Types and purpose of plasma cutters

Before you understand how to choose a plasma cutter, you need to study the existing types of devices. Depending on the area of application they are divided:

- Inverter. They have the ability to cut metal up to 30 mm thick.

- Transformer. Cut metal 80 mm thick.

There is a classification depending on the contact of the cutter with the part.

They are divided:

- Contact. During operation, contact between plasma and metal is required. Its thickness can be up to 18 mm.

- Contactless. In this case, the metal can be very thick and contact with it is not required.

Depending on the energy consumed, there are also varieties. These are the devices:

- Household. Operate from 220 W network.

- Industrial plasma cutter. Operates on a three-phase 380 W network.

Selected models of plasma cutting machines

Let's look at individual models of plasma cutting machines, comparing their main characteristics, performance and prices.

Cut 40

The modern plasma cutter Cut 40 Cedar is used for cutting metal workpieces with a thickness of 16 mm and less. Having quite solid characteristics, this device fully justifies its cost of 23,000 rubles. The Cedar plasma cutter cuts almost all metals that conduct electricity. These include stainless steel, cast iron and copper products, brass and bronze blanks.

Additionally, the Kedar delivery set includes a RT-31 plasmatron for the formation of a directed plasma jet. Electric current and air are supplied to the plasmatron through a flexible hose that does not hinder the cutter in his work.

The device does not lead to warping of the metal in the area adjacent to the cutting; the sheet steel does not change its internal structure. The cut is a clean zone in which no burrs or other types of defects are formed. As soon as an enterprise starts using this plasma cutter, everyone seems to forget about propane-oxygen cutting.

Aurora

The next device under consideration is the Aurora plasma cutter. This equipment is designed for cutting both soft steels, stainless steels and alloy steels. Aurora is also used for cutting aluminum and copper, and other alloys. With a cost starting from 21 thousand rubles, depending on the modification, the device is very economical in energy consumption and allows you to obtain high-quality cuts without deforming the area of the base metal of the workpiece adjacent to the cut.

The maximum thickness of the metal to be cut is 20 mm. The device uses compressed air and can operate for a long time without overheating. On construction sites, the relevance of this device is high due to the fact that it works well with carbon and stainless steels. It has a convenient switch for current plasma combustion modes. The warranty period for this device is 2 years.

Resanta

The Resanta inverter plasma cutter is a device that is very easy to carry. With its help, you can quickly, accurately and efficiently cut metal, both sheet metal and other shapes. In this case, the deformations occurring in the adjacent heat-affected zone are minimal. The device provides a smooth adjustment of the current strength with the ability to set its exact values.

The pressure in the hose of compressed air supplied to the apparatus must be at least 0.5 MPa. Cutting black and white steel is allowed with a workpiece thickness of up to 8 mm, stainless steel - up to 5 mm. At a cost of 29 thousand rubles, Resanta is very easy to use and, with intensive use, is well within the cost of its acquisition.

Blueweld

The Italian Blueweld plasma cutter is powered by a voltage of 220 V and during operation consumes a maximum power of 4.5 kW. The current load, depending on the operating mode, ranges from 7 to 40 A.

It is used for plasma arc cutting of various steel alloys and non-ferrous metals. The main advantage of this machine is its high cutting speed, combined with the excellent quality of the resulting products. The cost of the device is currently 60 thousand rubles. The delivery set includes a ground cable, current clamps and a four-meter supply hose.

Gorynych

The multifunctional plasma cutter Gorynych generates low-temperature electric arc plasma by heating and evaporating the working fluid to a state of ionization.

The Gorynych plasma cutter consists of two block modules - a plasma generator and a power supply. The device is very convenient both in the household and when performing repair and construction work. The working fluid, in other words the consumable from which vapors for plasma are obtained, is distilled water or 45% alcohol. The installation can work with materials of a very different nature, including some non-metallic workpieces. It can also be used to cut, cook or heat products using a blowtorch. In the latter case, the Gorynych plasmatron is used as a simple burner. The cost of Gorynych is currently 29 thousand rubles.

How the device works

The choice of a plasma cutter should begin with studying its structure. An electric arc heats ionized air to a temperature of 30,000 degrees. Electric current passes through it. It is directed towards the metal. In the area of the cut it is blown out. The device consists of the following elements:

- Plasmatron. This is a plasma cutter that is connected to the machine using a cable and hose. When cutting metal, an arc occurs between the workpiece and the cutter. Such plasmatrons are called direct action. If a non-metallic surface is cut, an arc is formed directly in the cutter. These are indirect plasmatrons.

