Today, not a single metal rolling and engineering industry can do without the technology of waterjet cutting of metal. Often, it is not possible to achieve the desired quality of cut even with the help of plasma cutting, so equipment for cutting using a waterjet jet of water is used.

Water jet cutting of metals with water was first used by an aircraft manufacturing company in America, which subsequently provided evidence that this technology was the best way to cut steel and other refractory metals . Since that time, the water-abrasive method has not ceased to be popular in various industrial fields.

Waterjet cutting process

The actual waterjet cutting process consists of four phases.

- Phase No. 1. Formation of a curved front cutting surface. A focused water jet cuts a narrow slot in the workpiece - the jet is gradually introduced into the workpiece and moves along it at a constant cutting speed.

- Phase No. 2. Beginning of the formation of a step (cliff). The angle between the jet and the cutting surface gradually increases.

- Phase No. 3. Completion of the formation of a step (cliff), moving it down. The material layer is removed only on a small section of the front cutting surface.

- Phase No. 4. Restoring the original state. The step is “pressed” into the workpiece quite quickly. As the step moves downwards, a flat cutting surface is formed again - the initial cutting state is restored.

The process described above is cyclical.

In the waterjet cutting process, water serves only as a carrier. Cutting is caused by the removal (chipping) of a certain number of layers of material, which is caused by impacts of solid abrasive particles. The presence of abrasive in the jet increases its technological capabilities and allows it to cut metal.

The most common abrasives are quartz sand, garnet abrasive, olivine, silicon carbide and electrocorundum. The widespread use of the above abrasive materials is explained by their relative cheapness, hardness and high cutting properties. For example, garnet abrasive is hard and heavy; thanks to this, it is virtually stable throughout the entire cycle of use. This makes it possible to obtain high quality cuts with a certain roughness depth, depending on the grain size and cutting speed. Due to its high viscosity, such an abrasive can be reused many times. Domestic enterprises mainly use quartz sand.

As with any type of material processing, the most favorable conditions for mastering the waterjet cutting process can be achieved by choosing its optimal technological parameters: the pressure of the working fluid, the shape and diameter of the opening of the water and abrasive nozzles, the amount of abrasive supplied at the distance from the nozzle to the cutting surface , feed speed, cutting surface quality. The analysis of these parameters requires detailed study and is essential when studying this technology.

Construction of waterjet cutting machine

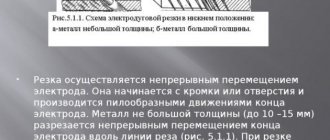

Oxygen gas cutting of metal

Regardless of the price and configuration, the machine most often includes the following elements:

- frame;

- water tank from 2 square meters in volume;

- a pump capable of pumping liquid from the reservoir to the cutting zone under high pressure;

- hoses for transporting water;

- filling tank and system for supplying and mixing water with abrasive;

- fitting with a nozzle as a water “cutter”. Its parameters are regulated automatically;

- work table for fastening the workpiece, it is located in a special bath;

- casing for protection;

- an automatic control unit for coordinating the movement of the steel worker and the water cutter, capable of monitoring and setting operating parameters.

Some parts of waterjet cutting machines also have their own characteristics. For example, the working bath where the cutting process takes place is equipped, in turn, with the following elements:

- load-bearing supports made of stainless steel, which can be quickly replaced when worn;

- quick-release ribs that support the material being cut. They are placed on supports;

- a system for the rapid intake and release of water, which ensures the processing of materials completely immersed in liquid.

And the abrasive tank allows you to replenish abrasive materials even during operation and is equipped with special sensors that monitor the amount of abrasives present.

- check the amount of incoming material during processing;

- help stop the machine if foreign material gets into the cutting head.

The high pressure pump is the key component of the machine; it compresses the water and delivers it to the working area. And the CNC system allows you to control all cutting parameters automatically.

There is also a constant gap support system in the form of a contact mechanism running along the sheet, which maintains the optimal distance between the processing surface and the focusing tube. This improves cutting quality and accuracy and prevents the tube and surface from colliding.

