Plasma cutting is a new excellent technology that allows you to cut metals of considerable thickness and of any nature, even the most capricious. The cutting object is not a knife, but a dense jet of plasma, which allows you to form a perfectly accurate cut pattern in a given time unit.

This method of working with metal has many advantages, which we will discuss below. Now let's start with physics - we need to understand the essence of the process.

Plasma physics

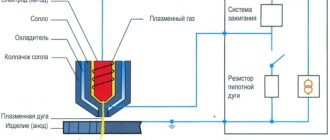

Plasma metal cutting technology gives the leading female role to our beloved electric arc. It is formed between the electrode and the nozzle. Sometimes instead of an electrode there is metal that needs to be cut. Let's figure out what plasma cutting is.

The beginning of the process is turning on the electrical power source and supplying high frequency current to the plasma cutter. The power source turns on automatically after pressing the ignition switch in the device.

First, a so-called intermediate arc is formed - it is temporary and connects the electrode to the tip of the cutter nozzle. This pilot arc is heated to a temperature level of about 8000°C.

This is an important point in the general process of plasma cutting - you need to remember that the real arc between the electrode and the metal is not formed immediately, but through its intermediate version.

The next stage of the process is the supply of air from the compressor, which is usually attached to the metal cutting machine. The compressor supplies compressed air. This air enters the chamber of the plasma torch, in which a temporary electric arc is located and already heated.

The arc heats the compressed air, the volume of which increases many times when heated. In addition to heating and increasing volume, the air begins to ionize and transform into a real conductor of electric current. It turns into that same plasma

The small diameter of the nozzle makes it possible to accelerate the flow of this hot plasma to enormous speeds with which the jet flies out of the apparatus. The flow speed can reach three meters per second.

Scheme of plasma cutting operation.

The air temperature is prohibitive, up to 30,000°C. Under these conditions, the electrical conductivity of the air - plasma is almost equal to the conductivity of the metal being cut.

The true terminal arc appears instantly as soon as the plasma flow reaches and touches the metal surface. The temporary arc, in turn, is automatically turned off. The metal begins to melt exactly at the cut point.

Liquid metal drops are immediately blown away by a jet of compressed air. This is the principle of plasma cutting. As you can see, everything is simple, logical and understandable.

Quality criteria for plasma cutting of metal

The classification of types of thermal cutting, dimensions of parts and quality of processing are established by the European regulation EN ISO 9013 “Thermal cutting”.

This standard applies to any material that can be separated by plasma, oxygen or laser. But when plasma cutting metal using CNC machines or manual equipment, the thickness should be in the range from 1 to 150 mm.

- Burr at the bottom of the cut and spatter at the top.

After plasma cutting of metal, hardened particles of the metal itself and its oxide can be seen on the surface below. This is grat. Spatter usually remains on the upper edge of the plasma-treated workpiece. Burr is formed under the influence of many factors. For example, its formation can be affected by a certain cutting speed, distance of the cutter from the surface being processed, current strength, voltage, choice of gas and the plasma metal cutting method itself.

Whether burr appears or not may also depend on the material itself, its geometric parameters, surface quality and temperature surges during the process. If the rate of metal separation is too low or, conversely, high, excess metal may also form. Most likely, it will not be there if you select medium speed. Properly selected gas and cutting technology will also help prevent burrs from appearing.

- Angular deviation.

When performing plasma cutting, different temperatures in the arc contribute to the fact that the cut surface is obtained at a slight angle. Due to the fact that the heating was stronger at the top of the cut, the material melted there to a greater extent than in the lower part. But the better the arc was compressed, the less noticeable the angular deviation will be. The latter is also influenced by the distance from the torch to the surface and the cutting speed. Standard plasma separation of material assumes that the cutting angle is 4–8° on both sides.

The workpieces being processed will have common cutting edges if the cutting angle becomes less than 1°. This result can be achieved using plasma separation technology with increased compression.

