The quality of the work it produces directly depends on the sharpness of the blade. A dull or deformed tip does not perform its functions and can not only ruin the cutting process, but also injure the operator. Throughout the development of all bladed weapons, sharpeners were invented that could restore the original quality of the cutting edge. The further progress developed, the more high-tech sharpening stones became, and the amount of time that needed to be spent on work was reduced. Models with a motor at the heart of the design are considered the most powerful and efficient. Their range of functions includes straightening a bent edge, removing chips and nicks, grinding, cleaning, and restoring the original sharpness. However, the turning process requires practical or at least theoretical preparation. Unlike manual abrasive bars, where a sharp change in the angle of the blade will not have a critical effect on it, on automated models any mistake can lead to damage to the product. We will explain how a knife sharpening machine works, how to properly sharpen knives on a machine, how to achieve maximum efficiency and avoid the most common mistakes.

How to sharpen knives on a machine correctly

Before you learn how to properly sharpen knives on a machine, you need to become more familiar with its design. Since all motor models are divided into automatic and semi-automatic, instructions for their use will vary.

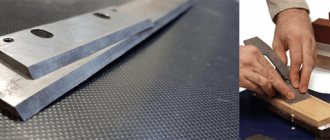

Figure 1. Wheels for sharpening knives: abrasive and felt

However, the operating principle remains the same:

- The electric motor rotates the axis on which a circle with a special coating is installed. For turning it is crystalline abrasive grains of various sizes, for grinding it is felt (Figure 1). The coarser the crystals on the wheel, the more severe dullness they can handle. It is prohibited to use coarse grain for thin, soft or partially dull blades - complete deformation will follow. The use of small crystals for a completely dull tip will also be ineffective;

- The rotation speed of the axis is selected by the operator himself, depending on the type of steel and the degree of dullness. If you choose the wrong mode, you can overheat the product and inevitably damage it under the influence of temperature;

This is where the similarities between automatic and semi-automatic devices end.

Figure 2. Options for professional knife sharpening machines

A professional automatic knife sharpening machine (Figure 2) operates according to the following algorithm:

- A motor and abrasive wheels of different grain sizes are built into a maximally closed casing with an opening (or several openings) for the blade. The system is designed in such a way that the inclination of the grinding wheel can change depending on the impact on the guides themselves. The operator inserts the product into the opening, and the guides automatically adjust the required angle;

- Since the turning inclination is individual for each tip, such devices imply the ability to adjust down to the millimeter;

- Most devices have several speed or time modes, so you need to know the characteristics of the gun in advance. By choosing too intense a mode, you can also deform the tip.

Figure 3. Typical “Epaper”

A manual machine (Figure 3) for sharpening knives (aka “emery”) requires an integrated approach to the entire process:

- Turning is carried out by applying the edge to a rotating wheel; precise inclination must be maintained. Otherwise, you can either grind off a significant layer of metal, or completely change the slope of the processing, which will ruin the blade;

- The attachment with grain is also selected according to the characteristics of the implement. For kitchen or travel models, fine sandpaper is sufficient, for working tools (for example, shoemakers) – medium sandpaper. Axes and other household and garden tools are sharpened using the coarse fraction;

- To ensure that the process proceeds smoothly, at first it is recommended to work with a partner who will monitor the uniformity and accuracy of the operator’s movements. Even an untrained person can act as an assistant: he only needs to concentrate on the work. At a more professional level, the operator copes independently;

- It is recommended to work in plastic safety glasses and closed clothing to prevent crumbs or sparks from touching soft or mucous tissues. Neglecting safety precautions when working with the machine is strictly prohibited.

Advantages and design features

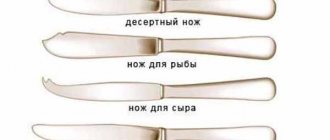

Today, stores offer a wide range of electric knife sharpeners. A review of popular models allows us to conclude that the most advanced devices can easily sharpen knives:

- Japanese and European manufacturers;

- with single-sided and double-sided sharpening;

- professional and household;

- kitchen, tourist, hunting;

- with any sharpening angle;

- scissors;

- with a wavy edge.

