The mechanics of each machine, regardless of its purpose and type, contains components that are considered basic. Therefore, it is unacceptable to ignore their parameters. It is generally accepted that guides are considered such an important component for metal-cutting or woodworking devices. They will determine error-free and cyclical work.

Therefore, anyone who decides to create a machine must ensure that its design uses high-quality CNC guides, which have a positive effect on the functionality of the device. They don’t skimp on purchasing components.

Main types of guides

In the process of designing and installing machines (factory-made and home-made), different types of guide devices are used. This is due to their purpose - milling, drilling or turning. They can be of two types.

Sliding guides

They are used in low-power equipment that does not require special precision and high productivity. Table-top drilling and turning units and woodworking machines are equipped with such parts.

The polished shaft, as a type of guide, belongs to the budget category. It is the most common.

IMPORTANT! It is made of high-alloy steel, induction hardened and subsequently ground. This treatment increases the operating time, and the shaft wears less.

The polished shaft has disadvantages:

- fastening at the end points, there is no fastening with the bed, which is why there is a lack of rigid connection with the table and the presence of errors in processing;

- sagging with increased length, so we allow a maximum of 1 meter. It is recommended to have an optimal ratio of shaft diameter to length (0.06-0.1) in order to achieve normal results.

How to make homemade guides for a CNC machine?

The operation of any machine is based on the precision of product processing, which is ensured by guide rods. You can do them yourself and do it without extra money.

For example, it is unlikely that you can make a working element of a milling machine yourself, as is the case with drilling and turning types of equipment. Therefore, you will have to use ready-made solutions, such as drills and drives. If you use guides, then everything is simpler, since their type and characteristics directly depend on the purpose of the device.

Homemade bearing guides

Self-made elements for CNC manufacturing can be made in several versions. In the simplest version, during the manufacturing process of the unit using this algorithm, you need to assemble a structure that consists of the following parts:

- bearings that receive the power of the motor;

- a metal corner that acts as a carriage;

- nuts and bolts corresponding to the internal size of the bearing.

First, the length of the metal corner is measured and the excess is removed. Next, drill holes of the same size symmetrically on both sides. The bearings are attached using bolts and nuts.

DIY roller guides for machines

You can make such elements yourself as follows:

- The frame of the fixed part should be placed vertically, which will facilitate the assembly process. You only need to install one guide in it - a non-adjustable one, which should be at the very bottom.

- Next, place a separator on it in the center and place a gear and balls in it.

- Install the moving part on the balls so that its guide is on top of them, and the gear is in the middle.

- The angle between the moving part and the frame should be approximately 80 degrees.

- Next, place the separator on the guide of the moving part and also insert the wheel with the balls into it.

- Place the remaining guide of the fixed part on top of it all.

- Install the entire package into the frame and secure the upper part.

- To prevent the balls from falling out, make small holes at the ends of the guides and drive in pins so that the ball, when approaching the edge of the guide, rests against this pin.

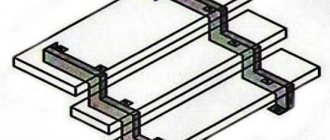

Rolling guides

They are designed using rolling bearings.

Linear bearings have more play than the carriage of rail guides; they are less loaded. But it has a number of disadvantages:

- low level of carrying capacity;

- fragility;

- manufacturing with significant play;

- sensitive to the effects of dust and chips on the shaft.

The material for the production of bushings is bronze, brass, caprolon. If tolerances are maintained, bronze plain bearings are as good as rolling bearings. From time to time, if the plain bearing is worn out, it is adjusted to eliminate the gaps. Therefore, the linear bushing is preferred due to its availability and interchangeability.

Shaft and its types

It is worth giving a brief description of the other types.

- The spline shaft is characterized by the presence of a special track for the bushing balls. Characterized by greater rigidity and wear resistance, compared to a conventional shaft, it is suitable for mechanisms in which it is desirable to install guides at the ends. They are used extremely rarely in the design of machine tools due to their high cost.

- The shaft on a support in the form of cylindrical rails of a linear type does not allow sagging under load and its own weight. It is mounted on the frame, securely fixing it. Despite the disadvantages, expressed in the presence of large play in the bushings and their short service life, cylindrical rails have a large load capacity. Different from linear bearings, the carriage reacts differently to the degree of load. A small CNC machine that has a heavy spindle has the potential for reduced accuracy.

