Calculation of engine power for a homemade screw wood splitter

To assemble a wood splitter with your own hands

An engine or walk-behind tractor with at least a power of 3.hp or 2.2 kW is required.

It's simple: the higher the engine power, the higher the performance. With good power, you can stab straight into the middle, and stab tangentially, disassembling it in parts.

Video of the operation of a screw (cone) carrot wood splitter on walk-behind tractors with a 6.5 hp or 4.7 kW engine. For the wood splitter with your own

manually, you need a walk-behind tractor engine + a mini set of pulleys or sprockets. Or you can immediately buy a kit for assembling a homemade log splitter.

The best hydraulic log splitters

The hydraulic splitter works on the principle of applying pressure to the log using a press. The main element that determines power and performance is the motor. For domestic use, a device force of 3–5 tons is usually sufficient. For industrial purposes, it is better to look for more powerful models. VyborExpera specialists studied the market for hydraulic axes and selected the 3 best representatives of this segment.

Champion LSH5001H

A good electric hydraulic wood splitter, which has the only limitation: the length of the workpieces should not exceed 50 cm. Thanks to a force of 5 tons, the machine copes with the most uneven and knotty logs. The model operates from a regular outlet, is safe to use, and does not require special skills to use. The recommended log diameter is up to 25 cm, but users note that the machine can easily split logs 40-50 cm wide. It is convenient to work with a low model while sitting, and if you come across heavy workpieces, you do not need to lift them high.

Advantages

- Convenient to use;

- Leaves virtually no debris;

- Fits into a car;

- Moderate power consumption.

Flaws

- The cross-shaped attachment only works on ideal decorative logs.

Hydraulic oil, which sometimes needs to be changed, is difficult to buy in small quantities. Everywhere it is sold in 200 liter barrels. Therefore, replacement can only be carried out at service centers.

Patriot CE 5215

Inexpensive wood splitter with engine. Thanks to a force of 4 tons and an electric drive, it copes with splitting firewood with a diameter of up to 25 cm. The horizontal model is located on stable supports. The durable frame ensures a long service life of the device. Thanks to its small size, the model is convenient to store in a shed or dressing room; it does not take up much space. You can buy a hydraulic log splitter at most stores.

Advantages

- Manufacturer's warranty – 3 years;

- Easy to install and use;

- There are wheels for moving around the site;

- Clear instructions.

Flaws

- Heavy.

The electric machine from Patriot is designed for summer residents and residents of small houses; the device is not suitable for industrial scale. The model copes well with dry logs; it also chops raw logs, but worse.

Al-Ko LSH 520/5

The safest wood splitter with hydraulics according to VyborExpert. The two-hand control system minimizes the risk of injury and ensures the most accurate splitting of logs. A protective guard protects the user from flying wood. The splitting force created in the machine reaches 5 tons. Electric motor power – 2.2 kW. This allows the device to cope with wide, knotty logs. The model is small in size and can be assembled for storage, so it will not take up much space in the shed. And the wheels are convenient for transportation alone.

Advantages

- 4-year warranty;

- Durable materials;

- Build quality;

- Comfortable height.

Flaws

- No cross.

The Al-Ko model will last for many years. The steel elements are coated with powder paint, which reliably protects the surface from corrosion. All materials used are of high quality.

Horsepower: history and modernity

The idea of measuring the power of an engine “in horses” capable of doing the same work was voiced in 1702 by the English inventor Thomas Avery in the book “The Miner's Friend”. The term “horsepower” was coined by Scottish engineer and inventor James Watt.

In Russia, horsepower is understood as the so-called. metric horsepower equal to 735.49875 watts. In Europe, horsepower is equal to 75 kgf m/s - this is the power expended when uniformly vertically lifting a load weighing 75 kg at a speed of 1 meter per second with standard acceleration of gravity (9.80665 m/s²); in watts it would also be 735.49875. In the UK and US, the more commonly used mechanical horsepower is 745.69988145 W (that's 1.01386967887 of metric).

The power of car engines is measured in different units and in different ways. Horsepower is gradually falling out of use, but in Russia it is needed to calculate transport tax. Some countries have now abandoned taking power into account when calculating taxes and paid attention to the dimensions of the car; other countries focus on kilowatts in this matter.