Classification of types of plasma cutting

Types of plasma cutting will depend on the environment in which metal work is carried out:

Simple

The main difference between the method is the limitation of the electric arc. Electric current and air are used for cutting. Sometimes gas in the form of nitrogen is used instead of air. If the metal sheet is thin - just a few millimeters - the process can be compared to laser cutting.

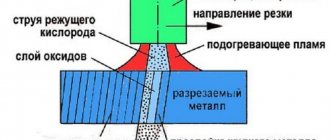

With this method, the thickness of the metals should not exceed 10 mm. The method works great for low alloy steels and other soft metals. The cutting element is oxygen, from which a compressed jet is formed, which ultimately turns into plasma.

The cuts produce very smooth edges that do not require further finishing.

Using shielding gas

With this method, instead of air, protective gases are used, which are converted into a plasma stream after conversion in a plasma torch. The quality of the cuts in this case is significantly improved due to the excellent protection of the process from environmental influences.

Gas for plasma cutting is nothing unusual: it can be hydrogen or argon - the “classic gas”.

With water instead of air

An excellent method with many advantages, one of which is the absence of the need for an expensive and bulky cooling system.

There are other classification criteria for plasma cutting. For example, types of cutting are separation and surface. The first one is used more often.

Another parameter is the cutting method. One type is arc cutting, in which the metal being cut acts as an element of an electrical circuit. Another type is jet cutting, where an electric arc connects electrodes rather than the metal workpiece.

Plasma cutters come in a wide variety of varieties on the market, so they can be classified by brand, manufacturer, and many other technical and commercial parameters.

There is, for example, manual plasma cutting - the most affordable method both in price and ease of execution. There are machine automatic technologies, the devices for which are much more expensive and complex.

Metal plasma cutting technology

Plasma metal separation is when cutting is carried out with a large plasma flow. The latter is formed during the blowing of an electric arc with gas, the molecules of which, when heated, disintegrate into positive and negative ions. The resulting flow has a temperature of several thousand degrees.

Main types of plasma cutting:

- dividing;

- surface.

The first type involves sinking the electrode into a section of the material. Also, during separation cutting, the angle between the workpiece and the electrode is approximately 60–90 degrees. Surface cutting does not allow an angle greater than 30°.

There are also two methods of plasma separation:

- plasma arc;

- plasma jet.

In the first case, a plasma arc burns between the surface of the workpiece and the non-consumable electrode. The second implies that it burns between the electrode and the tip of the plasma torch. When cutting with a plasma jet, the product is not included in the electrical circuit.

We recommend articles on metalworking

- Steel grades: classification and interpretation

- Aluminum grades and areas of their application

- Defects in metal products: causes and search methods

One of the most popular methods of cutting metals today is plasma-arc cutting, and for processing products made from other materials, plasma jet processing is more suitable.

The technology for separating metal with a plasma cutter has its own characteristics that must be taken into account:

- To cool the plasma cutter, a constant flow of air is required;

- the gas for separating metals should not contain oil and water particles, otherwise the equipment will break down;

- Thorough cleaning of the workpiece before cutting is a mandatory step;

- In order for the cut to be of high quality, it is necessary to correctly calculate the gas pressure and current strength;

- depending on the type of metal and current strength, the cutter must be moved at a speed of 0.2–2 m/min.

- during plasma cutting, the nozzle should be perpendicular to the part - it is best if they are 1.6–3 mm apart from each other.

The plasma torch allows you to cut absolutely any metal. You just need to choose the right type of gas.

Plasma metal cutting using air. If air is used to form plasma, then a wide variety of metal workpieces can be processed by its flow. These can be parts made of copper, brass, black and stainless steel, etc. Moreover, the price of plasma cutting of metal in this case is low. It is the air-plasma method that often underlies the operation of the simplest equipment, which is used, for example, in private households. The quality of metal cutting and speed are average here.

