What is a file and what is it for?

A tool designed to remove a layer of metal from a workpiece is called a file. It is a metal strip on which a so-called notch is applied. It consists of cutting teeth made according to certain rules described in GOST 1465-80.

To control it, use a handle mounted on a specially formed shank. Several grades of steel are used for manufacturing. As a rule, this is steel containing 1.1 - 1.25% carbon. The steel grade can be ШХ15 or У10А, the latter steel is classified as unalloyed improved.

One of the main requirements for it is high hardness. That is why after heat treatment it is not tempered. In working condition, the surface has a hardness of 54-58 HRC.

The handle with which the control is performed can be wooden, plastic, or metal.

Set of files with wooden handles

They are produced in different shapes, lengths and with different parameters of cutting teeth.

It should be noted that the abundance of this product allows you to perform many types of work, in particular, it can be used to remove various types of contaminants, grind workpiece planes, remove flash and sprues. Using these products of special shapes, it is possible to sharpen saw chains and process gears.

It should be noted that it can be found in almost any home, garage and of course in production.

Stage 3: Tool Test

Now let's get back to the file. Before you start testing it, you must wear safety glasses and place a sheet of black-painted plywood near the sanding wheel. On a black background, the sparkling metal is visible much more clearly, and the eyes have to strain less. If we forcefully run a file over the emery wheel and get abundant sparks of a bright yellow color with many stars separating from them, we can conclude that it is made of high-carbon tool steel (U10-U13). Conversely, a sheaf of orange-red long sparks with branches and stars at the end indicates that the file is made of alloy steel (ШХ6, ШХ9, ШХ15). Of course, in this way only the approximate chemical composition of steel is determined, but for amateur practice this is quite enough. Knowing that the file is made of tool steel of the indicated grades, the heat treatment mode is determined from the table.

The table shows that the U11-U13 steel from which the file is made is annealed at a temperature of 750°C and then gradually cooled in air. Annealing is carried out in a muffle furnace, forge or in the firebox of a conventional furnace. It is convenient to anneal metal objects in an electric school muffle furnace, since the built-in thermometer makes it possible to monitor the heating temperature. But the depth of the muffle furnace is limited. If the file does not fit into it, it is wrapped in several layers of tarpaulin and broken with a strong blow of a hammer.

The broken file is removed from the tarpaulin, annealed in a muffle furnace, and then slowly cooled. The resulting scale often interferes with machining. Therefore, wearing glasses and mittens, they knock it down with a hammer and a chisel.

Annealed and processed tool steel becomes quite soft: it can be easily filed, sawn and forged. With minimal hardness, it has maximum plasticity and viscosity. This makes it possible to make from it gravers for engraving, embossing, chisels, cutters, punches, and other tools for the artistic processing of metal.

Having made the desired tool from a file, it is hardened by heating according to the table to 780°C, followed by cooling in water. After hardening, the steel becomes brittle, so it is tempered: heated to 180°C and cooled in water or machine oil. When tempering, the heating temperature of the metal is controlled by the so-called tarnish colors, which correspond to a certain heating temperature.

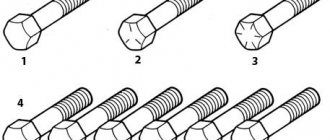

Classification of files by section shape

The parts processed with it can have different shapes. These can be sheets, profiles, etc. That is why, for productive work, manufacturers produce products of different shapes and geometric sizes. One of the classification options is by section shape. Manufacturers market products of the following types:

- flat;

- square;

- round;

- triangular;

- special;

- oval and some others.

Triangular file

Square metal file

Round file

In addition to the fact that products are distinguished by cross-sectional shape, they have different lengths and shapes. The minimum length is 50, maximum 500 mm. By the way, only the part on which the working teeth are applied is measured.

There is some relationship between the length of the working part and the size of the teeth. The longer the tool, the larger the size of the cutting tooth. Large is used when there is a need to remove a large amount of metal. But, after processing the material with a tool with large teeth, the surface turns out to be rough and scratched, and there is no need to talk about the accuracy of the processing. In cases where it is necessary to obtain a higher quality surface, products with fine teeth, for example velvet, are used.