Source

Adjustment

Splitting heights – used to adjust the vertical splitting cleaver to the length of the workpiece. It is worth paying attention to the number of split levels. The greater this characteristic, the easier it is to work with the wood splitter. Specific parameters differ in models from different manufacturers. For example, some devices allow you to change the split height by 51 cm and 105 cm, others by 55 cm; 88 cm and 130 cm.

Surface heights – makes it possible to change the height of the bed (frame) to suit the operator’s height, which makes it easier to use the wood splitter and reduces fatigue. This option is especially useful for older people and those who suffer from back problems.

Electrically driven screw splitter

A wood splitter with an electric or diesel drive is a unit capable of processing up to 10-12 cubic meters of logs about 60 cm long (firewood standard).

Producers use installations to reduce labor costs. At home, high-performance installations are not in demand. The device of a screw log splitter is based on the interaction of a screw-nut pair, where the nut is soft wood. A gearmotor with a tip in the form of a conical screw, rotating at a speed of 250-450 rpm, is mounted on a stable steel platform. The engine drives a thrust bar, which pushes the block of wood, standing at its end, onto a rotating cone. As a result of the cone of the wood splitter entering the side surface of the log, the wood splits along the grain.

When working with a wood splitter, precautions must be taken. Clothing should fit tightly to the body. Mittens are a danger factor. It is better to work with thick gloves.

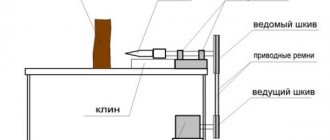

The gearmotor is replaced by a belt drive with the engine installed under the cutting table. Then the rotation is transmitted to the screw cone shaft by pulleys designed for optimal screw speeds. This design allows the use of a single-phase 220 V motor; with it, the price of a screw wood splitter becomes significantly lower. If the cleaver is equipped with an end cap, the working cone will return to its original position on its own. How a screw wood splitter works, you can watch the video:

Supply voltage

Single-phase (220 V) – used in household and semi-professional electric wood splitters. The power of such equipment does not exceed 3 kW.

Three-phase (380 V) – used in industrial electric cleavers. The device requires special wiring to operate. The power of such equipment reaches 5 kW.

Important: practice shows that for domestic needs, a hydraulic horizontal wood splitter with an electric motor (single-phase) or a screw unit is best suited.

When it comes to harvesting firewood for commercial purposes, choose a hydraulic vertical splitting splitter with an electric drive (three-phase) or a gasoline model with a hydraulic or screw system. And for solid fuel boilers, the rack model is optimal.

Making a wood splitter yourself

The cost of a factory-made screw cleaver, depending on the configuration, ranges from 16 to hundreds of thousands of rubles. The main working element is a cone for a wood splitter, which can be ordered from a turning workshop. To make a screw wood splitter work with your own hands, drawings for craftsmen are offered.

It will not be possible to make a thread with a grinder, since the persistent thread on the “carrot” must be maintained precisely. In addition, when making a cone, the turner must know the ratio of the length and cross-section of the base - 2:1, the thread is double-start with a pitch of 5-6 mm, the tooth profile is like that of a chisel.

Depending on the size of the part, it will cost up to 5,000 rubles. Completely finished working unit:

- screw cone;

- shaft with bearing unit;

- transmission pulley for belt drive.

Main types of wood splitters

Wood splitters, depending on the presence or absence of a drive, can be mechanical or manual.

Their structure is radically different from each other.

In addition, these machines differ in the method of movement:

- Stationary. They are often industrial machines that are large in weight and size. The use of such wood splitters in domestic conditions is impractical.

- Mobile - devices equipped with wheels for transportation, or have a low weight, which allows them to be moved. According to the method of laying logs, wood splitters are divided into horizontal and vertical.

Manual

The operating principle of manual wood splitters is based on the simplest physical laws, without the use of any additional special devices.

The person himself acts as a source of energy.

Manual wood splitters are preferred in everyday life, since they are not suitable for preparing really large volumes of fuel material.

In turn, they can be divided into several types:

- Manual

The stand is the base on which the blades are mounted in the upward direction.

The workpiece is placed on the blades, and a sledgehammer blow is made from above.

- Crowbar cleaver

It is a pipe with a cleaver at the end, inside which a heavy rod (crowbar) moves freely.

