06/17/2020 Author: VT-METALL

Issues discussed in the material:

- The essence of the gas cutting process

- 4 ways to cut metal with gas

- Technology of oxygen-flux cutting of aluminum

- No less popular methods of cutting aluminum with plasma and laser

- Gas for laser cutting of aluminum

- Gases for plasma cutting of aluminum

Cutting aluminum with gas is a rather complex process with a lot of nuances. The fact is that it is not possible to use oxygen, which is usual for this method of metal processing, since the latter simply does not generate the required amount of heat.

A way out of the situation was found with the advent of oxygen-flux cutting, which we will discuss in more detail in our article. In addition, we should not forget that laser and plasma cutting methods for processing aluminum also require the use of special gases.

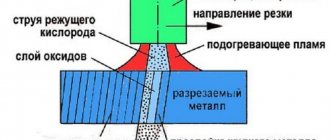

The essence of the gas cutting process

The process of cutting aluminum with gas involves heating the workpiece to a temperature of about +1,100 °C and then supplying an oxygen jet to the cutting zone. When gas interacts with heated metal, it ignites. A necessary condition for cutting is a constant and stable supply of a gas jet. In addition, the combustion temperature of the metal must be lower than the melting point. Otherwise, it will be difficult to remove particles from the work area that have melted but not burned.

Cutting aluminum with gas occurs as a result of combustion of the metal in a gaseous environment. The operation is performed using a cutter that supplies a mixture with the required proportions of gas (liquid fuel vapor) and oxygen masses. The cutter is also necessary to ignite the gas-air mixture and provide a separate supply of oxygen to the cutting area.

Gas cutting of aluminum is a high-performance thermal processing method that allows you to work with metals of any thickness. The daily output of a gas welder can be several tons of product. Experts include autonomy from electrical equipment as the advantages of this method of metal processing. This is important, since many works are carried out in conditions and at facilities where there are no power sources.

We recommend articles on metalworking

- Steel grades: classification and interpretation

- Aluminum grades and areas of their application

- Defects in metal products: causes and search methods

Using hand-held oxy-fuel equipment, you can cut a variety of metals. The exceptions are brass, stainless steel, copper and aluminum.

Oxy-acetylene cutting

Oxy-acetylene (gas) cutting is used mainly for cutting steel castings. This metal cutting is a highly productive and at the same time simple and cheap technological process, therefore it is widely used in almost all foundries, instead of mechanical cutting. The oxygen cutting process lends itself well to mechanization, which has made it possible to create a large number of special machines and devices that provide high productivity. With gas cutting, unlike mechanical cutting, there is almost no breakage or wear of the tool.

The gas cutting process is based on the intense oxidation of metal in a stream of oxygen at high temperature. For the normal process of cutting metal with oxygen, the following conditions must be met:

a) the ignition temperature of the metal must be lower than its melting point;

b) metal oxides formed during cutting must melt at a temperature lower than the temperature of its ignition and melting.

If the metal does not satisfy the first condition, then it will melt and turn into a liquid state even before its combustion in oxygen begins. If the metal does not satisfy the second requirement, then oxygen cutting it without the use of special fluxes is impossible, since the resulting oxides will not be in a liquid state at the combustion temperature of the metal and cannot be removed from the cut site.

The ability of steels to be cut with oxygen depends on their carbon content and alloying impurities. With a carbon content of up to 0.3% in steels, they can still be cut quite well. With a carbon content above 0.3%, steel is prone to hardening and cracking during cutting, so preliminary general heating of the material being cut is required.

The cutting speed depends on several parameters:

- on the thickness of the material, its properties, composition and temperature;

- on temperature and flame power;

- on the shape of the cutting jet and the speed of its flow from the nozzle;

- on the pressure of compressed oxygen and its purity.

Impurities in cutting oxygen reduce the cutting speed, from approximately 225 mm/min at 99% oxygen purity to 65 mm/min at 81% oxygen purity. Preheating the casting increases cutting speed. When steel is heated to 200-370 °C, the cutting speed increases by 50-100%.

