Kinds

Floors on the ground: types of structures, features and installation technology in a private house with your own hands

Rotary hammers from Bosch are divided into types:

Household models (engines 410-720 watts). Such units have three standard modes, their weight is small (no more than six kilograms).

The letter “P” identifies the model as a unit for domestic use. Typically, such a tool is marked with a green color. The disadvantage of such machines is not the best cooling and increased efficiency.

Such models have much more advantages than disadvantages, among which it is worth mentioning:

- average price;

- light weight;

- compact dimensions;

- good performance;

- reliability in operation.

The advantages of this model are effective cooling of the unit, minimal vibration, and operational reliability. If we talk about the disadvantages, we should mention the large size of such devices and the high price.

- Hammer drill. It has the following technical indicators: power – up to 1.6 kW;

- rotation – no more than 3980 revolutions;

- the number of beats is about 50 per minute.

What do you need to know about rotary hammer repair?

Undoubtedly, owners of such expensive equipment want their devices to be of high quality and perform one hundred percent of their functions. First of all, the correct use of the tool will protect you from serious damage; we will talk about this fact a little later. Nothing more than a timely repair of the device. Any minor failure should already be a cause for concern without preparation for repairs.

So, such “beacons” will be:

- Unstable operation of the hammer drill in operating mode;

- The appearance of strange sounds when turning on the hammer drill;

- The smell of burning;

- The hammer drill does not hammer, although apparent reason

for it.

When something like this happens to your equipment, it’s time for repairs. Just like any similar work, it requires care, understanding the cause of the breakdown and not knowing how to deal with it. Not your best move when performing repairs is to disassemble the tool into its components. For many, even this stage causes difficulties, if we need to know down to the nuances - how, what and why!

Disassembly procedure for a Bosch 2-26 rotary hammer

Drilling machine bosch pbd 40: customer reviews, characteristics

Since the disassembly procedure for Bosch rotary hammers is 2-20; 2-24; 2-26 is almost the same, let’s consider the order of disassembly using the Bosch 2-26 rotary hammer as an example.

Disassembling the Bosch GBH 2-26 dre hammer drill begins with disassembling the quick release chuck.

Disassembling the quick release chuck

Bosch rotary hammers most often use two types of chucks: SDS-plus chucks and SDS-max chucks. The difference between them is the principle of clamping the tail part of the working organ.

The design of the Bosch hammer drill chuck differs in the design of the tool mounting rods depending on the SDS-plus or SDS-max model. In addition to the listed types of cartridges, there are SDS-top and SDS-quick cartridges.

Difference between cartridge mounting points

The procedure for disassembling the Bosch 2-26 hammer drill chuck is simple:

- remove the rubber tip pos. 34;

- remove the retaining ring pos. 87;

- remove the steel washer pos. 833;

- remove the conical spring pos. 833;

- Carefully, so as not to lose it, using a magnet, remove the barrel balls pos. 89.

SDS-plus cartridge

Carefully inspect all parts of the cartridge.

SDS-plus quick-release chuck in disassembled state

SDS-plus chucks were developed specifically for drilling tools. The diameter of the tool shanks is 10 mm, the length of the working tool is in the range of 110...1000 mm. The diameter of the drills lies in the range of 4…26 mm.

How to remove the mode switch

With the hammer on its side, remove the mode switch pos. 832.

First, turn the switch to the “Drilling” position, press the screwdriver all the way into the end of the switch button (it is red) and turn the switch counterclockwise to an angle of 70º.

While rocking the switch handle, pull the switch handle out of the housing.

Disassembling the impact mechanism assembly

Having placed the Bosch 2-26 hammer drill vertically on the handle, unscrew the four screws pos. 90 holding the cover of the mechanical assembly housing.

Press the end of the impact shaft and remove the cover. The lid is black plastic.

Now you need to remove the barrel pos. 821 and the intermediate shaft pos. 826. They are not secured by anything.

Next, using a screwdriver, you need to remove the bracket pos. 48 of the rolling bearing pos. 830. By the way, in simple terms it is called a “drunk bearing”. The following are removed sequentially: the sleeve pos. 26 and the “drunk bearing”.

