Hammer brushes

Brushes are parts that conduct current from the cable cord to the commutator winding. The contact of these elements triggers the rotation of the armature and regulates its speed. In a rotary hammer or drill, they use a switch to control the direction of rotation. Even with the most careful use, tools tend to wear out and must be replaced.

The most common causes of wear are:

- Very stiff spring

- Poor quality collector, which wears out the brushes with its hard ribs

If the power tool is used infrequently, the brushes can be changed once a year to prevent breakdowns. If your tool is intended for daily intensive work, you need to take a closer look at it. There are some signs that indicate their wear:

- Sparking in the collector has increased

- The engine does not develop speed, and the power of the hammer drill has decreased during operation

Why does a hammer drill spark:

- Incorrect installation

- Worn condition

- Brush holders are installed incorrectly

- Poor fit to the manifold

- Parts are pressed too tightly

- The components used are not the same brand as the tool

Any of the above reasons means: the hammer drill should be disassembled and inspected.

The main malfunctions of a rotary hammer and their external signs

All unit malfunctions can be divided into two groups: mechanical and electronic.

Removing the cartridge

Disassembling the unit to search for defects should be carried out carefully, with inspection of each removed part. To make assembly easier, it is better to photograph the disassembly process. If you do not find any external flaws on the device, then it is recommended to start disassembling it with the cartridge.

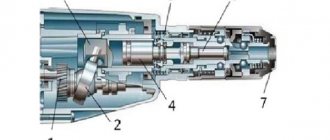

- First remove the boot (1), made of rubber.

- Carefully, so as not to lose it, use a screwdriver to remove the retaining ring (2) and then the plastic boot (3).

- In the next step, it is important not to lose the small ball that is located under the washer (4). Remove the washer (4), plate (5) and spring (6), also the ball (7). Specifically, when these parts wear out, the drill falls out of the chuck. Some cartridge models may have additional balls and washers.

Replacing brushes

If it’s time to change the brushes in a hammer drill, you can take the tool to a service center for this task, or you can do it yourself, which is quite easy. Replacement at a service center has a number of advantages:

- High-quality work if it is a specialized center

- Original parts for your tool model

- Extending the warranty if the period has not yet expired

- In addition to replacing the broken part, the service usually inspects the entire internal important parts, cleans them and lubricates them

Along with the advantages, repairing power tools at a service center also has disadvantages:

- If there is no guarantee, the work will be paid for

- Repairs will take time, you'll have to wait

- Service is not always close

If you are not satisfied with the indicated inconveniences of repairing a tool in a specialized center, it is better to complete the task yourself.

The process of replacing parts is carried out in stages:

- The hammer drill, which is disconnected from the socket, must be unscrewed to remove the top cover.

- After this, using a small screwdriver, you need to easily hook the brush holder, remove it and remove the old parts.

- Insert new ones into the holder, press them to the edges, and place them in place inside the hammer drill.

- Check that the brushes reach the contacts for smooth operation of the power tool.

- Close the lid and secure it with screws.

Tips from experts when repairing a rotary hammer

When replacing brushes yourself, experts recommend:

- When one is erased, both must be replaced.

- During repairs, it is also necessary to clean the collector from dust and carbon deposits.

- When replacing a part, it is better to grind it to the collector using fine-grained sandpaper

- It is better to install components that match the tool model

Replacing hammer drill brushes is a simple process that can be easily done at home.

Repair or replacement? The choice is yours!

A handyman with electrical experience can repair the fittings on a drill with his own hands. Start with troubleshooting. In the event of a break or short circuit in the turns of the armature winding, the reason for the “silence” of the punch or the slow rotation of its rotor (accompanied by intense sparking around the perimeter) is easy to establish: a tester. Sparking, as well as an attempt to turn the shock valve in different directions, is the result of short circuiting of part of the turns in the winding. If the spark has the character of a single, but long-lasting spark, the cause is a damaged wire or poor contact with the commutator itself.

When checking, you should also check for the possibility of damage to the valve body. When measuring actual resistance values, the values obtained must be at least several ohms.

During development of a hammer drill, significant imbalance in the axis of rotation of the valve is possible during punch operation. This fault is diagnosed after the open winding is not open. To do this, connect the drill to the rheostat and gradually increase the voltage to the nominal voltage. If during diagnostics the tone of the electric motor changes and the armature oscillations increase, rotor balancing is necessary.

Since it is almost impossible to rewind the anchor at home, it is recommended to use the services of specialized workshops. The price of winding an armature on a rotary hammer for most models (from Bosch, DeWalt, Makita, etc.) depends on the power of the tool and its performance (home or professional). If the drive power does not exceed 1000 W, the service will cost 1000. 1200 rubles, for a drive up to 1500 W. 1500. 1600 rubles, and for more powerful rotating hammers. Up to 2500 rubles. Comprehensive repairs (for example, replacing a bearing) can cost 3500. 4000 rubles. In this case, fault diagnosis in most workshops is free.

Replacing hammer drill brushes when they are missing!

