Before making a gate from a metal profile, you need to carefully select the required material and study the installation features. Building a metal gate with your own hands is quite simple. A huge selection of building materials for decoration allows you to install any type of fencing - from beautiful forged products to simple mesh structures. A properly installed metal gate or gate for a fence with your own hands has a long service life and an attractive appearance.

Metal door

Basic requirements for gates

There are no clear restrictions and rules when choosing the installation location and size of a wicket or gate. But when creating a project and a drawing or diagram with a sketch for the manufacture of the entrance door structure, it is necessary to take into account certain nuances:

- The height of the entrance structure of a wicket or metal gate is usually no more than 2.3 m. As a rule, the height of the products is selected taking into account the size of the installed fence. If the fence is more than 2 m, then the street door is mounted in a standard size, and an additional crossbar is installed between the supports. This will visually equalize the height.

- The recommended manufacturing width for the entrance door structure is 100 cm. This is quite enough to carry large objects through the opening. A very large sash will warp under its own weight, and hinges and canopies will be subject to premature wear.

- When choosing a future design, it is necessary to take into account the material. Forged entrance products are heavy, so they require the installation of reinforced supports and powerful wicket hinges. The doors, lined with chain-link mesh, are lightweight. But in this case, fastening of transverse strips is required to increase the strength of the structure.

- It is advisable to install the front street door to enter the site closer to the house. It's good if it can be viewed from the windows.

Metal picket fence

European picket gates

The construction market offers a wide range of different types of metal picket fences.

Fence leaf made of metal picket fence

It differs from each other according to the following criteria:

- Manufacturing technologies. A distinction is made between a piece Euro picket fence, where each metal picket is made separately, and a Euro picket fence made from a single profiled sheet.

- Method of dyeing. A powder-coated metal picket fence looks more beautiful.

- Edge processing method. The edges can be unrolled or rolled.

- This material has different colors. There are many options, the choice depends on personal preference. The most popular are coatings that imitate different types of wood.

Metal door

Installing a wicket or gate made of picket fence is similar to making a structure from corrugated sheets.

The main stages of manufacturing an entrance door:

- Fastening supports. For this purpose, as a rule, a metal pipe is used. But you can lay out brick pillars.

- Fastening of stiffeners. The joints are cleaned, primed and painted.

- After securing the supports, the metal picket fence is fixed to the prepared frame with self-tapping screws. Manufacturers recommend attaching 9 pickets per 1 linear line. m door leaf. The recommended height is 1.6–2.1 m. There are several ways to attach the planks - with a gap of about 3 cm or in a checkerboard pattern. The gaps between the pickets on one side are closed with slats on the other side of the door. After final assembly and installation, the entire structure of the entrance gate is painted.

Metal picket fence options

The cost of a turnkey gate made of metal picket fence 1000x2000 mm is approximately 6500–6900 rubles.

By watching the YouTube videos posted at the end of the article, you can learn in detail the technology for manufacturing and installing a wicket or gate made from a metal picket fence.

Installation diagram of a metal gate for a fence

Also, as a small lesson, there is a training video below.

Welded gates

These wickets are widely used. They are often installed separately or in combination with gates to fence a dacha. They can be solid or openwork, with decorative forged elements and handmade decoration. Metal or aluminum sheets or corrugated sheets can serve as cladding for welded wickets and gates. Gates made in this way are distinguished by their reliability, strength and durability. They are easy to make with your own hands if you have the skills to work with metal or follow the instructions.

At the same time, you need to know that if the frame of a welded gate is sheathed with corrugated sheets, it cannot be attached to the base like ordinary metal. For this, special self-tapping screws are used.

Such gates also include metal gates made of welded mesh. But even if they are used in dacha fencing, it is only to separate zones within the site or, for example, to separate a recreation area from a garden or vegetable garden.

Return to contents

Metal gate made of chain-link

The advantages of a welded mesh entrance door are:

- light weight structure;

- speed of installation;

- transparency.

Metal mesh gate

Most often, lattice metal products are placed in dachas or in the garden to delimit space.

Material selection

Before you begin manufacturing and installing a wicket or gate made of metal, you first need to choose the right material - mesh, load-bearing supports, pipes for making the frame.

Metal mesh fence

Experts advise purchasing a metal chain-link taking into account the following characteristics:

- The weight of the roll indirectly indicates the quality of the material. The greater the weight, the better the quality of the chain-link is made. A wire mesh with a diameter of 3.5 mm and a cell cross-section of 6x6 cm weighs approximately 37–39 kg. If you weigh less, it is advisable to refuse to purchase the product.

- The smaller the mesh cell, the stronger the fence or metal gate will be. To install a street door, a chain link with a mesh size of 45–65 mm is most often used.

- For load-bearing supports, you can choose a 45x45 or 65x65 mm profile pipe, and 20x40 mm pipes are used to make the frame. The recommended material is wire with a diameter of 3.5 mm or larger.

A photo of a do-it-yourself metal fence gate is presented below.

Gate in the fence at the dacha

Step-by-step manufacturing instructions

Before welding a metal gate, you need to develop a project. On a sheet of paper it is necessary to schematically draw the design of the product indicating the main dimensions.

