Equipment for truck tire fitting is distinguished by its relatively large size and weight, durable materials and increased wear resistance. Its composition in the workshop depends on the range of services provided, but most often consists of the following necessary machines and tools:

- truck tire changing stand;

- balancing stand for cargo wheels;

- vulcanizer;

- side expander;

- rolling jack;

- pneumatic impact wrench;

- piston compressor.

Tire changer

When choosing the main equipment for tire fitting, you should pay attention to the diameter of the rims for which it is designed. The standard size is 14-26”, but allows for extensions to extend the range to 42”. A larger diameter is necessary for servicing road and agricultural equipment, which is not always necessary when the workshop is located along a federal or regional road.

The second important indicator is the power of the machine’s electric motor: for trucks and passenger transport, up to 2 kW is sufficient power. Price range depending on characteristics: RUB 130,000–1,300,000.

Truck vertical tire changing machine TS-26

Cost : 130,000 rub.

Manufacturer : China.

Features : Built-in hydraulic wheel lift. Wall installation is acceptable. The hydraulic emergency valve releases excess pressure.

Specifications:

- disc diameter 19-26 inches;

- maximum tire diameter 1400 mm;

- maximum wheel weight 380 kg;

- working pressure 130 bar;

- engine power 3.3 kW;

- power supply 380 V;

- dimensions 1250x1190x1650 mm;

- weight 485 kg.

Truck tire changer FLYING TCS-26

Cost : 210,000 rub.

Manufacturer : China.

Features : Two rotation speeds. Pressure adjustment. Rapid change of position.

Specifications:

- disc diameter 14-26 inches;

- maximum wheel diameter 1600 mm;

- maximum wheel weight 500 kg;

- engine power 1.5 kW;

- voltage 380 V;

- dimensions 2000x1580x950 mm;

- weight 528 kg.

Truck tire changer up to 56” GIULIANO S551 XL

Cost : 800,000 rub.

Manufacturer : Italy.

Features : Suitable for agricultural machinery. Self-centering wheel clamp. Mobile remote control.

Specifications:

- disc diameter 14-56″;

- maximum wheel weight 1500 kg;

- maximum wheel width 110 mm;

- power supply 380 V;

- electric motor power 1.5 kW;

- weight 790 kg.

Tire changer M&B DIDO 30

Cost : 500,000 rub.

Manufacturer : Italy.

Features : Self-centering grip for all types of discs. Adjustment of fixation force.

Specifications:

- disc diameter 14–30″;

- maximum wheel diameter (mm) 1640 mm;

- maximum wheel weight 1200 kg;

- voltage 380 V;

- power 1.5 kW;

- gross weight 640 kg;

- packaging dimensions 185x147x97 cm.

Semi-automatic truck tire changer HOFMANN MONTY 5800 BA

Cost : 1,300,000 rub.

Manufacturer : Germany.

Features : For wheels of all types of trucks. High spin force.

Specifications:

- disc diameter 4–58″;

- maximum wheel diameter 2500 mm;

- bead pressing force 3800 N;

- maximum wheel weight 2000 kg;

- engine power 3 kW;

- power supply 380 V;

- dimensions 2000/2100/2960 mm;

- weight 1400 kg.

Rating of the best balancing machines

| Nomination | place | Name of product | price |

| The best balancing machines for passenger cars | 1 | M&B WB277N | 143 000 ₽ |

| 2 | STORM Proxy-8-2p | 265 000 ₽ | |

| 3 | ATIS WB986 | 105 000 ₽ | |

| 4 | Nordberg 4523PA | 113 000 ₽ | |

| Best balancing machines for trucks | 1 | Stankoimport ST-200A (T) | 140 000 ₽ |

| 2 | BT-850 AE&T | 153 000 ₽ | |

| 3 | Nordberg 45TRKE | 135 000 ₽ |

Balancing machine

To eliminate the displacement of the wheel mass relative to its axis, reduce vibration and increase service life after tire fitting, they work with it on a balancing stand. An important quality of this equipment is minimal error. Expensive Italian machines have optimal performance, while Russian-made machines have average performance. Chinese machines, at the most attractive prices, are equipped with sensors that are not of the highest accuracy and quickly break down. The simplest balancing machine will cost less than 90 thousand rubles, the most expensive model in this selection is 800 thousand rubles.

