I live in a house where grapes have been growing for over 40 years and I don’t know what to do with them (they have seeds, so I don’t eat them very much). I also have a great basement and project room and this year I decided to try making wine. Having tried to make grape jam last year, I realized that using a potato masher is inconvenient and ineffective.

I visited a local winery and asked about the brewing process and basic materials. The store manager said that 50 kg of grapes can make 35-40 liters of wine. From what I remember last year, we took about 7 kilograms of grapes (including stems) and got about 3 liters of juice after 45 minutes of rubbing and squeezing through a cloth. If we want to process all 50 kg, we need a more efficient processing method.

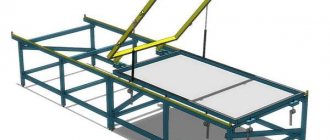

My basic crusher plan was to use a car jack to push a disc into a perforated pot to press the grapes. A little later you will see drawings of what I got and how to make a grape press with your own hands.

Squeeze it dry?

The very name of the equipment makes it clear that it is used to extract moisture from crushed raw materials. You can squeeze both juice and wort in a press, depending on the technology you use to prepare the wine.

How long should the pressing pressure be? The pulp is squeezed out until the juice stops flowing from it. In some cases, it is possible to carry out a secondary extraction, but for this the mass is crushed a second time. Sometimes a small amount of water is added to it to “revive” the pulp. The resulting juice or second-press wine will be inferior in quality to the first.

Grape press from a washing machine

If you have an old washing machine whose tank is made of stainless steel, then you can make a juicer out of it yourself. If the washing machine has a working centrifuge, then a centrifugal model of a juicer is made from the device.

In any case, the first step is to draw a detailed drawing of the future unit and prepare the necessary consumables and tools.

It is important to act according to the following scheme:

- All elements are thoroughly cleaned from scale, corrosion and rust. It is convenient to polish the surface with ordinary sandpaper;

- There will be only 2 holes in the design. Raw materials are loaded through one, and squeezed juice flows through the other. If there are other openings on the washing machine, they are closed using inserts cut from rubber;

- cut out a gasket from a stainless steel grinder, and also prepare a stainless steel grater. Many holes are drilled in a round stainless steel sheet, the circles are divided into several sectors, after which the cutting teeth are filled, and the entire element is secured with screws;

- Reliable metal stiffeners are inserted into the drum, and it is also equipped with a filtration mesh;

- The loading container is made from a cylinder, for example a polyethylene pipe, which is secured with metal corners. It is important to secure it with a slight shift to one side, so that the edge of this pipe coincides with the exit from the grater;

- to make it convenient to press the raw material, prepare a pusher from some cutting;

- to prevent the device from falling below the permissible level, install a limiter;

- prepare and secure the electric motor.

Depending on its power, the unit will be more or less powerful.

It is important that all structural elements are securely fastened and fixed; in addition, electrical elements must be insulated.

Preparation for pressing

It is very important to properly prepare the material for pressing. Only crushed material is pressed. Even if you are going to make wine from soft berries, you need to crush them into pulp, and only then put them under pressure.

Why crush the berries at all?

- To squeeze out more juice.

- In order not to break the press. If you put in whole berries, then trying to squeeze out the maximum amount of juice can break the machine.

If you press the pulp, then before the first pressing it is not processed additionally, but for the second and subsequent pressings the pulp also needs to be crushed.

The press ensures quick production of juice or wine

Stages of pulp pressing

I’ll say right away: the technologies for making red and white wine differ from each other. If you have the time, desire and inspiration to make real, proper red wine, you will have to work a little harder.

- First you need to make pulp and put it on fermentation along with berry peels and skins.

- After fermentation is complete, the pulp sinks to the bottom of the container with the wort.

- Part of the wine is drained by gravity, and the remaining pulp is unloaded from the container for pressing.

Pressed wines are richer in tannins, minerals and have a brighter color. To obtain pressed wine of good quality, the wort must be constantly stirred during fermentation for better aeration.

The simplest option is to crush the berries, squeeze out the juice and put it on fermentation. This is what they do when they want to get homemade wine with minimal labor.

Separation of wort by gravity

From the very beginning of draining, the wort flows under gravity rather than under pressure. Gravity in Bordeaux is called “big wine”. It differs not only in the method of production, but also in its characteristics. It balances sugar and acidity. The taste is more subtle and soft due to less tannins. At the same time, the product has a weaker color and a reduced amount of anthocyanins, which are responsible for the anti-inflammatory properties of wine. Gravity separated wines are more susceptible to developing yeasty and sour odors. That's why they are mixed with pressed wine to add depth of flavor and color.