Oxygen cutting. It is performed exclusively on professional equipment. By using pure oxygen, high-quality seams with a small layer of flash are obtained. In this case, the cut is strictly perpendicular to the surface, and the speed of metal separation is high.

Cutting metal workpieces with protective gases. Equipment created using the latest technologies operates on oxygen, nitrogen, argon and air. The prices for such devices are quite high. For example, a plasma torch can cost over 10 million rubles. However, the quality of processing of parts will not be worse than with laser cutting.

The advantages of metal separation using protective gases include:

- cutting speed – 2.5–10 m/min;

- jet thickness is about 0.5–2 mm;

- the ability to process workpieces with a thickness of 0.5–60 mm;

- gas pressure – 5–12 atmospheres;

- current strength ranging from 20 to 800 amperes.

Benefits of plasma cutting

The operating principle of plasma cutting.

The closest technology is laser cutting of metals, so it would be logical to list the advantages in comparison with its “neighbor”:

- Plasma cutting can handle metals of any nature, including non-ferrous, refractory and others difficult to process.

- The speed of the process is much higher than cutting with a gas cutter.

- One of the significant features is the ability to produce cuts of any shape, including geometric patterns and figured cutting of the highest complexity. In other words, plasma cutting is the implementation of the most daring creative ideas for metal and other difficult-to-cut materials.

- The plasma cutter does not care about any thickness of metal: speed and quality are in no way lost.

- This method lends itself not only to metals, but also to other materials: it is quite universal.

- Plasma cutting is both faster and more efficient in edge quality than any other mechanical cutting method.

- In this method, it is possible to work not only perpendicular to the metal surface, but at an angle, which helps to master wide sheets of metal.

- From an environmental point of view, this is a completely safe type of working with metal with minimal release of harmful substances or pollutants into the air.

- Excellent time saving due to the absence of the need to preheat the metal.

- Since the method does not use explosive gas cylinders, it is much safer than other methods.

Equipment for plasma cutting of metal

To cut metal using the plasma method, electric arc, high-frequency and combined plasma torches can be used.

Based on the type of arc formation, plasma cutters are divided into:

- Equipment with direct arc. This type assumes that the arc burns between a metal workpiece and a non-consumable electrode. The power source here is direct current.

- Plasma torches with an indirect arc. Here the arc burns between the nozzle and the electrode, which act as the anode and cathode, respectively. The arc is not connected in any way to the workpiece. Such equipment is connected to an alternating current source.

Cooling of the plasma torch can be:

- air;

- watery.

The second option is most common, since the heat capacity of water is higher than that of air. Water cooling of plasma cutters makes it possible to place high thermal loads on the nozzle and electrode. As a result, plasma welding productivity increases. As for the disadvantages of such cooling, these include the design of the device itself and the constant need for clean water.

Stabilization of the arc can be done in different ways. The following can be distinguished:

- vortex;

- double;

- water;

- magnetic;

- axial single.

The water method is quite complex in its design, and also has a system of automatic supply and regulation of the electrode, which is not highly reliable.

Disadvantages of plasma cutting

No metal processing method is without its drawbacks, and plasma cutting is no exception.

The disadvantages of plasma cutting are as follows:

- The entire range of plasma cutting machines is expensive, including even the simplest manual options.

- Limits on metal thickness for plasma cutting: the maximum thickness is only 100 millimeters.

- This is a noisy way of working because the compressed air or gas is supplied at great speed.

- The equipment is complex, expensive and requires competent and constant maintenance.

Advantages and disadvantages of the plasma cutting method

Let us note the main advantages of this technological operation:

- Plasma cutting is used for both ferrous (steel, cast iron) and non-ferrous (aluminum, copper) metals. Non-metallic materials (concrete) can also be cut;

- high speed, productivity, accuracy;

- the ability to cut out shapes of complex configurations;

- excellent edge surface quality. The edge does not need to be subjected to additional machining;

- safety, environmental friendliness of the technological process. It does not use flammable gas or compressed oxygen, and there are practically no harmful emissions;

- versatility of the operation: the ability to cut large-width parts, pipe blanks, and perform cuts at a certain angle;

- The workpiece does not need to be preheated before use. This significantly saves the time of the technological operation.