A situation arose when the brushes on the bosch 2-24 rotary hammer were worn out, and it would take at least half a day to work. I have neither the time nor the desire to go for new ones. We solve the problem in 20 minutes.

And so, we take out the worn brush and use sandpaper to make its end even.

well, or almost even.

Then we go to the trolleybus stop and ask the driver for a “coal” - a graphite insert for the rods. (in my case they are in the suitcase)

And we cut off an approximate piece.

Now, using sandpaper, we bring it to the size of a brush and check that it moves easily there.

We insert this piece along with the rest of the original brush and that’s it.

This will all work no worse than the original brush. Good luck to all.

We were at a site 21 km from the City, so that was an option.

I wrote that I have coals in my suitcase

On objects, when the tool works without rest - believe me, you won’t be able to keep track!

Reminds me of the procedure for drawing an owl.

everything is much simpler, you go to a car store and buy brushes, for example, from a VAZ generator or a gas starter or whatever your heart desires, in my case they fit into a Bosch earmuff without any modifications at all

PS: this graphite is very soft, it crumbles easily and as a result, everything inside the hammer will be covered in graphite dust, okay, if nothing short-circuits

I disagree, it is a little harder than the original brushes.

Judging by the structure in the photo, it only seems so to you. You can see from the edge of the cut that they are crumbling into rather large pieces.

Thanks for the first photo - it was very useful. The spring flew off, and here you can clearly see how it is supposed to stand correctly. By the way, the only photo that I managed to google for the request: “How to properly fix the brushes in a puncher drawing.”

What does “will” mean? Those. Have you tried it yourself yet?! :)))))

Replacing hammer drill brushes when they are missing, but there is a large piece of graphite that you don’t know where to put.

I already wrote where I got it and where I can get it.

Cool and thanks for the idea.

Question: Is the docking area getting hot?

And what to do if there are no trolleybuses in the city, what can replace the “charcoal”?

For those who don’t have trolleybuses, it’s more difficult. I can send one by mail - enough for several years.

for example https://ru.aliexpress (dot) com/popular/graphite-motor-brushes.html

And back in the times of shortages in the USSR, we took a 373 battery and removed the carbon rod from it - ground it and installed it - but this is the very edge - the graphite there is hard - the collector eats up little by little

buy auto starter brushes and drink from them

Should I carry the tram with me?

Yes, it’s just that my father works in a trolleybus depot and I once asked him for a few pieces - I made conductive glue, and so they stayed.

How much time?

Inspired by posts about noise in the house at night. One weekend, a neighbor was doing renovations in his apartment on the floor below. The hammer drill did not stop, first after ten, then after eleven. After twelve I went to him, Knocking. It opens, covered in dust, the music is still playing quietly. — Vitya, what are your plans for today? Of course, I didn’t ask in these words, but very politely - after all, we’ve known each other for a long time and are on good terms. But I give the answer almost verbatim. - What time is it? - Half past twelve. - Wow. The man plunged into work and noticed how time flew by. Sometimes it's enough to ask calmly.

Neighbours

- Why are you so boiled? – a work colleague asks me.

“Yeah, well, I didn’t get enough sleep,” I answer.

The long-awaited Friday evening is coming again. After a hard week of work, you will finally be able to get plenty of sleep and get up later than usual. The next day at 7 o'clock in the morning, a hammer drill begins to work furiously behind the wall. Can't be! Again? I look at the clock, roll over, cover my head with a pillow. It's all in vain! It will no longer be possible to fall asleep.

I lie on the bed and think. The house was commissioned almost 5 years ago. Are the neighbors really doing renovations all this time? Then how many people are involved in the construction site? Half a man? Subhuman? Apparently, the renovation of the apartment is carried out on a self-employed basis during free time from the main job. Why do apparently wealthy people who bought an apartment in a new building save on professional repairmen? How much work has already been completed? A simple calculation of the total operating time of the hammer drill shows that by this moment it was already possible to level the entire high-rise building and even go deeper into the surface of the earth’s crust a hundred meters. Maybe they are close to the goal? Any minute now I expect someone’s head to poke through the hole punched in the common wall and ask: “What floor is this?”

I can’t believe that iron androids without hearts and souls are working behind the wall, brazenly trampling on the fundamental human values of sleeping in on Saturday morning.

My mother once told me that when I was a child, there lived above them a short, skinny man who methodically hammered nails on the floor day after day. It feels like over many years of home practice, he must have collected at least a thousand wooden beer crates. When he died and people came to his apartment, it turned out to be completely empty.

OK. There's still Sunday left. I'll definitely get some sleep tomorrow. Before lunch!

The next day at 8 am, someone’s screams are heard behind another wall. What is this? I'm listening. It's clear. The neighbors bought a karaoke machine. The point is not even that a bear predictably stepped on their ear (and more than one), not that the choice of repertoire exclusively from chanson is a little at odds with my preferences, but that through the wall the musical stream is perceived only by low frequencies as African there-there. Why do these humanoids mock music? After all, their screams have nothing to do with art. Why is the work of Utesov and Chaliapin undeservedly forgotten?