We got to the drunken bearing

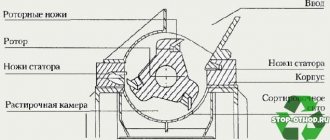

Disassembling the hammer mechanism barrel assembly

- dismantling the Bosch hammer drill barrel assembly begins from the side of the cavity, removing from it the cylinder pos. 26 with the hammer pos. 27;

- you need to remove the hammer assembly from the cavity;

- on the side of the chuck shaft, remove the lock ring pos. 85, the steel ring pos. 38 and another lock ring pos. 85;

- remove the spur gear pos. 22.

Impact mechanism assembly, intermediate shaft and bearing

Disassembling the cylinder

A hammer, pos. 27, is inserted inside the cylinder, from which the rubber ring, pos. 73, must be removed. During any disassembly, rubber parts must be replaced.

At the opposite end of the cylinder, a hinge, pos. 29, and two flat washers, pos. 41, are inserted.

Disassembling the intermediate shaft

The intermediate shaft is disassembled by removing the shaft, pos. 24, and pulling out the “drunk bearing” from the housing, pos. 77.

Bearings are removed with pullers or manually using a device.

Conclusions:

• Knowing the differences between the above models of Bosch rotary hammers will allow you to quickly disassemble the tool and replace faulty parts. To do this, you do not need to contact customer service.

• Structurally, Bosch rotary hammers are so simple that they allow you to carry out repairs of almost any complexity.

• All you need is desire and basic knowledge of mechanics.

It happens that you come across counterfeit models of Bosch hammer drills. Read more about this.

Video about disassembling a Bosch rotary hammer

Video: How to repair a hammer drill / 2-24 / How to change the impact bolt / Drunk bearing / Maintenance / Repair

To compact, and therefore strengthen the structure of concrete, you need to use a special tool - a vibrator. With its help it is easy to kick out.

The stage of constructing the foundation of any structure is considered the most expensive - the costs for it can be about 35-40% of the total estimate. Practically.

A well used for water intake is for many a source of autonomous water supply for a home or cottage. The rest of the plumbing system provides it.

Nothing lasts forever. And the most reliable Bosch rotary hammers begin to break over time. But any malfunction can be repaired with your own hands if you have detailed instructions for performing repair work. Below we offer you a guide to troubleshooting Bosch rotary hammers and a method for eliminating them.

Content:

- Mechanical malfunctions of the Bosch rotary hammer

- The hammer drill stops hammering, but drills

- The hammer drill has stopped drilling, but is chiseling

- Let's consider options in which the hammer drill does not hammer, but drills

- The rolling bearing race has fallen apart (drunk bearing)

- The cylinder, firing pin, and firing pin of the firing mechanism were destroyed

- The splines of the clutch, pos. 67, mounted on the intermediate shaft, were cut off

- Let's consider options in which the hammer drills but does not chisel

- The force of the conical spring pressing the clutch has weakened

- The locking roller does not lock the large barrel shaft gear

- The mechanism for fixing the tool in the drill barrel does not hold the drill

- Let's consider options in which the hammer drill does not drill or chisel

- Sheared teeth on the small rotor gear

- Hammer drill motor does not work

- No power to the electric motor of the Bosch rotary hammer

- General electrical faults of the Bosch 2-26 rotary hammer

- careless work with the tool;

- improper storage of the hammer drill;

- heavy loads when working on working parts when chiseling or drilling;

- tool overheating;

- long work without a break;

- failure to comply with maintenance schedules.

The main causes of breakdowns are:

Conventionally, faults can be divided into mechanical and electrical.

Next, we will consider faults according to their affiliation, dividing them into mechanical and electrical faults.

Anchor structures of various types of drilling rigs

Anchor. It is the rotating unit of any induction motor. Considering that during operation the hammer drill experiences significant resistance to the material it destroys, the loads on the rotor often reach extraordinary values. Sometimes they cause a significant reduction in valve speed, resulting in immediate engine failure.

The resistance of fittings on a hammer drill to combustion is determined by its design. There are two types of perforation anchors:

- With wound rotor.

- Rotor cell proteins.

The short circuit of the armature winding is formed by rods, which, when assembling the rotor, fit into the grooves of its core. In this case, the ends of the rods are connected by a special rotor ring. This design has no moving contacts, which has a positive effect on the durability of the assembly.