The angular head is also a very important element in the design of a waterjet machine. It is needed for the following tasks:

- ensuring movement of the cutting head in two planes, taking into account rotations at angles of inclination. Thanks to this, the machine can process chamfers and curved surfaces;

- ensuring constant angle and high accuracy when chamfering or compensating for the taper of a product;

- complex surfaces can be processed in five coordinates at once.

Additional machine elements

If necessary, the waterjet machine can additionally be equipped with an ultrasonic or laser surface scanning system to identify irregularities and maintain the gap, as well as ensure cutting accuracy.

Also, for an additional price, the equipment can be supplemented with a device for removing used abrasives. Its features are:

- includes a settling tank and pump;

- the pump is a membrane type, which can be used in aggressive environments;

- The tank is equipped with quick-release connectors for hoses and can be transported using a crane or forklift.

What water pressure is needed to cut metal?

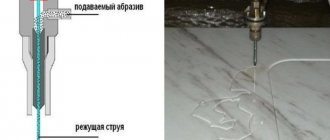

The water pumped by the pump should have a pressure of about 1,500–6,000 atmospheres. Coming out through a narrow nozzle at near-sonic or supersonic speeds (up to 900–1200 m/s and more), the water jet is directed into the mixing chamber, where it mixes with abrasive particles. The resulting jet comes out of a mixing tube with an internal diameter of 0.5–1.5 mm and cuts metal. To dampen the residual pressure of the jet, a layer of water 75–100 cm thick is used.

Disadvantages of technology

The disadvantages of this technology include:

- design difficulties that arise when creating high fluid pressure;

- insignificant resistance of water and abrasive nozzles - quick erasing (the service life of domestic nozzles is 50 hours, foreign ones - 500-1000 hours);

- complexity of nozzle manufacturing;

- formation of slants up to 1.5 along the height of the workpiece.

- a – at high cutting speed;

- b – at a very low cutting speed – the upper edges of the cut have a slight rounding

When the abrasive nozzle wears or the cutting speed increases, the width of the gap increases - the profile of the gap has a weakly expressed V-shape. At very low cutting speeds, the slot profile is A-shaped - turbulence causes erosion of the material. The case is considered positive if rounded top edges are required.

- a – with a distance between the nozzle and the workpiece of 2-4 mm;

- b – when the distance between the nozzle and the workpiece is more than 4 mm

Read also: Device for sawing logs into boards with a chainsaw

Every year, metallurgical enterprises around the world smelt hundreds of thousands of tons of steel. Increased demands on cut quality have led to the emergence of new processing technologies. Especially considering that many alloys are quite hard. The most advanced technologies are laser and water cutting of metal (water jet). We will consider the essence of the latter in detail in this article.

Waterjet cutting technology

The operation of waterjet cutting involves processing the workpiece with a water jet under high pressure with the addition of a cutting agent in the form of small particles of hard rock to the water. For precise positioning of the cutting jet, a laser and a special guide head made of durable alloy are used.

Rice. 1 The working operation of cutting material under high pressure on a waterjet machine.

The cutting operation takes place under the influence of an abrasive mixture through the use of a special pump, the characteristics of which determine the thickness of the cut and the processing speed of the workpiece. To control the process, a power regulator is installed on the machine, which allows you to change the thickness and cutting speed of the workpiece. When processing the most durable materials, a three-component filler is used, while less durable materials use a two-component mixture (water + abrasive).

A major role in the technological process is played by water pressure, which must have operating parameters of at least 4700 kg/cm2 and a speed of up to 1200 m/sec.

For precise positioning of the jet, special nozzles are used, which have different outlet diameters, which allows you to adjust the thickness of the cut by changing the head. The service life of water nozzles is usually 60 - 100 hours. after the expiration of which they are replaced.

To prepare the abrasive mixture, a special mixing chamber is installed on the machine, where various components are mixed according to a given program.

