Despite the fact that this tool is called a hair dryer, it is not at all intended for drying hair, since it is too powerful for this activity and is used exclusively for household purposes and in construction.

As for repair and construction work, the construction hair dryer has a very wide application in a variety of areas. A construction hair dryer is used for drying surfaces, welding plastics, laying linoleum, and heating various specific materials.

The hairdryer has proven itself to be excellent for removing old paint from wooden floors, windows and doors, baseboards and window sills, furniture, etc. A hair dryer is also often used for roofing work.

Membrane roofing

If we talk about using a hair dryer in roofing work, then, of course, you need to start with a membrane roof.

For membrane installation, a hair dryer is the main tool on which the quality and reliability of the finished coating largely depends.

The hair dryer used for PVC membranes differs from conventional construction hair dryers. It has its own specific cylindrical design:

For membrane roofing, a hair dryer is used with a number of attachments. Each of the nozzles is narrowed at the end and differs in the width of the hot air flow. The main nozzle is a nozzle with a width of 40 mm. It is used for soldering the main joints of the roof.

When installing the membrane, the hair dryer is used for soldering joints, that is, it is directly involved in the process of creating a roof seal.

The operating air temperature supplied by a hair dryer when working with a membrane roof is within 5500C.

What is it used for?

Welding guns with a power of 1600W or more are absolutely universal; they can be used for welding any products, depending on the type of nozzles used. Welding guns are mainly used for welding joints when installing flat roofs, as well as when waterproofing foundations using polymer membranes. Welding guns can also be used for welding passage elements when installing stylobate parts made of HDPE and LDPE membranes. Often, such hair dryers are used in automotive body work for welding plastic parts together with a welding rod (instead of welding extruders)

Accessories for hot air dryers

There is a huge number of different nozzles for welding guns - the most classic are 28 and 40 mm crevice nozzles, used in roofing work, as well as when welding other overlapped membranes. Less commonly used are round nozzles and nozzles for rod welding; they are mainly needed when working with plastic products. On the domestic market you can also find rare round nozzles with a built-in brass stitching roller; such an nozzle, by the way, will be used when installing linoleum floors in commercial or industrial premises.

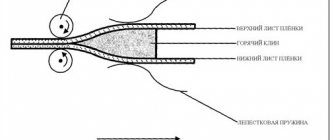

Membrane Welding Machine

To increase the speed of installation of membrane roofing, a hair dryer was included as a main part in automatic welding equipment.

So, to install the membrane, a tool such as a welding machine is used:

This machine not only simplifies, but also significantly speeds up the membrane installation process. Soldering speed reaches 4.5 meters per minute.

Operating the machine is simple and does not require any special qualifications:

PVC welding technology using industrial hair dryers.

The Mixt company presents on the market the unique technology and equipment (industrial hair dryers) of the Leister company for PVC welding. The complex configuration of PVC products to be welded (swimming pools, attractions, car bodies, tents, shelters, etc.), thick materials (thick PVC fabric), different melting temperatures of PVC require a careful approach to the selection and configuration of hair dryers for PVC welding. What do hair dryers provide for welding PVC

: this is welding using special industrial hot air dryers using special nozzles or welding using special automatic welding machines. The melting temperature of PVC is smoothly regulated on the equipment and you can set the exact temperature. We recommend starting the welding process with a test on similar materials (scraps) to select the temperature conditions.

The main device that Russian buyers choose is the Leister Triac S hair dryer. This is a reliable and proven hair dryer for PVC welding. But we believe that in the case of “heavy” PVC welding, where it is necessary to weld heavy fabric, it is better to use a Leister Electron ST hair dryer:

The most powerful (3400W), compact and durable device from the Leister line of hand-held hair dryers, suitable for performing various tasks where increased power is required. Its power is 2 times more than the popular Leister Triac S hair dryer model, but the price is almost the same!!

Features of the Leister Electron ST hand dryer:

Here are some features of a PVC welding gun:

- high air consumption at higher power (compared to other models)

- designed for long-term operation and non-stop operation

- brushes and heating elements can be replaced multiple times

- can be installed in technological equipment

- can be used for manual work

- many different attachments that allow you to use the hair dryer in various areas

Application of a hair dryer for welding PVC:

- thermal laying of floor coverings

- thermal laying of waterproofing in construction

- thermal laying of geomembranes (landfills, waste storage facilities, etc.)

- heat shrinkage of linoleum

- Application of plastic sealants;

- removal of old coatings by construction dryers

- heating pipes in winter;

- melting various bitumens

- hot air welding of pipes

- heating construction adhesive

- heating the adhesive layer before separation

- heating the epoxy resin to cure.

