Each carpentry workshop has a machine park. It is highly desirable to have a thickness planer available. This unit performs specific functions in the production of wood products. It can significantly facilitate and speed up the production of products.

What is a wood planer?

Wood is supplied to production in the form of boards, beams, and so on cut with a circular saw. To make workpieces suitable for further production from raw material, you need to process the surface more or less smoothly and maintain the size. A woodworking thicknessing machine is designed to give a wooden board the required thickness in one pass. The second function is to make the surfaces parallel. The output is a panel with two even, smooth sides and a given size in diameter.

Thicknesser for wood - device

The unit has a design similar to a jointer, but with some fundamental differences. The structure of a thicknessing machine for wood consists of the following blocks and mechanisms:

- a massive frame on which the assembly units are attached;

- drive consisting of an electric motor (one or two), sprockets, pulleys, drive chains and belts;

- working surface;

- feed rollers;

- shaft with knives;

- spring pressure mechanism;

- screw device for setting cutting thickness;

- sawdust suction system.

Thicknessing machines of industrial production are always equipped with a massive cast iron frame. The cylindrical cutter shaft can have up to four removable blades secured in the drum body with screws. The work table is guaranteed to have a length greater than 0.1 m according to TB requirements. Depending on the type, there are movable and fixed. Rollers move the workpiece during processing.

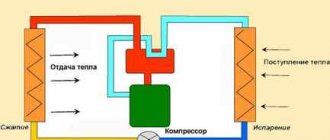

Thicknesser for wood - operating principle

The cutting knives are installed on top of the workpiece. The unit pulls the workpiece through feed rollers. They are installed below. Top mounting option available. The operator only performs the initial feeding and receiving of the processed part. The home workshop wood planer has an aluminum frame to reduce weight. The operating principle is the same as the industrial one. It doesn't make the side even. Initially, the curved workpiece will remain arched, only it will be calibrated in height.

Design Features

Thicknessers belong to the category of woodworking equipment; they plan dried boards and bars, making them the same in thickness. There are six main elements in them:

- knife shaft;

- Desktop;

- bed (base);

- clamps;

- guide slides;

- rollers.

The main working body is the knife shaft. Several knives are attached to it, the number of which depends on the purpose and type of unit. For example, single-sided machines have only one, while double-sided machines have two shafts.

The work table is a horizontal surface on which the cutting depth is formed. It is made of wood and carefully polished.

The main elements (shafts and table) are mounted on a hollow cast iron base, the purpose of which is to give stability to the thickness planer. The support table is made of wide metal corners (at least 100x100 mm) 1 m long. The table is connected to a cast iron base, and the structure is fixed with clamps. To adjust the height of the machine, you need to loosen the clamps and raise/lower the base along the guide slides.

Rollers are elements of the feed mechanism of a thickness planer. There are two pairs of them: some are located above the trajectory of the workpiece and are called drive (since they are started from the engine), others are located below them in parallel and are called feeders.

Thicknesser for wood - characteristics

To use equipment in work, you need to know its qualities. A household thicknessing machine for wood has the same characteristics as a unit for large-scale production, except for the position of different thicknesses. Indicators have different values depending on the brand. For industrial designs, the following basic values exist:

- width of the treated surface (up to 800 mm);

- thickness (10-180 mm) and length (up to 400 mm) of the material;

- maximum removable layer (4 mm);

- difference in the thickness of several simultaneously processed parts (4 mm);

- the size of the cutting shaft in diameter;

- workpiece feed speed;

- number of engines.

Equipment based on planing shafts

Most often, homemade craftsmen use a knife shaft. It is made of steel 40X or HVS. The strength of the metal is quite high, the hardness is at the level of HRC 42...48, which allows processing using metal-cutting tools.

General view of the knife shaft:

Drawing:

Knife shaft structure: 1 – cylindrical shaft; 2 – support bearings; 3 – knife; 4 – clamping (wedge) strip; 5 – clamping (fixing) bolts; 6 – spring.