Round velvet file

That is, processing is carried out in at least two stages using different types of files. At the first stage, rough processing is performed, and the finishing of the surface of the part is carried out by bringing the workpiece to the required parameters.

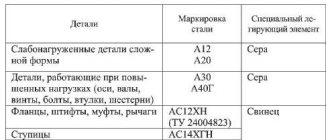

Stage 1: determination of steel grade

Having selected used tools (needles, files, rasps, braids, etc.), first of all you should determine what grade of steel they are made of. To keep your search as limited as possible, you should know what types of steel a particular tool is made from. Thus, files can be made of both tool carbon steel (U10, U11, U12, U13) and alloy steel (ShKh6, ShKh9, ShKh15). You can learn more about this from the list of tools below. The files presented in the KovkaPRO assortment are made of high-alloy steel with a hardness of 64-66HRC

Read also: Tooth stem height formula

Products made of tool and alloy steel:

Files – U10, U11, U12, U13, ШХ6, ШХ9, ШХ15 Needles – U10, U11, U12 Rasps – U7, U7A Scrapers – U10, U12 Chisels, chisels – U7, U8 Taps – U10, U11, U12, P9, 9ХС , Р18 Wood drills – 9ХС Metal drills – Р9, Р18 Reamers – Р9, Р18, 9ХС Mills – Р9, Р18 Chisels, screwdrivers – У7А, У8А, 7ХФ, 8ХФ Punches – У8, У8А Punch punches – У7А, 7ХФ, 8ХФ Sewing needles - U7A, U8A Hacksaw saws - U8GA Bow saw blades - U8GA, U10 Hacksaw blades - U8, U8A, U9, U9A, U10, U10A, U11, U12 Metal shears - U12A Hammers and sledgehammers - U7, U8 Axes - U7 Scythes, sickles – U7, U8 Forks, teeth (peckers) – U7, U8 rake Blacksmith tools – U7, U8

File Features

Handmade products of this type can be divided into the following categories:

- Locksmith - we can say that this is a multi-purpose tool. It can be found in almost any enterprise, workshop, or household.

- Needle files are small-sized products designed for processing small parts. They are widely used by engravers, jewelers, and pattern makers. In addition, needle files are indispensable when processing in hard-to-reach places.

- Sharpeners - they are used for sharpening saw chains, hacksaws, etc.

- Rasps are products with the largest teeth and are used to work with non-metallic materials, that is, in cases where the usual one is not suitable for solving the assigned production or household tasks.

Bench square file

As already noted, working teeth are applied to the working surface. It can be single or double. For processing soft materials, a tool with an arc cut is used.

Point teeth are made on the surface of the rasp.

Types of notches

There is a classification option based on the type of notch applied. A little has already been said about single and double execution.

Meanwhile, there are two types of double notching. The first is called crossover. This is, in fact, a combination of a single and a second, small (auxiliary) one, it is performed at an angle to the base one. At the intersection points of the grooves, the resulting chips are broken. This type is most often used in the production of bench files.

The second version of the double notch is called Oberg. Auxiliary grooves are less frequent. In fact, this option can be called intermediate between single and double notches in terms of the quality of part processing.

Numbering of notches

The application is determined by taking into account the type, size and configuration of the applied teeth. To obtain a working surface, various technologies are used:

- roll;

- milling;

- slicing and many others.

Many manufacturers, in order to increase labor productivity, use specialized equipment that allows them not only to speed up the production of these products and expand the number of their types, but also to maintain their quality at the appropriate level.

The size of the tooth directly depends on the size and type of notch applied per unit length, usually 1 cm. That is, the fewer grooves per centimeter of length, the larger the size of the cutting tooth. In practice, files with cuts from 0 to 5 are used.

Notch No. 2

The largest types include teeth with No. 0 and No. 1. They are used when it is necessary to remove a layer of metal from 0.05 to 0.1 mm in one pass. Such a tool has the following disadvantage - low accuracy, it ranges from 0.1 to 0.2 mm.