The cleaver is placed on the workpiece, after which the rod drops sharply (it hits the cleaver inside the pipe).

- Spring

It is a lever, on one side of which there is a blade, and the opposite side is movably fixed to the frame.

In this case, the connection point is spring-loaded.

The principle of operation is a large shoulder of force.

- Rack and pinion

The mechanism for feeding logs into the blades is made in the form of a rack with notches.

Mechanical

There are many more varieties of mechanical wood splitters than manual ones, since different types of engines can be used to feed workpieces to the blades, as well as the feeding method itself.

In addition, not only blades are capable of splitting wood well.

- Mechanical wood splitters are a frame with a motor, on the shaft of which a conical screw is located.

The principle of operation is to screw this screw into the wood, due to which the fibers of the material are easily separated.

The block is placed on the cone by means of a stop driven by hand force.

- Cone log splitters are structurally similar to ordinary mechanical options, however, the logs are placed on the cone manually.

Another name for these devices is screw splitters. The cone itself is fixed directly on the axis of the electric motor.

- Geared wood splitters - in their design, a reduction gear is used to reduce the speed on the cone.

Allows the use of a high-speed engine.

Geared wood splitters are often referred to as machines that consist of a frame with blades attached to one side.

On the reverse side there is a motor with a special gearbox that converts the rotational movements of the shaft into reciprocating movements of the piston, which feeds the workpiece to the blades.

Depending on the type of engine used, wood splitters are divided into:

- Electric is the most common option.

The electric motor, which is powered from a household network, is not demanding in operation and maintenance, and has sufficient power for domestic use.

In addition, electric wood splitters are also environmentally friendly devices.

Among the disadvantages, one can note only the low mobility of such machines.

- Petrol – variants with a petrol engine.

They are much more powerful than electric ones and are not tied to a power source (fuel).

Suitable for both domestic use and for harvesting firewood on an industrial scale.

- On tractor traction, the energy source is either the tractor’s hydraulic system or its power take-off shaft.

Another variety is hydraulic wood splitters.

Due to their power, they are able to split wood of any species, both dry and wet.

Due to their productivity, such production devices are often used in logging.

The simplest hydraulic option is a frame on which blades are fixed on one side (they can be at different angles relative to each other in order to completely process an entire block of wood in one pass) and on the other a pushing piston.

This piston can be connected to the tractor's hydraulic system or to its own motor-hydraulic pump system.

Such devices are capable of producing pusher pressure of up to 12 tons.

Operating principle, advantages and design of a screw wood splitter

The cone of the wood splitter rotates using an electric motor. It enters the log and, due to a gradual increase in diameter, tears it apart along the fibers. Firewood is supplied to the propeller manually. A homemade screw wood splitter has the following advantages:

- Simplicity of design.

- Low cost of nodes.

- Easy accessibility of units (almost all, except for the cone, they are available in everyday life).

- High productivity (up to 12 m3 of firewood about 60 cm long).

- Easy to use.

This device also has disadvantages. Firstly, it does not cut wood with interwoven fibers well. Secondly, the logs are not completely separated into logs - you have to complete this process manually. And this requires some effort.

Thirdly, to make the cone you will need a lathe. Although, you can make the screw yourself - there is a lot of information on this matter on the Internet. In addition, this part can be purchased ready-made.

The cone shaft must be mounted on a strong, stable platform. The recommended cone rotation speed range is from 300 to 500 rpm. In this scheme, the electric motor rotates the propeller via a belt drive.

The advantage of this scheme is that any engines can be used here. And the required propeller rotation speed is achieved through a belt or chain drive. A pulley of a smaller diameter is installed on the electric motor shaft, and a larger one on the propeller shaft.

To simplify the design of the unit, it is recommended to use an electric motor with a gearbox. This decision will not affect performance in any way.

There is an option in which the electric motor is connected to the cone directly. The maximum engine speed in this case should be 500 rpm, the minimum power should be 3 kW.

The option in which the engine is located under the tabletop is more preferable. In this case, the length of the tabletop will be shorter. In addition, this will protect the motor from splinters. In this scheme, a single-phase electric motor is suitable, which will help reduce the cost of manufacturing the device.