The disadvantage of the armature of this design is the limited starting torque, which in relation to hammer drills requires limiting the intensity of use at the initial time after turning on the tool. Of course, this is impossible to keep in mind, so if you use the hammer drill carelessly, the longevity of the protein cell motor will be low.

The problem is solved by installing electric motors of protein cells on all rotating hammers. The number of poles of the armature winding in this case fully corresponds to the same parameters of the stator, and the contacts of each phase are brought out into the external circuit using carbon-graphite brushes. Replacing the brush. This is a relatively simple process that you can perform (for out-of-warranty equipment) yourself. In other cases, you should use the services of specialists. Often the price of this type of service is associated with the need for static and dynamic balancing of the armature on a drill, which uses special technologies and equipment.

Disassembling the cartridge

The cartridge is perhaps the most important part of the tool. Instrument manufacturers make cartridges in different designs and apply them to the main part of the device in different ways. Main types of cartridges:

- Camera type. To insert and secure the drill, a special key is used, which is attached to the tool.

- Collet type. To insert and secure the drill, simply turn the cartridge.

- Double or single shot type. No special tools are required for insertion and fastening.

After determining the type of cartridge, we will try to remove it. The type of cartridge is not important, the removal process is more or less universal:

- First we need to loosen the cartridge screw. To do this, simply tap the head of the instrument lightly.

- Take a screwdriver and unscrew the mounting screw.

- Fix the chuck in a vice and rotate the spindle.

In addition, the hammer drill needs lubrication and varnishing. Even if you use it once a year, lubrication will help prevent corrosion and premature damage to the tool.

Disassembling the hammer drill

The case of most devices is made of two halves: rear and front. They are tightened together using screws located parallel to the direction of the drill installation axis. But it happens that the halves are attached using side fastenings. Before unscrewing the fastening element connecting the halves of the housing, you will need to remove the cartridge.

The cartridge used corresponds to the SDS-plus or SDS-Max standard. To disassemble it you will need a flat-head screwdriver. At the first stage, the chuck clamp is released from the installed drill. If the mechanism itself is jammed and cannot be untwisted, then you should tap it in a circle with gentle blows of a rubberized hammer. It would not hurt to apply flushing fluid. At the next stage, the plastic casing is pulled down and the rubber boot is removed with a screwdriver. After this, all that remains is to remove the retaining ring, using a screwdriver, and remove the spring with the ball and the retaining plates.

When the cartridge is removed, the housing parts are removed. When disassembling the tool, you should be careful, remembering the order in which the elements are removed and their location. If there is a cover on the handle, you should remove it too. After that, all that remains is to carefully separate the housing and gearbox in different directions. Using the resulting gap, the switch button is removed. The brush holder is removed.

The button for setting operating modes, despite the types of devices, is removed in the same way. The switch is set to the strike position (shown on the body as a hammer), after which it is slightly pryed and turned counterclockwise one or two centimeters. Then, the switching pad is removed by pulling it towards you and the seat is freed up.

How to disassemble a hammer drill

Disassemble the hammer drill sequentially. Inspect all details carefully. Even if you are looking for a problem in one unit, you may find damaged parts in other units. When disassembling the tool, the body should be cleaned of dust and dirty grease.

How to disassemble a cartridge and remove stuck equipment

Start by disassembling the cartridge so that it does not interfere with the removal of the gearbox housing.

- Remove rubber boot 1, retaining ring 2 and plastic boot 3.

Ball in the groove of the sleeve

If a drill or other equipment cannot be pulled out of the chuck, there are two options for solving this problem:

The second option is used as a last resort. If after several blows the drill or chisel cannot be pulled out, stop. You may damage the hammer drill. Disassemble the cartridge and gearbox. Try to knock out the equipment with a drift. After this procedure, the raster sleeve will most likely need to be replaced. To avoid this problem in the future, lubricate the end of the equipment.

How to remove a stuck drill bit from a hammer drill chuck

How to remove the mode switch

In some models of hammer drills, the switch is removed by turning it to the extreme right, in others - to the extreme left. Consider the extreme right position.

- Set the mode switch to strike. If there is no impact mode, use drilling impact.

Switch in impact mode

Pry up the switch with a screwdriver

Disassembly of the electrical part of the hammer drill

- Unscrew and remove the back cover.