Files with tooth sizes No. 2 and No. 3 are used in cases where it is necessary to remove a layer of metal from 0.02 to 0.06 mm. The accuracy of such a tool is from 0.02 to 0.05 mm.

For surface finishing, a product is used that allows you to remove a layer of metal from 0.01 to 0.005 mm. An instrument of this type is sometimes called a velvet instrument.

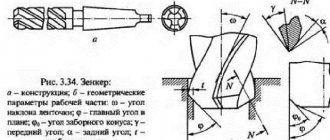

Geometric parameters of the notch

In accordance with the requirements of GOST 1465-80, set out in clause 2.1. On the surface of the tool, the notch is applied at an angle of 65 degrees relative to the axis.

In addition, it is also specified what technology it should be used to carry out. For example, round files can be made either by knurling or threading. All other types must be made using a notch.

File appearance

Today, a large number of this tool of various shapes are used. It can be classified not only by the shape of the section, but also by the shape of the bar itself.

Use of files of various shapes

Indeed, the shape of the bar largely determines the scope of application. That is, flat, used for processing flat surfaces located inside or outside the part. Square ones are used to develop holes of various shapes. Triangular has found its application in the processing of grooves and other parts. In addition, it is used for sharpening saws and other tools.

Sharpening a saw chain with a file

Semicircular, which can have a rectangular or pointed shape, are designed to work with convex or concave surfaces.

Round, used for working with round or oval holes. Diamond-shaped files are used to process gears.

Such an abundance of this tool (shape, size, etc.) can lead to confusion. And many sincerely believe that you should keep as many files as possible in your home workshop. But this is nothing more than a misconception. In fact, most surface treatment work can be done using tools of the following shapes - straight, round and triangular.

Set of files

By the way, the service life depends on the material, heat treatment parameters and the size of the notch.

How to sharpen skates

Understanding how to sharpen skates will be useful even for those who turn to a machine for help.

It’s still better to finish the skates by hand.

To work with “shoes”, you will need a needle file - a small file.

Its diameter should be equal to or slightly greater than the thickness of the skate blade.

In addition, you will need a simple device in the form of a block of wood with a cut in the middle.

The thickness and depth of the groove is equal to the thickness and depth of the blade.

At the bottom, the cut is slightly widened so that a needle file can fit into it.

How to use this device:

• the blade is clamped in a vice, after which a block with a file is put on the blade;

• make a groove with light efforts, and then, with more powerful pressure, deepen it.

“Working” on ice in such “shoes” is still difficult - the blades need to be perfected.

For this, sandpaper is already used - 400-600, and then about 1000.

The sharpness of the edge and the depth of the groove depend on the ice and the nature of skating on it.

Smooth ice and fast skating require sharp edges and grooves 1.3-2.5 mm deep.

“When working” on loose ice, the parameters of the sharpness and depth of the blade should be reduced.

Teeth size

In addition to the tooth size, products of this class differ from each other in the cutting density.

For rough surface treatment, products with large notches are used. It is called No. 1; there are from 5 to 15 teeth per centimeter. Its use makes it possible to remove a fairly thick layer of material in one pass, especially from soft materials; I call files of this type wrangler files.

Files No. 2 have from 14 to 25 grooves per centimeter of surface. This is perhaps the most popular type of this instrument. In fact, this file is most often used in practice.

Double cut file

Indeed, it can be used to process almost any material. But there is one subtlety: when working with soft metals or wood, after a fairly short time the notch will be clogged with processing waste. This is why it is necessary to clean the work surface with a wire brush.

Products with notches from 26 to 80 grooves per 1 centimeter are used for final surface treatment. After proper processing, there are practically no traces left on the surface.

Required tools and materials

The process of making a knife involves many difficulties, including the selection of materials. For manufacturing, you need to select a file more than 3 cm wide; it is advisable to look for a Soviet-made tool. The cross-section of the file surface should be flat or diamond-shaped; if the latter is found, this will be the best option, since the shape of the steel is stronger and will withstand loads.

The manufacturing process will require the following tools and items:

- Rivets made of brass alloy.

- Etching is performed with ferric chloride.

- Magnet for checking the degree of hardening.

- To process surfaces you will need sandpaper.