At optimal cutting conditions, fluctuations in oxygen pressure within ±0.1 MPa change the cutting speed by 25–50%. Excessive increase and decrease in oxygen pressure affects the cutting quality. The cutting speed is also affected by the grade of steel and type of fuel. The speed of manual cutting of carbon steels largely depends on the type of fuel: acetylene, pyrolysis gas, gasoline or kerosene.

The time of oxygen-acetylene cutting in minutes per linear meter is determined by the formula

| , | (156) |

and the speed of oxygen-acetylene cutting and

(in m/s) can be determined as follows

| , | (157) |

where d is the thickness of the metal being cut, mm;

t –

cutting duration in minutes per 1 linear meter;

Oxygen cutting of elements of gating systems, as well as cutting of steel castings, differs from cutting of rolled material. The process of cutting castings is complicated by insufficient cleanliness of their surface, the presence of tides, burnt marks and sand. Internal defects in castings also complicate the cutting process. The specific nature of foundry production creates special working conditions for the carver and places increased demands on the operation of equipment and tools.

Cluttering of workplaces with castings, profits, sprues, molding sand, and a highly dusty atmosphere in the workshop sharply reduces the production standard and reduces the productivity of the cutter.

To correctly trim the profits, you must be guided by the part drawing, which indicates the tolerances for trimming the profits and the necessary templates and devices. In cases where the cut-off areas are subjected to further machining, it is necessary to leave some additional allowance over the drawing size, which is removed during subsequent machining. This allowance should make it possible to process the part to a given surface finish, which determines its smallest value. The unevenness of the cut and bevels along the thickness of the metal must be within the difference between the largest and smallest tolerances. Compared to the allowances for sheet and long material, the dimensions of the allowances when cutting castings are somewhat larger. This is caused by the fact that cast metal is less pure and dense than rolled metal.

For some time it was believed that only steel could be cut with oxygen, but cutting methods for cast iron have now been developed. The oxy-fuel cutting mode for cast iron involves the use of a manually controlled torch. The surface condition of cast iron after cutting is much worse, and the width of the cut is greater than when cutting low-carbon steel. These disadvantages are inherent in most cast irons. The exception is ductile graphite cast iron. This cast iron, like low-carbon steel, is easy to oxy-fuel cut. Nodular cast iron is cut using a conventional oxyfuel cutting device.

Some difficulty arises when cutting round elements due to the fact that when moving the cutter, the mouthpiece must always be at an equal distance from the surface of the metal being cut.

The cutting speed is determined by the cross-sectional size of the metal being cut. When striving for maximum cutting speed, it is necessary to take into account that the metal has a variable thickness along the cut line. Acceleration of the cutting process when working on variable metal thickness can be achieved by varying the speed of movement of the cutter. At the beginning and end of cutting, the speed should be the highest, in the middle - the lowest.

A kerosene cutter can also be used for oxygen cutting. In a kerosene cutter, kerosene or gasoline vapors are used as fuel for oxy-fuel cutting.

Oxy-flux cutting technology for aluminum

The efficiency of oxygen-flux cutting of metals is 15–20% higher due to the powerful flame and the absence of the need for additional heating of the workpieces. This method is much more effective in comparison with those used previously. Thanks to the high processing speed, clean, high-quality cut edges are obtained. The flux used in the process has high thermomechanical or mechanical properties.

Oxygen flux cutting is used to work with:

- high-alloy steels containing chromium and nickel, particles of which during welding form refractory oxides that are not removed under the influence of an oxygen jet;

- with cast iron and non-ferrous metals sensitive to temperature changes.

Fluxes can be of the following types:

- aluminum and iron powders;

- quartz sand;

- ceramic (silicocalcium and ferrosilicon) for working with low-alloy steels;

- ferrophosphorus, suitable for cutting non-ferrous metal workpieces.