Special grooves are machined on the cylindrical shaft 1; a wedge strip 4 and a knife 3 are installed in them (high-speed tool steel is used). Springs 6 installed in the internal groove allow the knife 3 to be pulled out. Fixation in a given position relative to the center of the shaft is performed with fixing bolts 5.

On the frame, shaft 1 is mounted on bearings 2 (usually cast housings are used). Choose a design of the bearing assembly that is protected from moisture and sawdust. Then long-term operation of the shaft is guaranteed.

Options for installing knives on the shaft: 1 – adjusting screw; 2 – knife; 3 – thrust nut; 4 – fixing bolt; 5 – wedge (fixing) strip.

Sometimes other types of knife shaft designs are used. Each manufacturer has its own designs and manufacturing preferences.

Attention! To secure the knife in a certain position, you need to unscrew the bolt. It acts against the groove

This solution is due to the fact that when vibration occurs, bolted connections tend to come loose. The decision was dictated by the safety of the product.

The process of planing a board: 1 – guide bar; 2 – board being processed; 3 – feeding surface; 4 – receiving surface; 5 – knife shaft.

The jointing process occurs in a certain sequence.

- The workpiece is placed on the feeding surface of the table.

- It is pressed against the guide bar.

- The knife shaft removes part of the wood layer (usually 0.3...0.7 mm).

- The processed part is moved to the receiving surface of the table.

The distance between the supply and receiving surfaces corresponds to the thickness of the cut layer.

V-belt drive in a jointing machine: 1 – knife shaft; 2 – electric motor; 3 – machine body; 4 – tension spring; 5 – hole for the pipeline from the chip remover (vacuum cleaner).

The rotation drive from the electric motor to the knife shaft is performed using a V-belt drive. The linear speed of the belt V of the belt reducer is determined by the formula:

V = (π·D·n)/60, m/s, where D is the diameter of the drive pulley, m; n – engine shaft rotation speed, rpm; π = 3.14.

The belt type (profile) is selected depending on the speed and power transmitted. Tables are used for this.

Determination of the belt profile depending on the amount of transmitted power and linear speed of the V-belt:

| Drive power, kW | Belt speed, m/s | ||

| less than 5 | 5…10 | more than 10 | |

| 0,5…1,0 | Oh, Ah | O | ABOUT |

| 1,0…2,5 | O, A, B | O, A | Oh A |

| 2,5…5,0 | A, B | O, A, B | Oh, Ah |

| 5,0…10,0 | B, C | A, B | F, B |

| 10.0…20.0 and more | B | B, C | B, C |

At home, motors up to 5 kW are used. It is advisable to use motors operating at a frequency of 2880 rpm. Then the quality of the treated surface will be higher. When selecting pulleys, they try to create a step-up gearbox. But with the help of pulleys, it is possible to increase the rotation speed of the knife shaft by 1.5...2.5 times compared to the speed of the electric motor.

Formation of roughness when planing a board:

If you move a workpiece with high feed at a low speed of rotation of the knife shaft, then a wave-like roughness can be observed on the machined surface.

The manufacturer faces the following tasks:

- A rigid machine frame made from an angle or profile pipe is required.

- A fixed support for the feeding surface is required.

- An adjustable support must be installed on the receiving surface. When adjusting, it is moved relative to the feeding surface.

- For production, sheet steel with a thickness of more than 6 mm is used.

- The shaft is mounted on bearings housed in special housings. Fixed on the frame.

- The electric motor is suspended on the lower support and is additionally equipped with a tension spring.

Why do you need a wood planer?

The primary processing of solid wood is jointing. The thickness planer will be used secondarily. First, the board is planed using a rotating shaft with knives, feeding it manually along the table surface. This makes one side flat without bending and smooth. The jointer has a side plane perpendicular to the table. The sidewall is processed on it, forming an angle of 90°. Having planed two sides, you get one right angle. To maintain strict perpendicularity at other angles, it is necessary to carry out many additional operations on this machine.

