Soldering iron device

A soldering iron is a device that is used when working with various wiring diagrams and electrical circuits of various devices. The usual sting is used as a heating element.

Most often this part is made in copper. This metal is a good conductor and quickly reaches the required temperatures. The tip is heated by passing a small voltage current through it.

Pulse soldering irons are much more economical in this regard, compared to traditional ones. This is due to the operating principle of the latter. Voltage is supplied to the heating element only at the very moment of soldering, therefore there is no idling at all.

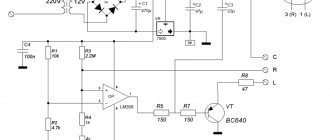

The first to meet the power is the converter, which operates at high frequency. It supplies the device with voltage with a frequency of 20 to 45 kilohertz.

Another, no less important detail is the step-down transformer, in front of which there is a simple microprocessor circuit that controls the circuits. Last but not least is the secondary winding that holds the tip.

Characteristics

One of the most popular on the market is the STING pulse soldering iron model. This device has the following characteristics:

- Supply voltage 145-270 V

- Voltage frequency 50-60 Hz

- Power consumption 30-125 W

- The heating time of the tip reaches operating temperature is 1.5-6.0 seconds.

- Maximum temperature of the working area St 500 °C

- IP 2.0 protection rating

- Dimensions 176 × 130 × 26 mm.

- Cable network 1 m long

- Weight 0.18 kg

You may be interested in Measuring with a multimeter with current clamps

Soldering iron STING

Nichrome soldering irons

The types and design of pulse soldering irons have their differences. In the case of the device inside, they are insignificant. The models themselves differ more. There are quite a few types of soldering irons, which is due to the features of their design, operating principle and purpose. Let's look at the main ones.

Nichrome soldering irons have a spiral of the same name through which electricity passes. It can be constant, as from an electrical network, or variable, such as that which can be obtained from transformer installations.

More expensive models are equipped with a special temperature sensor, which can limit the device’s operating temperature, depending on the user’s preferences. This is done using a good old thermocouple.

The design of such soldering irons may vary slightly, depending on the manufacturer and price category. Cheaper modifications work with a nichrome spiral.

This option is not very economical, so more expensive modifications already use an insulator system to which a nichrome element is attached. This increases useful energy transfer and reduces energy losses. This design is similar to a ceramic tip, which is why buyers are often confused. We will talk about such models a little later.

Design features and soldering iron control

As mentioned above, the pulse device resembles a pistol in appearance. Its L-shaped shape made it possible to hide all control modules in the handle, which is very convenient to use.

The process of managing the device itself is very simple. There are two buttons on the body:

- The first is intended for stepwise voltage regulation. To set the required parameters, just select one or another level.

- The second button starts the tip heating process. It must be constantly held during operation so that the tool remains hot.

Some models of soldering irons are equipped with a miniature display that shows the selected tip heating level.

More details about pulse soldering irons

Next come impulse soldering irons. Compact, productive, if you wish, you can figure out how to make a pulse soldering iron yourself. The reason for this is a very simple design, which we discussed a little above.

They only work when you press a button that you need to hold with your finger. Thanks to this, they have become so profitable in terms of energy consumption. The copper tip heats up quickly, and now, after 5-7 seconds, you can use the device.

By releasing the soldering iron button, it stops supplying power to the tip, which begins to rapidly cool down. Most soldering irons on our market are manufactured in Russia.

Their distinctive feature is the design, which involves connecting the copper tip to the general electrical circuit of the device, which already contains a transformer and converter. Due to the latter, the operating frequency increases, and the former equalizes the voltage inside the device during idle moments.

What fasteners are needed to fasten drywall: types of fasteners, selection criteriaRating of household guns for polyurethane foam 2021

TOP 15 popular models of multitools

If you make a pulse soldering iron with your own hands, then you should know that its structure will be slightly different from that described above, in view of the fact that some components can be replaced with parts that are identical in functionality.

Operating principle

The design and principle of operation of this type of device is based on a simple physical effect in which the conductor is heated when a large current flows. When the device is turned on by pressing a button, the primary circuit of the input signal source is turned off, the transformer switches to low voltage on the secondary winding. In this case, there is a current in the output circuit to quickly heat the tip. When the button is released, the circuit turns off, the current stops flowing and heating stops.

At a low voltage of about 2 volts, the current in the operating circuit reaches 25-50 amperes. The secondary winding of the transformer must be wound with wires, and the cross-section of the winding must be several times larger than the cross-section of the tip. The same rule must be followed for the conductive busbar that connects the end of the spike to the secondary winding. This will prevent energy wasted on heating. Switching power supplies are replacing transformer power supplies, and their popularity is slowly growing. They allow you to significantly reduce the weight and size of equipment with the same performance.

Ceramic soldering iron

Let's return to the topic of ceramic soldering irons. A ceramic rod is used as a heating element in such devices. This option is considered more modern and more reliable.

The temperature of such an element rises much faster, in addition, they are more durable in comparison with analogues made from metals and various alloys. Also, the ceramic tip is excellent for various temperature conditions and the accompanying power.

Advantages

Soldering iron with temperature control

The advantages of pulse soldering irons are as follows:

- Successful ergonomics of the IP design. A pulse soldering iron, unlike conventional rod soldering equipment, has the shape of a gun, which allows you to hold and turn on and off the tool with one hand.