- Nozzle. This is the element through which air passes. Depending on its size, the size of the cut and the speed of the work change. The smallest nozzle diameters are 3 mm, and the maximum are 9-12 mm. The nozzle length is selected 1.5-1.8 times greater than the diameter. The longer it is, the higher the speed. But if this value is too large, then the nozzle quickly collapses.

- Electrode. This is a hafnium metal rod located inside the plasmatron. Its other name is cathode.

The cutting process uses air. However, in some cases oxygen, helium or hydrogen are added. This is due to the fact that the surface of the material can oxidize, and these gases act as protective media.

Main types of plasma cutting of metal

It is important to understand the technology of such metal cutting in order to understand what is needed for plasma cutting. Let's start with the fact that it allows you to work with sheets with a thickness of up to 220 mm

A spark is formed in the electric arc circuit between the nozzle tip and the non-consumable electrode, after which the incoming gas flow is ignited. When the burning gas is ionized, it turns into controlled plasma. Its exit speed is very high and amounts to 800–1,500 m/s.

The outlet has a narrowing, which allows you to increase the plasma flow rate and temperature up to +20,000 °C. So hot, narrowly directed plasma flow, when subjected to a point effect on the metal, melts it

What is important is that this ensures a slight increase in heating of the area adjacent to the cut site

There is one serious difference between the two main methods: plasma-arc technology and the plasma jet cutting method. The first method involves closing the surface of the workpiece into a conductive circuit. Whereas when working with a plasma jet, they resort to the third-party formation of a high-temperature component in the working circuit of the plasma torch. In this case, the sheet of metal is not a component of the conductive circuit.

Plasma jet cutting.

This method allows you to cut materials that are not capable of conducting electric current.

The arc burns between the forming tip of the plasma torch and the electrode, while the workpiece cut using a plasma jet is not included in the electrical circuit.

Plasma arc cutting.

When working with conductive materials, this technology is used. The essence is that the arc burns between the workpiece being cut and the electrode, its column is combined with the plasma flow. The latter is formed during heating and ionization of the supplied gas. It is blown through a nozzle, compresses the arc, gives it penetrating properties, ensuring the formation of plasma.

Due to the strong heating of the gas, the highest speed of its movement is achieved, and the degree of impact on the workpiece increases. The gas not only performs the main function of cutting, but also blows metal particles out of the processing area. The process is activated due to a direct current arc of direct polarity.

Plasma arc cutting is used during:

- manufacturing parts with rectilinear and shaped shapes;

- cutting holes or openings;

- production of workpieces, which must subsequently undergo welding, stamping, and machining;

- processing of forging edges;

- cutting pipes, strips, rods and profiles;

- casting processing.

It is customary to distinguish three types of plasma cutting depending on the environment used in the process. This:

- Simple using air/nitrogen combined with electric current.

- With protective gas, and the gas can be plasma-forming and protective. The second is designed to protect the treated area from external influences, due to which it is possible to significantly improve the quality of the cut.

- With water, where the liquid plays the same role as the shielding gas in the approach described above. But it has additional functions: it helps reduce the temperature of system elements and absorbs harmful substances released during operation.

Recommended reading

- Cutting copper with a laser: advantages and disadvantages of technology

- Types of metal cutting: industrial applications

- Metalworking according to drawings: convenient and profitable

Through the use of plasma cutting, based on the principles listed above, it is possible to achieve high equipment performance and complete fire safety. The latter is due to the fact that the materials used when working with this technology are not flammable.

Advantages and disadvantages of units

To understand which plasma cutter is better, you need to know the advantages and disadvantages of the devices. Benefits include:

- in addition to ordinary metal, you can cut aluminum, stainless steel or cast iron;

- no surface preparation required. The presence of rust and paint is allowed;

- the cut is smooth without scale;

- even with a small thickness of the workpiece there is no thermal deformation of the surface;

- safety in operation;

- possibility of forming complex cuts.

However, with all the advantages, the plasma cutter also has disadvantages. These include:

- limitation on cut thickness. The maximum value is 100 mm;

- the workpiece must be positioned clearly perpendicular to the cut;

- You cannot work with two cutters connected to one machine.

How to choose the right plasma cutting tool

Any welder who has worked with plasma cutting will note that the higher the current applied to the electrode, the faster the process. But there are certain conditions that are affected by other equipment parameters.