- Unscrew the bolts securing the power cord.

- Remove the button and wires from their grooves.

Analysis of the mechanical part of the hammer drill

- Remove the plastic gear housing. You will see an aluminum housing with a fixed bearing, an intermediate shaft, and a raster bushing inserted into it.

Raster bushing and screwed bearing

Removing the helical gear

Removing the spur gear

Raster sleeve removed from the sleeve

Sleeve with striker

Operating rules or how to protect the device from damage

To ensure long-term and efficient operation of an electric hammer drill, it is enough to follow a few simple rules. In particular:

- When working, it is not advisable to put too much pressure on the tool; at least this is not necessary, and moreover, with excessive pressure, the tool will fail faster.

- It is not permissible to operate the electric hammer drill in idle mode.

- When working with porous materials, it makes sense to turn off the impact mechanism. When working with particularly hard materials, it is advisable to use a lubricant.

- When working, especially for a long time, it is necessary to monitor the heating of the housing, especially in the place where the gearbox is installed. If there is noticeable heating, you must stop the work and wait until it cools down. Water cannot be used for cooling; its use may damage gearbox parts.

- Work with the tool should be carried out in the following mode - at least a 10-minute break after half an hour of work.

Reasons for disassembly

You will like many reasons for disassembly, let’s consider the main ones:

- Prevention. When the tool works well, it must be periodically disassembled for lubrication and dust removal.

- Unstable work. The tool may then work, then not work, and then continue to work incompletely. This is a reason to be on guard.

- Strange noises. For about 30 years, the instrument worked quite quietly, alas, now some strange buzzing sounds are heard from inside. Something is wrong with the instrument.

- The smell burns during operation. This could indicate a faulty motor or bad wires.

- Grinding has become noticeably more difficult, although there is no obvious reason for this purpose.

Now we need to consider our working tool.

Specifications

The Bosch hammer drill is a tool that is especially popular among professional builders. These units rarely have to be seriously repaired, but, like any equipment, Bosch rotary hammers eventually require preventive repairs.

Bosch units are divided into two large classes:

- hammer drills in which the engine is horizontal (the layout of the barrel and armature are parallel);

- hammer drills, where the engine stands vertically - in this case, all working components are located at a certain angle.

The hammer drill has mechanical and electrical units. The second block consists of the following nodes:

- engine;

- engine control device;

- button and switch block;

- replaceable cord;

- block that reduces interference.

The mechanical assembly is assembled from the following elements:

- gearbox (mounted directly on the engine shaft);

- mechanism providing shock impulse;

- cartridge, brushes, anchor;

- a clutch that provides traction.

Also, along with the hammer drill itself, the kit includes various replaceable removable elements:

- drill;

- borax;

- crowns;

Do-it-yourself Bosch rotary hammer repair

If any parts in the tool are damaged, broken, or do not perform their function well, then they simply need to be replaced. If the brushes are worn out, then during disassembly they are simply replaced with new ones. When the rim rotates slowly, the hammer drill cartridge, worn boot, and failed bearings are also replaced. But there are other problems that you can fix. If a breakdown of the winding occurs, then the stator and armature must be rewinded. You need to monitor the lubrication and lubricate some parts from time to time.

Repair of Bosch 2 26 rotary hammers

Before you fix anything in this model, you need to familiarize yourself with the features of the device, the circuit and the principle of operation. The rotor shaft transmits rotation to the barrel shaft through an intermediate shaft, the bearing of which directs the return movement to the impact piston.

When disassembling the barrel shaft in the impact block, you need to pay special attention to fixing the spur gear. Before removing it, you need to remove the 3 pins that secure it in this model.

Repair of Bosch 2 24 rotary hammers

In this bosch gbh 2 24 dsr hammer drill, the intermediate shaft consists of a switching part, a bearing assembly and a clutch. The latter deteriorates most often because its teeth wear out quickly. Repairing this damage consists of correcting the profile of the engagement teeth. You can often notice that there is no impact. The hammer drill may gradually stop chiseling due to wear of the rubber parts, which need to be replaced in time. And if you apply more force than necessary, this can lead to the firing pin jamming in the impact piston.

Repair of Bosch 2-28 rotary hammers

In this model of tool, the splines sometimes wear out. In this case, it is necessary to disassemble the gearbox (it is almost similar to the Bosch 2-24, only the bearing is different). It is better to replace the entire barrel, because along with the splines, the firing pins also wear out.