Ten of the best home wood splitters

CHAMPION LSV6000

The device is optimally suited for home use. It is equipped with an electric drive, which allows it to work with logs up to 100 cm long. The pressure generated is 6 tons - the device effectively splits even the hardest and most viscous wood species. The engine power is 2.7 kW, it is connected to a standard electrical network, the working position is vertical. The maximum diameter of a log that this tool can split is 30 cm. The hydraulic system contains 4 liters of oil. The device itself has a mass of 97 kg, and during operation the noise is not too loud - at a level of 90 dB.

More: Top 10 best onion varieties, choosing the best onion varieties!

The wood splitter is equipped with a durable asynchronous motor. The set includes attachments that allow you to split the log into four parts at once. It has a carefully thought out security system, the device is characterized by high speed of operation and does not require various skills from the operator.

Advantages:

- A fairly powerful semi-professional unit;

- The engine has a high performance indicator;

- The length of the logs can reach one meter;

- Equipped with high tread wheels.

Flaws:

- Decent weight of the unit;

- The control handles are equipped with bolts that are too long - because of them, the handles often fly off the brackets.

Wood splitter CHAMPION LSV6000

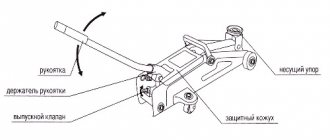

Texas 600VG

The first model in our review is equipped with a gasoline engine, the power of which is as much as 5 horsepower. This is an excellent alternative to electrical devices, as it can be used in holiday villages where there is no electricity supply. Using hydraulics, it is possible to provide a maximum force of 6 tons, due to which it will be possible to effectively split logs of any type of wood. The kit does not include any additional attachments - all elements will need to be purchased separately. For greater ease of transportation there are wheels. Operate the equipment with both hands, and the operator’s hands will be reliably protected from possible injuries by means of metal casings.

The unit is started using a manual starter, the engine shaft rotates clockwise. The wood splitter itself has small overall dimensions - 313x376x335 mm with a weight of 128 kg, which makes it easier to store. The manufacturer provides a two-year warranty on its products. The working length of the logs ranges from 50 to 105 cm. The hydraulic tank contains 8 liters of oil, the fuel tank capacity is 3.6 liters. A fully filled gas tank is consumed within 4 hours of continuous operation.

Advantages:

- The manufacturer has done a good job on the safety of the unit;

- There are comfortable wheels;

- Powerful gasoline engine;

- Control is carried out with two hands;

- Compact overall dimensions.

Flaws:

- The equipment is extremely poor - all additional elements have to be purchased.

Wood splitter Texas 600VG

PROFI PLS 700E

Domestic hydraulic products. It has an increased hydraulic force of 7 tons, which has a positive effect on operating time. The maximum log length does not exceed 52 cm. The overall dimensions of the device are not very large. It is small and high; it comes with an attachment that can be used to split the log into four parts.

Users in their reviews claim that the device is characterized by unpretentiousness and durability, creates significant force, so it copes even with very hard and strong types of wood. The device is equipped with an electric motor connected to a household power supply; its power is 2.3 kW. The maximum diameter of the log should not exceed 25 cm, the weight of the unit is 75 kg.

Advantages:

- Compact overall dimensions;

- Increased piston force;

- Reasonable cost;

- There is everything necessary for comfortable work;

- The security of the device is well thought out.

Flaws:

- You cannot load a log larger than 25 cm in diameter.

Wood splitter PROFI PLS 700E

AL-KO KHS 3704

The splitting power is a little less compared to other models that we have talked about before. However, it will be quite sufficient for domestic use of the unit. The device is perfect for chopping wood for a fireplace or stove (home, bath, outdoor, etc.). The maximum length of logs should be no more than 37 cm. Often such a wood splitter is purchased by heating complexes that are engaged in the formation of a fuel supply to ensure stable operation of wood-burning boiler houses.

More: Top 10 best garden washbasins

The device can work with dry and wet firewood. The unit has maneuverable wheels that can easily move over bumpy terrain and grass. The wedge is well-tempered and perfectly balanced, so it splits the wood perfectly evenly. The hydraulic system holds 2.7 liters of oil. In general, the manufacturer recommends using all-season oil so that the wood splitter can be used in winter.

Advantages:

- Quickly and conveniently adjust the working height;

- The wedge has the highest strength and is well balanced;

- The model is equipped with reliable and large wheels;

- Operate the wood splitter with both hands;

- It features compact overall dimensions.

