A scrap metal press is indispensable when processing metal waste. It is used for mechanical compression of metal and the creation of compact press packages for their subsequent remelting. It has high reliability, productivity, and is unpretentious in operation and maintenance. Used in metallurgy and mechanical engineering.

Scrap metal press

Purpose

To remelt ferrous metal, it is necessary to ensure its high density. Most of the fragments of various structures take up a lot of space during storage and transportation, which is ineffective and also financially costly. A baling press allows you to form press bags of given sizes with certain characteristics.

All types of metals can be compressed, except chips. These can be parts, mechanisms, assemblies, pipes, profile products, rods, waste from the metallurgical industry.

Briquetting presses for metal

Netmus LLC supplies high-performance equipment for scrap metal processing - baling presses and hydraulic shears. The equipment is manufactured at a leading Czech company, which during its existence has manufactured and supplied more than 600 baling presses and more than 200 hydraulic shears, including additional equipment, to Europe and Asia. Deliveries of this equipment are carried out within the framework of a design solution, turnkey deliveries, through piecemeal equipment to service repairs, spare parts and modernization of outdated equipment.

The advantages of metal presses include:

- The structural designs of all machines are computer simulated and controlled by finite element analysis to ensure minimum deformation and satisfactory stress in critical components and their subsequent structural finishing so that under a given load spectrum, trouble-free operation is ensured throughout the service life.

- The material for parts subject to wear (primarily the friction sheet) is selected so that it provides high wear resistance in heavy use and at the expense of high own costs for processing these materials.

- Additional equipment and parts are selected from reputable companies with long-term experience, good recommendations and service.

- The technical solution is traditionally very progressive, focusing on productivity, simple maintenance and care, and not least on safety and reducing the environmental risk of operating machines.

- Progressiveness and exclusivity of the technical solution, often protected by a patent held by the manufacturer.

- Baling presses are designed to work with metal waste generated during metal processing, metal from press shops, and light bulk scrap metal.

- A whole series of baling presses has been developed to process scrap metal and depreciation scrap metal generated during processing. Their use depends on the specific conditions of the processor, on the quantity and type of scrap being processed. The presses can be used for steel and non-ferrous metals up to a thickness of 8 mm*, according to the dimensions of the press.

- The most common loading method for a baling press is loading using a plate conveyor, a polyp grab device or a lifting electromagnet.

- The average weight of packages can vary from 1 to 1,000 kg*, depending on the size of the press.

- The productivity of the presses is commensurate with the type and shape of the processed material, the cross-section and length of the packages and, last but not least, the power of the hydraulic drive.

- Press control can be performed in several modes: automatic, semi-automatic, manual, adjustment.

Design and principle of operation

Scrap metal presses consist of the following components and mechanisms:

- working cylinder with connecting rod;

- plunger mechanism with a fixed working tool;

- a slider on which the plunger is attached;

- beds;

- crank shaft;

- friction transmission;

- spindle;

- scissors for forming press bags of a given length;

- retractable table for loading scrap metal;

- power pumping equipment.

To increase functionality, presses can be equipped with loading devices, areas for unloading packages, and automated control devices.

Operating principle of pressing equipment:

- Scrap metal is poured into the working hopper manually or using cranes.

- After filling, the box is closed with a lid.

- Launch.

- The working cylinders, under the influence of hydraulic pressure, compress the working volume, pressing the metal.

- During the compression process, the punch pushes the press packages out of the hopper, and the scissors cut them to a given length.

- Pressed blocks are delivered to a container for transportation.

The working cylinders are located in 3 perpendicular planes: two horizontal and one vertical. The metal is compressed first along the vertical center line and then horizontally.

The use of hydraulic drive is due to the following reasons:

- uniform force along the entire surface of the working tool;

- sufficient time for the traverse to be in the extreme forward position;

- multi-stage compression.

Design and principle of operation of pressing equipment

The design of any stamping equipment consists of the following elements:

- drive motor;

- motion transmission mechanism;

- actuating mechanism.

Main parts of mechanical crank press

Depending on how the drive motor of the press is connected to its actuator, machines with a connection are distinguished:

- mechanical;

- non-mechanical, carried out by liquid, gas or steam.

The actuating mechanism with which equipment for stamping is equipped can be traverses, a slider, rolls, rollers and women.

Crank type presses

The main structural element of these presses is the crank mechanism, which converts the rotational motion it receives from the drive into the reciprocating motion of the slider. The actuator, which is equipped with a stamping press of this type, is connected directly to the slider, capable of developing a force of up to 100 tons. The movement of the slider in such presses occurs at the same frequency.

Crank press assembly die

Crank-type presses can be simple, double or triple acting equipment. Using such machines, you can perform the following technological operations:

- stamping using open and closed type dies;

- sheet metal cutting;

- firmware;

- formation of the finished product by extrusion;

- combined processing.