As you can see, you can repair rotary hammers at home with your own hands. At the same time, do not spend large sums on various types of repairs in service centers, which, as we know, are very expensive. But do not forget that you must adhere to the rules of use and safety precautions.

The most widespread among professional builders in Russia are Bosch rotary hammers, and among amateurs the household models Bosch 2–20, 2–24, 2–26.

Rotary hammers not only work well, but are also easy to repair. You can easily find any broken part on them.

The designs of the described rotary hammers are based on the same principle: transmitting torque from the rotor to the shaft of the impact block barrel while simultaneously transmitting a translational impulse to the working tool.

Structurally, hammer drills are made according to the same design, but individual components or parts have their own characteristics.

If you know the specific differences between the models of the described Bosch rotary hammers, then disassembling and repairing them yourself will not be difficult.

Along with the originals, there are a large number of counterfeit tools on the Russian market, including Bosch rotary hammers.

Below we describe the design features of the models and how to disassemble and repair them yourself.

Read also: Emergency lamp with battery

Operating principle of a Bosch rotary hammer

The operating principle of rotary hammers is the same, but the design features differ.

The main parts used in the listed models of Bosch rotary hammers are interchangeable. This applies to the mechanical and electrical components.

But there are units made that differ in the parts used.

To repair a Bosch 2-20, 2-24, 2-26 rotary hammer, you need to know these differences. Knowledge of the design features of each rotary hammer facilitates the repair process, finding breakdowns and eliminating them.

The designs of Bosch rotary hammers are so simple that they allow you to perform simple repairs, practically with your own hands, and replace any part without contacting service departments. You must have assembly skills, have basic knowledge of electrical engineering and understand the principle of operation of a rotary hammer.

How the tool works

Literally, the word perforator means “drill hammer.” To increase productivity in mining operations, the jackhammer was developed in the early 19th century. The principle of operation of the device was to use a flywheel. He set in motion a bar with special tucks attached to it. The rod, under the influence of a spring, struck and returned back with a piston.

The device was constantly improved. In 1932, in Germany, the Bosch Corporation released the first rotary hammer powered by electricity. This device combined impact and torque. The operating principle developed by the company is still used in modern models of electric hammer drills.

A rock drill is a device designed to drill holes and destroy hard rock. Drills of different diameters and chisels are used as consumables. The tool is divided by application class:

- domestic;

- semi-professional;

- professional.

In addition, it is distinguished by its operating mechanism, which can be electromagnetic or pneumatic. The last type of mechanism is available in one-, two-, and three-mode. That is, you can perform drilling, striking, or both operations simultaneously.

The tool resembles a pistol in appearance and can be operated with an electric, fuel or pneumatic drive. The latter are in demand under hazardous working conditions, during which there is a possibility of explosion.

The operating principle of a hammer drill, which distinguishes it from other similar tools, is based on the impact mechanism. The electromagnetic type uses two electromagnetic coils to provide reciprocating motion of the core. It transfers inertia to the drill shank. The pneumatic type is based on the movement of a piston in a cylinder, which also performs reciprocating movements.

Each manufacturer strives to improve the design through the use of design features. These are mainly minor modifications related to the use of various materials and their location. In general, the main elements remain unchanged. Such details include:

- power button;

- engine;

- impact mechanism;

- safety clutch;

- drill clamp.

Additional design features include a dust removal system and a vibration suppression unit. For a multi-mode type of tool, a work switching button is installed.

Possible electrical faults

Malfunctions of the electrical part of a Bosch angle grinder can be divided into simple and complex.

Simple malfunctions of the electrical part of the Bosch angle grinder

If you turn on the angle grinder and it refuses to work, start looking for the problem with a broken power supply wire. Most often, a wire break appears at the entry point into the angle grinder or into the plug. Avoid twisting, as this will cause a short circuit in the tool.

To determine such a malfunction, it is necessary to open the covers of the grinder handle. In Bosch angle grinders up to 1000 W, the lid is secured with one screw at the end. For Bosch angle grinders over 1000 W, the handle cover is secured with several screws.