Balancing load stand TS-850

Cost : 88,000 rub.

Manufacturer : China.

Features : For passenger cars and trucks. Pneumatic trolley included. Works only on flat surfaces.

Specifications:

- maximum wheel weight 150 kg;

- wheel diameter 1200 mm;

- disc diameter 13″–24″;

- measurement time 8 s;

- rotation speed 200 rpm;

- supply voltage 220/380 V;

- power 0.6 kW;

- dimensions 1220x960x1190 mm;

- weight 226 kg.

Universal balancing stand STORM MAXI

Cost : 180,000 rub.

Manufacturer : Russia.

Features : Automatic mode without pressing buttons. Adapts to operator habits. Two operating modes for passenger and truck wheels.

Specifications:

- Max. disc diameter 10–30″;

- Max. wheel width 500 mm;

- voltage 220 V;

- wheel weight up to 200 kg;

- power consumption 0.75 W;

- overall dimensions with casing 1360x1360x1375 mm;

- weight 130 kg.

Automatic balancing stand SIVIK TRUCKER LUXE

Cost : 230,000 rub.

Manufacturer : Russia.

Features : Load wheel in 50 s. Pneumolift. Function for dividing large loads.

Specifications:

- disc diameter up to 28″;

- power supply 220 V;

- wheel weight up to 200 kg;

- maximum tire diameter 1200 mm;

- dimensions 2100x1370x1800 mm;

- weight 308 kg.

Truck balancing machine SICE S-696

Cost : 560,000 rub.

Manufacturer : Italy.

Features : Self-diagnosis, self-balancing. Equipped with a pneumatic lift. Special program for alloy wheels. Automatic data entry.

Specifications:

- maximum wheel diameter 52”;

- wheel weight up to 200 kg;

- power supply 230 V;

- rotation speed 99 rpm;

- overall dimensions 2600x880x2350 mm;

- machine weight 255 kg.

Balancing stand with pressure roller HUNTER GSP9600HD

Cost : 800,000 rub.

Manufacturer : USA.

Features : Roller with imitation road surface. Prediction of wheel behavior on the road. Automatic positioning of weights.

Specifications:

- disc diameter 10–30″;

- maximum wheel diameter 1321 mm;

- wheel weight up to 227 kg;

- power 2.53 kW;

- weight 486 kg.

Selection process

A passenger balancing machine designed for servicing wheels weighing up to 70 kg is very popular This category includes not only cars, but also light trucks, motorcycles and scooters.

This tool is multifunctional and allows you to work in different modes. An alternative is service wheels up to 200 kg. With their help, you can repair full-fledged trucks, off-road vehicles, and tractors. Bright balancing machine is popular with customers .

Used in auto repair shops in the process of eliminating wheel imbalance. This is required to increase driving safety and extend the service life of the chassis.

Depending on the correct choice, you can ensure optimal productivity of the enterprise, determine its direction, as well as the quality of work.

An important factor in determining the direction of activity is the division of stands into equipment designed to work with trucks and cars. You can choose the Best balancing machine for these two categories.

Wheels of cars, as a rule, have a diameter of up to 20 inches, trucks - up to 60. If you decide to service both of them, you can choose one for trucks; it can serve as a universal one.

To achieve maximum measurement results, it is necessary to use equipment specifically designed for each category of vehicle.

When considering the type of data entry, automatic and manual entries are used. These characteristics will determine the efficiency of the work process, since automatic equipment significantly reduces time and quickly measures wheel parameters; electronic rulers are used for this.

Stands operating in manual mode have a liquid crystal display.

An important criterion that can determine the choice is the type of software. As a rule, programs for static balancing are installed for metal wheels, as well as several for light alloy wheels. It is possible to purchase with the possibility of self-diagnosis and self-calibration. With their help, the quality of work improves. Self-control and precision are essential in the balancing process. The HPMM balancing machine can provide this .