One Friday we had some guests over and we turned on the music channel at a quarter volume. The time was around 7 pm. Exactly 15 minutes later the lights in the house went out. An inspection of the landing showed that caring neighbors snuck into our switchboard (which for some reason has free access to everyone) and turned off the electricity. What an idea! Although one of the greats said that one must respond to evil with good.

It’s okay, today I’ll definitely go to bed early to get some sleep. Tomorrow is Monday, I have to go to work.

At 2 o'clock in the morning I wake up. Someone is walking right above me. The steps are getting faster. Someone is already running there. Yes there are two of them! I imagine dwarfs running races. It turns out that these mini-Frankensteins sleep during the day and lead a strictly nocturnal lifestyle. However, in the evenings the light in their windows is never on. The apartment on the floor above looks completely uninhabited. What if they are thieves? Or are terrorists laying out bags of explosives? What can you actually do in an apartment after 2 am? They don't reproduce on the run, do they? Maybe these are ghouls hunting bats with a net? Now these gnomes drop onto the floor and roll the cast iron balls they get from the dungeon. These creatures are probably building a spaceship to return to their planet.

How to Change Brushes on a Bosch Rotary Hammer

The hammer drill is your assistant for all types of repair work. As annoying as it may sound, just like what our client can do here with the sun, he also does not work forever. The moment comes when you have to deal with its maintenance and repair. The more carefully you treat it, the longer it will last.

Nettle, your hammer drill has lost power. Does this indicate this fact? Is the instrument expected to be repaired or has “its time come”? Mostly something special, probably - it’s just time to change the brushes in the hammer drill

.

Content

What are brushes and what are they for?

The brush is part of the electric motor switching circuit, a current conductor to the armature commutator. Since the armature rotates due to the electromagnetic field, there cannot be a fixed connection, as in the stator. A way out of the situation was realized using pieces of graphite, which slide along the collector plates, thereby supplying current to the sectioned armature winding. In turn, a magnetic field is created in the winding of the latter. According to the law of magnetism, opposite poles attract, this creates the movement of the armature. As pictured below.

But we can say that this is the weakest point of commutator electric motors, since the brushes are worn out during operation, and coal dust clogs the commutator - this leads to disruption of the normal operation of the electric motor.

The structure of the brush itself is very simple: a contact terminal, a wire from the terminal to the working surface of the brush, and a spring that presses the surface to the commutator plate.

We’ve figured out the purpose of the brush, now let’s look at their types. There are three types of current collection brushes. How to change the cartridge on a rotary hammer In fact, there are more of them - but they are not used in rotary hammers. For example, the so-called “generator” (copper-graphite, copper-carbon) brushes .

In a hammer drill

The following types of brushes are available:

- graphite - long service life, but due to the hardness of graphite, the “grinding in” is not ideal, and the collector suffers from this;

- carbon brushes for rotary hammers – good contact with the working surface of the commutator, but short service life;

- carbon-graphite brushes as an alternative to the two previous types.

Carbon brushes for Bosch

How to check the effectiveness of an anchor?

The sequence of this kind of routine maintenance is considered using the example of Makita brand punches, although other manufacturers do not have the fundamental features of such a tool.

The need to replace the armature may arise when the hammer drill does not produce the required number of revolutions, the rotor rotation slows down sharply, and characteristic sparks and cracks appear.

The motor armature consists of the following parts:

- A cylindrical element that is formed from tightly joined stamped plates of low-silicon electrical steel or Armco EA or EAA mild steel;

- The shaft on which the cylinder is mounted;

- Phase coils, the windings of which are offset relative to each other by an angle of 120 0;

- The sliding rings are mounted on the shaft, but are electrically isolated from it and from each other.

The armature on the hammer drill is in mechanical contact with the gears of the hammer drill, so to completely disconnect it, it is enough to disconnect the assembly from the worm, which is located on the rotor shaft.

The test begins with an external inspection of the collector plates: there should be no traces of soot or scratches on it. In this case, the motor brushes are considered to be working and cannot be replaced.

Slow rotation of the valve on the hammer drill can be caused by contamination of the bearing support washer; in this case, it is removed from the housing and thoroughly washed with technical solvent. Acceptable fluids are usually specified by the manufacturer in the drill's manual. It is necessary to clean not only the outer surface, but also the inner surface of the protective washer.

Although the outer armature winding is also protected from dust, you should check the condition of the winding cords and use a regular vacuum cleaner to clean their surface.

The integrity of the collector is checked by a tester. In accordance with the existing electrical circuit of the tool, all elements of the electrical circuit of the punch are checked. In the event of a short circuit, the armature must be replaced. For durable tools, the price of the issue is determined by the drill model: the warranty shop may not accept drills of a certain brand for repair, and you will have to send a request for the required anchor model to the manufacturer’s warehouses.

If the unstable operation of the hammer was caused only by contamination of its moving parts, then after thorough cleaning, assembly is carried out in the reverse order. In this case, make sure that the gear contact with the gear worm is complete and that the dust ring completely covers the outer bearing housing.