Screw

The design of most pumps and other equipment is related to the features of the auger. That is why it is necessary to consider in detail what a screw is and what properties it has. An auger is a rod with a continuous helical surface, which is located along one axis. When considering its characteristics, you should pay attention to the following points:

- Often the auger acts as the working part of the mechanism; its purpose is to move a load or other medium.

- The prototype device for the auger was the Archimedean screw. It has also become very widespread in the creation of various critical structures.

- The purpose may be related to the movement of various bulk materials.

In general, we can say that the auger is a rather complex product that resembles an ascending screw. In this case, the product may differ in a fairly large number of different characteristics, according to which classification is carried out.

How to make a screw with your own hands - make a flexible one

About two and a half thousand years ago, the ancient Greek mathematician, physicist and engineer Archimedes invented a water-lifting machine, which later became known as the Archimedes screw. It was this invention that served as the prototype of modern screw conveyors.

Augers, as they are otherwise called, have extensive applications in industry and beyond. Meat grinders, drills, drilling tools, all of this works with the help of augers.

Well, today we will talk in detail about the use of screw conveyors in snow blowers, consider the causes of malfunctions of its belts (read about them here), and learn how to replace worn-out machine elements with your own hands. Read more about DIY repairs here.

Classification

As previously noted, there are a variety of types of screws; the scope of application largely depends on the shape and other characteristics. The main features of the classification include the following points:

- Gutter slope.

- Spiral direction.

- Step Variability.

- Shaft diameter.

- Design versions.

All types of products are characterized by their own specific characteristics. Some types of augers are very widespread, others are installed much less frequently. An example is a reverse screw, which has a special direction of turns.

Horizontal auger

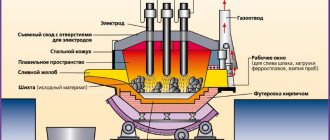

Belt-type conveyors are found today in a wide variety of production facilities. It is installed in industrial premises and is characterized by increased productivity. The main components of such a mechanism can be called the following:

- Drive unit. As a rule, it is represented by a combination of an electric motor and a gearbox designed to reduce the number of revolutions and significantly increase the transmitted force.

- The rotating screw is the auger that transports bulk materials.

- A trough with a semi-cylindrical base acts as a transport belt. It is this shape that provides the most favorable conditions for the accumulation and movement of bulk materials.

A hole is often created at the bottom of the chute through which bulk material is discharged. The key features of such a screw are the following:

- The surface of the propeller can be tape, solid, shaped, bladed and other shapes. The choice is made depending on what kind of cargo is to be transported.

- To transmit rotation, the part has a shaft. It can consist of separate sections, made in tubular form or solid.

- The shaft is fixed using an end or intermediate bearing.

- The required performance qualities are ensured due to the fact that one of the bearings is created as a thrust bearing.

Conveyors of this type are today installed in a wide variety of industrial facilities. This is due to their relatively low price and increased reliability, as well as the required efficiency.

Types of auger screws used in conveyors

The screw is the main working part of the device. Its shape and material used for manufacturing depend on the specific purpose of the unit.

The main screw designs used are as follows:

- Solid. Stamped steel segments are connected into a single spiral and installed on the shaft using welding or threaded connections. Used for transporting fine and medium-grained powdery substances that are not prone to caking. The pipe is filled with a load by 30-40%, the rotation speed is from 50 to 120 rpm.

- Tape. It differs from a solid screw in that there are gaps left on the shaft side. They provide lower productivity due to the fact that the load partially falls back through the slots. This design is used for media prone to caking and ensures their mixing and crushing of compacted lumps during transportation. Can handle gravel, crushed stone and similar materials. The gutter filling rate is 24-40%, rotation speed is from 25 to 100 rpm.

- Bladed. The propeller is divided into separate blades. They walk at equal pace. Simultaneously with the supply of material, the blades loosen and mix it. Used for feeding lump materials, the chute is filled by 25-35%, rotation speed is from 40 to 100 rpm. Also used for moving wet media such as cement mortar or moistened clay. In this case, the filling is 15-25%, the rotation speed is from 30 to 60 rpm.

- Shaped The solid profile of the screw is complemented by shaped cutouts and protrusions on the outer edge. Performs a number of operations at once, such as moving, grinding, stirring. Suitable for concrete, asphalt and clay mixtures. The gutter is filled by 15-30%, rotation speed is 30-60 rpm.