Some equipment has mechanisms that allow the wheels to move vertically. This makes it possible to prevent potential errors arising from unstable rotation rates, which is observed when using stands with manual transmission.

In some cases, choosing balancing equipment is a difficult task. Some brands are similar in the main parameters. The selection must be taken responsibly, since the quality and speed of work, respectively, the reputation of the establishment and the profit of the owner, depend on this.

Vulcanizer

Equipment for restoring the tightness of a tire using a hot method is called a vulcanizer. This is one of the most popular repair areas among truck drivers. In truck tire fitting, tabletop and floor-mounted vulcanizers with a power of more than 1 kW, equipped with a timer, are more often used. The cost of a unit of equipment varies from 25,000 rubles. up to 140,000 rub. depending on the maximum wheel diameter and heating technology.

Electric vulcanizer for truck wheels GARO 6140

Cost : 25,000 rub.

Manufacturer : Russia.

Features : Tabletop. Low power.

Specifications:

- supply voltage 220 V;

- power consumption 970 W;

- heater temperature 143 C;

- dimensions 405x350x630 mm;

- weight 55 kg.

Vulcanizer "SIBEK Maxi"

Cost : 52,000 rub.

Manufacturer : Russia.

Features : Electronic timer. Variable geometry of the working surface.

Specifications:

- supply voltage 220 V;

- power consumption 1200;

- heating temperature 145±10% C;

- overall dimensions 360x740x1230 mm;

- weight 55 kg.

Roll-away vulcanizer "Sibek ELF-P"

Cost : 89,000 rub.

Manufacturer : Russia.

Features : Easy access to the repair area. Two positions. Automatic control system. Built-in tool cabinet.

Specifications:

- working surface temperature 145±10% C;

- supply voltage 220 V;

- power consumption 1200 W;

- overall dimensions 520x940x1710 mm;

- weight 90 kg.

Vulcanizer TECH S1018-220

Cost : 120,000 rub.

Manufacturer : USA.

Features : One-stage and two-stage repair methods. High strength patches.

Specifications:

- weight 33 kg;

- dimensions 660x200x920 mm;

- heating plates 2 pcs.;

- clamp width 200 mm.

Truck tire vulcanizer "Complex-2"

Cost : 140,000 rub.

Manufacturer : Russia.

Features : Temperature control at several points. Automatic shutdown.

Specifications:

- power supply voltage 220 V;

- rated power 1400 W;

- working temperature of vulcanization 140 C;

- size 850x950x1500 mm;

- weight 60 kg.

How does it work

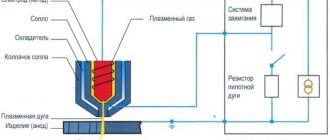

Without equipment of this type it is extremely difficult to imagine a modern tire service. Even in small workshops there is room for a device that will take up to 3 square meters. m area. Preliminary strengthening of the foundation is also not required. The base of the structure is reinforced. On one side the shaft for the wheel is mounted. A protective casing is attached to the top. Depending on the power of the electric motor and the dimensions of the casing, the size of the wheel that is attached to the stand depends.

The principle of balancing is to spin the wheel, which detects axle deviations during rotation. This happens differently in each model.

For convenience, below is a comparative table with an overview of the main indicators.

| type of drive | Description |

| Auto | The best solution for most enterprises in this service sector. The necessary operations are performed automatically - by machine. The wheel is spun by a shaft. Measurements are carried out using an electronic ruler. Detected deviations are displayed on the monitor. After a short processing of the data, the installation locations of the weights are determined automatically, as is their weight. Voice commands can be used for greater control convenience. |

| Semi-automatic | The tire spin-up also occurs automatically. No outside efforts should be made for this. Regardless of the brand, data will have to be entered into the computer manually. |

| Manual | The shaft is untwisted manually. To measure basic parameters you will need a mechanical ruler. The information received is compared with the GOST manual on deviations. |

What should you pay special attention to when choosing popular models? On the manufacturer, consumer reviews and the cost of the basic kit. Most modern enterprises rely on the quality of equipment, thereby reducing the number of employees. In this case, preference should be given to expensive and fully automated designs made in Russia or China.