Taking into account the drawing or diagram with a sketch, you can calculate the amount of material required and make cutting.

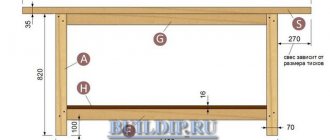

Wicket drawing

Fastening metal support pipes. The supports are buried in the ground using the same technology described above.

Stages of work:

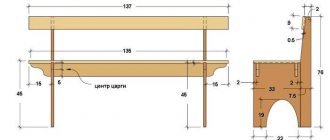

- preparation of materials: lower and upper parts of frame pipes – 980 mm, side racks – 1420 mm;

- additional stiffening ribs are installed;

- from the blanks you need to weld a frame 980x1500 mm;

- check the correct assembly of the structure.

Door drawing

Fastening metal hinges:

- Use self-tapping screws to fix one part of the hinges to the frame structure;

- attach the frame to the supporting posts, mark the places for fastening the canopy and hinges;

- grab these parts by welding;

- check that the hinges are installed correctly, install the gate level in the opening;

- you need to weld using a regular welding seam;

- clean the welding areas, paint the frame.

Diagram of a metal frame for making it yourself

Covered with metal mesh. Fastening the chain-link to the corrugated pipe can be done in the following ways:

- fastening to the frame by welding - thread a metal rod with a cross-section of 5 mm through the cells and point-fix it to the frame;

- fastening the mesh with metal or plastic clamps.

Forged gates

Forged wickets and gates are made by hand from metal using the forging method. They are distinguished by their aesthetics and rich appearance. The price of such gates is high, so for a large number of consumers they remain an unaffordable luxury.

Such gates are most often made to order. Handmade elements make each piece exquisite and unique. Forged gates are an element of dacha decor that indicates the status and strong financial position of its owner.

To prevent forged gates and wickets from looking too transparent, they are supplemented with a sheet of metal, corrugated board or polycarbonate. To make such an exhibit with your own hands, you need to have good forging skills and proficiency, so most often forged fences are simply purchased.

Return to contents

Manufacturing of forged metal structures

The most beautiful pattern can be made on the entrance street doors using forging elements. Custom assembly is very expensive, and making it yourself will require some experience and forging equipment. But often home craftsmen purchase decorative blanks of various monograms or simply make them using cold forging.

Metal and brick

Machines for the production of forged elements

You can forge simple monograms yourself if you buy one of the following machines:

- Torsion bar – helical twisting of rods, production of various decorative elements from volumetric spirals.

- Twisters twist thin-section iron rods. You can also prepare templates in the form of narrow heart-shaped spirals.

- Bending – production of spirals, zigzags, rings.

- Stamping-inertial - flattens the ends of the rods into tips. It is possible to produce fastening clamps and stamp waves like corrugations.

Fence gate

You should not purchase machines for the production of several decorative elements. The required machine can be rented.

Manufacturing of forged products

It is advisable for novice craftsmen to choose the simplest forging elements. Even when the product mainly contains smooth vertical rods made of ordinary iron, a few monograms will add “softness” and attractiveness to the overall entrance structure of the street door.

Forged metal door

Taking into account the drawing, calculations are performed. To manufacture a standard entrance door design you will need:

- steel strip 14x8 mm thick;

- rods 14x14 mm;

- professional pipe 35x25 mm.

To determine the size of the strip that is required to make one monogram, you need to draw a sketch on a scale of 1:1. The pattern is made with chalk on the floor, and the measurement is taken with a ruler.

This result must be multiplied by 10 (the standard number of monograms on the front door).

Wrought iron gate with door

Step-by-step manufacturing process:

- Weld a frame from a 40-20 mm corrugated pipe.

- Cut steel strips according to the pattern and weld them to the frame.

- Using a twister machine, bend the rods.

- Place the frame horizontally and try on the monograms.

- Mark the joining areas on the frame and weld the joints.

- Clean weld seams and sand.

- Weld the hinges onto the door leaf and supporting pipes. Clean the welding areas and paint the structure.

Beautiful metal gate

The cost of simple models of forged entrance gates ranges from 3.5 to 10 thousand rubles per 1 m². Complex models – up to 60 thousand rubles.

Getting ready for work

So, if you want to make a high-quality, beautiful and reliable gate, then it is important to do good preparation. If you want to include forging elements for a metal fence and gate, it is best to order them from a specialized company.

In general, it is quite possible to make an iron gate yourself. To do this, you can successfully use a profile pipe or metal profile. However, in your case this will be possible if you have skills in working with welding equipment. If you don’t have such skills, much less suitable equipment, then you can invite a friend and help him. So, you can save a lot if you had to contact a specialized company.

So, to perform the work, you need to have the following equipment:

- Welding machine.

- Special protective suit for welding work.

- Welder protective mask.

- Grinder with cutting and grinding wheels.

- Hammer.

This is perhaps the main set of tools and materials.

Reminder! Don't neglect your protective equipment. Working with welding equipment involves high temperatures. Therefore, there is always a risk of injury.