Flaws:

- Not too high power and hydraulic force.

Wood splitter AL-KO KHS 3704

Raptor t700

The design of the tool is quite simple - it includes a conical screw measuring 250x80 mm, made of high-quality, carefully hardened steel. It is connected to a high-power electric motor through a control unit, and there is also a stand and a flywheel. Compared to hydraulic products, this screw splitter is considered more productive. Its effectiveness largely depends on how quickly the operator reacts to what is happening around him.

There are no hydraulic elements provided here, due to which the device becomes more durable and has a simple design. Unfortunately, the manufacturer has not thought through the safety system very well when working with this product, so you will have to be as careful as possible to avoid injury. In this case, the logs are fed at right angles to their longitudinal axis.

Advantages:

- Low weight of the unit;

- Simple design;

- Decent power of the product.

Flaws:

- Very high risk of injury.

Wood splitter Raptor t700

Texas 520H

A very simple, but quite powerful device designed for harvesting wood logs. It is worth noting that the manufacturer initially developed it for use exclusively in private households, but today it is often used for industrial purposes if it is not necessary to stock up on too much firewood. The maximum force is 5 tons, which allows you to cope with any type of wood, including twisted and knotty logs. The device is equipped with a powerful 1.5 kW electric motor.

The maximum dimensions of the log that can be loaded into this machine are 52 cm in length and 25 cm in diameter. The weight of the equipment is 46 kg - not a very heavy tool, but it is still equipped with wheels for more convenient movement around the site.

Advantages:

- Optimal force for household equipment;

- Copes well with the tasks assigned to him;

- Working with the device does not take too much time.

Flaws:

- The wheels have a smooth tread.

Wood splitter Texas 520 H

AL-KO KHS 5204

Belongs to the group of semi-professional equipment; the maximum splitting pressure of the device can reach 5 tons. This design is optimal for preparing firewood for a fireplace, the length of which will not exceed 52 cm. Small industrial enterprises often purchase such a wood splitter where there is a need to prepare a small amount of firewood. The unit is capable of operating at ambient temperatures from -20 to +50 degrees. Its hydraulic system is filled with oil that can easily resist low temperatures; its volume is 3.1 liters.

The frame can be adjusted in height if necessary, but it is quite light. If there is a need to split large logs, there is always a chance that the device will tip over, so in this case the equipment is installed on a leveled area.

More: Where to buy Eurocubes? TOP 5 companies in Moscow and the Moscow region

Advantages:

- You can choose the optimal working height;

- The wedge is durable and does not become dull for a very long time;

- There is a reliable system for protecting hands from injury;

- The wheels have low tread, but are very wide, so the wood splitter can be transported on any surface;

- The engine power is 2.2 kW.

Flaws:

- May tip over if working with logs that are too thick.

Wood splitter AL-KO KHS 5204

Champion LSH5000

It is made on the basis of a metal frame of increased strength, which is coated with special anti-corrosion substances that can significantly extend the service life of this equipment. The product is equipped with a high-power motor - 2.2 kW, while the wood splitter is designed to operate from an ordinary household electrical network. It is capable of developing a force of 5 tons.

The device is designed to work with logs with a diameter of up to 25 cm and a length of up to 52 cm. The weight of the unit is about 43 kg. There is a dividing knife on the splitting chute; with the help of such a wood splitter you can stock up on a significant amount of firewood in a short time. The set includes a nozzle that splits the log into 4 parts. 3.6 liters of oil is poured into the hydraulic system; the manufacturer recommends using universal oil, suitable for any temperature conditions.

Advantages:

- High-quality frame protection from mechanical damage and corrosion;

- High engine power and effort;

- The kit includes everything you need for convenient work.

Flaws:

- The power cable is short - you have to use an extension cord.

Wood splitter Champion LSH5000

Gorynych 6T

It is characterized by an accelerated piston stroke, due to which it is possible to ensure the highest possible performance. Such a solution will be very useful for people who prepare firewood for subsequent sale. The design is designed for long-term operation without interruption - this approach makes it almost irreplaceable if it is necessary to prepare a significant amount of fuel. The position of the knife is adjustable if necessary, there is an attachment for splitting firewood into 4 parts.