Such devices are capable of identifying problems in one cycle and eliminating them if necessary. During a work shift, you will be able to serve more clients, which means your income will be higher. Customers spend less time visiting a service station, which means they will prefer to return there again.

Extender

The presence of equipment to widen the tire beads in order to improve access to the inside of the tire is an optional option. However, the presence of a bead expander greatly simplifies the work in complex repair cases and increases the speed of work.

Depending on the method of operation, side expanders are divided into hydraulic and pneumatic, the latter of which are widely used in truck tire repair. Their cost varies from 46,000 rubles. up to 80,000 rub.

Extender SIVIK KS-116

Cost : 46,000 rub.

Manufacturer : Russia.

Features : Pneumatic tire lifting system.

Specifications:

- maximum tire weight 80 kg;

- pressure 8-10 bar;

- working height 550 mm;

- dimensions 500x780x790 mm;

- weight 59 kg.

Pneumatic bead expander Rossvik BT-62C

Cost : 60,000 rub.

Manufacturer : Russia.

Features : Suitable for agricultural machinery.

Specifications:

- load capacity 100 kg;

- working pressure 10 bar;

- side extension 540 mm;

- voltage 220 W;

- weight 120 kg;

- overall dimensions 1250x810x800 mm.

Pneumatic bead expander TROMMELBERG TS-S203

Cost : 80,000 rub.

Manufacturer : China.

Features : Stability. Light source on a flexible base.

Specifications:

- lamp lamp 12 V;

- power supply 220 V;

- operating air pressure 8-10 bar;

- dimensions 1860x920x1080 mm;

- weight 133 kg.

Pneumatic side expander POLARUS BR-P

Cost : 63,000 rub.

Manufacturer : Russia.

Features : Pneumatic lift. Long-term fixation in a given position.

Specifications:

- maximum tire width 300 mm;

- power supply 220 V;

- operating air pressure 8–12 bar;

- flange height 145–275 mm;

- dimensions 1880x1200x1140 mm;

- weight 140 kg.

Truck side spreader NORDBERG D5

Cost : 70,000 rub.

Manufacturer : China.

Features : Installation table, lift.

Specifications:

- Max. tire weight 150 kg;

- voltage 220 V;

- operating pressure 8–12 bar;

- dimensions 1500x1200x1200mm.

What is a balancing machine and how it works

In order to remove wheel imbalance, a balancing machine is used, which is special equipment. The technician determines the difference in the distribution of the wheel mass in relation to the center of the wheel. Different machine models may have different options and technical capabilities. The principle of operation of the balancing stand is based on the fact that the product rotates, at which point pressure or vibration is recorded by sensors. What exactly will be recorded depends on the type of equipment purchased.

On the balancing stand, the car's wheels begin to rotate, as if they were actually driving on the road. The indicators are recorded electronically, and the master receives the values necessary for selecting loads. Then they are fixed on the disk, due to which the centrifugal forces are equalized.

Depending on what additional options and what equipment the machine has, the wider or narrower its functions will be. The machine itself consists of parts:

- the shaft on which the wheel itself is attached;

- the motor that drives the mechanism;

- sensors through which the received information is recorded and transmitted to the computer.

Balancing must be carried out on fully functional equipment with a caliber. If this condition is not met, then the quality of the wheel balancing procedure is called into question and the car itself may be damaged. After such an incident, the tire shop will lose its reputation and will work for a long time to restore it.

Jack

Rolling jacks are used to lift and hold the vehicle while the wheel is being repaired. For freight transport, the required lifting capacity of the equipment is from 5 tons and above, the lifting height is from 35 cm. The price range is from 13,000 rubles. for a simple Chinese lift up to 175,000 rubles. for the Spanish model made of especially durable alloy.

Pneumohydraulic rolling jack ZX1001F

Cost : 13,000 rub.

Manufacturer : China.