Screw feeder

The screw is only an executive part. For rotation, a kind of feeder is installed, which may have various design features. The classic version is represented by a combination of the following elements:

- Electrical engine. Such a device in most cases ensures the creation of rotational motion. There are models that can be powered from 220V and 380V.

- The safety clutch eliminates the possibility of damage to the electric motor when a large force occurs. There are many different types of safety couplings installed, all of which have their own specific properties.

- As a rule, at the output of an electric motor, the shaft receives a large number of rotations. In this case, the transmitted force is not significant. This can be changed by installing a gearbox, for example, a worm gearbox.

- The gearbox is connected to the working unit using a gear drive. It is characterized by increased wear resistance and can last for a long period. By changing gears, you can change the transmitted force or the number of output revolutions.

The feeding device can withstand high loads and will last for a long period.

Vertical auger

A vertical version of the auger can also be installed. Let's call its key points the following:

- The part is represented by a combination of a short horizontal screw, which is protected by a special cylindrical casing.

- The auger is mounted suspended on a special thrust bearing. To reduce the likelihood of damage to the bearing, it is protected and periodically lubricated.

- Bulk or other cargo is fed into the lower part of the structure. In this case, the pitch of the main screws can be constant or variable.

It is worth considering that a vertical auger can only be used when the height is 15 meters.

In some cases, they are installed as the main element of a tool intended for drilling wells and carrying out other excavation work.

Design versions

There are different tool designs available for different drilling tasks. In general, equipment is produced with a diameter from 72 to 750 mm, the length of drill rods from 0.4 to 12500 mm.

Rotational torque is transmitted from one rod to another by connections in various forms:

- triangular;

- quadrangular;

- hexagonal;

- conical

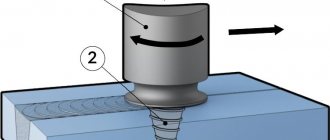

The axial moment is transmitted through fingers inserted into special holes in the drill rods. An auger is a replaceable drilling tool, which is a screw structure with several turns of a certain size, placed along the entire length of the auger or on part of it.

The lower part of the auger, which begins drilling, is equipped with a drilling element and cutters that destroy the soil during operation, which is then led to the wellhead along the screw groove.

The screw element is the most worn part of the auger; it is not replaceable and, ultimately, determines the lifespan of the auger itself.

Use of screws and their principle of operation

The simplicity of the part and its relatively low cost determined its wide distribution. An example is the following:

- The principle of operation determines that the auger is installed as the main part of various equipment with which drilling is carried out.

- Equipment in the food industry is also often created based on this part.

- Many equipment from the agricultural field are also represented by a combination of an electric motor and auger.

- Mechanisms designed to transport various goods.

Today it is difficult to imagine industrial enterprises without a left or right screw device.

The principle of operation is primarily associated with the use of a rotary screw, the spiral part of which performs the main actions. Bulk material can be located between the body and the screw feather.

Due to its versatility, it is possible to create a wide variety of equipment without requiring significant financial investments.

Basic operating schemes

On the Internet you can find a drawing of a screw. It should be taken into account that there are several operating schemes: pulling and pushing. In the first case, the drive is located on the unloading side, in the second, on the loading side. In this case, a calculation formula can be used to calculate the maximum permissible load.

The concept of extrusion is often used. This method of molding plastic materials significantly speeds up the production process and also eliminates the possibility of the human factor influencing the result. It is used in the production of rubber products and is associated with the vulcanization process.

During operation, constant friction of the working surface occurs. Because of this, the degree of wear increases significantly, and you have to constantly spend money on maintaining the mechanism in working condition. Even minor damage can cause serious wear and tear. You can solve the problem by making such a part yourself, as this is much cheaper.

Manufacturing methods

If you need to reduce your own costs, you can create a screw yourself. For production you will need the following:

- Sheet steel, which has a thickness of 3 mm.

- A shaft through which force is transmitted.

- Fastening connections that ensure the fixation of the part.

- Two-stage gearbox. To select, the screw is calculated; the purpose of the gearbox is to reduce the number of revolutions and increase the force.

- An electric asynchronous motor transmits the main rotation. Today, in most cases, a 220V model is installed, as it is characterized by high efficiency and low energy consumption.