The main rule is to load crushed raw materials into the press

First pressure wort

After the wine has been drained or siphoned off, we need to press the remaining must. The wort is removed from the vat or bottle, moved to a press and pressed. The result is pressed first-press wine. It contains a reduced alcohol content and an increased sugar content, but there is no excess sugar content. First pressure wort has a brighter color and a more tart taste due to the increased content of anthocyanins and tannins. There is no malic acid in it, the taste qualities are bright.

The wort can be blended (mixed) with “big wine” immediately after the end of pressing. This is how young table wines are produced.

Second pressure wort

But the first pressing does not completely free the pulp from the wort. Therefore, a second and even a third spin is acceptable. Before each subsequent pressing, the residue is further crushed in order to achieve a greater degree of grinding of the material. Naturally, repeated crushing causes the destruction of the pulp material, releasing more bitter and astringent fractions. Second-press wort contains sugar, malic acid, and has a high tannin content. It is not blended immediately, but is allowed to mature separately, and only after that it is put into production. The second pressing must is used to produce dessert wine.

Third pressure wort

We grind the pulp again and put it under the press again. As a result of the third pressing, we obtain a wine with high acidity, high tannin content, but the level of sugars in it is minimal. The anthocyanin content decreases, as does color saturation. Third pressing must is not added to young wines. It is used to produce vintage wines, as well as strong red wines.

If you continue pressing the wort, the resulting raw material can be used to prepare grape alcohol.

Grape crushers - what are they?

This crusher is a small, fairly simple device that allows you to quickly crush berries and then use the resulting mixture to make wine or squeeze juice.

Crushers are used both at home and in businesses.

The simplest apparatus includes a hopper for loading berries or fruits; in the lower part of this hopper there are two rollers, which are located parallel to each other. This hopper is located on a metal or wooden frame; the device is driven mechanically - by a handle that rotates the rollers through a gear system. Some crusher models have a container into which the crushed raw materials fall.

The rollers are located at a short distance from each other, and when the berries fall between the rollers, the grapes are crushed without damaging their seeds. When the handle rotates, the rollers rotate in different directions, and the berries falling between the rollers are crushed, after which the juice and pulp fall into a container or vat located at the bottom of the crusher. They manufacture electric and mechanical crushers.

So, there are many different types of grape presses. You can either buy a finished device in a store or construct it yourself. Self-assembly is not at all difficult, the main thing is to prepare all the necessary consumables, tools, and act strictly according to the scheme.

Living wood or cold steel?

No matter what technology you use to prepare wine, you still can’t do without a press.

What to prefer - a press made of wood or metal? For the manufacture of presses and their individual elements, hardwood is used. Beech is widely used as a hard and relatively affordable material. It must be said that today presses made of solid wood are becoming less and less common, and they are expensive. The most common option is a combination of materials, when the frame is made of metal and the basket is made of wood.

If you come across a press made entirely of wood at a price below 6-7 thousand, then do not rush to grab your wallet, but check the material of manufacture. Most likely, the device is made of plywood and will quickly become unusable if exposed to moisture.

Metal presses have many advantages, which is why they are very popular. They are characterized by ease of maintenance and operation, they are sold in a huge range of volumes and prices. The main condition is that the metal for the press must have a protective coating that protects against the formation of rust. Stainless steel presses are not at risk of corrosion.

As a rule, we choose material for the press based on taste preferences and capabilities. In addition, if you are looking for productive automatic presses, the vast majority of them are made of metal and other lightweight modern materials.

These wooden wine presses were in use in the 19th century

Basic design of wine presses

The general structure of a wine press is well described by its colloquial name: a crusher.

There is a place for laying crushed raw materials, there is a tray for draining the liquid fraction. Pressure is applied to the plate or drainage grid, which is in direct contact with the pulp, using various mechanisms. For a screw press it is a screw, for a hydraulic press it is a hydraulic jack or a membrane. Liquid is squeezed out of the pulp under pressure. It flows into the pan, and from there into the prepared container.

There are other designs, for example, barrels with a membrane, popular in hydraulic and pneumatic presses. Expanding, it crushes the pulp, and the liquid is squeezed out of the barrel, flowing down the outer walls into the pan. The cake remains on the walls.

Even the simplest screw hand press turns out to be an order of magnitude more effective in squeezing than manual labor. If we talk about automatic or mechanical presses, then spinning takes place literally “with one left hand.”

The main rule for the safety and security of the press is to add only crushed raw materials, since the pressure must be uniform. Adding unchopped fruits or berries is fraught with failure of the pressing mechanism.

Screw press - self-assembly

A screw-type mechanical press is one of the most reliable units that can be made quite easily and quickly with your own hands.