Features : Large diameter metal wheels. Rubberized drive handle.

Specifications:

- load capacity 50 t;

- lifting height 280-470 mm;

- dimensions 1350x300x295 mm;

- weight 33 kg.

Pneumohydraulic jack Nordberg N-3322L

Cost : 17,000 rub.

Manufacturer : China.

Features : Telescopic working piston. Low axis position.

Specifications:

- load capacity 22 t;

- pick-up height 185–465 mm.

Rolling hydraulic jack GARO ZD-2210L

Cost : 33,000 rub.

Manufacturer : China.

Features : Optimal model for various types of trucks

Specifications:

- load capacity 10 t;

- lifting height 170-570 mm;

- dimensions 1660x520x350 mm;

- weight 58 kg.

Mobile pneumohydraulic jack PASQUIN P 102

Cost : 90,000 rub.

Manufacturer : Italy.

Features : Two-stage lifting system

Specifications:

- height 175–360 mm;

- load capacity 15 t/30 t;

- weight 28 kg;

- working pressure 9-12 bar.

Rolling pneumohydraulic jack MEGA N20-3

Cost : 175,000 rub.

Manufacturer : Spain.

Features : High quality alloy, impact resistant. Modular design. Lowering with control system.

Specifications:

- load capacity 20 t/35t/65 t;

- lift up to 415 mm;

- packaging dimensions 1500/420/370 mm;

- weight 70 kg.

Impact wrench

Pneumatic impact wrenches are used to loosen the connections of cargo wheels. The main characteristics that you need to pay attention to are: power, torque, tightening torque. The same parameters also affect the cost: various models can be purchased with a budget of 14,000 rubles or 115,000 rubles.

Reinforced tire changer ROTAKE RT-5770

Cost : 14,000 rub.

Manufacturer : China.

Features : Metal body. Two handles. Built-in reverse.

Specifications:

- maximum force 3200 Nm;

- free rotation speed 3200 rpm;

- air flow 651 l/min;

- connection 1/2″;

- working pressure 6.2 bar;

- weight 16 kg.

Pneumatic impact wrench KING TONY P33622-075B

Cost : 25,000 rub.

Manufacturer : Taiwan.

Features : Compact, lightweight.

Specifications:

- weight 7 kg;

- maximum tightening force 1085 Nm;

- air flow 198 l/min;

- rotation speed 6500 rpm.

Impact wrench for trucks Chicago Pneumatic CP7780-6

Cost : 39,000 rub.

Manufacturer : Belgium.

Features : Aluminum housing. Ergonomic handle.

Specifications:

- maximum torque 2320 Nm;

- air consumption at load 23.4 l/s;

- idle speed 5000 rpm;

- length 520 mm;

- weight 7.7 kg.

Pneumatic impact wrench SUMAKE ST-55881-8

Cost : 57,000 rub.

Manufacturer : Taiwan.

Features : Fit size 1”.

Specifications:

- air flow 566 l/min;

- working pressure 6.5 Atm;

- torque 2439 N/m;

- rotation speed 4200 rpm;

- weight 10.6 kg.

Rolling electric impact wrench KRAFTWELL KRW12

Cost : 115,000 rub.

Manufacturer : China.

Features : For nuts of cargo and passenger vehicles. Does not require compressed air. Easy.

Specifications:

- power 0.75 kW;

- network 380 V;

- torque 450-950 Nm;

- rotation speed 1400 rpm;

- force 4000 Nm;

- dimensions 1340x560x1070 mm;

- weight 64 kg.

Compressor

The characteristics of the compressor are selected for the pneumatic equipment used. Important indicators in this case are the need for continuous operation, compressor power and receiver capacity. On average, the cost of a compressor is from 45,000 rubles. up to 170,000 rub.

Piston compressor KronVuz Air BV300

Cost : 45,000 rub.

Manufacturer : Czech Republic.

Features : Efficient cooling system. Small cast iron parts.

Specifications:

- receiver volume 300 l;

- productivity 1325 l/min;

- pressure 12.5 bar;

- mains voltage 380 V;

- power 7.5 kW;

- rotation speed 2900 rpm;

- overall dimensions 1610x590x1170 mm;

- weight 288 kg.