You can finish finishing corners faster, better and more accurately using a surface planer. It will remove exactly the layer that is set with the screw device. The machine will calibrate the workpiece parallel to the surfaced side. Then the second sidewall is processed. In two passes, three right angles are obtained. This is what makes a wood planer very useful in production. It is recommended to complete the processing by running the surfaced side through a thicknesser to prevent warping.

Specifications

Thicknessing machines can have different characteristics, depending on the capabilities of a particular unit.

Here is one example:

Buy a metal workbench from us. Description of air compressor price here.

- possibility of processing parts with thickness from 160 to 1250 mm;

- the thickness of the layer that can be removed in one go is up to 3 mm;

- rotation speed of working shafts - 5000 rpm;

- the working shaft can have a diameter of 100-165 mm and be equipped with 2-4 knives;

- maximum engine power is 45 kW. For domestic needs, 2.2 kW is sufficient.

How does a thickness planer differ from a jointer?

Both machines are very similar to each other. A thicknesser and a jointer both plan. However, they differ in purpose and design. Purpose of jointer:

- primary processing of one side of a piece of solid wood until it is smooth to the touch;

- giving the surface of the workpiece a flat plane (without curvature);

- jointing the sidewall of a part to form a right angle.

The design of this machine involves installing a shaft with knives on the table. The cutting edges are located below the part. Feeding is carried out manually along the table plane. When working, you must use a special stop to push the workpiece. The operator is forced to press hard on the part to the end of the pass in order to obtain a flat surface.

Thicknesser is intended for:

- calibrating the thickness of a part according to a given value;

- ensuring parallelism of opposite sides.

The drum with knives is located on top of the wood board. This processing method requires significant effort to feed the workpiece. It will no longer be possible to push it manually, so the machine is equipped with upper or lower feed rollers. The movement of the part in the working area occurs automatically. This makes working on a thickness planer safer and makes the operator’s work easier. The disadvantage of the machine is that it does not provide a flat surface.

Difference from surface planer

Thicknesser and jointer machines are used for processing wood products and other soft materials. The differences between these tools are as follows:

- Thicknesser must be used for finishing workpieces.

- The quality of the cut when working with a jointer depends on the skills of the operator; when working with a thickness planer - on the technical characteristics of the equipment.

- To align the 4 sides of a block using a jointer, a side rip fence is required.

- When working with a jointer, it is necessary to adjust the depth of penetration of the cutting elements into the surface being processed.

In industry, jointing and thicknessing machines are used together. The jointer sets the geometry of the wooden parts, the surface planer calibrates the processed workpiece by thickness.

Types of thicknessing machines

There are many designs designed for use in different operating conditions depending on the needs and production volumes. According to power they are distinguished:

- industrial stationary;

- mobile for large production;

- medium power for carpentry workshops;

- mini planer for wood.

According to the number of surfaces processed:

- one-sided;

- double sided;

- multilateral.

Machines with one (upper) processing plane are used in everyday life and in small industries. The class of professional equipment includes units with two- and multi-sided simultaneous planing of planes. Double-sided analogues have two knife shafts. They work on two opposite sides at once in one pass. Multilaterals are convenient in that they can create a workpiece configuration of any shape. Disadvantages include difficulty in maintenance and repair. However, a planer for wood of this type in large-scale production fully covers all costs.

Types of jointing equipment

Homemade equipment for long planing of wood can be made using different starting tools:

- Knife shafts - they are produced by separate factories as consumer goods. Three or four knives are installed on them, located at an angle of 90 or 120 ⁰. The working length of the shafts can range from 250 to 650 mm.

- Electric planers are a ready-made tool equipped with devices for setting, removing chips, turning on and off. For mounting on a table, there is a support frame that can easily be adapted for a small machine in a home workshop.

- Hand milling machines are power tools that provide high quality surface finishes. The productivity of the cutter is lower than that of the planing cutter. However, when processing wood, scuffing is practically eliminated. For hard wood, the use of this type of device is indispensable.

Some craftsmen create small jointing machines that have small overall dimensions and weight. They can be transported to the site. Already on site, the equipment is installed on trestles. Then the required amount of work is completed.

