The development of the pellet market - a worthy alternative to traditional fuels - began in our country relatively recently. The increase in the number of consumers in this market who use this fuel to operate high-power solid fuel boilers used for heating industrial facilities and large residential buildings has led to the fact that an increasing number of companies operating in various fields are thinking about purchasing equipment for the production of pellets. According to experts, the demand for pellets in Russia will only grow. First of all, this applies to sawdust fuel pellets.

The mini-line for the production of fuel pellets consists of several technological sections

When organizing pellet production (as well as any other), you should first of all study all its nuances, as well as get acquainted with the equipment that is used for its practical implementation.

Technological process for the production of pellet fuel

In order to produce pellets from sawdust, a whole list of technological manipulations must be performed with the source material, each of which solves specific problems.

The technological process for producing pellets from sawdust is a sequence of certain actions performed using appropriate equipment.

Such actions, in particular, are:

- cleaning sawdust from foreign impurities;

- preliminary grinding of the purified material;

- drying of raw materials for pellets;

- final grinding of already dried sawdust;

- bringing the moisture level of the prepared material to the required value;

- sawdust mass granulation process;

- cooling of finished products and their packaging.

Industrial scheme of pellet production

Since all of the above stages of the technological process for the production of fuel pellets are carried out for a specific purpose and are of great importance for obtaining quality products, each of them should be discussed in more detail.

Assessment of the quality of raw materials

The main influence on the quality of pellets is provided by the characteristics of the raw materials. Important in this case are such parameters as the type of wood from which the sawdust was obtained, the degree of contamination with foreign impurities, humidity and fraction size.

The sawdust storage must be dry, spacious and comply with fire safety standards

The qualitative characteristics of the material for making pellets and the degree of its preparation for the production process determine the technology for obtaining the finished product, as well as the choice of equipment. In this case, it is necessary to take into account the following nuances.

- If the humidity of the source material is high enough, powerful dryers will be required to bring it to normal levels. The use of such equipment in the pellet production process will lead to an increase in both energy and labor costs during the implementation of the technological process.

- If the feedstock contains a lot of large wood particles, then the production line for the production of pellets should contain not only a crusher, but also equipment for separating the crushed mass. The operation of such a production line will also be associated with increased energy costs.

- The efficiency of the technological process and the stability of the pellet production line largely depend on how uniform the source material is in terms of wood species.

- When assessing the quality of sawdust mass that is planned to be used for the production of pellet fuel, you should pay attention to the presence of tree bark, rot and waste from processing old wood in its composition. A large number of such inclusions in the total mass for the production of fuel pellets reduces their energy value and, accordingly, reduces the cost of the finished product.

- The feedstock may contain foreign impurities such as sand and stones. In this case, the pellet line must be equipped with special catching devices. Preliminary washing of the material also solves the problem with such impurities, but in any case this increases production costs and, accordingly, the cost of the finished product.

Thus, the characteristics of sawdust should be assessed before using it for pellet production.

To measure the moisture content of sawdust, moisture meters are used, consisting of an electronic unit and a sensor, the probe of which is placed on a conveyor or in a hopper

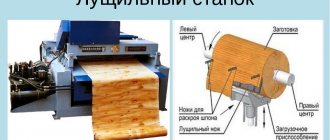

Sawdust pre-grinding process

In most cases, waste from wood processing enterprises is used for the production of pellets, which is supplied to pellet production without preliminary sorting. Naturally, such waste, in addition to the sawdust itself, also contains other components - tree bark, large chips, bars, slabs, etc.

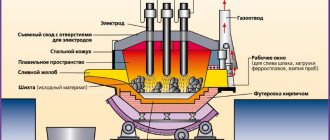

The working parts of crushers used for coarse grinding of material are rotating hammers

In order to bring the raw sawdust mass into a homogeneous state in terms of the size of the fractions it contains, a grinder is used. As such equipment, at the stage of preliminary crushing of the raw material mass, hammer crushers of the deck type are used. A crusher of this type can be successfully used for sawdust, the humidity of which reaches up to 80%, and there is practically no sticking of it to the elements of the internal structure of the equipment.

Hammer crusher device for wood

Drying process

Pellet production can receive raw materials with varying degrees of moisture, but directly during pressing, the value of this parameter should not exceed 8–12%. Thus, a pellet production line must include an installation for drying raw materials, which, as a rule, is a drying drum. Screw-type conveyors are used to feed wet raw materials into such equipment, which is the most economical option for solving this issue.

Diagram of a multi-circuit aerodynamic dryer

An aerodynamic sawdust dryer, which is based on a drying drum with the ability to regulate the rotation speed, includes several technical devices:

- source of generation and supply of hot air, running on natural gas or any other type of fuel;

- a cyclone into which the sawdust mass enters after drying;

- storage hopper from which sawdust is fed into the working chamber of the drying drum;

- cyclones, whose tasks include cleaning flue gases from dust, as well as capturing fine particles contained in the dried raw materials;

- a smoke exhauster that ensures the passage of hot air at a certain speed through the chamber of the drying drum and the air channels of the cyclones;

- screw conveyors - equipment that supplies wet raw materials into the chamber of the drying drum and transports already dried sawdust to the storage hopper.

Drying complex with a capacity of up to 1000 kg/hour with a furnace operating on wood, sawdust or wood chips

The process of drying sawdust, for which an aerodynamic dryer is used, is as follows.

- The sawdust mass that needs to be dried is fed into the chamber of the drying drum, the axis of rotation of which is located in the horizontal plane. When such a drum rotates, the uniform distribution of the loaded raw material mass in its working chamber is controlled. To ensure the safety of the sawdust drying process in the drum, its design includes a special explosion valve.