To automate processing operations, an automation unit is used, which regulates the cutting operation and the feed rate of the cutting material, and also compensates for taper through the use of Flow Dynamic Waterjet technology. The system automatically adjusts the positioning of the head with a change in the direction of the nozzle angle.

Waterjet machines are used for cutting materials:

- of stainless steel;

- aluminum;

- titanium;

- granite;

- marble;

- carbon fiber;

- glass

with the formation of an even cut of the required thickness.

First tests

Back in the 30s of the 20th century, American and Soviet scientists were puzzled by this issue. The impetus was that it was necessary to achieve high accuracy and speed of work. The first developments began in the 50s of the 20th century by engineers from the USA and the USSR. In 1979, they began to use sand, which was added to a stream of water, and the concept of “waterjet” appeared. The key requirements are high pressure and speed of water supply to the surface being treated.

Already in 1983, serial production of equipment for waterjet cutting (WJC) was launched. In fact, even today it is one of the most ideal tools for cutting, since it has no wear and it is possible to regulate the diameter of the jet. This method can work with sheet thicknesses up to 300 mm. This led to the fact that metal cutting with water began to be actively used in aircraft construction, mechanical engineering, stone processing and the production of armored vehicles and the space industry.

Operating principle and technology description

It is based on the principle of erosion processing. It consists in the fact that a jet of water under high pressure with abrasive particles is applied to the metal being processed. As a result, particles of the metal being processed are separated. Various parameters such as speed and depth are adjusted using the jet diameter and size, as well as the abrasive flow rate.

The main component of the system is a high pressure pump (4,000 bar). It compresses the water and delivers it to a special water nozzle, behind which there is a mixing chamber. There the pomegranate sand and water are mixed. Then the mixture enters a diamond or carbide nozzle, which has a diameter of up to 1.2 mm. From it, at a speed of more than 1,000 m/s, the waterjet falls directly onto the metal being processed. This is how metal cutting with water occurs, and now we move on.

Use of waterjet machines and operating principle

Devices for cutting metal with waterjet are universal in use, since their capabilities do not end with cutting metal products. The technology is based on a specially created system for supplying water under high pressure to the surface being processed.

An additional element of the liquid is an abrasive added to the water. As a rule, sand microparticles are used as an abrasive additive. Water and sand simultaneously enter the mixer from separate containers, in which they are thoroughly mixed. Then the resulting mixture is fed under high pressure into the nozzle of the machine.

Afterwards, a working water-abrasive cutter, in the form of a strong jet with certain characteristics, is fed onto the part and cuts it.

In this case, the speed of waterjet cutting can only be compared with the speed of a plasma cutter, but the quality of the cut made by this method corresponds only to the quality of laser cutting.

The rapid development of modern technologies has made it possible to improve machines by expanding their operating capabilities. Due to this, their scope of use has increased significantly.

Today, water-abrasive machines allow:

- Cut products of any geometric shape using numerical programming. In this case, processing occurs completely automatically and does not require an operator. The machine is controlled by a specially installed computer program. Waterjet cutting of pipes makes it possible to make the required circle without any errors;

- Make a non-standard cut of any material, and the changing inclination of the cut does not negatively affect the quality. The work process, which is carried out at any angle, allows us to obtain an absolutely finished product at the output and not subject it to finishing;

- The waterjet method has also found its application in the field of art. The equipment makes it possible to produce various decorations and design objects; as a rule, the processing of figures is done using CNC;

- Installations for waterjet processing used in rolled metal allow cutting of the maximum thickness of any metal, this can be seen in the video. Thus, the processing of a product made of medium-carbon metal can be done using a material whose maximum thickness is 20 cm. The maximum thickness of a titanium alloy is 16-18 mm; high-strength metals can be 11 mm thick. But the thickness of the copper product reaches only 6 mm.