Piston compressor FIAC AB 300-858/16

Cost : 90,000 rub.

Manufacturer : Italy.

Features : Cast iron piston block. Drain valve.

Specifications:

- receiver 270 l;

- productivity 850 l/min;

- pressure 16 bar;

- power 7.5 kW;

- voltage 380 W;

- dimensions 1650x510x1150 mm;

- weight 205 kg.

Piston compressor Remeza SB4/F-500.LT100

Cost : 120,000 rub.

Manufacturer : Belarus.

Features : Two-cylinder. Belt drive.

Specifications:

- receiver 500 l;

- productivity 1400 l/min;

- pressure 16 bar;

- power 11 kW;

- voltage 380 W;

- dimensions 2000x610x1250 mm;

- weight 320 kg.

Piston oil compressor NORDBERG AUTOMOTIVE NC500/1000-15

Cost : 150,000 rub.

Manufacturer : China.

Features : Oil. Horizontal receiver.

Specifications:

- productivity 1390 l/min;

- receiver volume 500 l;

- idle speed 1100 rpm;

- working pressure 15 bar;

- power 11 kW;

- overall dimensions 1980x600x1450 mm;

- weight 345 kg.

Piston compressor FIAC ABT 500-1700B/16

Cost : 170,000 rub.

Manufacturer : Italy.

Features : Four-speed. Belt drive type.

Specifications:

- receiver 500l;

- productivity 1660 l/min;

- pressure 16 bar;

- power 15 kW;

- voltage 380 W;

- dimensions 2050x600x1250 mm;

- weight 340 kg.

Balancing machines are high-precision equipment with an electronic measuring system that determines the magnitude and location of dynamic (static) imbalance of machine parts and mechanisms that are symmetrical relative to the axis of rotation (shafts, rotors, wheels, disks, etc.).

The BALTECH company is a supplier of universal machines of the BALTECH HBM (horizontal), BALTECH VBM (vertical) and BALTECH SBM (special) series, which have been manufactured in accordance with GOST 20076-2007 (ISO 2953:1999) for more than ten years.

Over the years, we have launched the production of more than fifty models of pre-resonance and post-resonance balancing machines for balancing rotors and parts weighing from 1g to 110 tons.

Advantages of BALTECH balancing machines:

- Full compliance with international requirements according to the ISO standard;

- Universal platform (with cardan or belt drive) for different types of rotors;

- Automatic calculation of balancing masses and their automatic selection (optional);

- Simple and intuitive interface;

- Software in Russian (additionally 15 languages);

- High precision balancing equipment;

- Low cost of operation and maintenance;

- Free training for all users in the educational

- Permanent calibration;

- Availability of control (test) rotors for all types of machines;

- Quick changeover when switching from one type of rotor to another;

- No special tool required for changeover;

- Extended warranty up to 5 years;

We draw the attention of all users of balancing machines from different manufacturers that from this year we offer a free technical audit of machines to make a decision on maintainability or replace your balancing equipment with our new machines under the “TRADE-IN” program.

When delivering any balancing equipment, our specialists carry out supervision of installation, checking the correct installation of machines, commissioning and balancing training at the Customer’s enterprises.

Post-warranty service - provides lifelong service support for all supplied equipment.

Types of supplied balancing machines and automatic balancing lines:

- for fan rotors and impellers

- for electric motor armatures

- for press cylinders

- for machine and running spindles

- for pump and compressor impellers

- for turbine units

- for cardan shafts and crankshafts

- for grinding wheels

- for separators, centrifuges

- for disks and spare parts

- for assembled mechanisms

According to the technical specifications, special balancing machines and balancing equipment of other standard sizes and purposes not included in the standard specifications can be produced.

Bottom line

To equip a truck tire service with the necessary machines and tools, an average investment of 360–560 thousand rubles will be required. The exact amount depends on the niche focus on a certain type of truck, the degree of automation of the equipment and its projected service life.