Industrial installations are quite heavy; they use cast iron or duralumin casting. For homemade designs, they use rolled metal or wood.

How to choose a planer for wood?

Depends on operating conditions and production goals. To answer the question of how to choose a thickness planer, you need to know:

- electric motor power;

- functional features (how many sides it processes);

- basic processing parameters.

Having learned the preliminary characteristics, you can consider the design of the machine in more detail:

- The digital display is preferred.

- Feed rollers made of polymer do not track on wood.

- What type of knife mechanism is it?

- Convenient handles make it easy to carry.

- Does the home planer have a sawdust removal system?

Knives of thicknessing machines

There are different designs depending on the shaft design. It comes with a straight knife arrangement and a screw arrangement. The second type of shaft cuts into the wood smoothly, without impact. Allows you to achieve improved processing quality and reduced noise during operation. The disadvantage is the difficulty of installing many cutting elements.

Knives for thicknessing machines are divided into:

- flat straight with angular sharpening;

- thick two-layer;

- thin crescent-shaped for screw shafts.

Device and principle of operation

The purpose of a thickness planer is to give wooden blanks the desired size and shape. It is used to process boards, bars and slats. The width and thickness of the products are set on it with an accuracy of up to a millimeter. The main element of the equipment is an electric motor with a blade shaft attached to it. Adjacent to it is a working surface and special rollers designed to supply material for processing.

Manufacturers produce machines with various design features. They differ in power, shaft rotation speed and dimensions. The performance of the equipment and its functional features depend on these indicators. The operating principle of the machine is flat planing.

Wooden blanks are fixed on the working surface with special mechanisms, after which they are planed using knife blades fixed to the shafts. In automated models, the material feed rate is set before starting work. The maximum cutting depth for most thickness planers is 145-155 mm.

Thicknesser for wood - rating

The choice was made based on the main characteristics and owner reviews posted on several specialized sites. Rating of thicknessing machines:

- Metabo DH 330

. The double-sided machine produces mirror-like surfaces at the output. - Special SRM-2000

. Along with other quality characteristics, it is lightweight, which is convenient when working outdoors. - Interskol RS 330-1500

. There are double-sided knives that can be swapped and work for a long time without sharpening. - Craton WMT 318

. Ensures reliable operation without significant repairs during daily operation for up to five years.

Information about the manufacturer of the thickness planer SR-6-9

CP 6-9 thickness woodworking machine is the Stavropol Machine Tool Plant Krasny Metallist , which has specialized in the production of woodworking machines since 1932. The plant was founded in 1902 and is located in the city of Stavropol.

Machine tools produced by the Stavropol machine tool plant Krasny Metalist

- SR-6-6

Thicknessing machine, one-sided - SR-6-9

Thicknessing machine, one-sided - SR-6-10

Thicknessing machine, one-sided - SR-8-2

Single-sided thickness planer

Do-it-yourself thicknesser for wood

It is quite possible to make the unit at home. Plan for how to assemble a thickness planer with your own hands:

- Select a kinematic scheme.

- Develop drawings of parts and assemblies (or find ready-made ones on the Internet).

- Weld a rigid metal frame.

- Mount the feed rollers.

- The unit with the cutting shaft is equipped with an adjusting screw.

- The table can be made from an oak slab and bolted to the frame.

- Install the drive by connecting the V-belt and chain drives.

- A vacuum cleaner can be used for the sawdust removal system.

- The first start is made at idle.

Types and methods of troubleshooting possible problems

| Problem | Cause | Elimination |

| The knife shaft does not rotate when starting the machine | 1.No power supply. 2.Automatic shutdown of thermal relay. 3.The guard is not secured to the knife shaft | 1.Check the electricity supply. 2. Turn on the thermal relay. 3.Install and fix the device, check and adjust the operation of the switch that blocks the safety fence |

| It is not possible to drive the workpiece into the machine (the part is slipping) | 1. The feed rollers do not apply enough pressure to the part. 2. Insufficient protrusion of the lower rollers | 1.Adjust the pressing force of the feed rollers. 2.Adjust the height of the rollers |