About the features of GAR

High cutting properties can be achieved due to the presence of high-strength abrasive. In this case, a stable flow is ensured only if the garnet sand particles do not exceed 30% of the jet cross-section. Water, for the most part, performs exclusively a transport function. The size of the abrasive also depends on the requirements for the quality of the cut. The lower they are, the larger particles can be used.

When cutting metal with water, it is extremely important to select the optimal abrasive hardness. The indicator depends on the material being processed. The harder it is, the harder the sand is used. It is recommended not to use abrasives with a hardness less than 6.5 on the Mohs scale. At the same time, it is worth paying attention to the wear of the nozzle. The harder the sand, the faster it wears out. Therefore, at this stage it is extremely important to carry out theoretical calculations and only then begin work.

Cutting metal with a jet of water: advantages

The key advantage of this method is that it allows you to achieve high quality cuts, that is, obtain the necessary roughness after processing. In addition, it is worth highlighting the following advantages:

- the possibility of a fire or explosion during processing is eliminated;

- environmentally friendly process (no gases are formed during cutting);

- alloyed additives in the processed metal do not burn out;

- possibility of processing metal up to 30 cm thick;

- low temperature in the cutting zone (90 degrees Celsius);

- high efficiency due to the absence of idling of the cutting head.

As you can see, cutting metal with water under pressure has a number of advantages over other methods. It is environmentally friendly, safe and effective. Modern machines even allow processing several sheets at once in one stroke, if the thickness allows it. In general, GAR is developing more and more every year, and therefore the characteristics are significantly improving.

Current scope of application

The trend of technological growth has not spared the hydraulic abrasive cutting machine. Modern equipment of this type allows:

- Cut almost any shape from a variety of materials. During the working process, due to cutting at different angles, the cut line does not change in any way, due to which it is possible to achieve high quality when working with each material. When leaving the machine, the workpieces do not require finishing and are ready for further manipulation.

Cutting metal with water - A waterjet machine allows you to produce workpieces of any required geometric shape. In this case, the master only needs to set the program with his own hands, and the CNC equipment will independently cut out the necessary workpiece. Specially developed software is simple and understandable for any master, and allows you to set almost any parameters regarding cutting.

Cutting metal over 20 cm with water - The equipment, which is used in large-scale metal rolling production, can cut thick metal. For example, processing of a carbon steel workpiece can be carried out with a thickness of up to 20 cm. If production is focused on processing titanium, then the maximum thickness is 1.5-2 cm. High-strength steel alloys can have a thickness of up to 1.5 cm.

- Modern craftsmen have found use of hydraulic cutting in the field of art. Using the machine, you can cut out solid decorative items, jewelry and various auxiliary items from various materials. Naturally, the production of such products requires high precision and is carried out on CNC machines.

Briefly about the disadvantages

But this system cannot be ideal. Therefore, there are some disadvantages here. Firstly, due to the high speed of supply of water with abrasive and serious pressure, the process is quite noisy; it is advisable to only wear earplugs near it. Secondly, the low processing speed of thin sheet steel. But this is when compared with laser and plasma technologies. In addition, the cutting head wears out quite quickly. This in turn leads to high operating costs. Therefore, any machine for cutting metal with water must be regularly maintained and faulty or worn-out mechanisms must be replaced. Otherwise, work efficiency and cut quality will gradually decrease.

The influence of material on the cost of work. Functions of abrasives

Waterjet cutting of metal, the price of which is often determined by the personal preferences of the welder, can cost differently and due to the use of different abrasives. The main disadvantage of abrasives is their high cost. The abrasive is used for the so-called “punching” - that is, it allows water to penetrate into the deep layers of the metal that is being processed.

When cutting metal sheets, they try to use only cutting with water, without mixing with abrasives. However, here you need to take into account that the water consumption in this case will be very high!

Equipment in industry

Modern machines for professional use allow processing stainless steel up to 20 centimeters thick. In this case, the strength indicators and group of metals are not important. The small jet diameter (1 mm) allows cutting to a very high tolerance. If an industrial machine is used, then it becomes possible to process stone and other hard rocks, such as marble, etc.

