High frequency hardening technology

HDTV surface hardening is a heat treatment process to increase the strength characteristics and hardness of the workpiece.

The main stages of surface hardening of HDTV are induction heating to a high temperature, holding at it, then rapid cooling. Heating during hardening of HDTV is carried out using a special induction installation. Cooling is carried out in a bath with a coolant (water, oil or emulsion) or by spraying it onto the part from special shower installations.

TRANSISTOR GENERATORS TGI

TGI transistor generators are serially produced by INTERM LLC to power induction installations with a power of up to 160 kW and higher in the frequency range from 10 to 500 kHz.

Advantages of TGI:

- High efficiency – 96%

- Low cooling water consumption – 0.1 l/min per 1 kW

- Pulse modes

- High level of automation, user-friendly interface

- Control and regulation of heating temperature

- Logging of heating processes

- Protection and diagnostics in many parameters

The nomenclature and general technical characteristics of the TGI series of transistor generators produced by INTERM LLC are given in the section “TRANSISTOR GENERATORS”

Temperature selection

For the correct completion of the hardening process, the correct selection of temperature, which depends on the material used, is very important.

Steels based on carbon content are divided into hypoeutectoid - less than 0.8% and hypereutectoid - more than 0.8%. Steel with carbon less than 0.4% is not hardened due to the resulting low hardness. Hypoeutectoid steels are heated slightly above the temperature of the phase transformation of pearlite and ferrite to austenite. This occurs in the range of 800-850°C. Then the workpiece is quickly cooled. When cooled sharply, austenite transforms into martensite, which has high hardness and strength. A short holding time makes it possible to obtain fine-grained austenite and fine-needle martensite; the grains do not have time to grow and remain small. This steel structure has high hardness and at the same time low brittleness.

Microstructure of steel

Hypereutectoid steels are heated slightly lower than hypoeutectoid steels, to a temperature of 750-800°C, that is, incomplete hardening is performed. This is due to the fact that when heated to this temperature, in addition to the formation of austenite, a small amount of cementite, which has a higher hardness than martensite, remains undissolved in the metal melt. After rapid cooling, austenite transforms into martensite, and cementite remains in the form of small inclusions. Also in this zone, carbon that has not had time to completely dissolve forms solid carbides.

In the transition zone during high-frequency quenching, the temperature is close to the transition temperature, and austenite with ferrite residues is formed. But, since the transition zone does not cool down as quickly as the surface, but cools down slowly, as during normalization. At the same time, the structure in this zone improves, it becomes fine-grained and uniform.

Overheating the surface of the workpiece promotes the growth of austenite crystals, which has a detrimental effect on brittleness. Underheating prevents the complete ferrite-perrite structure from transforming into austenite, and unhardened spots may form.

After cooling, high compressive stresses remain on the metal surface, which increase the performance properties of the part. Internal stresses between the surface layer and the middle must be eliminated. This is done using low-temperature tempering - holding at a temperature of about 200°C in an oven. To avoid the appearance of microcracks on the surface, it is necessary to minimize the time between hardening and tempering.

You can also carry out the so-called self-tempering - cool the part not completely, but to a temperature of 200 ° C, while heat will remain in its core. Then the part should cool slowly. This will equalize internal stresses.

OPTIONAL EQUIPMENT

- External sensor for temperature control: K-type thermocouple (XA) with normalizing amplifier UST-K-1;

- infrared pyrometer (Lumasense technologies, Raytek GmbH, Mikron, Optris);

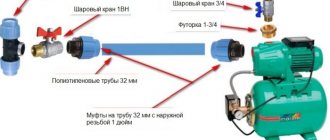

Induction installation

The HDTV induction heat treatment unit is a high-frequency generator and inductor for HDTV hardening. The part to be hardened can be located in or near the inductor. The inductor is made in the form of a coil, with a copper tube wound on it. It can have any shape depending on the shape and size of the part. When alternating current passes through the inductor, an alternating electromagnetic field appears in it, passing through the part. This electromagnetic field causes eddy currents known as Foucault currents to occur in the workpiece. Such eddy currents, passing through layers of metal, heat it to a high temperature.

HDTV induction heater

A distinctive feature of induction heating using HDTV is the passage of eddy currents on the surface of the heated part. This way, only the outer layer of the metal is heated, and the higher the frequency of the current, the smaller the depth of heating, and, accordingly, the depth of hardening of the high-frequency frequency. This makes it possible to harden only the surface of the workpiece, leaving the inner layer soft and tough to avoid excessive brittleness. Moreover, you can adjust the depth of the hardened layer by changing the current parameters.

The increased frequency of the current allows you to concentrate a large amount of heat in a small area, which increases the heating rate to several hundred degrees per second. Such a high heating rate moves the phase transition to a higher temperature zone. In this case, the hardness increases by 2-4 units, to 58-62 HRC, which cannot be achieved with volumetric hardening.