| The size of the processed workpiece does not correspond to the specified parameters | 1.The table is not configured correctly. 2.The table is not fixed. 3. The knives are dull | 1.Adjust the table. 2.Secure the table. 3.Change knives |

| The surfaces of the machined part are not parallel to each other. | 1.Knives are not installed level. 2.The lower rollers are not parallel to the table surface | 1.Adjust the position of the knives. 2. Correctly align the lower rollers |

| Transverse gouges at the ends of the workpieces | 1.The lower bolsters protrude too much above the table. 2.Clamps are not positioned correctly | 1. Set the lower rollers to the correct position. 2. Correctly align the clamps in relation to the pressure shaft |

| Longitudinal grooves on the machined part | Local defects on the cutting blade edge | When planing narrow parts, avoid defects or replace knives |

| The processed part acquires a wavy surface | 1. Knives are not positioned correctly. 2. The knife shaft hits the workpiece | 1.Adjust the position of the knives 2.Balance the knife shaft by selecting the knives by weight, weighing them on balancing scales |

| The grooved shaft leaves marks on the processed workpiece | The front shaft presses the workpiece too hard | Adjust the shaft clamping force |

| During processing, wood fragments are chipped and torn out in places. | 1. The knives protrude too much above the knife shaft housing. 2.Insufficient planing allowance left | 1.Adjust and set the knives in relation to the body by 1-2 mm. 2.Blanks are sorted into scrap |

| When processing, lint rises on the surface of the part | 1. The knives are dull. 2. Replacement inserts worn out to prevent chipping | 1.Change knives. 2.Change earbuds |

As you can see, the productivity and quality of the machine is determined by many different factors that must be taken into account during the work process. If more serious problems occur, please contact qualified personnel.

How to use a thickness planer?

Proper operation of the equipment will allow you to obtain excellent products for a long time. A thickness planer for wood requires a certain procedure:

- Before work, inspect the exterior for any visible defects.

- Make sure the hood is connected.

- Apply voltage. All lights, indicators and display screen (if equipped) should be illuminated.

- Let it idle.

- Use the adjusting screw to set the desired thickness.

- Put on safety glasses, turn on the machine, and feed the workpiece onto the rollers.

- Accept the outgoing part.

Which machine to choose for furniture production

The determining factors when purchasing a thickness planer are:

- cost of equipment;

- area of the premises intended for production;

- performance;

- power consumption;

- maintainability.

In small furniture workshops, you can get by with a mobile thickness planer. It is small in size and has sufficient productivity to ensure the production process. Large furniture production plants install stationary machines. Separate auxiliary rooms are allocated for their installation.

Electrical equipment of the single-sided thickness planer SR-6-9

Location of electrical equipment on the thickness planer SR 6-9 Fig. 16

Electrical equipment of the machine. General information

The electrical equipment of the single-sided thickness planer CP6-9 (Fig. 16) contains:

- Ml - electric motor for driving the knife shaft;

- M2 - electric motor for driving the table feed and movement;

- Em1 - brake electromagnet of the blade shaft drive;

- Em2, Em3 - electromagnetic couplings for table movement;

- Em4 - electromagnetic brake clutch for table movement;

- Control equipment, alarm system - located in the control panel and the electrical cabinet niche

The following voltage values are used on the machine:

- power circuit 50 Hz, 380 V;

- control circuit 50 Hz, 110 V;

- signaling circuit 50 Hz, 24 V.

- power supply circuit for electromagnetic couplings = 24 V.

Electrical circuit diagram of thickness planer SR 6-9 Fig. 17

Description of the operation of the electrical circuit

List of elements for the electrical circuit (see Table 6). Before turning on the machine, it is necessary to open the electrical cabinet door and check the condition of switch B2 and fuses Pr1...Pr3, and then close the electrical cabinet door.

Voltage is supplied to the power circuits and control circuits by turning on the input switch B1. At the same time, the milky-colored signal lamp L1 on the control panel should light up. The knife shaft drive is turned on using the Kn5 button. In this case, the magnetic starter P1 is turned on, closing its contacts in the power supply circuit of the electric motor of the knife shaft. The knife shaft drive is turned off using the Kn4 or Kn1 button.