Machines for working with large agricultural vehicles in the maximum configuration will cost the business owner 2.7 million rubles, which is significantly different from the cost of a set of equipment for vans and passenger transport.

Top 10 foreign brands

| 1st place Hofmann Country - Italy Turnover - $3.4 billion (Snap-on Incorporated, 2021) Number of employees - 12,000 (Snap-on Incorporated, 2021) The Hofmann brand is 80 years old. The quality and technical excellence of Hofmann machines is evidenced by the fact that they are used for primary tire fitting by European automakers. In the secondary market, the position of the Italian company is strongest in Italy, Germany, Austria, France and the UK. Nowadays, Hofmann is one of the most valuable assets of the Snap-on concern. | 2(3)** place Hunter Country - USA Turnover - $30 million (2015) Number of employees - 400 (2015) The name of entrepreneur Lee Hunter is included in the US Automotive Hall of Fame. The Hunter Engineering Company, founded by him in 1946, remains independent in the 21st century even though it is small in size - the entire engineering staff is 75 people. — remains one of the leaders in the global garage equipment market. Outside the US, Hunter's position is strongest in Canada, China, Germany and Russia. | 3(4) place AE&T Country - Russia/China The AE&T brand belongs to a Russian company that develops both its own auto service business and the supply of Russian auto repair shops with equipment and tools. AE&T equipment is reportedly manufactured under contract in China. |

| 4(5) place Trommelberg Country - Germany In the garage equipment segment, the main players include many small and young companies. Among them is August Handel GmbH, founded in 2003 and specializing in garage equipment. The company strives to be a technical leader by investing 10% of turnover in R&D - a traditional strategy for German business | 5 (6) place SICAM Country - Italy SICAM was founded by talented Italian engineers Franco Magnani and Dido Boni in 1975. In their niche, they were able to become leaders: automakers recommend SICAM equipment to their dealers, and the area of its workshops exceeds 15 thousand square meters. m. The focus of the brand is the safety of the service provider. Since 2007, SICAM has belonged to the Robert Bosch concern. | $2.01 billion global market for wheel repair and tire fitting equipment in 2021 |

4.1% growth forecast over the next 10 years for the global garage equipment market | 6 (7) place M&B Country - Italy Having sold SICAM in 2005, Franco Magnani and Dido Boni immediately founded a new family business of the same profile, M&B Engineering - the letters in the name correspond to the surnames of the founders. M&B has a rather unusual positioning: focus on quality and at the same time on the budget segment. According to its own statement, M&B purchases all components from European manufacturers. | 7 (8) place Nordberg Country - Russia/China The budget brand of garage equipment Nordberg belongs to the Russian company, well known to service specialists. Since Nordberg equipment is mostly manufactured in China on a contract basis, we classify it among the brands of foreign manufacturers. |

| 8 (10) place Unite Country - China The Unite brand is owned by the Chinese manufacturer of garage equipment Shanghai Balance Automotive Equipment - a young company founded in 2005. In total there are 4 product groups: lifts, tire changing and balancing machines, wheel alignment stands - the company offers more than 200 different models. In the low-price niche typical for Chinese manufacturers, Unite provides a price-quality balance better than its competitors, judging by the assessments of Russian experts. | 9 (11) place Beissbarth (Postolovsky Oscillograph ) Country - Germany Number of employees - 200 The Beissbarth company boasts that its founders Daniel and Hermann Beisbarth were friends of Gottlieb Daimler himself. The Munich manufacturer of garage equipment has been operating since 1899, has recommendations from car manufacturers for use in dealer networks and has 250 distributors in different countries of the world. In 2007, Beissbarth, simultaneously with SICAM, came under the control of Robert Bosch. | 10th (12th) place Bosch Country - Germany Turnover - 73 billion euros (2016) Number of employees - 389,000 (2016) Number of employees in Russia - 1700 Bosch's tenth place is natural, given the brand's focus on high-tech products: the company strives separate your brand from associations with hardware. Nevertheless, Bosch garage equipment has a good reputation, and in Russia the company also stands out as one of the best packages of financial and information services. |