For the correct implementation of the HDTV hardening process, it is necessary to ensure that the same clearance is maintained between the inductor and the workpiece over the entire hardening surface, and mutual touching must be avoided. This is ensured, if possible, by rotating the workpiece in the centers, which allows for uniform heating, and, as a consequence, the same structure and hardness of the surface of the hardened workpiece.

The inductor for hardening HDTV has several versions:

- single- or multi-turn annular - for heating the outer or inner surface of parts in the form of bodies of rotation - shafts, wheels or holes in them;

- loop - for heating the working plane of the product, for example, the surface of the bed or the working edge of the tool;

- shaped - for heating parts of complex or irregular shape, for example, the teeth of gear wheels.

Depending on the shape, size and depth of the hardening layer, the following HDTV hardening modes are used:

- simultaneous - the entire surface of the workpiece or a certain zone is heated at once, then also cooled simultaneously;

- continuous-sequential - one zone of a part is heated, then when the inductor or part is displaced, another zone is heated, while the previous one is cooled.

Simultaneous high-frequency heating of the entire surface requires large amounts of power, so it is more profitable to use it for hardening small parts - rolls, bushings, pins, as well as part elements - holes, necks, etc. After heating, the part is completely lowered into a tank with coolant or sprayed with a stream of water.

Continuous-sequential hardening of high-frequency particles allows you to harden large-sized parts, for example, the crowns of gear wheels, since during this process a small zone of the part is heated, which requires less power of the high-frequency generator.

Equipment for performing induction hardening (HFC)

Induction hardening requires special technological equipment, which includes three main components: a power source - a high-frequency current generator, an inductor and a device for moving parts in the machine.

High-frequency current generators are electrical machines that differ in the physical principles of the formation of electric current in them.

- Electronic devices operating on the principle of vacuum tubes that convert direct current into alternating current of high frequency - tube generators.

- Electrical machine devices operating on the principle of inducing electric current in a conductor moving in a magnetic field, converting three-phase industrial frequency current into alternating current of high frequency - machine generators.

- Semiconductor devices operating on the principle of thyristor devices that convert direct current into alternating current of high frequency - thyristor converters (static generators).

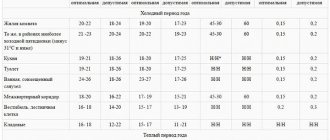

Generators of all types differ in frequency and power of generated current

Types of generators Power, kW Frequency, kHz Efficiency

Lamp 10 - 160 70 - 400 0.5 - 0.7

Machine 50 - 2500 2.5 - 10 0.7 - 0.8

Thyristor 160 - 800 1 - 4 0.90 - 0.95

Surface hardening of small parts (needles, contacts, spring tips) is carried out using microinduction generators. The frequency they produce reaches 50 MHz, the heating time for hardening is 0.01-0.001 s.

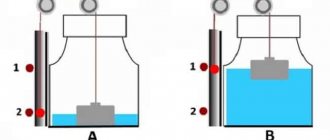

Cooling parts

Cooling is the second important stage of the hardening process; the quality and hardness of the entire surface depends on its speed and uniformity. Cooling occurs in coolant tanks or by spray. For high-quality hardening, it is necessary to maintain a stable temperature of the coolant and prevent it from overheating. The holes in the sprayer must be of the same diameter and spaced evenly, this way the same metal structure on the surface is achieved.

To prevent the inductor from overheating during operation, water is constantly circulated through the copper tube. Some inductors are made combined with a workpiece cooling system. Holes are cut in the inductor tube through which cold water enters the hot part and cools it.

Hardening with high frequency currents

INDUCTORS

Inductors are designed to form an alternating magnetic field that transfers energy to the metal for heating.

The design of the inductor is determined by the requirements for the localization and heating intensity of a particular part, therefore, for each heated part, an optimal inductor must be designed.

To heat cylinders, internal surfaces of cylindrical holes, planes, complex surfaces, for example, a tooth or cavity between gear teeth, water-cooled inductors are designed from a copper tube, in the design of which, if necessary, a magnetic core and a sprayer are used.

For large parts, flexible inductors are made from wire or copper tape.

INTERM LLC carries out calculations, design and manufacture of inductors for heating parts in various technological processes. The manufactured inductor is tested on a sample of the part to ensure that the heating parameters comply with the technical specifications; the parameters of the equivalent circuit of the inductor and the range of their change during heating of the part are measured. These data are used to determine the optimal parameters of the matching unit - the transformation ratio of the matching transformer and the capacitance of the compensating capacitor.

Examples of inductors developed by INTERM LLC using calculation and experimental methods, measured parameters of inductors and the ranges of their changes during the heating process are given in the “INDUCTORS” section

Advantages and disadvantages

Hardening of parts using HDTV has both advantages and disadvantages. The advantages include the following:

- After high-frequency quenching, the part retains a soft center, which significantly increases its resistance to plastic deformation.

- The cost-effectiveness of the process of hardening HDTV parts is due to the fact that only the surface or zone that needs to be hardened is heated, and not the entire part.