- Tedding of sawdust in the drying drum, which makes it possible to dry them more quickly and evenly in a stream of hot air, is provided by special blades attached to the walls of the working chamber of the device.

- After drying to the required moisture level, the sawdust from the drum enters the cyclone, where it is deposited and dosed into the storage hopper.

- Cleaning of used hot air from wood dust is also ensured using cyclone equipment.

- The automation unit is responsible for compliance with all operating modes of the drying equipment.

Crushing technology

The technology for producing pellets from sawdust provides that the raw material entering the granulator should not contain particles whose length exceeds 4 mm. Most modern models of equipment for the production of fuel pellets operate on raw materials whose particle sizes are no more than 1.5 mm, and the bulk mass is within 150 kg/m3. To achieve such parameters of the raw material, a grinder is used before feeding it into the pressing equipment. As a rule, this is a hammer-type crusher, which is capable of working with sawdust mass with a moisture content of no higher than 25%.

The grinder, which is used for finishing crushing of sawdust raw materials, must meet certain performance indicators both for the processed raw materials and for the air flow created.

This is explained by the fact that the grinder, which is equipped with a pellet production line, not only performs crushing functions, but also generates an air flow that removes crushed raw materials from the working chamber of the equipment. That is why, when choosing a shredder, you should focus on the characteristics of the control cyclone.

Rotary hammer crusher designed for grinding wood pulp in the process of producing fuel pellets

Supply of raw materials to the storage hopper

The supply of sawdust raw materials crushed in a hammer crusher to the cyclone equipment, as mentioned above, is ensured by the air pressure created when the hammers rotate in the working chamber. The task of the cyclone, which is equipped with almost any modern pellet production line, is to separate sawdust from the air flow transporting it from the grinding device. This installation works as follows.

- The air flow entering the cyclone along with crushed sawdust is twisted in a spiral.

- Under the influence of centrifugal force, sawdust, moving along with the air flow, is pressed against the walls of the equipment’s working chamber.

- Gradually losing speed, the sawdust, under the influence of gravity, is deposited in the lower part of the cyclone chamber, and the air with which it moved exits through the exhaust pipe.

- The sawdust that accumulates in the lower part of the equipment chamber is discharged into a storage hopper.

The pellet production line includes a cyclone for dry biomass removal

Bringing the sawdust moisture content to the required level

After several stages of preliminary preparation, the sawdust may become too dry, which will not allow them to be formed into granules with a dense and uniform internal structure. The production of pellets from sawdust requires that their moisture content immediately before pressing should be in the range of 8–12%. If this requirement is not met, the pressed raw materials must be additionally moistened.

Modern equipment for the production of pellets from sawdust is equipped with screw mixers, in which the moisture content of the raw material is increased using steam supplied to them under pressure. When performing such a technological process, you should constantly monitor the moisture level of sawdust raw materials in order to stop steam treatment in time.

Formation of fuel pellets

The main technological operation that the equipment performs for the production of pellets is the formation of granules with a dense and uniform internal structure from crumbly sawdust raw materials. To carry out this procedure, devices with round or flat matrices are installed on modern pellet production lines. Equipment equipped with round dies is more suitable for pressing materials that are not very hard. Such equipment, in particular, produces not fuel pellets, but pellets from more elastic and soft materials, which are used in the chemical, feed and food industries.

Ring type die pellet press

The production of wood pellets, the equipment for the production of which, according to the principle of its operation, is not much different from devices intended for pressing softer raw materials, is carried out using flat-type matrices. The production process for forming pellets, performed on equipment with both round and flat dies, is as follows. Rollers with a ribbed working surface, rolling over the surface of the matrix, presses crumbly raw materials through the holes in it, forming dense cylindrical granules from it. The length of the finished pellets coming out from the back of the matrix is adjusted using a special knife that makes reciprocating movements.

The thickness of the matrix wall depends on the diameter of the working holes

Final stages of the technological process

Since the pellets leaving the pressing equipment are heated to a significant temperature, they must be forcibly cooled to prevent them from “steaming” in a sealed package, which will lead to their saturation with moisture. Pellets that undergo this process cannot be used as fuel. On modern production lines for the production of pellet fuel, special equipment is used to carry out the cooling process, which is a straight-through column in which a stream of cooled air is passed through the finished pellets.

Granules from the cooling column are transported through a conveyor into the finished product bunker and then sent for packaging

Modern mini-lines for the production of fuel pellets and lines of higher productivity are also equipped with dosing devices and equipment that allow you to quickly pack the finished product into containers of the required volume and weight.

Technological process

Regardless of which machines are used for the production of fuel pellets, the production process consists of such technological operations as:

- Cleaning and preliminary grinding of raw materials, which are brought to such a state that the length of its particles does not exceed 2.5 mm.

- Drying sawdust mass, the humidity of which is brought to a level of 9–12%.

- Final grinding on a machine, which is carried out so that the maximum length of the particles that make up the sawdust mass does not exceed 1.5 mm.

- Mixing the crushed raw material with water or treating it with hot steam (this technological operation is used if the moisture level of the sawdust after drying and grinding has dropped below the minimum permissible value).

- Pressing the sawdust mass, as a result of which cylindrical granules are formed from it (for the practical implementation of this technological operation in a production environment, matrix installations of a cylindrical or flat type can be used; at home, homemade installations of a lever, screw or hydraulic type are suitable for the formation of fuel briquettes) .

- Cooling of finished pellets, which during their formation using high pressure spontaneously heat up to a significant temperature.

- Sorting of finished fuel pellets and their packaging.

Pellet production line

The waste generated after the implementation of the above-described technological process can be recycled. At the same time, pellets from them are created using the same algorithm.