When thinking about how to choose an electric knife sharpener, decide on the type of tool you plan to sharpen yourself and make sure that the model meets the specified characteristics. Most sharpeners work in two directions, straightening/finishing the cutting edge (if there are bends or small nicks) and directly sharpening/polishing – giving maximum sharpness.

The design of electric knife sharpeners is hidden in a plastic case, inside of which there are discs with an abrasive coating of the appropriate grain size made of metal or ceramic for coarse and fine sharpening. The body has slots for the knife blade at different angles. Inside there is also an electric motor that runs on mains power and a container for collecting metal shavings.

Sharpening or straightening knives?

Before moving on to the instructions on how to sharpen knives on a sharpening machine correctly, you need to determine what kind of care the blade of your tool needs - sharpening or sharpening. What is it for? The fact is that for different types of deformation, the principles of care will also differ. For example, when bending an edge, one nozzle and one speed are used, when removing chips, a completely different disk and different settings are used. Using standard bent edge turning techniques, you can cut off too much metal. Therefore, it is recommended to edit the gun first. Among the mechanical analogues, musat is used to eliminate wavy irregularities and curves - a round oblong file with a handle (Figure 4). However, if you have a machine, processing with hand tools is too energy-intensive.

Figure 4. Variant of the Musat file

Editing is carried out at minimum speed:

- The wave-bent metal is removed completely under the base. It will be impossible to bend it back. It is worth considering that cutting the deformed layer must be done with pinpoint precision, so as not to double the time of further processing and not accidentally shorten the length of the blade;

- Based on the initial edge angle, further work is carried out.

How to sharpen knives on an emery machine

An electric sharpener, which is based on an emery disc, is used both at home for sharpening cutting edges and in production (Figure 5). The machine is used for sharpening jointing knives, countersinks, dies, drills, spatulas, hand scythes, household and travel blades, scissors and even screwdrivers.

The main requirement for the operator’s work is accuracy and adherence to the algorithm.

Figure 5. Electric grinder in production

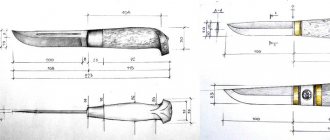

How to sharpen knives on a sharpening machine:

- The standard set of sandpaper includes two abrasive discs of different grain sizes. At the first stage of processing, large grains should be used to give the primary shape and sharpness. Finishing is carried out on small crystals. If the blade is made of thin metal, then it is recommended not to use large crystals at all;

- The RPM for most tools should be up to 150 rpm. This value is the maximum, so you can reduce it if you have doubts about the speed;

- The point is made exclusively on the side of the abrasive nozzle. First, the blade is installed parallel to a special stand, then tilted at the required angle (Figure 6). For thin kitchen blades this value will be up to 20 degrees, for tourist and shoe blades - up to 35 or 40 degrees;

- The width of the approach (the transition from the “body” of the blade to the tip) should be 2-3 millimeters. A larger value of 4-5 millimeters is used for rough tools such as an ax or garden shears;

- During the entire process, it is necessary to make smooth and symmetrical movements, barely touching the disk and moving the blade from side to side with the same amplitude. This is necessary for uniform turning;

- To prevent the tool from overheating, if it is impossible to reduce the engine speed, it should be cooled regularly. A container of cold running water will suffice for cooling.

Figure 6. Sharpening a knife: parallel and at an angle

Processing a blunt instrument on a machine

The industry produces various electric knife sharpeners.

The entire mechanism is located in the housing, which makes working on the machine completely safe. No effort or special skills are required, so any housewife can easily cope with this task.

An electric motor rotates an axis on which several abrasive wheels for various purposes are located. From rough to give the primary shape or restore the geometry of the blade, to polishing, which is used for final finishing.

Since the sandpaper has a fixed shape, the contact angle is set by guides that can be adjusted or simply changed depending on the type of tool.

To work, you need to know at what angle to sharpen your knife. To avoid mistakes, when purchasing, you should ask the seller what the parameters of the blade you are purchasing are, or take measurements on a new tool.