But in the modern, innovative plasma cutting process there are also negative aspects:

- when cutting thick workpieces, it is necessary to use high-power sources of electricity;

- the need to attract trained qualified personnel for work;

- limitation on the thickness of processed parts;

- Plasma cutting work is accompanied by a high noise level;

- high price of equipment.

Tips and nuances

Another distinctive positive characteristic of the method is that during the process only a small local area is heated. And this area cools down much faster than with laser or mechanical cutting.

Cooling is necessary only for two components - the cathode and the nozzle, as they are the most loaded. This can be done without any problems using working fluid.

Plasma arc and jet. The arc begins to work stably as a result of the working relationship between the cathode and the nozzle with steam from compressed hot air. A negative charge is localized at the cathode, and a correspondingly positive charge is localized at the nozzle tip. As a result, an intermediate arc is formed.

Excess moisture is absorbed by a special material located in the reservoir of the plasma torch chamber.

Safety rules for this method are of the strictest nature, because all plasma cutting devices can be very traumatic for the master. This is especially true for models with manual control.

Everything will be fine if you follow the master's recommendations for protective equipment: visor, tinted glasses, safety boots, etc. In this case, you can protect yourself from the main risk factors of this method - drops of molten metal, high voltage and hot air.

Another safety tip is to never tap the cutter on the metal to remove metal spatter, as some craftsmen do. You risk damaging the device, but the main thing is to catch pieces of molten metal, for example, with your face or other unprotected part of the body. Better take care of yourself.

Saving consumables is not the least important factor in efficient cutting. To do this, we light the electric arc not too often, but precisely and on time, so as not to interrupt it unnecessarily.

Resource savings also extend to current strength and power. If you calculate it correctly, you will get not only savings, but also an excellent cut without burrs, scale and metal deformation.

To do this, you should work according to the following scheme: first apply a high-power current, make a couple or three cuts with its help. If the strength and power of the current are too high, scale will immediately form on the metal due to significant overheating.

After examining the slices, it will be clear whether to leave the current at this level or change it. In other words, we work experimentally – in small samples.

Typical operator mistakes when choosing a plasma cutting mode

Consumables for plasma cutting are selected depending on the material being processed (stainless steel, ordinary steel, brass, etc.), the thickness of the workpiece, the arc current that is set on the equipment, gases (both protective and plasma-forming), etc.

The employee (operator) of the equipment has a special manual, which identifies the consumables proposed for use in various processing modes.

Plasma cutting modes and settings are reflected in the instructions for use, which must be followed.

Electrodes and nozzles should only be used that correspond to the selected processing mode, otherwise the cutting quality will significantly deteriorate and the number of consumables used will increase. It is important to carry out plasma cutting using the arc current for which the consumables used are designed.

An example would be plasma processing a 100 A metal with a 40 A cutter. This should not be done! The best results are achieved when the equipment current is 95% of the rated current for which the nozzle was designed.

If a processing mode with an excessively low arc current is used, the cut becomes slagged, and an excess of burr is formed on the back of the workpiece. Thus, the resulting cut will be of low quality. If the current set on the plasma processing device is too high, the service life of the nozzle is reduced, and significantly.

The plasma gas pressure and flow rate, as well as the cooling fluid, require daily checks. If the flow rate is insufficient, the parts of the device are poorly cooled, which reduces their operating time. Coolant may be supplied in insufficient quantities due to wear on the pump and filters clogged with waste. Lack of cooling is a common cause of equipment failures.

For quality cutting and arc support, it is necessary to maintain an even pressure of the gas that forms the plasma. Excessive gas pressure makes it difficult to ignite the arc. This happens even if other requirements for equipment setup, processing and operating parameters are met.