Type of metal and cut thickness. The choice of equipment to work with will depend on these parameters. Namely, such a parameter as current strength. Below is a table of ratios.

| Type of metal | Current strength for cutting a metal sheet 1 mm thick, A |

| Non-ferrous metals | 6 |

| Ferrous metals and stainless steel | 4 |

To cut a copper sheet 2 mm thick, you will need a plasma cutter with a current of 12 A. And so on.

Attention! It is recommended to purchase equipment with a reserve current. Because the parameters indicated in the table are maximum, and you can only work with them for a short time.

Factors influencing choice

When choosing a plasma cutter, you need to consider some factors. These include:

- Current strength. Depending on this value, the arc power increases and the metal melts faster. If you have to work with aluminum, copper or its alloys, then the current strength is selected 6A. For stainless steel and ferrous metals - 4A.

- Duration of switching on. Some devices can work 50% of the time, and then have to rest for the same amount of time. This is enough to cut a certain number of pieces. For industrial purposes, a device with 100% operating time is selected.

- Built-in or external compressor. If the compressor is built-in, then such devices do not have much power and are classified as household devices. If there is an external compressor, it is possible to operate continuously. The pressure in the plasma cutter should not be higher than that produced by the compressor.

- Frequency of nozzle and electrode replacement. This depends on the duration of the work and the thickness of the material being cut. When working with metal 10 mm thick, some consumables can withstand 150 cuts, others 500-600, and industrial consumables last the entire shift.

- The length of the cable and hose should not exceed 20 m, otherwise inconvenience will be created when unwinding them.

The best plasma cutters with high-frequency ignition

Models of this type are characterized by ease of use and high cutting quality. They quickly start working, are suitable for long-term use, and are therefore recommended for professional tasks.

Aurora Airforce 80

4.9

★★★★★ editorial assessment

96% of buyers recommend this product

This model has high operating speed and high-quality cutting, which guarantee comfort during intensive use. The owner can adjust the burner blowing time (from 5 to 25 seconds). The maximum cutting thickness is 30 millimeters, the duration of activation at maximum current is 40%.

The durable case is not afraid of sharp impacts. The wide handle of the unit ensures ease of movement. Other features of Aurora Airforce include a built-in pressure gauge, small dimensions and convenient control of basic parameters.

Advantages:

- high performance;

- quick installation and commissioning;

- flexible setup;

- durable body;

- long service life.

Flaws:

heavy weight.

Aurora Airforce can be used to cut any alloy and is intended for professional use.

Fubag Plasma 65 T

4.9

★★★★★ editorial assessment

95% of buyers recommend this product

A conveniently located central connector allows you to quickly connect the torch to this cutter. The built-in filter and air dryer improve the quality of work and extend the service life of consumables. Round legs contribute to the stability of the device on the surface.

The power of the device is 9.5 kW, the maximum cutting thickness is 35 millimeters. The durable case reliably protects the internal elements from external influences and mechanical damage.

Advantages:

- high-quality cut;

- very high power;

- convenient control;

- long service life;

- reliable body.

Flaws:

high energy consumption.

Fubag Plasma 65 T is good for cutting steel and aluminum workpieces. Useful in a professional workshop.

Svarog Real CUT 45 (L207)

4.8

★★★★★ editorial assessment

92% of buyers recommend this product

The plasma cutter has a simple and intuitive control panel, which makes it easy to operate even for an untrained user. A large number of ventilation holes on the case cover quickly remove heat, eliminating the risk of overheating of internal components.

The maximum power is 4.3 kW, the cutting thickness is 12 millimeters. Quick connection of the cable to special connectors simplifies the commissioning of the device. Small dimensions and weight facilitate comfortable movement and installation in the chosen location.

Advantages:

- light weight and compactness;

- ease of carrying;

- fast connection;

- simple controls.

Flaws:

The cable is a bit short.

Svarog Real CUT 45 is recommended for professional use - when high-quality cutting is important.

Resanta IPR-40

4.8

★★★★★ editorial assessment

91% of buyers recommend this product

An easy-to-grip handle and a durable shoulder strap make the unit easy to transport. The case is not afraid of sharp impacts and reliably protects internal elements from damage.

The control panel contains an operating current regulator, a pressure gauge, and light indicators. This simplifies setup and makes it easier to monitor the current state.

The duration of switching on the cutter at maximum current is 35%, the metal thickness should not exceed 12 mm. The forced cooling system guarantees stable operation of the equipment during intensive use.