To assemble this equipment, you will need a stainless steel sheet, the thickness of the sheet should be at least one or two millimeters. This sheet will be used to make the squeezing chamber, as well as the tray and protective cover to protect against splashes.

The frame of this device is made of iron pipes or channels. A hole is drilled in a channel placed horizontally on top of the structure; the diameter of the hole should be greater than the thickness of the screw. A nut with a coarse thread is inserted and welded into the drilled hole.

The long screw that will be screwed into this nut must also have a large pitch.

Structurally, the device is quite simple: raw materials are loaded into a perforated basket, the screw is unscrewed along the thread, and thanks to the pressure exerted by the metal plate on the berries, the juice is squeezed out. All the pulp remains in the basket, and the juice flows through the holes into the tray and flows, for example, into a bucket.

To manufacture this device, the required size of stainless steel sheet is first prepared. Future holes are marked on this sheet and drilled with a drill. The diameter of the holes should not be too large so that the pulp does not come out. The diameter of the holes should be within 0.2-0.7 centimeters.

After this, the perforated metal plate is rolled up so that it acquires a cylindrical shape, then the joint is welded with a welding machine.

Next, a protective cylindrical casing is made of stainless steel, which is placed over the perforated cylinder. This casing is needed so that the squeezed juice does not splash in all directions; along this casing it will flow into a round or square tray with a spout.

Let's watch a video about making a grape press yourself:

After this, a stable frame is welded from the channels. When it is ready, a round piece of stainless steel plasticine is welded to a long metal screw with a large thread, matching the diameter of the perforated basket; it is this plate that will press on the berries.

A handle is welded to the top of the screw, with which they will unscrew the screw and squeeze out the juice.

Types of wine presses

As I said above, the types of presses are very diverse in terms of their operating principle. All of them are actively represented on the market and are intended to make the work of winemakers easier. Let's talk about the most popular and common types.

Mechanical hand press

Its structure and principle of operation will seem familiar even to those who have never dealt with pressing. Here are the main structural elements.

- Perforated basket for storing pulp.

- Cover or bag to prevent splashing.

- Screw mechanism.

- Pressing plane.

- Bed with receiving tray.

The pulp is loaded into the basket. Manual rotation activates a screw mechanism that lowers the plane onto the pulp. The descending piston creates the necessary force for pressure; under pressure, the liquid flows into the receiving pan, and from there into the collection container.

Design advantages.

- Easy to manage and operate.

- Cheapness

- Compact dimensions

- Variability.

- Relatively high productivity, higher than that of the same juicer.

- Maximum gentle and high-quality spin.

- It can be made of wood, which ensures the most natural taste of the future drink.

- Does not require additional water or electricity consumption.

One of the disadvantages is the need for significant muscular effort.

It is best suited for small volumes of pressing, for example, for seasonal wine from the harvest of a private farm. Easily allows you to get from 4 to 15 liters from one batch of raw materials, depending on the model. The cheapest and most economical press option.

Pneumatic press

In the design of this press, the force is created using compressed air.

The principle of operation is simple. The pulp is loaded into a barrel or basket. The presser is a membrane driven by compressed air. Under air pressure, the membrane expands, squeezing juice out of the pulp.

Advantages of a pneumatic press.

- High performance.

- High efficiency.

- A minimum of effort - even a woman can work with the press.

The downside is the rather high cost, which is increased by the need to additionally connect a compressor as a source of compressed air.

A pneumatic press is suitable for those who plan to engage in winemaking on a relatively regular basis or create a family business. Of the mechanical and manual presses, it is the most expensive. Even higher are the prices for pneumatic membrane presses.

Hydraulic Press

As the name suggests, pressure is provided by a hydraulic mechanism. This may be a hydraulic jack, as in some hand presses. Or maybe an expanding membrane.

Among hydraulic devices, there are designs that use drainage frames rather than a plate or membrane. Between them are placed raw materials packed in fabric bundles or bags. Using a hydraulic jack, the device is driven, developing great force and showing excellent efficiency.

Advantages of a hydraulic press.

- Efficiency.

- High performance.

- Does not require electricity, which means there are no additional costs for it.

- Available in a variety of options, so you can choose what you need.

The downside is the rather high price, water consumption, and placement of some structures, for example, a hydraulic drainage press, requires quite a lot of space.

The hydraulic press ensures high productivity. Many models yield 30–40 liters from one pulp. Suitable for trying your hand at craft winemaking on an ongoing basis. Costs less than pneumatic models, but more than manual screw models.