Excessively high pressure of the gas forming the plasma leads to damage to the electrodes. Purification of gas from impurities before its use is mandatory. The reason is the accelerated consumption of materials and failure of the plasma torch itself. Equipment for supplying air (compressor) to the device is often contaminated with moisture, various oils, as well as particles of dirt and dust.

How to use a plasma cutter?

Electrical circuit of a plasma generator.

Cutting metals using a plasma stream is too serious a task to tackle without prior study and careful preparation. This will help you cut more efficiently from all points of view, and, importantly, minimize the risks associated with industrial hazards.

First of all, you need to know the principle of operation of plasma cutting - to see the whole picture of physical phenomena.

The plasma torch must be held very close to the surface and edge of the metal, unlike laser cutting. When the “start” toggle switch turns on, the temporary electric arc will light up first, and only then the real one, which will be the main cutting element. The torch with the cutting arc must be guided across the material evenly and slowly.

The cutting speed should be strictly controlled. This can be done by observing sparks on the back of the sheet of metal being cut. If there are no sparks, this means that the cutting of the metal was incomplete.

This can happen for several reasons: due to too high a speed of the torch or the passage of the apparatus, or too insufficient power of the supplied current, or failure to maintain a right angle of 90° between the torch and the metal surface.

The fact is that complete melting of the metal occurs only when the plasma cutter is tilted to the metal surface at a right angle and not a degree more or less.

After completing the job, the cutter must be tilted. Air will continue to escape for a short time even after the device is turned off.

Before work, it is not harmful to study the diagram of your device: it is there that you can read the most reliable information on the permissible thickness of the metal that can be cut or made a hole in it. The design of a plasma cutter may vary, it all depends on the functions of its purpose.

Choosing the right mode

Correct organization of current supply plays an important role. It is determined by the technical characteristics of the plasma torch and the cutting mode used. An incorrectly selected cutting mode can lead to double arcing (when the arc burns from the electrode to the nozzle, and from the nozzle to the metal). This destroys the nozzle and electrode, and also deforms the edges of the cut workpiece. To choose the right mode, you should know some indicators. First of all, its choice depends on:

- type of material to be cut;

- nozzle diameter;

- thickness of the sheet being cut;

- average cutting width;

- current strength;

- tension;

- cutting speed.

To guide you in choosing a mode, you can use the data from the table below. It presents average parameters using air plasma cutting as an example.

| Type of metal to be cut | Thickness(mm) | Nozzle diameter(mm) | Current strength A | Cutting speed(m/min) | Average cutting width(mm) |

| Steel | 1-10 | 0,9-1,1 | 40-60 | 2-0,2 | 1-1,3 |

| 10-15 | 1,4 | 60-90 | 1,8-0,3 | 1,5-1,8 | |

| 15-20 | 2,7 | 90- 140 | 1,5-0,5 | 1,8-2,2 | |

| 20-25 | 1,9 | 100-150 | 1,2-0,15 | 2-2,5 | |

| Aluminum | 1-15 | 1,4 | 60-90 | 1,5-0,5 | 1,5-2 |

| 10-30 | 1,7 | 90-140 | 1,2-0,5 | 2-2,5 | |

| 20-40 | 1,9 | 100-150 | 0,5-0,1 | 2,5 | |

| Copper | 10 | 3 | 300 | 3 | 3 |

| 20 | 1,5 | 3,5 | |||

| 30 | 0,7 | 4 | |||

| 40 | 0,5 | 4,5 | |||

| 50 | 0,3 | 5,5 | |||

| 60 | 3,5 | 400 | 0,4 | 6,5 |

Taking into account the tasks set for plasma cutting, the indicators may be changed. After the necessary parameters have been set, you should check the operation of the device. To do this, you need to make a test cut with an increased current strength. This way you can adjust the cutting speed and current strength.