Currently, this is one of the most effective and popular glass cutting methods. GAR works with both thin crystal and bulletproof glass with micron accuracy. Today, GAR machines are used for the production of gaskets and the processing of foam materials such as rubber and plastic. But to achieve optimal results, it is necessary to use modern electronic systems and various scanners.

About the design features

To achieve the required result, industry uses exclusively CNC machines. Therefore, the process is almost completely controlled by electronics. A professional machine includes various systems. For example, controlling the optimal clearance. This system provides the best distance between the cutting head and the metal being processed for the greatest accuracy in the cut location. A material scanning sensor is also used. It is needed to scan the metal for irregularities. The readings are transmitted to the CNC, as a result of which the gap changes.

Read also: DIY gearbox lift, drawings

To automate the process, an abrasive supply control sensor is introduced into the system. It regulates the amount of pomegranate sand. In addition, such a system stops operation if foreign elements (burlap, coarse particles) enter the high-pressure pump. All this must work as one, and only in this situation can optimal results be achieved. A modern industrial machine costs a lot of money and therefore requires regular maintenance. If this is not done, it may fail completely.

Control

For efficient operation of the machine, the work of several engineers and operators is required. The designer is required to create the project in a special computer environment. The file is then placed in the device memory. The machine itself distributes functions to other nodes. The employee is responsible for ensuring that there is a sufficient supply of consumables, for launching the program, monitoring its implementation, and providing timely notification of breakdowns. The equipment specialist is required to carry out technical inspection (preventive) and also troubleshoot problems.

CNC waterjet machines

Numerical control allows the most difficult parts to be produced with an error of half a millimeter. The production process is fully automated, it does not require constant commands, it only needs to set the program once (select from a list or enter into memory) and start it. Such equipment is expensive, but more effective. There is no human factor, that is, the risk of errors is minimized.

DIY metal cutting with water

It is quite logical that no one will purchase industrial CNC equipment for single use. In this case, so-called manual machines are very helpful. They do not have software control, so all cutting parameters are set by the operator. Actually, the quality of the cut depends entirely on the qualifications of the specialist. With the proper approach, you can achieve results no worse than with professional equipment. Manual machines still have their advantages. They consist in the low cost of equipment and the ability to produce a workpiece of the desired geometric shape at a certain angle on your own. But to do this, it is advisable to completely understand the controls, and then cutting metal with water will be a completely simple task.

Features of CNC machines

CNC waterjet machines are one of the opportunities to expand the range of applications of devices, improve work efficiency and at the same time increase productivity .

CNC machines are used to manufacture products from copper, aluminum, steel and other types of metals. The high cutting accuracy of water-abrasive CNC machines has almost no deviations from the required conditions.

CNC waterjet machines have the following advantages:

- If on devices without CNC the choice of cutting jet can be selected incorrectly, then in this situation this factor is excluded. The equipment automatically controls the quality of the cut and then independently adjusts the set mode;

- Machine tools that have CNC operate in accordance with the established program. Moreover, the processing of any product is done using individual computer software. Using it, the jet pressure, composition of the cutting mixture and other parameters are automatically selected;

- At the end of waterjet processing, an absolutely finished part is obtained from the workpiece, which does not need to be subjected to additional processing or grinding in the cut area;

- Metal processing using computer software also implies the ability to make holes of the required cross-section.

Let's sum it up

Currently, the most popular processing method is cutting metal with water. The pressure in this case is very high, which should not be forgotten. Failure to comply with safety precautions can lead to dire consequences. Please also note that it is not possible to make such equipment yourself. This is due to the fact that the parts must be of very high quality.

A manual machine is most optimal for home use. It does not cost as much money as an industrial one, but at the same time it has flexible settings and allows the owner to make a very high-quality cut. It is quite possible that in the near future cutting metal under water will improve and even here it will be possible to apply such a principle as GAR.