- During mass production of parts, it is necessary to set up the process and then it will be automatically repeated, ensuring the required quality of hardening.

- The ability to accurately calculate and adjust the depth of the hardened layer.

- The continuous-sequential hardening method allows the use of low-power equipment.

- A short heating and holding time at high temperature contributes to the absence of oxidation, decarburization of the top layer and the formation of scale on the surface of the part.

- Rapid heating and cooling does not result in large warpage and distortion, which allows for a reduction in finishing allowance.

But it is economically feasible to use induction installations only for mass production, and for single production, purchasing or manufacturing an inductor is unprofitable. For some parts with complex shapes, induction production is very difficult or impossible to obtain a uniform hardened layer. In such cases, other types of surface hardening are used, for example, gas-flame or volumetric hardening.

MATCHING BLOCKS

Inductors are varied and have unique parameters, as they are designed for a specific part and technological process. To match a serial power source with a specific inductor, a matching device is used, which includes a high-frequency matching transformer and a capacitor that compensates for the reactive power of the inductor. The transformation ratio and capacitance of the capacitor must be selected so that this inductor is optimally matched with the generator, i.e. The rated power in the frequency range of the power source was transferred to the part.

Standard design solutions of our matching blocks allow us to quickly produce blocks with the required parameters through prototyping.

Additional opportunities for coordination are provided by the provided switching of the transformation ratio or capacitance of the capacitor.

The section “MATCHING BLOCKS” provides matching circuits and a method for determining their optimal parameters based on the range of changes in inductor parameters during the heating process.

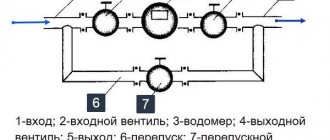

Electrical circuit diagram

Circuit of an induction heater from 12V

Here is the original circuit of the induction heater generator, and below it is a slightly modified version, according to which the design of the mini HDTV installation was assembled. There is nothing in short supply here - you only have to buy field-effect transistors; you can use BUZ11, IRFP240, IRFP250 or IRFP460. The capacitors are special high-voltage, and the power will be from a 70 A/h car battery - it will hold current very well.

The project turned out to be surprisingly successful - everything worked, although it was assembled “on the knee” in an hour. I was especially pleased that it does not require a 220 V network - car batteries allow you to power it even in the field (by the way, can you make a camp microwave out of it?). You can experiment in the direction of reducing the supply voltage to 4-8 V as from lithium batteries (for miniaturization) while maintaining good heating efficiency. Of course, it won’t be possible to melt massive metal objects, but it will work for small jobs.

Useful: Homemade Rogowski coil for current up to 10,000 Amperes

The current consumption from the power supply is 11 A, but after warming up it drops to about 7 A, because the metal resistance increases noticeably when heated. And do not forget to use thick wires here that can withstand more than 10 A of current, otherwise the wires will become hot during operation.

Heating a screwdriver to blue HDTV

Heating the knife HDTV

Areas of application of ultrasonic welding

Ultrasonic welding today is the leading method of joining polymer materials, and in some cases the only possible one. Ultrasonic welding of plastics is based on artificially created mechanical vibrations, which are applied to the contact zone and converted into thermal energy.

More than half of the known thermoplastic polymers are welded by ultrasound. Ultrasonic welding of plastics is all the more valuable because for a number of polymers it is the only possible reliable joining method. Polystyrene, one of the most common polymers for the manufacture of various products in large-scale production, is most rationally welded by ultrasound.

Ultrasonic welding machines are used for welding hard polymers and plastics, synthetic fabrics, plastics with metals, soft plastics, artificial leather.

The disadvantages of using an ultrasonic connection are the rather low power of the welding process, which often leads to the need to use a two-way method of supplying energy, and the lack of an accurate and practical method for monitoring the quality of the seam.

Muffle furnace for metal hardening

Muffle furnaces are called furnaces in which the metal being processed is isolated from the heaters. High-temperature electric heaters have made the electric muffle installation the most popular type of such equipment.

Muffle furnace for metal hardening

Traditionally the oven consists of:

- Metal body and muffle made of heat-resistant material and forming the working chamber;

- Spiral type heaters, wound onto ceramic tubes and placed in the grooves of the muffle;

- Thermal insulation, which fills the gap between the working chamber and the body;

- Ceramic door;

- Holes on the back surface for the use of a thermocouple providing temperature control;

- Thermostat operating in automatic mode.

In muffle devices, as a rule, three-sided heating is implemented, provided by heaters on the side surfaces and the bottom. Thanks to this placement of heaters, the temperature is more evenly distributed in the work space.

High-quality insulation in several layers minimizes heat loss and helps save energy resources. Plates made of refractory ceramics or heat-resistant stainless steel provide protection for the hearth of the device.

In many modern models, the door opens upward, so the operator is reliably protected from thermal radiation. Sensors turn off the current the moment the door opens.