Choosing a plasma cutting machine

Purchasing any technical equipment is a matter for which you do not need to spare time and effort: the risk of an unsuccessful decision and loss of money is too high. And the money here is considerable; you won’t find a plasma cutter cheaper than 500 USD in principle.

First, let's look at the parameters and technical characteristics of the device.

The choice should be made only according to your plans and needs. The task is not to find the best cutter, but the most suitable one for you based on the “here and now” principle.

Two large groups of plasma cutters are inverter and transformer. The names speak for themselves.

Open and closed plasma jet.

If you need a compact cutter for working with thin metals, you can opt for an inverter-type cutter. They take little energy, are light and have small dimensions.

At the same time, they work intermittently and easily fail due to changes in mains voltage. The price of such devices is quite reasonable; these are the most inexpensive of all plasma cutters.

Another thing is transformer cutters. Here, both the dimensions and the weight are “all right”: serious devices in all respects.

They consume a lot of energy, but they can work almost without interruption throughout the day. And the thickness of the metal can be greater than when cutting with an inverter model. The cost of such devices is high – from 3,000 to 20,000 USD.

Selecting a plasma cutter by power

We begin our discussion with the properties and technical characteristics of the parts that you plan to process and cut. It is this that the power of the cutting device is calculated, because both the nozzle in its diameter and the type of gas used will differ.

The use of plasma cutting is extremely broad, so you only need to talk about your specific needs.

For example, if the thickness of the metal workpieces is about 30 mm, a cutter with a power of 90A will be enough for you. It can easily handle your material.

But if your metal is thicker, look for a suitable model in the power range from 90 to 170A.

Selecting a cutter based on time and speed of cutting material

The speed of plasma cutting of metal is measured in centimeters per minute. This speed also varies from machine to machine and depends on their overall power and the nature of the metal being cut.

For example, all other things being equal, steel is cut the slowest, and copper and its alloys are a little faster. And even faster - aluminum with its aluminum alloys.

Plasma cutter device.

If speed is important to you, do not forget about such an indicator as the duration of operation without overheating, that is, without interruption. If the technical specification for the machine says that the operating time is 70%, this means that after seven minutes of cutting the machine must be turned off for three minutes to cool down.

Among transformer cutters, there are champions with an operating time of 100%. In other words, they can work all day without shutting down. They cost a lot, of course. But if you have long cuts ahead, consider purchasing “champion” transformer plasma cutters.

Pros and cons of plasma metal cutting

The advantages of the method are:

- Versatility. The technology makes it possible to separate any metals, including ferrous, alloyed, titanium, aluminum and copper alloys.

- The material is cut in a few minutes. For example, the portal device MTP "Jupiter", equipment "Omega" and even a fairly cheap machine "Hermes" allow plasma cutting of metal workpieces at speeds of up to 12 m/min.

- Cutting material up to 30 mm thick has a low cost. But it increases significantly with a thickness from 30 to 50 mm. When air plasma cutting of metal workpieces, production costs will be minimal.

- In the area of the cut, the zone of exposure to high temperatures on the sheet of material is very small.

- High quality processing. The use of plasma torches together with correctly selected plasma-forming and cooling gases makes it possible to obtain a minimum width and taper of the cut, as well as uniform smooth edges that do not require any further processing. High-precision plasma separation of metals meets all conditions.

- Safety. Unlike gas cutting, plasma technology does not require the use of flammable gases such as acetylene and propane.

The disadvantages of the principle of plasma cutting of metal include the following:

- Separating scrap metal with a thickness of 50 to 100 mm is quite expensive.

- The thickness of the material to be cut is usually limited to a maximum of 100–110 mm.

- When cutting ferrous metal, the cut taper is 1–10°, and when cutting non-ferrous metal, it is 1–20°. Moreover, this figure only increases if you choose air as the gas used or cut metal of increased thickness.

- The equipment used in the process is very complex. Therefore, it will not be possible to connect two plasma cutters to one machine and use them at the same time.