- placing thermal insulation on wires;

- and much more

There are several options of different power and voltage consumption, but the main and most popular model in Russia is Leister Electron ST- 3400 W.

Application options for PVC welding equipment

For high-quality PVC welding, you need a set of equipment and attachments. Below we will talk a little about the equipment necessary for welding.

Hairdryer and bitumen shingles

Due to the structural features of flexible tiles, as well as components and related materials for their installation, a construction hair dryer has become firmly established in the toolkit of roofers in this area.

As for the brand and characteristics of the hair dryer, for the work they use the most common technical hair dryers sold in construction stores.

Where is a hair dryer used for flexible tiles?

The range of works where a construction hair dryer is used is quite extensive. Since the shingles are based on bitumen, this roofing material hardens at low temperatures. This can cause a number of specific problems, which a hair dryer will help solve.

Thus, installing ridge tiles in the ridge and hip joints can cause a number of troubles. As you know, the edge of the ridge is determined by preliminary bending the ridge tiles in half. At low temperatures, this bending process can lead to breaks and cracks in the tiles. Therefore, the bend is made by first heating the ridge tiles with a hairdryer in the center.

Drying surfaces in areas where sizing is applied

The surfaces on which adhesive for bitumen shingles will be applied (junctions, penetrations, roof windows, gable drips, etc.) must be perfectly dry. Even the slightest ingress of moisture is not allowed, since the adhesive for flexible tiles is afraid of moisture.

Fortunately, moisture is clearly and clearly visible on all surfaces: on the roof, on the lining, as well as on other elements. Therefore, it is very effective to use a hair dryer to quickly dry surfaces.

Heating roofing mastic (bitumen adhesive)

Glue for bituminous shingles is applied using a spatula in a minimum layer so that it covers the entire surface to be glued but there is no excess. This is due to the fluidity of the glue when heated.

Almost all brands of glue for flexible tiles become viscous even at temperatures below 200C and the glue itself is difficult not only to apply to the surface to be glued, but even to scoop it out of a bucket onto a spatula. Therefore, very often, using a hairdryer, the glue is heated before applying it directly in the bucket, as well as directly when applying it to the areas to be glued.

Hair dryer device

All professional technical hair dryers have identical operating principles and design. They are capable of heating air to temperatures above 600 degrees Celsius, which will be quite enough to perform the above tasks. For this purpose, special heating elements are used, which consist of a metal spiral and a ceramic tube. Hot air enters the nozzle under the influence of a fan located at the rear of the power tool. It is powered by a conventional electric motor.

All such devices differ in their characteristics. First of all, this concerns the volume of hot air that comes out of the nozzle per minute. In a modern soldering gun, this figure can be about 200 - 700 liters. Everything directly depends on the power of the motor.

What parameters to consider when choosing such a power tool?

Today, the best place to buy a technical hair dryer is in our online store. It is worth considering the characteristics of such a device, because the price will directly depend on this. Each buyer should pay special attention to the following parameters:

- temperature and volume of blown air. Professional hair dryers can heat air up to 650 - 700 degrees Celsius while its productivity is up to 700 liters per minute. For domestic use, a model that can heat the air to 300 - 400 degrees will be quite sufficient;

- possibility of adjusting the flow rate and temperature of the blown air. Most modern models have such functions. On professional soldering guns, there is a smooth adjustment of these indicators, which significantly simplifies a person’s work when performing specific tasks;

- the ability to maintain stable air temperature. This is possible thanks to the use of an electronic stabilization system. It can be found on most models;

- protection of internal elements from possible overheating;

- presence of a thermal protective casing. This element will protect against burns during operation. Also, soldering guns often have a removable casing, which makes it possible to work in hard-to-reach places;

- the presence of a handle, which greatly simplifies the process of using the tool.

For a technical hair dryer, the price depends on the above parameters. When choosing, it is better to consult with specialists, which will allow you to choose the most optimal option among the presented models.

Also, before making a purchase, it is better to read technical reviews about the selected hair dryer, which will allow you to be aware of how it performs in operation.

Why should you buy a hair dryer from us?

Nowadays, the best deals on the sale of such power tools can be found on our website. Thanks to close cooperation with manufacturers, our soldering gun price is minimal in the domestic market. And this is not the only advantage of our online store. It is also worth highlighting the following:

- a large assortment. You can buy a soldering gun from the world's most famous manufacturers, and you won't have to pay a lot of money;

- fast delivery to the specified region of the country;

- choosing the most optimal payment option for the goods. This can be either cash or non-cash payment;

- guarantee for all sold soldering gun models. In this case, repairs occur as quickly as possible, and if necessary, the product may be replaced.

Our store of technical hair dryers will definitely pleasantly surprise you with the highest level of service and low prices for the products presented.