Advantages:

- long service life;

- durable body;

- convenient to carry;

- flexible setup;

- There is an indication of states.

Flaws:

works noisily.

Resanta IPR-40 is suitable for cutting any metals and is used where precision work is required.

FoxWeld Varteg Plasma 70

4.8

★★★★★ editorial assessment

87% of buyers recommend this product

The FoxWeld plasma cutter has an emergency indicator that can operate in two modes, signaling when the compressed air pressure in the system is insufficient or the permissible temperature of the components is exceeded. This prevents damage and ensures high-quality work.

The maximum cutting thickness is 20 mm, the created pressure is 5 bar. The device is equipped with a ventilated front panel. A convenient control unit facilitates quick commissioning of the plasma cutter, and an ergonomic handle simplifies transportation.

Advantages:

- clear indication of states;

- rapid cooling;

- convenient control;

- ease of transportation;

- durable body.

Flaws:

large dimensions.

FoxWeld Varteg Plasma 70 is worth purchasing for working with aluminum, copper, steel, etc. A universal choice for regular use.

Rating cutting machines

When choosing a device, you need to focus on the plasma cutter rating. The best models include:

- Svarog CUT 40B (R34). Has a power of 3.84 kW. Operates at a voltage of 220 W. Dimensions are 425 x 205 x 355 mm. The device is designed to work with thin sheet metal; lightweight and easy to manage.

- AURORA PRO AIRFORCE 60 IGBT. Connects to a voltage of 380 W. The maximum thickness of the cutting surface is 20 mm. You can work with any grade of material that conducts current. The cutting current is 60 A.

- BRIMA CUT 120. Operates at 380 W. Has the ability to cut sheets up to 35 mm thick. The power of the device is 20 kW. Dimensions: 475 x 330 x 370 mm.

- CEDAR CUT-40B. Voltage consumption - 220 W. Cuts metal sheets up to 12 mm thick.

- Lincoln Electric Tomahawk 1538. Powered by 380 W. Has a carbon electrode. The cutting current is 30-100 A. Dimensions - 455 x 301 x 640 mm.

When choosing a plasma cutter, you need to focus on its parameters. At home, there is no point in purchasing an industrial device; a household one is quite sufficient. The device will work 50% of the time and rest for the same amount of time. During this period, a significant portion of the work can be completed. You can also assemble a plasma cutter yourself, read how here.

The best plasma cutters with a built-in compressor

The presence of a compressor eliminates the need to purchase it separately and allows you to use the device immediately after purchase. Such devices are easy to operate and do not require particularly complex maintenance.

Hypertherm Powermax 30 AIR

5

★★★★★

editorial assessment

100%

buyers recommend this product

Among the features of the model, it is worth highlighting the ability to connect to various power sources with a voltage of 120-240 volts. The innovative design of consumables guarantees stable operation of the cutter by optimizing air flow.

The dimensions of the unit are 420x195x333 mm. For ease of movement, two handles are provided.

Maximum power 3.8 kW. The always-on pilot arc makes it possible to quickly cut through grates or rusty metal. Resistance to overheating extends the life of the plasma cutter during intensive operation.

Advantages:

- convenient connection;

- light weight;

- high performance;

- overheat protection;

- quality cut

Flaws:

- high price.

Hypertherm Powermax 30 AIR is suitable for working with a variety of metals. An excellent choice for regular use.

Blueweld Prestige Plasma 54 Kompressor

4.9

★★★★★

editorial assessment

97%

buyers recommend this product

The torch control panel is equipped with a rotary potentiometer control, as well as indicators for torch voltage, phase presence and mains voltage. This provides ease of setup and monitoring of the device status. High cutting speed makes it easier to work with a large number of workpieces (their thickness should be no more than 10 mm).

The power of the device is 4.5 kW. The plasma cutter is protected from overload, overheating, voltage surges and can be operated in the most difficult conditions. Small dimensions and weight simplify installation in the chosen location and transportation.

Advantages:

- compactness;

- long service life;

- operator safety;

- convenient control;

- status indication;

- complex of protection

Flaws:

- short cable.

Blueweld Prestige Plasma 54 Kompressor is recommended for neat and precise processing of metals. Professional solution for shape cutting.

TCC Top CUT-50K

4.9

★★★★★

editorial assessment

95%

buyers recommend this product

The device does not require the purchase of additional equipment or special settings. High cutting speed and accuracy make it possible to process a large number of workpieces in a short time without loss of quality.