The device has a high engine power - as much as 4 kW, but it needs to be connected to an industrial power supply with a voltage of 380 V. Firewood must be stacked horizontally, the maximum force is 6 tons, the dimensions of the logs are 50x50 cm.

Advantages:

- High speed;

- Good stability;

- Decent power of the unit.

Flaws:

- Operates only on 380 V.

Wood splitter Gorynych 6T

GOMARK – LANCMAN SL10

The leader in our review of the best wood splitters was a Slovenian-made model. The products are characterized by a high level of strength, reliability, and can last for a long time. The device can be used even on an industrial scale when harvesting not only firewood, but also charcoal.

It operates from various sources - a household electrical network, a gasoline engine, or a power take-off shaft installed in the tractor. The model has the highest performance and is very convenient to work with. It creates a force of 10 tons. The log splitter can load logs up to 50 cm long and up to 65 cm thick. The device weighs a lot - 275 kg.

Advantages:

- Highest quality manufacturing and assembly;

- Runs on gasoline or electricity;

- High speed;

- Long period of operation.

Flaws:

- Very heavy unit;

- Expensive.

Wood splitter GOMARK – LANCMAN SL10

Design elements

To work you will need:

- Sheet of metal 4-5 mm thick.

- Cone (the best material for the main part of the entire mechanism is tool steel).

- Shaft.

- Pulleys (for transmission using a belt) or sprockets (for transmission using a chain).

- Belt or chain.

- Bearings having a housing.

- Electric motor.

- Wires.

- Button to turn the unit on and off (alternatively, you can use a magnetic starter).

- Angles for making a frame (steel pipes are also quite suitable for this purpose).

- Bolts and nuts.

Almost all of the parts listed can be recovered from old equipment. You can make the cone yourself. However, this will require certain equipment. The screw thread pitch should be 2:1. Therefore, it is advisable to purchase it so that the unit works without any problems.

You will also need the following tools for the job:

- electric drill with drills of different sizes;

- hammer;

- welding machine;

- Bulgarian;

- tape measure, keys;

- marker.

Manufacturing

First, cut the angles and pipes according to your measurements. From the sheet, cut out the table cover and the platform on which the motor will be installed. Connect the upper and lower frames, weld the legs. For mobile installation, axles will need to be welded to the frame. Install wheels on these axles.

After this, install the tabletop and shelf on which the engine will be mounted. Install the motor. Connect the motor shaft to the drive pulley. Assemble the cone shaft assembly. To do this, you will need to place the bearings in the housings, install the pulleys and shaft. Now drill holes in the frame and secure the assembled unit to it. To do this you will need bolts and nuts. Check the rotation of the shaft - there should be no resistance.

Installing the motor and main shaft

After this, you can install the belts. Having done this, check the trajectory of their movement - it should be straight. If this is not the case, drill new holes in the tabletop and install the shaft there. After this, check the trajectory again. Do this procedure until you get the desired result. The belts must move without beating, otherwise they may fly off.

Place the cone on the shaft and secure it with screws. The cone must be installed firmly, without play. Make flats on the shaft. They can come in handy if the cone gets stuck in a log. You will have to remove it using a pipe wrench. The flats will ensure the key adheres to the shaft. After this, install the divider (an old hammer may be useful for making it).

Cone installation

After this, proceed to connecting electrical equipment. That's it - the wood splitter is ready! You can clean its surfaces, prime them and apply paint. Now you can test the device.

The dimensions of the unit can be arbitrary. The main thing is that it is convenient to use. To do this, the dimensions of the machine must correspond to human height. Recommended sizes:

- length – 850 mm;

- width – 450 mm;

- height – 650 mm.

Video: do-it-yourself screw wood splitter.

Safety precautions

You need to put the wood on the cone without gloves. Otherwise, they may become caught on the screw, which may result in injury. Only feed the workpieces in a vertical position. This will protect the working part of the unit from jamming and failure. Don't forget to ground the engine.

So, making a screw log splitter is a process that does not present any particular problems. This may only take one day. But in the future you will save a lot of time and effort when preparing large quantities of firewood. Just follow safety precautions when working.

A large number of questions through feedback and comments on the site prompted me to write this article, which helps to select hydraulic components for a hydraulic wood splitter.