Oxygen-flux cutting of aluminum and other metals is possible both manually and using special equipment. The design of the latter consists of a cutter, a flux feeder, and a transmitter that supplies flux to the cutter.

Oxy-flux cutting devices use metal-cutting tools of a larger diameter than cutting equipment using oxygen alone. The gas environment is formed by oxidizing agents, propane, nitrogen, flux-carrying gases, and carbon dioxide. For manual cutting, a special device is used - a spear holder. Machine processing is carried out using automatic portal devices and installations. Devices for manual and automatic cutting are suitable for working with steel, cast iron, concrete, aluminum, and various alloys of non-ferrous metals.

When working with the oxygen-flux method, it is necessary to calculate the flux composition for cutting a workpiece from a certain metal according to the phase diagram, obtaining a slag composition that has a minimum melting point and viscosity. The cutters used in this method differ from devices for oxyfuel cutting in that the gas supply channels have a smaller diameter. The cutting technique is similar to the oxygen method, but with a more powerful flame (15–20%), allowing the flux to heat up until it ignites.

No less popular methods of cutting aluminum with plasma and laser

- Laser cutting.

This type of cutting requires a laser resonator that excites a narrow beam with a wavelength of the required length. The beam is directed to the designated cutting line and melts the metal of the workpiece due to the energy concentrated in it.

The advantages of cutting aluminum with a laser are:

- high performance;

- the ability to obtain parts of the required size and configuration without further modification;

- no deformation of cut edges;

- the ability to create products of various, including complex, configurations.

This method is used when it is necessary to make holes of complex shapes in workpieces, maintaining precise tolerances and fits. Due to the lack of contact with the metal being processed, it does not deform during the cutting process. The essence of the treatment is the transmission of pulsed laser radiation excited using a fiber, gas or carbon dioxide laser system.

- Plasma cutting.

To create a plasma flow, ionization of gas supplied under pressure by an electric arc is used. Ionized gas (hydrogen, nitrogen, argon) is heated to several thousand degrees Celsius. Aluminum and other metals are subjected to a short-term high-temperature effect; molten particles are removed from the cut zone instantly.

The advantages of plasma cutting of aluminum are:

- efficiency;

- ability to cut metals with a thickness of 200 millimeters or more;

- high performance;

- a wide range of processed metals and alloys;

- excellent quality of products;

- the possibility of producing products with complex configurations - both in mass production and according to individual drawings.

When cutting aluminum and other metals with gas, the choice of gas is made based on the thickness of the workpiece being cut: less than 20 mm - nitrogen is used, less than 100 mm - a mixture of nitrogen with hydrogen, more than 100 mm - a mixture of argon and hydrogen.

Features of acetylene cutter

All features of an acetylene cutter are determined by the working gas – acetylene. Unlike other types of fuel, it can heat up to temperatures of about 3100 degrees Celsius. This is what ensures:

- Highest productivity - using an oxy-acetylene gas knife you can cut material more than 300 mm thick.

- Low proportion of oxidative processes - structural bonds in molecules are instantly destroyed without forming compounds with oxygen.

- High cutting quality.

There is a wide range of Mayak acetylene cutters on the market. The models differ mainly either in the design of the barrel or in its replaceable part - the mouthpiece, on which the intensity and size of the gas jet depend.

Gas for laser cutting of aluminum

When laser processing of metals, 4 types of auxiliary gases are used:

- oxygen, which is an active gas;

- nitrogen, classified as conditionally inert;

- argon and helium are truly inert;

- atmospheric air.

However, laser cutting of aluminum is performed using conditionally inert nitrogen, which participates in chemical reactions but is not an oxidizing agent. And when working with most metals, specialists try to prevent oxidation and combustion reactions.

In addition to the fact that nitrogen does not enter into oxidation reactions in the cut area, it displaces oxygen-containing atmospheric air from it. Thus, O2 also does not cause oxidation of the cut edges.