Waterjet cutting is a metal processing technology that is carried out using water and an abrasive mixture as a working tool. Moreover, the liquid is supplied under enormous pressure and at high speed.

The essence of technology

A metal sheet blank is placed on the work surface. It is cut out according to the required format. The cutting areas are exposed to water with the addition of abrasive particles. These substances interact with the surface, destroying it. In this case, it is necessary to maintain a certain pressure and pressure, which ensures the required flow rate of liquid and solid particles. The task of equipment using this technology is to separate a part from the whole. The power of the device is great, but its capabilities are limited by the density of the alloy and its thickness.

Consumables

The main raw materials are water (clean, undergone multi-stage filtration so that there are no impurities that could react with the workpiece) and abrasive particles. The consumption is quite large, and the thicker the metal, the more consumables are used per second. The most inexpensive abrasive is fine sand. Sand grains measuring about 650 microns effectively cope even with refractory, high-strength alloys. At the same time, they have an affordable price. It is also regularly necessary to replace spare parts - tubes and hoses, seals. Less often - the motor, tanks, nozzles.

What pressure is needed to cut metal with water under pressure?

The minimum pressure is 1500 atmospheres, the maximum is 6000. The indicator is adjusted depending on the density of the steel and the required operating speed. You can do this manually or trust the smart control unit.

Operating principle of waterjet metal cutting

During the cutting of rolled metal, the following processes occur:

- The engine drives the pump, which creates a water jet - it is supplied to the mixer from the tank.

- On the other hand, at the same time, abrasive of the required quantity and particle diameter is supplied.

- The two elements mix to form a relatively homogeneous liquid.

- The mixture is directed at high pressure to a nozzle, which controls the inclination and speed of the process.

- The material comes into contact with the surface of the workpiece, cutting it.

In this case, the metal cools.

Operating principle and materials to be cut

Metal cutting: technologies used

Cutting metal products occurs with a water jet to which abrasive is added, after which it passes through a nozzle. Pressure of 200-600 atmospheres allows you to cut many materials. Work can be carried out at any angle; to do this, you just need to change the angle of the nozzle. In this case, you can effectively cut:

- metals (ferrous and non-ferrous) and their alloys;

- stone products from marble and granite;

- steel (stainless steel, heat-resistant, alloy);

- armored, ordinary and composite glass;

- ceramic products (concrete, tiles, ceramics, ceramic granite);

- composite;

- rubber;

- plastic;

- cardboard.

Cutting of particularly hard raw materials is carried out with water and special sand made from minerals. Soft materials (rubber, plastic, cardboard) are cut exclusively with water without any impurities.

Application area

The prevalence of the method is explained by the great capabilities of the device. It can be used on virtually any natural and synthetic materials. This does not apply only to diamond and tempered glass. The peculiarity (and at the same time the demand) is that it is possible to process substances that cannot be heated - they lose or change their physical and chemical properties or are susceptible to easy ignition. And cutting with a jet of water occurs without changing the temperature. Thus, the range of possible work is significantly expanded. Most often metalworking is carried out on:

- stainless steel;

- tool steel;

- aluminum;

- titanium;

- brass.

Granite, marble and other natural and artificial stones are also cut using this method. The use of the machine is possible only in a workshop, established production. The video will show where it is used:

Water cutting equipment

They call it “dusty-free.” Indeed, there are virtually no chips, or rather, they are immediately washed away with water, resulting in a very smooth and clean cut, which, in most cases, does not even require grinding. The technological process is based on a natural phenomenon of reservoirs - erosion, that is, the ability to erode the banks, while grinding away stones and tree roots. The essence remains the same, but in order to speed up the effect many times over, an abrasive is added to the liquid.

This mixture is released with a very high pressure jet. The pressure reaches 6 thousand atmospheres, and a speed develops that is three times higher than the propagation of a sound wave in the air - 800-1000 meters per second. Two main tasks of the equipment:

- separation and washing out of particles of workpiece material;

- instant cooling and cleansing.

Read also: How to install a vice in the garage