The auger drive is characterized by its small size in the case where it is not necessary to significantly change the output parameters of the electric motor. The standard housing is made in the form of a pipeline, which is divided into several sections. In this case, the sections are connected with bolts. There are also two sections: one is for loading, the second is for unloading the transported material.

You can often encounter a situation where self-manufacturing of a mechanism involves remaking an old one. Many experts note that such an approach is impractical. You can calculate productivity by applying certain formulas.

To produce a screw device, a certain set of tools is also required:

- Welding machine.

- Bulgarian.

- Hacksaw for metal.

- Various measuring instruments.

To increase the efficiency of the device, you should monitor the shape of the coil. Even minor defects can cause a significant decrease in equipment performance.

How to make a screw with your own hands

The manufacture of the screw is carried out in several successive stages:

- We make a frame from pipes. Typically, the drawings give dimensions of 50 x 70 cm. Based on the size of your motor and the size of the bucket 50 x 30 cm, you can choose the most suitable frame size yourself.

- The auger itself is made of a pipe; a 270 x 120 mm blade made of two or three mm steel is installed in its center. The screws can be made from conveyor belt, but it is preferable to use steel.

- Balance the screw by removing excess metal with a grinder. To do this, install the screw in the finished seat and turn it by hand, so you can find out where the metal needs to be removed.

- If you decide to use a conveyor belt, you will need about 1.5 meters one centimeter thick. Four rings with a diameter of 28 cm are cut from the tape.

- Use a rubber plug to cover the bearings in which the shaft will rotate. Otherwise, they will immediately jam.

- The bucket can be made from ten-millimeter plywood. For rigidity, the walls of the bucket should be attached to the frame.

- When making such structures, it should be remembered that if an electric motor is used (for electric snow blowers), it must be protected from snow. If you choose a walk-behind tractor, decide in advance on the adapters to connect it. Read the article about how to make a snow blower for a walk-behind tractor with your own hands.

Today you learned a little more about the design, use, and replacement of snow blower belts. At the same time, you learned how to make augers with your own hands; as it turned out, there is nothing difficult about it if you make a plan and approach the process headlong.

We hope this article will also help you save a little, take care of your equipment and yourself.

Read about other spare parts for snow blowers in this article.

Making a screw: possible mistakes and recommendations

The complexity of the screw and the mechanisms based on this part means that some errors can cause a decrease in efficiency. The main recommendations are as follows:

- The screw is represented by a straight axial pipe, on which a gripping plate is located in a spiral.

- During manufacturing, it is important to give the product as close a balance as possible. Otherwise, vibration, noise and many other problems may occur during operation. Serious defects cause wear of the part.

- There are also belt versions of the auger. Such a part is made of a pipe and a wide tape, which passes through special intermediate ribs to ensure reliable fixation. This version is installed in the case of transportation of bulk and sticky substances.

- In most cases, screw production is carried out on turning equipment. High precision of the product increases the performance properties of the mechanism.

The production procedure involves drawing out the coils. In such a case, it is necessary to eliminate the possibility of making the following errors:

- It is necessary to accurately calculate the step sizes.

- The final location of the ends must be selected taking into account the centerline of the shaft.

In production, metal is used, which is characterized by increased resistance to environmental influences. An example is stainless steel, which does not develop corrosion during prolonged use at high humidity.

Development of the surface of a straight annular helical conoid

When designing, screw reaming is often considered. Let's call its features the following:

- The development of one turn is represented by a part of a flat ring, which is located between two concentric arcs.

- The length of the major arc is the length of one turn of the outer helix.

A variety of methods can be used to calculate the main parameters; analytical and graphical ones have become quite widespread.

Analytical method

This method involves the use of certain formulas in the calculation. It is important to have input parameters. The main ratio is represented by the formula: L/l=R/r.

Also, if necessary, you can calculate the angle of the cut. It is derived from the following relationship: a/360=2пR-L/2ПR.

Graphic method

Also, when making calculations, a graphical method can be used, which is characterized by less accuracy and difficulty in application.

When plotting graphically, the main indicators that are used in analytical calculations are also noted.

Development of the surface of an oblique helical helicoid

A similar screw can also be used if necessary. Let's call its key points the following:

- The surface formed during development is parallel to the corresponding line obtained by rotation of the coaxial cone.

- There is a certain angle at the apex, which is often called the guide cone.

Such a sweep is also taken into account when carrying out a wide variety of calculations.