The knife shaft drive cannot be turned on when the exhaust hopper is open or the side cover is open (right and left). The blocking is carried out by microswitches B4, B5, B6.

The feed drive is turned on by button Kn6 when the knife shaft drive is turned on. In this case, the magnetic starter P2 is turned on, closing its contacts in the power supply circuit of the electric motor M2. The feed drive cannot be turned on if the knife shaft drive is not turned on, due to the presence of the closing contacts of the P1 starter in the power circuit of the P2 starter coil.

The table is moved by turning on the Kn2 or Kn3 button in jog mode with the knife shaft drive turned off. When the knife shaft drive is turned on, the table movement drive will not turn on, since its circuit contains a break contact of the magnetic starter P1.

The Kn2 button turns on relay P3, which closes its contact in the power circuit of the electromagnetic clutch Em2 and turns on the upward movement of the table.

Button Kn3 turns on relay P4, which closes its contact in the power circuit of the electromagnetic clutch Em3 and turns on the drive to move the table down.

To fix the table in a given position, an Em4 brake clutch is used.

Switch B3 is used to turn on the local lighting lamp L2.

The Kn4 button, located on the control panel, and the Kn1 button, located on the machine frame, serve for emergency shutdown of the machine.

Protection of electrical equipment from short circuit currents and overloads is carried out by the input switch B1, switch B2 and fuses Pr1...PrZ.

Zero protection is provided by magnetic starters.

Preparation of the electrical equipment of the machine for initial start-up and initial start-up.

When initially starting up the machine, it is necessary first of all to check the reliability of grounding and the quality of installation of electrical equipment by external inspection. After inspection in the electrical cabinet at the terminal blocks, disconnect the power wires of the motors Ml and M2. Turn on the input switch B1. Using the buttons located on the control panel, check the precise operation of the starters. Then restore the circuit to its original position and check the correct direction of rotation of the electric motors.

Let's take a closer look

Let's look at the example of a board that needs to be leveled on four sides.

A simple groove-type cutter will be needed, ideally the wider, the fewer passes will be created for leveling. On the other hand, the narrower it is, the deeper the immersion into the wood will be, which makes it possible to remove more material in one go. Note: If you need to remove a little wood, take a wide cutter, and if there is a lot, then use it already.

These methods can be combined

The workpiece is placed on a vertical surface. Now you need to make sure that the workpiece is motionless. This can be done using wood chips or thin pieces of wood. The main thing is that she is immobilized in a vertical position.

Afterwards we will need rails, instead of which we will use a profile pipe.

We will need: two rails of the same size, a device along which we plan to move the hand router. We will use the simplest cutter.

Processing with our device will not be a bit inferior to a jointer and surface planer, only it will take more time.

First, the rails are attached to the tabletop using a clamp. The rails must be pressed as tightly as possible.

The square pipe used as rails is made slightly smaller in size

Note: There must be a spacer between the rail and our material so that during operation the metal does not cling to the cutter.

Next you will need to fix the rails using clamps.

After everything is securely fixed, a certain device will be needed that will stand on the rails, along which the part will move up and down and select the tree.

Important: The workpiece is well secured so that there is no movement during milling.

The last device on which the cutter will move. Why do we take 4 pieces of square pipe and fasten them together. We screw the slats on the sides. Next, install the device on the pipe rails.

Let's start milling. If there is a need to plan a lot of wood, then it is better to do it in stages. If everything is prepared, we decide on the depth at which milling will take place. We now move on to direct milling, for which the cutter is driven along the surface of the workpiece.

Important: The work must be done very carefully so that the cutter does not touch the rails. This completes the jointer's work.

During cooking, the boundaries of the cut of wood fibers with a milling cutter will be visible. These areas are sanded to create a perfect surface.

Top best models in the mid-price segment

JET JPT-10B

A high-quality device with a power consumption of 1500 W, suitable for semi-professional use. The maximum rotation speed is 9000 rpm. There are two knives that are made of high-speed steel, which makes it possible to work with hard and soft wood.