- A high-frequency voltage converter heats up the tool tip within a few seconds.

- With a power regulator, the scope of use of the soldering iron expands from soldering small elements to joining large parts.

- Pulse operation reduces power consumption.

Gas soldering irons

Soldering irons that use gas in operation are devices independent of an alternating power source—autonomous. This is a huge plus of this option, but perhaps the only one.

The tip can be made of different materials, but it is always heated by gas, which is burned inside the body and directed to the tip.

TOP 10 best construction mixers according to expertsRating of the best riveters in 2021

Do-it-yourself welder’s table: step-by-step instructions with e dimensions and useful tips

A simple canister is used as a gas source, which in some cases can be refilled. If you remove the nozzle with the tip, you can get a small gas burner. This may be useful to someone.

As you can see, the types and design of pulse soldering irons do not differ as much as soldering irons in general, but there is plenty to choose from. At a minimum, you can pay attention to models with a battery. They are well suited for small components, which are often found on the microprocessor circuits of small household appliances.

Selection and cost of the device.

The choice of pulse soldering irons on the Russian and foreign markets nowadays is quite wide. Therefore, when purchasing a device, you will most likely have many questions. And yet, which device should you choose to buy? There are a lot of recommendations to choose from. Therefore, below is a small rating of pulse soldering irons that you may encounter on the sales market today.

Pulse soldering iron Sparta 913095.

Pulse soldering iron Sparta 913095, 100 W (Fig. 4)

Specifications:

| Type | pulse soldering iron |

| Power | 100 W |

| Power adjustment | No |

| Nutrition | circuit |

| Supply voltage | 220 V |

| Max. heating temperature | 600°C |

| Warm-up time | 90 s |

| Tip material | copper |

| Handle material | plastic |

The Sparta 913095 pulse soldering iron has not earned love and recognition on the market, as it has a number of significant shortcomings. Firstly, poor heating of the tip, due to the thickness of the wire. The power of the soldering iron is simply not enough for proper heating. Often, garage kulibins solve this problem by sharpening the tip with a file. Secondly, the low quality of the device’s materials. Thirdly, the massive dimensions, which do not contribute to comfortable work with this soldering iron. The cost of this device is about 600 rubles.

Pulse soldering iron PATRIOT ST 501.

Pulse soldering iron PATRIOT ST 501 (Fig. 5)

Specifications:

| Type | pulse soldering iron |

| Power | 100 W |

| Power adjustment | No |

| Nutrition | circuit |

| Supply voltage | 220 V |

| Max. heating temperature | 500°C |

| Warm-up time | 4 s |

| Tip material | Copper coated |

| Handle material | plastic |

| Additional Information | work area lighting |

One of the advantages of this device is its fast heating, which is 4 seconds. But in addition to its advantages, the soldering iron also has disadvantages:

- Large mass of the device;

- The soldering iron does not cope well with its main task. Compared to a similar Soviet-made soldering iron with a power of 60 W, this heats even worse, with a declared power of 100 W.

- The housing itself, where the transformer is located, becomes very hot.

The market price of this device is 1129 rubles.

Pulse soldering iron ZD-507 220.

Soldering iron gun imp. ZD-507 220 (Fig. 6)

Specifications:

| Type | pulse soldering iron |

| Power | 100 W |

| Power adjustment | No |

| Nutrition | circuit |

| Supply voltage | 220 V |

| Max. heating temperature | 500°C |

| Warm-up time | 6 s |

| Tip material | Copper coated |

| Handle material | plastic |

Another representative of the Chinese market. Inside there is a 50 Hz transformer, the current of which is only enough to heat the steel tip. It takes a long time to heat up; when you try to warm up massive parts, the protection is triggered and it turns off. You have to wait a long time for it to cool down. The cost of the device is 790 rubles.

Pulse soldering iron BISON 55412-H4.

Soldering iron ZUBR 55412-H4 (Fig. 7)

Specifications:

| Type | pulse soldering iron |

| Power | 150 W |

| Power adjustment | No |

| Nutrition | circuit |

| Supply voltage | 220 V |

| Warm-up time | 7 s |

| Tip material | Nickel |

| Handle material | plastic |

| Additional Information | work area lighting |

Perhaps this is the most expensive, but also the best option of the presented devices. Among the advantages: good workmanship, fast and quiet heating. Disadvantages: a little heavy (weight is 1 kg), high cost. The cost of this device is 1850 rubles.

In conclusion, I would like to say that there are currently a sufficient number of pulse soldering irons on the market. Therefore, before purchasing a device, you should weigh the pros and cons and base it primarily on your needs. As practice and reviews from owners show, representatives of the Chinese market in this niche have not proven themselves properly. Therefore, it is worth taking a closer look at domestic representatives.

Nov 3, 2020HowElektrik

Flaws

Soldering iron EPSN

Along with the positive characteristics, the disadvantages of IP should be noted:

- When working for a long time, your hand gets tired from having to hold a heavy soldering gun suspended.

- A modern pulse soldering iron with additional options is quite expensive.

Important! Due to the accumulation of high-frequency voltage on the IP tip, sensitive microcircuits can be destroyed during soldering.