role of the abdominal muscles and their biomechanics in as much detail as possible. Add a few exercises to your workout routine, and don't be afraid to switch them up and move on to more challenging exercises. Do everything technically!

Remember that the abs work when performing heavy compound exercises. This is why it is important to train comprehensively, developing large muscle groups and adding abs to them - not the other way around! Otherwise, you are unlikely to have strong, defined abs. Also don't forget about genetics. Some people may initially have 8 raised cubes, while others may have 4 barely visible ones. But this does not mean that you should give up and not work on your stomach!

And finally, without getting rid of the fat layer, the attractive “abs cubes” will not be visible, so you should think about reducing the amount of subcutaneous fat. Without proper nutrition, it is impossible to get rid of excess fat, just as it is impossible to gain muscle mass, including pumping up your abs. Remember this every time you have the desire to pump up a sporty, beautiful stomach. Well, if you need help in creating a nutrition and training program, feel free to contact me by private message on the website. Thanks to competent individual programs, you will achieve your goals much faster.

Your personal trainer, Pavel Korneychuk, was in touch! Good luck!

Hydraulic press: drawings and designs

For home use, a press that creates a force of 15-25 tons or less is sufficient - it depends on the required tasks. In addition to effort, this device has the following basic criteria:

- weight;

- dimensions;

- bed performance characteristics;

- presence of a pressure gauge;

- piston stroke.

In the working cylinder, a separate manual or built-in hydraulic pump is usually used to create pressure. This will depend on the choice of equipment for assembling the press. The simplest, easily manufactured version of the press is a design based on a bottle-type hydraulic jack , where there is a built-in hand pump.

Before you start assembling a hydraulic press with your own hands, you need to decide for what needs it will be used and, naturally, what force it needs. Then you need to select and buy the required jack , if it is used in the manufacture of the press.

The next, most important stage is creating a drawing of the assembled press. All drawings offered on the Internet for the manufacture of a hydraulic press are developed and made on the basis of existing hydraulic equipment and metal materials. Therefore, if you strictly follow other people’s diagrams, then making a press with your own hands can take forever and will consist of adjustment and alteration, based on the diagram for a purchased hydraulic jack.

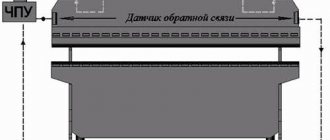

When making a drawing, you first need to select a diagram of the equipment operation:

- the jack is fixed on top of the frame and presses downwards;

- The jack is located on the base of the frame and presses upward.

Moreover, we should not forget that for manufactured jacks the normal working position, which is provided by the factory, is vertical, with the output rod up. The jack must not be turned over!

Most often the second option is chosen. The first is more convenient for certain types of work, for example, for pressing bearings out of some parts or bushings.

Press drawing design

Then they design a bed - a frame where the jack inside will put pressure on the products. The frame must be strong and include the force that the jack develops, with a reserve, because the press that is put into operation will begin to press up and down simultaneously , trying to tear the frame.

The base of the frame must provide sufficient stability for the press and, best of all, be in the form of a platform. The width of the bed opening will depend on the dimensions intended for pressing materials, but it must be no less than the sum of the widths of the existing elements of the press equipment. The height is summed up from the dimensions of the jack, the required free movement of its rod, the height of the parts intended for pressing and the thickness of the mobile work table. In the second work scheme, the jack is attached to the base, and the top of the frame serves as a stop for the products. The pressure from the rod is transferred to the part using a movable work table. It is installed on top of the jack on the frame, along which it must move freely up and down , held by guides on the sides.

Springs are attached to both sides of the jack: one eye to the base of the frame, and the other to the movable table. Their purpose is to compress the jack to its original state, when the rod does not protrude (the size and stiffness of the springs are selected appropriately). You can also make an option when a mandrel-shaped device is put on the rod, where one eye is attached, and the other is attached to the base.

The first scheme of the press operation implies that the support for the products will be the base of the frame, and the jack is attached to a movable table suspended from the top of the frame on springs. In two schemes, a socket is made at the interface unit under the base of the jack rod. This may be a small piece of pipe of the appropriate diameter.

To regulate the free movement of the jack rod and, naturally, the height of the workpieces, the following solutions are possible:

- provide for the installation of replaceable inserts-linings made of a hollow or solid metal profile;

- make a removable stop in the form of a movable work table, which can be fixed to the frame with rods or nuts and bolts. To do this, holes are made in the frame with a distance in height less than the movement of the jack rod;

- A screw drive with a steering wheel is installed on top of the frame. By tightening the screw with the plate at the end, you can reduce the clearance for products inside the frame;

- combined use of the above options.

All dimensions in the project must be indicated taking into account the dimensions of the pressing objects, the jack, as well as the dimensions of the intended rolled metal for use during the manufacture of the press with your own hands.

Myths about the press

Myth No. 1 – Abs are just “abs”

After a detailed anatomical analysis of the abdominal muscles and their functions, it became clear to us what the same abs that many people dream of consist of. At first glance, there may be an illusion that the abs are just “packs” on the abdomen (rectus abdominis muscle), nothing more, but as we see, in addition to the “packs” there are a number of equally important muscle groups that are part of the abdominal press . They are all interconnected, which means they complement each other.