With dimensions of 450x190x520 mm, it weighs 24 kilograms. The air cooling system reduces the risk of overheating of the plasma cutter when working in intensive mode. The device does not take up much space in the workshop and is easy to transport thanks to the presence of a special handle, although, of course, it weighs a lot.

Advantages:

- rich equipment;

- rapid cooling;

- ease of carrying;

- simple controls.

Flaws:

- heavy.

TCC Top CUT-50K is used for cutting various metals and conductive materials. Compact solution for use on a repair and installation site.

Telwin Technology Plasma 54 Compressor

4.8

★★★★★

editorial assessment

90%

buyers recommend this product

Small dimensions make it easier to place the device in the chosen location. In addition, the model is equipped with a shoulder strap for easy carrying. A large number of ventilation holes promotes rapid cooling during intensive use.

The maximum power of the unit is 4.5 kW, the duration of switching on at maximum current is 30%. Overvoltage and undervoltage protection ensures the stability of the machine during the cutting process. The current regulator and current status indicator help control the operation of the plasma cutter.

Advantages:

- compact and easy to carry;

- durability;

- easy setup;

- status indication;

- precise operation even with unstable network voltage.

Flaws:

- noisy.

Telwin Technology Plasma 54 Kompressor is worth purchasing for cutting steel, copper, brass, aluminum and other light metals. The right solution for a small workshop.

READ ALSO

11 best semi-automatic welding machines

Advantages of a manual plasma cutter

- High quality cut;

- No preparatory work required;

- You do not risk bending the workpiece;

- Ability to make products of any geometric shape;

- Wide range of metals for cutting;

- Cutting speed;

Below we will look at each of the points in more detail:

- High quality cut. The grinder leaves a lot of burrs and in some cases it is impossible to make an even cut with the disc. Then we turn to an automatic metal saw, but the problem is not solved. A gas cutter doesn’t help, because after it you have to correct a lot of leaks. The plasma cutting machine leaves no burrs or scale. After plasma, follow-up is rarely required

- No need for preparatory work. Using a grinder to cut metal with traces of paint or rust is a dubious pleasure. Small fragments injure the skin, and dust and dirt make it difficult to monitor the quality of the cut. At the same time, the operating principle of the plasma cutter is such that no preparatory work is required at all.

- Minimal risk of bending the workpiece. Plasma, like mechanical threads, heats the metal. But the surface heats up only within a very small radius from the cut line. The metal remains rigid and the risk of bending the product is minimal.

- No restrictions in geometric solutions. It is difficult to make a figured cutout with a grinder due to the geometry of the disc. Cutting metal with a plasma cutter is somewhat similar to working with a milling cutter. Therefore, it easily copes where curved cutting is needed. For example, in decorative metalworking.

- Ability to work with almost any metal. Mechanically it is easy to cut soft metals such as copper or aluminum. A little more complicated - steel and cast iron. And it's nearly impossible to cut hard metals like titanium. Plasma can easily cope with any metals and alloys.

- High speed of product processing. When cutting metal up to 10 millimeters thick, the advantages of plasma are not so obvious. But in the case of processing metals of greater thickness, the cutting speed increases up to 10 times compared to the mechanical method.

Of course, when talking about the advantages, we cannot leave the disadvantages in the shadows. There are fewer of them, but you also need to know about them.

Types of plasma cutters

Understanding the principle of operation of a plasma cutter and its design, let’s consider the types of equipment. This will help determine the details of the choice for specific production tasks.

Plasma cutters by cutting type

Plasma cutters are manual and automatic

It is important to take this into account when choosing so that the equipment is suitable for the upcoming processes

Plasma cutters for manual cutting

Used to work with small sections 1-10 mm. This is relevant for garages and small workshops where doors, gates, gates, and barbecues are made. They are convenient for cutting holes, cutouts for locks and hinges, and cutting blanks for canvases and bent boxes. More expensive equipment can cut through 10-30 mm.

This expands the scope of use and is suitable for cutting workpieces for subsequent mechanical processing in production (manufacturing flanges, shafts, cutting pipes, etc.). Such installations are mobile and convenient.

Plasma cutter for manual cutting.

Plasma cutter for automatic cutting

Used with cutting heads moved on portal or console type brackets. CNC controlled. They can simultaneously cut with 2-4 heads at once. Suitable for cutting parts with dimensions from 1x1 to 3x30 m. They require sufficient space and are difficult to transport.