After setting the correct angle, we begin sharpening:

- If the cutting edge is very dull or has jagged edges, we first process it using coarse sandpaper. The knife moves with little effort from the handle to the tip. After each pass, we check the degree of sharpening to prevent excessive material removal. Then we move on to a fine-grained polishing pad;

- To restore the sharpness of a normal blade, it is enough to edit it on a polishing wheel;

Each machine comes with instructions that indicate the direction of sharpening, as well as the parameters of the sanding wheels and guides.

Electric knife sharpeners

An automatic electric knife sharpening machine does not require special care. Previously, such models were used in public catering places - canteens, cafes and restaurants and were a bulky structure. Over time, their dimensions began to decrease, and now they are compact devices with connectors for different types of blades. The entire system is hidden under a plastic or metal casing, thereby increasing the safety factor.

Figure 7. Sharpening a knife on an automatic machine

Let's look at how to properly sharpen knives on an automatic machine (Figure 7):

- First, the point is inserted into the opening for rough processing, brought to the end and fixed between the plates. Since the device is equipped with guides, the disks will be positioned at the required angle as soon as the product is inserted into the slot;

- Then you should turn on the device, selecting standard or individual mode, depending on the provided functionality;

- Sharpening is done by lightly pressing the tip and moving it with the same movements in one direction. It is forbidden to drive first towards yourself, then away from yourself, since nicks will appear in the best case, and the edge will deteriorate in the worst case;

- After initial processing, the tool is inserted into a second slot with fine-grained discs, where it undergoes final grinding and finishing.

How to sharpen knives on a machine with an abrasive wheel

Another way to sharpen knives on a machine correctly is to use a grinder with a granular disk attachment (Figure 8). This method is popular among both professionals and amateurs, since there is no need to buy a separate device for turning.

Figure 8. Sharpening knives using a grinder

Turning on an angle grinder is carried out according to the same algorithm as on emery.

It is enough to fix the device vertically on the surface and install a medium or fine abrasive nozzle. Since the grinder produces over 11,000 rpm at its lowest power, it should be handled very carefully.

Is it effective to sharpen knives with sandpaper or can it ruin the blade?

Almost any garage or shed has an electric sharpener (emery). Many home craftsmen use an angle grinder for these purposes - but this does not change the essence.

We suggest you read How to restore the color of a shirt

So, we have a fixed electric motor with an installed abrasive wheel. It's good if there is a speed controller. However, most of these devices have fixed speeds. A picture immediately appears with a spectacular sheaf of sparks flying out from under the blade of a knife.

Two or three movements - and the edge is sharp again. It is this method that is the biggest mistake. At high speed and strong pressure, the steel overheats, it “releases”, or even worse – annealing. It would seem that a well-sharpened knife will very soon become dull again.

The next question is how to press the blade? To the flat side of the abrasive or to the outer surface?

The correct angle of the knife blade when sharpening on sandpaper

Both methods are acceptable if the technology is followed:

- The abrasive should be fine-grained; you are not sharpening a hoe. Material – electrocorundum;

- Rotation speed no more than 150 rpm;

- The surface must be cooled. Plain water is enough. If it is not possible to continuously supply liquid to the contact point, it is necessary to install a bath under the circle. Of course, care must be taken to ensure that splashes do not enter the electric motor;

- And most importantly - at least a tool rest, or better yet, a device for controlling and fixing the angle of the blade.

Pay attention to the angle of the blade when sharpening

There are similar devices for working on a flat side. Basic principles of sharpening on an emery wheel:

- The rotation of the abrasive should be from the butt to the cutting edge;

- The knife moves across the circle in only one direction - from the handle to the tip. After each movement, the blade is inspected and time is given to cool down;

- The pressure of the blade to the sandpaper should be minimal;

- If the sharpening is double-sided, the angle of the fixing device does not change, we simply move the knife to the other side.

Despite all the disadvantages, sharpening a knife with emery also has its advantages. Only with the help of an abrasive wheel can one obtain a so-called concave lens, when the descent planes change their angle to a more acute one as they approach the working edge.

This technology is practically not used for sharpening professional tools. Real craftsmen who know the rules of sharpening knives do it only by hand. However, if you have no claims to a samurai sword, the method is quite suitable.