Conclusion: The abs are not only the abs (rectus abdominis), but also other abdominal muscle groups, such as the external oblique, internal oblique, transverse and pyramidal abdominal muscles.

We've sorted that out, let's move on.

Myth No. 2 – Pumping only the upper or lower abs

Often my clients ask about how to pump up their upper or lower abs. I, in turn, upset them by saying that upper and lower abs do not exist. J Top and bottom abs are one of the most persistent myths in fitness.

As we have already seen, the rectus abdominis muscle consists of two parallel, integral, flat, rectus muscles, separated by the linea alba, the muscle fibers of which, in turn, are separated by tendon jumpers. This knowledge allows us to dispel this myth and makes it clear that it is impossible to pump the lower abs (namely, the lower rectus abdominis muscle) separately from its upper part and vice versa. When lifting legs while hanging on a horizontal bar, many people feel like their lower abs are on fire, and they conclude that only their lower abs are working. This misconception is caused by the work of the iliopsoas muscles, because they are the ones that actively work in this exercise and, as a result, burn. Of course, the abs are also burning, but it is more correct to say that the lower part of the rectus abdominis muscle is burning, but not to say that only the lower part of the abs is working. When crunches on the floor begin and the abs themselves begin to work, a burning sensation appears and the person begins to believe that only the abs are working upward. A burning sensation in one part of the rectus abdominis muscle does not exclude the work of the other! These are all myths that make no sense.

Conclusion: No matter what exercise you do, be it crunches or hanging leg raises on a horizontal bar, the ENTIRE rectus abdominis muscle works (both TOP and BOTTOM). The fibers contract along their entire length; division into independent parts is anatomically impossible! Leveling up the two lower dice in isolation from the two upper ones is completely absurd. The only true statement is a greater contraction of the lower or upper part of the rectus abdominis muscle in certain exercises, but not independent work of the upper part from the lower one and vice versa.

Myth No. 3 – I pump up my abs and burn belly fat.

It is important to remember one important rule - the more we pump our abs, the less fat we lose. Paradox. The fact is that there is no difference between 3-4 sets of abs several times a week and 3-4 sets of abs every day. In the second case, you only waste time and do not allow the abdominal muscles to recover, instead of training other muscle groups. Belly fat does not go away by pumping up your abdominal muscles; this rule is also true for all other muscle groups. Getting rid of fat in any specific area is impossible, because... fat disappears everywhere from the entire body, including from the face. This is physiology. Even in your imagination, it’s quite difficult to imagine a person with sculpted abs, full arms and a double chin. This is only possible in Photoshop. Even our imagination tells us that it is impossible to burn fat only on the stomach. J

Conclusion: don't do abs to lose weight.

Myth No. 4 – I’m thin, so I don’t need to work out my abs.

It is important to understand that running on an elliptical or treadmill will not build up your abs. Any muscle group in the body needs work to develop, and the abdominal muscles are no exception. Without training your abs, but losing weight only through nutrition, you will find that your abdominal muscles leave much to be desired, as do the rest of the muscle groups in your body. This is a natural result in the absence of strength training. Training your muscles allows you to tone them and significantly improve their appearance, which equals a beautiful, toned body with beautiful abs. It is important and necessary to pump up your abs, but in moderation, not forgetting the largest muscle groups (chest, back, legs). The paradox is that people who only train their abs do not have abs, while people who train fully (legs, back, chest) do. This is explained by the fact that many complex compound exercises involve the abs to one degree or another, since the abs muscles are stabilizers of the core. Also, training large muscle groups allows you to accelerate the body's metabolism and provoke the release of testosterone into the blood, which is very important for gaining muscle mass, not to mention the fact that training large muscle groups allows you to burn much more calories than low-cost crunches. If you only train your abs and don’t train anything else, you may not expect results.

Conclusion : Only strength training can give the muscles of your body (and stomach, respectively) an aesthetic appearance. This rule applies to all other muscle groups of the human body.

Myth No. 5 – I’m thin, but I have fat on my stomach, I don’t want to lose weight

In the case when you are already thin, but there is belly fat, it is important to reconsider your nutrition plan and add high-intensity strength training, be patient and work. The required amount of protein in the body will help maintain muscle mass. Controlling carbohydrates and fats combined with high-intensity strength training (high-repetition workouts in the gym combined with strength aerobics) will reduce the amount of subcutaneous fat.

Conclusion: To remove belly fat from a thin person, it is important to have, first of all, a proper diet and high-intensity training to maintain and develop muscle mass. Proper nutrition, by the way, is the first thing a person needs who is thinking about getting rid of excess fat in the body.

Tools and materials for press assembly

You will need the following tools:

- angle grinder or hacksaw;

- electrodes;

- welding machine.

The power device is a purchased hydraulic press. Door springs from the front seats of the car or other suitable ones. When the jack is in the lower position, you can select the bridge fungus as an element of the pulling device. It is put on the rod, springs are fixed to it and the base of the frame.

Parts that may be required:

- a piece of metal sheet from 8 millimeters - if it is necessary to lay it on the base or other parts of the structure to level the surface;

- channel more than No. 8, square or rectangular profile pipe from 35x35 mm, angle from 45x45 mm - for the frame, its base, mobile work table, removable stop;

- a piece of pipe for the rod head (of appropriate cross-section, approximately 1 cm long);

- metal strip 1 cm - for stiffeners, frame guides (if necessary).