Oxygen when cutting aluminum with gas negatively affects the quality of processing, preventing you from obtaining clean and even cut edges. When cutting aluminum with O2, you can get uneven edges with many burrs. Some time ago it was used for cutting aluminum, since more powerful equipment did not exist. Then the uneven edges of the products were processed mechanically, improving their quality. However, additional mechanical processing increased the time spent on production and, accordingly, increased the cost of the finished product.

Currently, more powerful equipment is used; the use of nitrogen allows you to immediately obtain a high-quality cut that does not require further processing of the edges. This gas is suitable for cutting aluminum, stainless steel, high alloy steel, and nickel.

Advantages of cutting steel with gas

Thermal gas cutting of steel has a number of advantages over mechanical cutting methods, including:

Gas cutting allows you to cut steel at a speed 2 times faster than using a torch with an internal combustion engine, even in the hands of an experienced and physically strong operator.

Especially when cutting large sheets or when frequently cutting in one place, the light weight and ease of use of a portable gas cutter are of particular importance - on the other hand, a portable gas cutter is very heavy, clumsy, vibrates strongly and is equally noisy during operation and requires the operator to significant efforts to control work.

A portable oxy-acetylene torch can easily cut through 2-inch thick sheets of steel, and with special attachments, up to an inch or more. Stationary gas cutting installations can cut sheets of metal of generally indefinite thickness. For portable gas cutters, the maximum thickness of metal to be cut does not come close to 8 inches.

With the help of stationary gas cutting installations, equipped with a nozzle positioning system based on servo drives and program control, it is possible to cut shapes of almost unlimited complexity from a steel sheet - at the same time, such installations can also be equipped with nozzles that make an especially clean and precise cut. Mechanical cutting methods cannot provide anything like this.

In cases where a clean cut is not required, instead of acetylene, you can use propane as a fuel component of the gas mixture: a metal cut when cutting with propane/oxygen is not nearly as neat as with acetylene, but propane is much cheaper. Propane-oxygen mixtures are used, for example, when cutting steel into scrap metal.

Gas cutting also has its disadvantages. Perhaps the main one is the limited range of metals that can be cut. Gas can only be used to cut low and medium carbon steels and ductile iron; high-carbon steels cannot be cut with gas, since their melting point is very close to the flame temperature - therefore, when cutting, scale is not ejected from the back of the sheet in the form of sparks, but rather mixes with pure molten metal near the cut. This, in turn, prevents oxygen from reaching the metal and burning it. In the case of cast iron, in addition to malleable iron, both the graphite between the grains and the shape of the grains themselves interfere with the cutting process.

Gases for plasma cutting of aluminum

High-quality cutting of non-ferrous metals is obtained as a result of plasma cutting. The plasma with which aluminum and its alloys are processed is formed through the use of inactive gases: hydrogen, argon or nitrogen.

Active gases, such as air and oxygen, are used to work with ferrous metals.

Cutting aluminum with gas using a plasma cutter is possible with a workpiece thickness of no more than 70 mm.

Gas mixtures containing nitrogen and argon are not suitable for working with aluminum, since they are intended for processing high-alloy steels 50 mm thick.

The device of acetylene cutters

Any oxygen gas cutter consists of three main parts - gas cylinders, barrel and tip. The barrel is a handle with nipples that are used to connect gas hoses with oxygen and acetylene. There are also three valves on the body, with the help of which the supply of cutting and heating oxygen, as well as working gas (acetylene) is regulated.

One of the main elements included in an acetylene cutter is an injector - a charged particle accelerator. A mixing chamber is immediately connected to it, in which a flammable mixture of acetylene and chemically pure oxygen is formed. The mixing chamber smoothly passes into the heating oxygen supply tube.

Just before the injector there is a branch on the barrel - a cutting oxygen tube. There is a valve on it that regulates the supply of chemically pure oxygen. The ends of the tubes for supplying the heating mixture and cutting oxygen are attached to the tip. It consists of an inner and outer mouthpiece, which are placed in a special cutter head.