Processing is carried out with a grinder or grinder. You also need to decide on the material of the handle of the future knife. A file knife can have a metal or wooden handle, its weight and purpose depend on this. Before manufacturing, it is worth preparing a sketch of the future product; usually it is drawn on paper.

The process of making a knife from a file

Sharpening a cutting tool using a file

The group of cutting tools includes cutters, cutters, axes, saws and many others. The operating mode and the material from which the cutting tool is made determine the frequency of its sharpening. This operation is performed in two passes. The first is the sharpening itself, the second is bringing the cutting edge to the necessary requirements. That is, it must be brought into working condition. The cutting edge must be sharpened at a certain angle, it must have a certain shape. These parameters are determined by the material of the part.

Sharpening a shovel with a file

During the finishing process, burrs formed during the primary sharpening process are removed from the cutting edge.

For finishing cutting tools, products with fine notches are used. These can be files, bars and other abrasive materials. Finishing operations can be performed either using special equipment or manually.

Stage 2: determination of carbon content in steel

How can you determine specifically whether, for example, a file is made of carbon or alloy steel? To do this, you should resort to a simple old method. Craftsmen noticed that small metal shavings obtained when processing metal with an abrasive wheel, when heated, produce a sheaf of sparks, which have their own characteristic features for each metal. The “straws” that make up a sheaf of sparks, each brand has its own special ones: long, short, continuous, intermittent, heaped and sparse, smooth or thickened; from each of them small bright stars can be separated, sometimes very abundantly; The brightness of the glow of the sheaf of sparks is taken into account, as well as color shades - from light yellow to dark red.

Which notch to choose

When choosing any tool, first of all you need to understand what goals should be achieved when processing the part. Files are most often used to remove layers of material. Undoubtedly, if we are talking about removing material within 0.1 mm, then it makes sense to use files with a notch of No. 0 or No. 1.

File with cut No. 3 for metal

To perform more delicate work, for example, preparing the surface for coating, you can use a tool with a notch No. 2 - No. 4.

To perform work related to threading the cutting edge, grinding the surface and other particularly precise work, so-called velvet tools are used.

How to make a file handle

Those who often use a file in their work sooner or later are faced with the fact that its handle becomes unusable and therefore the question of replacing it arises. Of course, you can go to a hardware store and buy a ready-made part. But this is not always the best solution. As a rule, they sell handles made of plastic or unknown types of wood. This is why many people prefer to make pens with their own hands.

Material selection

Practice shows that the optimal material for a handle can be considered materials such as walnut, maple. These are quite durable materials; in addition, they have an attractive texture.

Handle walnut

But in addition to the material for the handle itself, you will need to select glue. To connect the component parts of the tool, it is advisable to use adhesives based on epoxy resin.

How to make it

To make a handle, you can use a lathe. If this is not possible, then you can remember your childhood and sharpen it with a knife.

When making a handle, it makes sense to maintain the following dimensions:

- working part diameter 25 – 30 mm;

- working part length 120 – 150 mm;

The depth of the hole for securing the tool shank should be slightly longer than the shank itself.

The final operation in the manufacture of a file handle is to treat its surface using abrasive sandpaper. This is necessary so that there are no burrs left on the surface of the handle that could dig into the worker’s hand.

Making the handle

Before making a handle for a product, you should decide on the appearance, materials and shape. You can use any material that is at hand. A wooden handle is considered a harmonious option.

File knife handle

The process includes several stages:

- Selection of materials, it is possible to use different types of wood for a unique design.

- It is necessary to make a bolster, the lower part of the knife. The remainder of a file or other metal is used.

- Wooden pieces are placed on top of each other and glued together with epoxy glue.

- To glue the pieces together better and faster, you need to use a press.

- The excess parts are trimmed with a saw, after which they are processed with sandpaper to the required shape.

- When finished, the handle is varnished for greater preservation; it is possible to use stain to darken it.

It is important to understand that all knives, regardless of category, are considered edged weapons. However, a cutting product whose blade length is no more than 90 cm and whose thickness is more than 6 mm can be removed from the category of edged weapons.

Sharpening is done in the usual way on a grinding machine.