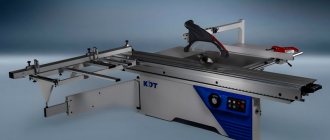

Plasma cutting machine.

Plasma cutters by type of gas used

To operate a plasma cutter, air is needed to ionize in the electric arc. There are two types of equipment here:

Compressed air plasma cutters

Household and semi-professional class. They are cheaper, easy to control (only the current strength is adjusted), and universal. Very small devices are designed for cutting sections up to 10 mm. More powerful ones can handle 12-25 mm. The main advantage is inexpensive maintenance (price of nozzles, one-time purchase of a compressor). Subsequently, you won’t have to buy anything expensive.

Plasma cutters using argon, oxygen, nitrogen or mixtures thereof

Used on large plasma cutting machines. They require lengthy adjustments, but are able to perform cuts faster, more accurately and more complexly. It is necessary to regularly spend money on purchasing gas cylinders. This type is suitable for large enterprises with a large volume of products.

Argon plasma cutting machine.

Plasma cutters based on arc ignition type

Plasma cutters are also divided according to the method of exciting the electric arc:

- Contact. This type of ignition is found in household inverters. The plasma torch nozzle must touch the product to which the mass is connected. The simple design of the burner is less likely to break, but the nozzle becomes covered with scale faster.

- Pneumatic. They form an arc independently when gas is supplied (without touching the product). This is convenient for frequent moving and making small cuts. Saves nozzle life and increases productivity.

- High frequency (HF). The most comfortable type of ignition, achieved using an oscillator. The arc is excited by a high-frequency pulse between the cathode and anode in the nozzle. When brought to the product, it automatically switches to cutting. The ignition type is suitable for precisely starting the cut so that no electrical traces are left on the workpiece.

Plasma cutters by cooling type

Air

Used in household and semi-professional models. Heat from the burner is removed naturally into the surrounding air. Inside, the channels are cooled due to the supply of oxygen or inert gas. In the case itself there is a fan that blows air over the transformer and the rectifying unit. Periodic breaks will be required during operation to avoid melting the nozzle.

Air-cooled plasma cutter.

Liquid

Used on industrial versions of equipment. The plasma torch has channels through which, using a water pump, distilled water and ethyl alcohol circulate. This quickly absorbs heat and allows the device to work without interruptions. Suitable for large-volume tasks or operation of a plant in two shifts.

What types of plasma cutters are there?

Plasma cutters are usually divided into several categories - by type of operation, type of gas used, and cooling. Each option has its own advantages and disadvantages.

Manual

The devices are used to work with sheet metal up to 10 mm. Most often, such models are purchased for home workshops and garages. Manual plasma cutters help make holes for hinges and locks, cut out blanks for canvases, they are even used in the manufacture of wickets, barbecues and gates.

A manual plasma cutter is the most common choice for a home or garage

Automatic

Expensive industrial CNC machines have cutting heads that move on brackets in accordance with a given program. They provide ample opportunities for cutting parts with dimensions from 1 to 30 m. They are rarely purchased for private use; usually such capacities are simply not in demand outside of production.

Plasma cutting machines are usually purchased for production; they are expensive

On compressed air

Household and semi-professional models operate from a compressor, are cheaper and are versatile. Suitable for working with materials with a section edge of 10-25 mm. Compressed air plasma cutters are easy to operate; you only need to adjust the current strength.

Some models of plasma cutters using compressed air have a built-in compressor

On nitrogen, argon or oxygen

This type of gas is usually consumed by large professional-class machines. They are more difficult to control and require careful adjustment, but they perform very accurate and fast cutting of workpieces. They are quite expensive to maintain; the more actively the unit is used, the more often gas cylinders need to be purchased for it.

Plasma cutters using argon or oxygen are usually used in enterprises

Air cooled

Heat in household models is naturally dissipated into the environment, and from the inside the channels are cooled with oxygen or other inert gas. A fan for blowing the transformer is built into the housing of such plasma cutters. Air-cooled cutters are less expensive, but they often overheat and require breaks during operation.

Cooling for household plasma cutters is usually air, not the most efficient, but simple

Water cooled

Industrial expensive plasma cutters are equipped with special channels through which water with the addition of alcohol passes. This mixture quickly removes heat from the internal parts of the machine, and the cutter can work without interruption.

For plasma cutters in production, water-type cooling is used