The maximum planing depth is 2 mm, and material up to 254 mm thick can be used. The dimensions of the machine are 980x470x1120 mm, which makes it possible to place it anywhere. For greater convenience there is a large work desk.

The average price is 30,655 rubles.

thickness planer JET JPT-10B

Advantages:

- External execution;

- Durability;

- Strength indicators;

- Compactness;

- Appearance;

- Planing quality;

- Comfortable feet.

Flaws:

- Not found.

Bison RS-330

A reliable device from a domestic manufacturer that processes boards at high speed. The maximum planing width is 330 mm, while the thickness of the workpiece starts from 250 mm. For efficient processing there are two knives. The design is intended for longitudinal planing. The electric motor is made of high quality, and there is also effective overload protection.

A distinctive feature is the presence of an electronic display, so the settings are more accurate. The manufacturer also equipped the design with a large work table. There are rollers on the top that make it easy to return the part for reprocessing.

Average cost: from 30,300 rubles.

thickness planer Zubr RS-330

Advantages:

- Planing depth – 3 mm;

- Electronic display;

- External execution;

- Sustainability;

- Durability;

- Efficiency;

- Good processing;

- Sharp knives.

Flaws:

- Not found.

ELITECH PAGE 1833 E

A high-quality device that will ensure clean planing of wooden boards. The board is passed through automatically, where it is processed with two sharp knives. After finishing the work, the output is an even and smooth product that does not have burrs. The machine is capable of operating from a single-phase network, the frequency of which is 50 Hz.

The structure is operated only at positive temperatures up to 40 degrees, and the humidity level should not exceed 80%. There are two workpiece feed speeds and a thermal fuse for the electric motor. The work surface is also equipped with a passage height scale.

Sold at a price: from 34,800 rubles.

thickness planer ELITECH STR 1833 E

Advantages:

- Simple controls;

- Efficiency;

- High service life;

- Easy handling;

- Reliability.

Flaws:

- Not found.

DeWalt DW733

An effective device that will provide high quality processing of any breed. The design is equipped with 4 support posts, so the cutting part moves smoothly and with high precision. The machine is equipped with a powerful electric motor, which allows you to process workpieces of large width.

The external part is made of high quality, the dimensions of the device are standard. Idle speed – 10,000 rpm. The noise level is 95 dB, so you should work with headphones.

Sold at a price: from 65,000 rubles.

Thicknesser DeWalt DW733

Advantages:

- Beautiful appearance;

- Durability;

- Easy maintenance;

- Efficiency;

- Strength indicators;

- Convenience;

- High quality engine.

Flaws:

- Not found.

Rating of the best budget machines

CALIBER SSR-1600

A high-quality machine that is assembled in China. The product is intended only for surface treatment of soft wood workpieces. Planing is carried out to the size specified by the operator. For greater convenience, the machine is equipped with a magnetic starter, which prevents the device from being turned on arbitrarily and increases operational safety.

The maximum planing depth is 2 mm, which is a good solution and suitable for most tasks. The movement speed is 6 meters per minute, this is not enough for professional equipment, but for private workshops this value is acceptable. The design has a chain drive, which increases the reliability of the device. Min. and max. The width of the workpiece is 120 and 204 mm, respectively. Number of knives – 2.

It is powered by a mains voltage of 220 V. The maximum power consumption is 1600 W.

Average cost: from 15,750 rubles.

thickness planer CALIBR SSR-1600

Advantages:

- Reliability;

- Small sizes;

- Magnetic switch;

- Convenient operation;

- Power;

- Two sharp knives made of tool steel;

- Durability.

Flaws:

- Not detected.

BISON SRF-204-1500

A combined device that is capable of processing wooden products, as well as planing to a certain size. Switching from one operation to another is carried out with a simple click, which is convenient for most operators. The manufacturer has equipped the product with an economical electric motor that has built-in overload protection. The workpieces are fed automatically and do not require any effort, making operation easier.