Most of the requests begin like this: I want to assemble a hydraulic wood splitter with my own hands, I have such and such a pump (or a hydraulic cylinder or an electric motor), help me connect the system to a 220 volt outlet.

Let's face it, this approach to selecting components is extremely wrong! You need to select components based on the task at hand, and not on what is in stock.

Features of screw wood splitters

Given the complexity of the trajectory of movement of a mechanized splitting wedge, some advantages are also achieved:

- Speed. When encountering knots or knots of wood fibers, the screw wedge will deal with them faster, since with such a movement the axial force is divided into two components - vertical and horizontal. If one fails, the other will work.

- Insensitive to the location of the original workpiece - it can have both a vertical and horizontal position. This is convenient if it is not possible to allocate sufficient space to the screw log splitter.

- Quality of separation. A forward-moving wedge will get stuck in hard wood, which (when using any type of drive) will lead to overload of the motor in terms of torque.

There are also disadvantages, the main one of which is the increased danger of use: it is enough to get caught on the wedge with a small piece of clothing - and serious injury is guaranteed. At the same time, it is very problematic to reduce the level of danger, except perhaps by installing a mesh fence around the processing area.

Carefulness in the initial installation of the screw wedge is also essential - if it is done even at a slight angle, the tool will break.

Stage two

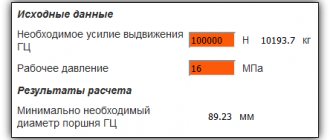

We select the volume of the oil pump to ensure the specified time for extending the rod. Let's move on to the second part of the hydraulics calculator.

Enter in the field “Sleeve diameter. " value 90 , in the field "Rod diameter. “ the value is 50 , in the “Hydraulic cylinder stroke” the value is 510 , in the “Full extension time” the value is 5 , in the “Working pressure” the value is 16 .

To ensure a hydraulic cylinder rod extension speed of 5 seconds, the required oil pump flow is 38.9 l/min

Stage three

We select an electric motor of the required power so that the oil pump can develop a working pressure in the system of 16 mPa. Let's move on to the third part of the hydraulics calculator.

In the field “Estimated rotation speed. “ set the value to 1500 . The most optimal speed for the NSh oil pump. In the field “Required feed. “ set the value to 38.9 . In the field “Pump volumetric efficiency. “ set the value to 0.9 . In the “Working pressure” we set the value 16 .

We get the theoretical result: 28.8 cc. Minimum required volume of the oil pump to ensure the rod extension speed in 5 seconds. The minimum electric motor power for this pump is 12.2 kW.

Best models

The Splitter cone splitter is very popular. This technological device allows you to split logs with a diameter of up to 50 cm.

The speed of movement of the cone screw varies from 150 to 400 rpm. The installation capacity is 1 cubic meter. m/hour, and power – 1.5-3 kW.

The mass of the unit is 90 kg.

The wood splitter-screw “Carrot” is very popular . This mechanism is simple, but at the same time effective, and thanks to the electrical principle of operation, such a mechanism can be used in almost any household.

The power of the wood splitter is 2.2 kW, the rotation speed is 3000 rpm.

The working part of the bed has dimensions of 40x70 cm.

The heavy flywheel creates quite powerful kinetic energy, so with the help of the “Carrot” you can stack the most complex logs without stressing the motor. At the same time, splitting logs is so effective that the logs literally “tear apart.”

However, when splitting logs, the main thing is not to make money, since the wood splitter is a rather dangerous structure and can pull the sleeves of your clothes onto its cone in a matter of seconds.

The “Screw” cone wood splitter works on a simple principle : while rotating, the cone enters the wood like a screw, splitting it into pieces.

Often such devices are built independently. However, when working with this wood splitter, it is necessary to observe basic safety precautions.

Stage four

We select a standard volume oil pump and an electric motor for it.

Let's move on to the fourth part of the hydraulics calculator.

In the field “Rotation speed. “ set the value to 1500 , in the “Pump displacement” set the value to 32 , because pump NSh-32 is the most affordable pump, the closest in volume. In the field “Volume efficiency. “ set the value to 0.9 . In the field “Adjustment pressure. “ set the value to 16 .

We get the result: To drive the NSh-32 pump, a 13.5 kW drive is required. The closest electric motor in terms of power is 15 kW.