Electro-hydraulic press

A productive and powerful device that is used in cases where the power of mechanical and, especially, manual models is not enough. The design of the device resembles a hydraulic screw press, which is driven by an electric motor.

Among the advantages, I note high productivity, ease of operation, and spin efficiency.

The disadvantages include the high price and additional costs for electricity. The electro-hydraulic press is heavy. It cannot be transported like a conventional manual device. But it saves your energy and time as much as possible. Its use is justified in cases where you want to make your own wine on an ongoing basis. Well, or if you are a champion of ergonomics and want your every movement to bring maximum effect.

Different Types of Wine Presses

What is a grape press, what types are used?

A grape press is a kind of juicer that allows you to quickly squeeze out all the juice from grapes.

This device includes the following components:

- barrel;

- frame on which the press device is installed;

- a lever or screw device that operates the juicer;

- a filter mesh or a special surface through which grape pomace does not pass;

- container in which pure squeezed juice is collected.

Today, different types of these units are used to quickly extract juice. For their production, only environmentally friendly materials that are safe for human health are used, such as stainless steel and wood.

The following types of grape presses are used, differing from each other in productivity, design features and operating methods:

- manual or mechanical devices. This type of press is used at home; it is not at all difficult to make yourself, but its operation requires certain physical strength;

- electric presses. These juice extraction units are hydraulic, pneumatic and auger. The equipment has high performance indicators and does not require physical labor to operate, but these devices are quite expensive;

- universal units. These electrical devices are suitable for processing not only grapes, but also any other fruits, vegetables and berries.

At home, you can make both a wooden and metal press.

What to look for when choosing a wine press?

What criteria should be used as the basis for choosing a press?

Mounting location: floor or tabletop

For large rooms, it is logical to choose a floor press. As a rule, such devices have a large capacity.

If the size of the room is limited, you need to place the equipment compactly and conveniently, then opt for tabletop presses, especially since among them there are capacious models for 8–10 liters of the finished product.

Volume

The press has two volume characteristics - loading (basket volume) and output.

The basket volume shows how much raw material the press can accept at one time. The second is how much juice or wine the press produces in one cycle of operation with a full load.

Thus, a press with a 20 liter basket produces 8–12 liters of product. Equipment for 10 liters of raw material loading will produce 4–6 liters of juice.

The choice depends on what volumes you expect to work with. Take the press not “for growth”, but based on real needs.

Draw your attention! It is impossible to achieve the same juice yield for all types of raw materials. If it is said that a press allows you to get 4-6 liters of juice from 10 kg of product, then this is an average figure. Pressing, say, grapes will give you this volume, but from currants there will be much less juice. Therefore, I give average figures for the output volume.

Automatic or manual

I have already spoken about this above. The greater the volume of raw materials for processing, the more work. Therefore, to obtain wine from your own grapes or apples, you can use a hand press. If you have plans to process hundreds of kilograms of fruit and berry products, then it is worth investing in a productive automatic press.

Material of manufacture and price

Depends on your tastes and capabilities. Moreover, most modern models still have a stainless steel working part.

A press is a must-have attribute for craft fans.

Hydraulic grape presses

Hydraulic juicers are used to squeeze juice from grapes and many other berries, fruits and vegetables, such as currants, apples, carrots, etc.

Hydraulic presses are convenient and practical to use; they are manufactured in two main varieties.

Jack press. This equipment has a square or rectangular metal frame equipped with a stop for attaching the jack rod. Moreover, in different designs the jack is installed either in the upper or lower part of the device, strictly in the center of the press.

This equipment is quite easy to operate; both men and women can handle the work of squeezing juice, because during use it is not necessary to exert much physical force.

The principle of operation is as follows: the jack rod extends and presses the pancake, squeezing out the juice from berries or fruits. But there is one problem - often the length of the rod is not sufficient for the entire height of the basket for squeezing juice, so it is necessary to place something under the jack, for example, blocks of wood.

To solve this problem, you can purchase a special 2-stage jack.

Presses with hydraulic cylinders. These devices are manual and electric, that is, partially automatic. Electrical devices are connected to the mains and activated by pressing a button; grapes have to be loaded into the basket manually.

Semi-automatic models are usually used in industry; the equipment is used for squeezing juice from any fruit, berries and vegetables.

Let's watch a video of how a hydraulic grape press works:

A pump with a hydraulic cylinder is installed on the metal frame of such a press; through the pump, oil is supplied to the hydraulic cylinder, and the plasticine presses on the raw material, squeezing the juice out of it. The volume of baskets varies and can reach 200 liters.

Electric hydraulic juicers are quite expensive; they are rarely purchased for home use; such presses with hydraulic cylinders are used mainly in enterprises.