There is a convenient adjustment of the tilt of the guide part, where the minimum value is 0 degrees and the maximum is 45. To reduce operating noise and protect the engine from overloads, a belt drive was installed. The surface of the wooden product is even and smooth, this became possible thanks to the high speed of rotation of the knife shaft. There is also a place to install a dust collector, which guarantees constant cleanliness in the work area.

The power of the electric motor is 1500 W, the rotation speed is 9000 rpm. Powered by a regular outlet.

Average cost: from 19,200 rubles.

thickness planer ZUBR SRF-204-1500

Advantages:

- Safety;

- Economical engine;

- Two high-speed steel knives;

- Easy transition from one operation to another;

- Polished desktop.

Flaws:

- Not found.

PATRIOT TP 255

A high-quality machine that will provide the user with clean planing of wooden boards. The equipment automatically passes the product through itself, and inside two blades carefully process the surface. The output is an even and smooth workpiece that has a certain thickness. The device does not require special knowledge, so it is suitable for beginners and amateurs. The body is made of durable steel, which is coated with protective paint on top.

The rotation speed is 8000 rpm, while the idle speed is 6 meters per minute. The maximum planing depth is 2.5 mm. Electric motor power – 1800 W. Powered by regular network.

Sold at a price: from 22,900 rubles.

thickness planer PATRIOT TP 255

Advantages:

- Durability;

- Strength;

- Works with hard and soft rocks;

- Convenience;

- Doesn't take up space;

- Magnetic switch;

- The motor is protected from overloads;

- Planing depth – 2.5 mm.

Flaws:

- Not detected.

STAVR SDR-318/2000

A good budget option that is suitable for many private workshops. The feeding mechanism is made from high-quality elements, which makes the operator’s work easier. The manufacturer also equipped the device with folding tables, which makes it possible to work with large boards.

To keep the workplace clean, a dust collector is provided. Transportation is carried out using special handles, which are located on the sides of the structure. The package contains all the necessary elements for convenient maintenance and operation.

Planing depth varies from 0 to 3 mm. Desk size – 690x318 mm. There are two planing knives, which are made of steel. Feeding of workpieces is fully automatic, so no effort is required. The thickness of the processed material is 5-152 mm.

Average cost: 24,840 rubles.

thickness planer STAVR SDR-318/2000

Advantages:

- Easy maintenance;

- Doesn't make much noise;

- Efficiency;

- Reliability;

- Value for money;

- Sharp knives;

- High-quality processing;

- Convenient transportation;

- Doesn't take up space.

Flaws:

- Not detected.

Advantages and disadvantages of jointing and thicknessing machines

In addition to the thicknessing units presented in our rating, planing machines perform a similar function. Let's briefly consider the pros and cons of the equipment, comparing them with each other in order to finally understand what type is needed for a specific activity.

| MACHINE TYPE | ADVANTAGES | FLAWS |

| THISER | +MOST MODELS HAVE A DRAWING MECHANISM + LOW WEIGHT 30-40 KG +INCREASED SECURITY + COMPACT DIMENSIONS WILL NOT TAKE MUCH SPACE IN THE WORKSHOP + LOW ELECTRICITY CONSUMPTION | - THERE IS A LIMITATION ON THE HEIGHT AND WIDTH OF THE WORKPIECE -IT IS DIFFICULT TO PLAN CURVED PARTS - IT IS INCONVENIENT TO WORK WITH BOARDS OVER 1.5 M LONG - LESS POWERFUL ENGINES |

| FUGAL | + EASY TO PROCESS BOARDS 2-3 M LONG +POWERFUL MOTORS 5-7 kW +NO LIMITATION ON THE HEIGHT OF THE WORKPIECE + CHOOSE A QUARTER + LESS VIBRATION DUE TO POWERFUL BODY | -TAKES A LOT OF SPACE IN THE WORKSHOP -THE BEAM HAS TO BE PUSHED BY HANDS -MORE DANGEROUS WORK -SIDE STOP NEEDS RIGHT ANGLE ADJUSTMENT -STATIONARY INSTALLATION ONLY |