Graphic method

The method of displaying the mechanism under consideration involves dividing the horizontal projection into equal parts, after which each is taken as an isosceles trapezoid.

In such a case, a fairly large number of different values are taken into account. An example is the width, as well as the angle of the ratio.

Analytical method

The easiest to use is the analytical method. It is based on the principle of dividing the surface of an oblique helicoid into single-sheet hyperboloids of revolution.

In technical documentation you can find formulas that are used to determine the size of the development of one turn.

Advantages of auger pump

Screw pumps are often installed. They are characterized by the following features:

- High performance. There are models of equipment on sale that have a fairly high throughput. This is due to the fact that many other characteristics of the created mechanism depend on the geometric features of the screw. That is why problems with choice, as a rule, do not arise.

- During operation, the possibility of vibration and noise is eliminated. This disadvantage is characteristic of a fairly large number of different products. Due to strong vibration, as a rule, the service life is significantly reduced, and fastenings lose their reliability.

- The device can create pressure in the system independently. Some types of pump cannot create a vacuum in the system, so after a long period of inactivity, a quick start is almost impossible. In the case under consideration, liquid injection occurs almost immediately after power is applied.

- The operation of the pump does not involve damage to the walls of the well. Therefore, the well can last for a long period.

- The design is quite easy to maintain. Most of the elements can be replaced independently, and they cost a relatively small amount of money.

- No pumping technique required. Due to this, the required pressure is ensured throughout the entire service life.

- There are quite a few models on sale, designed to work in a wide variety of conditions.

- The pump can be used at almost any depth. This is due to the fact that the structure can withstand high axial loads.

- The device can be used to pump out sewage.

The information above indicates that the pumps of this category have a fairly large number of advantages, due to which screw pumps are installed in a wide variety of areas.

When is auger drilling used?

When auger drilling, shallow wells (up to 20 meters) are most often drilled with small diameter augers (up to 1500 mm).

We list some of the most popular areas of work in which auger drilling is used:

- installation of road barriers, road signs, fences, pillars, supports,

- taking soil samples from different depths,

- creation of bored piles,

- tree replanting,

- screwing screw piles,

- leader drilling for driving piles.

Most often, such drilling is carried out with drilling augers in soils of categories III-X according to the Protodyakonov rock hardness classification. In hard soils of categories III–IV, the drilling process requires highly qualified workers and the use of the most reliable, professional working tools.

The most common methods of rotary auger drilling are traveling and in-line.”

Disadvantages of auger pump

The device in question has many disadvantages that must be taken into account. The main ones can be called:

- The cost of the structure can be significantly increased. Products from domestic manufacturers are much cheaper, but industrial ones are characterized by higher performance characteristics.

- Design features do not allow the device to idle. This can lead to overheating and increased wear of the mechanism.

- The volume of transported water is constantly at the same level. In other words, such a pump cannot be used to regulate the pressure in the system.

The disadvantages of the screw pump do not allow its operation in certain conditions.

Pros and cons of auger drilling

The disadvantage of the auger method is the limitation on the maximum depth that can be achieved without the use of additional equipment. However, the advantages make auger drilling the most popular method of creating wells.

Everyone who drills wells with mounted hydraulic drills appreciates the speed of the work performed, the versatility of using the equipment, financial accessibility, as well as the relatively simple technology.

Photo: Drilling auger

Centrifugal screw pump

The screw pump in question is characterized by certain features related to the principle of operation. Its features are as follows:

- The auger rotates at high speed.

- Due to rotation at high speed, centrifugal force is created.

- The main part is located in a sealed housing, which in most cases is made using steel or plastic.

- The blades create certain chambers. While the pump is running, they are gradually filled. During production, attention is paid to high accuracy of screw fixation; there is a slight gap between the blades and the walls.

The advantage of this design option is that even a significant impurity does not cause serious wear and tear on the structure. That is why such a pump began to be used in a wide variety of industries.

Features of an auger compared to a garden auger

When performing work with a garden auger, you often have to remove it from the hole to extract the loosened soil. When using an auger tool, this operation can be performed much less frequently, since the soil rises along the auger. The limiting factor is the mass of the soil. It is quite possible that you will need to perform this operation with an assistant.

With the use of an auger drill, using extension inserts, it is quite possible to drill a shallow well on the site and use it for water supply.