Using a tester, test the power circuit from the input plug pos. 5 to the switch. If the circuit is intact, proceed to check the operation of the switch. Bosch angle grinders use simple switches controlled by a power lever.

But the electrical contacts of the switch burn out and cause the grinder to fail. It is not practical to restore the contacts of the plastic switch; it must be replaced with a new one.

If the switch is intact, use a tester to check the presence of a circuit from each pin of the plug to each carbon brush. If the circuits are intact, the angle grinder should turn on. If it does not rotate, then there is a mechanical fault. Gears may jam or bearings may be damaged.

Checking the electric motor

If your Bosch grinder picks up speed regardless of you, starts to get very hot and sparks, you need to pay attention to the integrity of the rotor and stator windings. An involuntary increase in engine speed indicates a malfunction of the stator windings. The integrity of the windings is checked with a tester, and a short circuit between the turns is checked with a special device

An involuntary increase in engine speed indicates a malfunction of the stator windings. The integrity of the windings is checked with a tester, and a short circuit between the turns is checked with a special device.

How to determine whether a rotor is faulty

Rotor repair is a complex technological process accessible to skilled craftsmen.

A rotor malfunction is indicated by a drop in engine speed and the appearance of a long sparkling trail on one of the brushes. This is the first sign of a short circuit in the armature winding turns.

It is preferable to carry out rotor repairs in special workshops. Or you can rewind it yourself if you decide to repair the Bosch angle grinder yourself.

The dark color of the rotor winding and burnt commutator lamellas indicate a short circuit in the rotor circuits. The malfunction can only be eliminated by replacing it with a new rotor.

Stator repair

Repair of a Bosch angle grinder includes restoration of the stator. The main sign of stator failure is a spontaneous increase in the speed of a working angle grinder, which cannot be reduced by adjustments. The burnt stator winding changes color and becomes darker. The stator core also darkens due to high temperature.

It is easier to rewind the stator, although here you must follow certain rules and sequence.

If you have removed the stator housing cover, carefully inspect the condition of the carbon brushes and lamellas of the rotor commutator.

The length of carbon brushes should not be less than 8 mm. By the way, Bosch angle grinders use carbon brushes with a “shot”, a device that stops the operation of the angle grinder when the carbon brush is at a minimum length.

The collector lamellas should not show signs of carbon deposits or wear. Carbon deposits are easily removed with cotton wool soaked in alcohol.

Stator overheating and rotor short circuit

Speed controller malfunctions

Bosch series angle grinders, especially low-power ones, have speed controllers. Access to the speed controller is achieved by opening the handle of the stator housing, which is held on by one end screw.

The speed range of the regulator can be set using a potentiometer hidden in the handle panel.

The faulty regulator is quite easy to remove, since it is attached only to the guide.

Repairing an angle grinder speed controller is a complex process, the implementation of which requires not only special knowledge, but also tools and equipment.

If the speed controller is faulty and there is no new one, then disconnect the supply wires and install a jumper.

The jumper that is installed when the speed controller fails is shown in red.

Uncharacteristic malfunction of the Bosch rotary hammer

Bosch rotary hammers are very reliable. But there are malfunctions that are practically not encountered in practice. Below is one of them.

Bosch rotary hammer drills, but does not chisel

If the hammer drill has stopped hammering, but still allows you to drill, the most likely reason may be the destruction of a “drunk bearing”. This malfunction does not occur often and is not easy to find.

To fix it, you don’t need to go to a repair shop. Any person with the slightest knowledge of mechanics can fix such a malfunction.

New drunken bearing

First you need to disassemble the Bosch hammer drill down to the intermediate shaft. The disassembly procedure is given above.

By removing the intermediate shaft, you will get to the “drunk bearing”. The destruction of a rolling bearing is indicated by a broken race, scattered balls, or pieces of the race.

You take out the bearing, remove dirt and all parts of the destroyed mechanism.

You buy a new “drunk bearing”, and, having lubricated all the parts with new grease, replace and reassemble in the reverse order of the disassembly steps.

Which lubricant is best to use for which hammer drills?

The best option is to use only branded lubricants. To prevent craftsmen from racking their brains about what is the best and best way to lubricate a rotary hammer, the manufacturers of these devices made sure that their range included special tools for this.