Guides for CNC machine

CNC machining centers for small-scale and home use are an expensive thing and not everyone can afford to buy a format boring or CNC lathe, but you can easily make a device with your own hands that is decent in terms of processing quality and cleanliness of the cut. Let's look at several designs, but first we'll look at the factory-made parts to understand the basic principles of operation.

All guides for programmable machines are of circular motion or linear type, this depends on the trajectory along which the moving unit moves in coordinates. We will consider only linear ones, as they are the most popular among DIYers, and there is no particular need for the use of circular devices.

Which designs to choose?

Not everyone can afford to purchase, say, a CNC machining center for the production of small-scale parts at home, a format-type machine or for turning. But a homemade CNC unit, made with your own hands, is real. The assembled device in capable hands will demonstrate examples of correct processing of parts.

When assembling the mechanics of programmable machines, homemade linear guides are usually used, since there is no need for devices with circular motion. Let us pay attention to some of the designs used in this case.

Galvanized or chrome-plated pipes

They come with different diameters and can be used as rods when installing low-power devices - surface grinders, drilling or lathes. The bronze bushing moves along a polished cylindrical rod. Sometimes a support is made without it. Pipes have low prices and are easy to process. Although there is a minus: a short resource (the protective layer wears off after 15-20 penetrations, after which the steel wears out more intensively); there is no required level of strength under high loads.

Fraser

An effective router is one in which the guide mechanism is made from a used dot-matrix printer or Yantar typewriter. With this option it will last a long time. There is no need to look for very wide bearings; their internal diameter should be equal to the diameter of the bolts.

Linear guides for machine tools

All parts, machine parts, equipment and machines used in various fields of mechanical engineering are produced in a special field of mechanical engineering - machine tool building. No matter how small or large, light or heavy, complex or precise the part, all the characteristics of the machine for its production are a step above the complexity and accuracy of the part being manufactured. THK linear systems provide this precision, complexity and speed.Linear guides

- ball guides

- roller guides

- miniature guides

Ball Screws

- standard ball screws

- high precision ball screws

- rolled ball screws

Shafts and bushings

- splined shafts

- ball bushings

Actuators, linear drives

Horizontal machining center

The most complex and precise among metal-cutting machines are machining centers. High-precision and rigid linear guides with a cage and ball screws (ball screws) are used both for work tables that position and move the workpiece quickly and with high precision, and for moving the processing tool. Cross roller bearings (slewing rings) – ensure smooth rotation of the turntables.

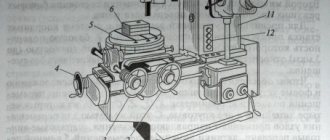

Guides for milling machines

Although machining centers and CNC lathes have become the most popular products in the machine tool industry, milling machines retain their scope of application in advanced areas of mechanical engineering. The most advanced machines that allow processing parts with ultra-high precision can only work under the supervision of highly qualified workers. To eliminate this highly skilled but manual labor, THK supplies ball screws and linear guides for milling machines, which are used in linear motion systems and avoid unnecessary movements of machining units and workpieces.

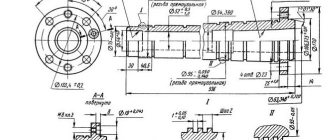

Guides for CNC (Computer Numerical Control) lathes

Along with machining centers, CNC (Computer Numerical Control) lathes play an important role in mechanical engineering. THK lathe guides and ball screws are in demand for moving lathe tool holders due to their high rigidity and precision. The compact design of THK linear systems helps reduce equipment size.

Guides for longitudinal milling machines

A longitudinal milling machine is a large milling machine. Obviously, the workpiece for such a machine is also large and heavy. However, if THK high rigidity linear guides are used to move the work table, the table moves smoothly and with high precision.

Guides for CNC gear hobbing machines

In gear hobbing machines, which produce gears for gearboxes for various purposes, linear sliding guides have traditionally been used. Their design was complicated by piping and a control and lubricant supply system. It is possible to simplify the design and increase the time between maintenance by using linear guides and THK lubricated ball screws.

Guides for grinding machines

Until recently, hydraulic cylinders were used to move the worktable with the workpiece. Servo systems with ball screws are now used to move the worktable. This solution increases the speed and accuracy of positioning and increases the productivity of the machine. It does not require the use of a hydraulic system, which promotes cleanliness and eliminates harmful effects on the environment.

To buy guides for machine tools or ball screws for machine tools, please send their designations, necessary characteristics and information about operating conditions.