You may be interested in: How to work with a hammer drill: 7 nuances that are important to know. BOSCH

BOSCH

The brand produces universal lubricant for gearboxes of power tools. Its volume is 45 ml. Product code for search – 1615430005-000.

How else can you lubricate individual elements of a BOSCH hammer drill?

| Assortment (item) | Purpose of the lubricant |

| 1615430009, 1615430010 | for insertable instrument tips |

| 1615430012 | drill oil |

| 1615430014 | lubricant for hammer drills (45 ml) |

| 1615430015 | lubricant for hammer drills (225 ml) |

| 1615430016 | lubricant for hammer drills (1 kg) |

| 1615430019 | lubricant for hammer drills (1 l) |

| 1615437509 | grease included with sealing frame |

| 1615437511 | |

| 1615437512 | |

| 3605430008 | hydraulic oil |

DEWALT

The brand produces more than 300 types of various tools, including hammer drills. And for all these devices there are also thousands of accessories.

To care for the “destructive” weapon, the company produces the following products:

| Assortment (item) | Purpose of the lubricant |

| 870889-02 | gear lube |

| 328771-07 | for the Boers |

| 328771-03 | for the Boers |

HITACHI

The Japanese brand's assortment includes:

| vendor code | Purpose of the lubricant |

| 308471 | lubricant for drills and impact mechanism parts (70 g) |

| 335782 | lubricant for drills and impact mechanism parts (60 g) |

| 714833 | lubricant for gearbox parts (100 g) |

| 980927 | lubricant for drills and impact mechanism parts (500 g can) |

MAKITA

The Japanese corporation also took care of its customers and provided a wide choice of what to lubricate a Makita hammer drill.

| Assortment (item) | Purpose of the lubricant |

| 042005-4A | for SDS+ rotary hammers (16 kg) |

| 042024-0A | for gearbox of rotary hammers SDS+ (2.5 kg) |

| P-08361 | for gearboxes of rotary hammers SDS MAX (30 g) |

| 183477-5 | for rotary hammers SDS+ (30 g) |

| 181573-3 | grease for drills (100 ml) |

SPARKY You can use universal lubricant, for example, 042005-4A. Or use separate lubricants for specific elements of devices from SPARKY - gearboxes (042024-0A) or drills (181573-3).

ENERGOMASH

Many Energomash models already come with lubricant for gearboxes and tails. If there is none or the product has run out, use universal lubricant 042005-4A.

May be of interest: Unconventional use of a drill - 4 interesting life hacks.

Basically, all manufacturers of rotary hammers equip their products with branded lubricants included with the delivery of equipment. You can use both universal options and substances for gearboxes or drills. Many masters prefer to use ordinary lithol instead of original products, which is fundamentally wrong, because... it is not resistant to moisture. This may lead to corrosion on the internal components of the device. Therefore, it is worth using branded lubricants, cleaning and treating power tools as necessary, and then they will last 100% for more than one year.

Safety clutch

When the load on the tool increases, exceeding its characteristics according to the operating instructions, in order to prevent damage to the elements, a safety clutch is installed. Its main task is to stop the mechanism from trying to rotate the cartridge when the drill jams. If such a coupling had not been in place, then when jammed, the hammer drill would have been twisted out of the hands.

According to the type of use, clutches can be claw and friction. The first type consists of two parts with beveled edges and connected to each other through a spring. As the pressure increases, the spring straightens and the parts come out of the clutch. The clutch disengages. This condition is characterized by the appearance of a crackling sound. In a friction clutch, the torque is transmitted to the connected mechanism due to the tight compression of the discs. When overloaded, the compression force disappears and rotation is not transmitted.

Disassembling the impact and removing the cartridge

To repair a rotary hammer, it must first be disassembled. And we start doing this by disassembling the cartridge.

- Remove the rubber tip and ring;

- Remove the washer and conical spring;

- We get side balls (preferably a magnet);

- We put the operating mode lever in a position equivalent to the maximum and remove the switch handle. We correct the situation;

- Remove the rear cover on the engine handle and the brush;

- Remove the 4 screws near the drill bit to remove the front cover;

- We take out the barrel and shaft using a screwdriver. bracket and bearing;

- Open the rear cover and remove the reverse switch;

- Remove the rotor, for which we unscrew the fins and disconnect the terminals from the starter, which also need to be removed by removing the protective cover.