In cases where more powerful equipment is required to form a finished product from a metal billet, hydraulic type machines are used.

ESSA crank press machine

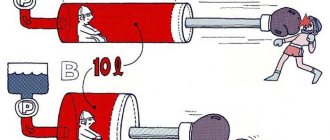

Hydraulic presses

Using a hydraulic press, you can press both larger and thicker-walled metal parts. Such equipment for sheet metal stamping, die stamping, forging, bending and other technological operations, depending on the specific model, can develop forces from 150 to 2000 tons or even more.

The main structural elements that any hydraulic press is equipped with are two cylinders of different diameters, which are filled with working fluid and communicate with each other. Each of these hydraulic cylinders has a piston that creates pressure of the working fluid or moves under its influence. It is the movement of pistons in hydraulic cylinders that ensures the movement of the actuator of the equipment. The amount of force that such a stamping press can create is determined by the difference in the diameters of its hydraulic cylinders.

Radial forging presses

A radial forging machine is a forming press on which preheated metal blanks are converted into finished products of a cylindrical configuration. The design of presses of this type is:

- an induction furnace in which the workpiece is preheated;

- conveyor for feeding the workpiece into the processing zone;

- gripping mechanisms, with the help of which the metal part being processed, constantly rotating, passes through the forging zone;

- a worm gear connected to an electric motor and responsible for the operation of the gripping mechanisms;

- four shafts with eccentric axle boxes that transmit movement to a connecting rod with a striker, between which a slider is fixed (the shafts themselves, through a V-belt transmission, receive rotation from the drive electric motor);

- copying drums, responsible for the synchronous approach of the strikers and the subsequent movement of the workpiece;

- a spring clutch that provides braking of the part while it is being processed by the strikers.

Radial forging machine is used to produce square or round forgings close to the profile of finished products

Electromagnetic type presses

This is a new type of pressing equipment. The principle of its operation is based on the properties of a core placed in a wire coil through which an electric current passes and moving under the influence of an electromagnetic field. The electromagnet core of such presses acts on the actuator of the machine, directing it to the metal workpiece being processed.

Three-position electromagnetic press for installing fittings

Distinctive characteristics of electromagnetic presses are high productivity of processing and cost-effectiveness of use.

And in conclusion, we suggest watching a short video demonstrating the operation of a jig punch press.

Varieties

Baling presses for compressing scrap metal are classified according to the following principles:

- engine power, compression;

- according to the type of chamber installed, inside which compression occurs;

- by camera functionality;

- according to the parameters of the created packages.

According to the intended purpose, a hydraulic press can be:

- specialized;

- general purpose.

Specialized equipment can be sheet bending and flanging, and general-purpose presses can be single-column or frame.

Automatic equipment is classified according to functionality into the following types:

- multi-position top drive;

- bottom drive;

- quick-start cutting machines;

- Triple action finishing punches.

Based on power, the following types of equipment are distinguished:

- low-power, force up to 2.5 MN, productivity up to 6 tons/hour;

- medium-power, rated force up to 6.3 MN, productivity up to 20 tons/hour;

- high-power, compression up to 31.5 MN, productivity up to 45 tons/hour.

Baling press for scrap metal

Selection principles

When choosing presses for metal, you need to pay attention to the following parameters:

- hopper volume for loading;

- installation method: stationary or mobile;

- engine power, displacement compression ratio;

- size of briquettes, availability of control over their size and quality;

- desktop dimensions;

- performance level.

Advantages and disadvantages

Presses for recycling scrap metal have the following advantages:

- reduction of costs for storage and transportation of secondary metal;

- high cost when delivering finished bags for melting;

- equipment reliability, ease of operation and maintenance;

- adjustment of compression parameters, geometric dimensions of briquettes;

- low processing costs compared to rolling machines;

- increasing the plastic properties of refractory metals due to deformations in several planes;

- ease of reconfiguration for new compression parameters.

The disadvantages of pressing equipment include:

- the presence of unevenness in density due to the compression of metals of different compositions, the difficulty of controlling deformation processes;

- high cost of equipment, long payback period;

- increased wear of working tools due to high mechanical loads;

- low productivity compared to rolling equipment.

The advantage of recycling

Manufacturers and cost

Scrap metal presses are manufactured at the following enterprises:

- Machine-building enterprise "PromStroyMash";

- CJSC Nelidovsky Hydraulic Press Plant;

- CJSC Kubanzheldormash;

- JSC Kuvandyksky;

- JSC Salsky Plant KPO.

Prices in Russia for machines are as follows:

- a new mobile phone with domestically produced scissors - from 14 million rubles;

- used, made in China on a single frame - from 3.95 million rubles;

- new hydraulic with a manipulator - from 900 thousand rubles;

- new automated hydraulic made in China - from 4.3 million rubles.

Presses for baling scrap metal, productivity 500 - 2000 kg/hour.

Please note that we sell the widest range of scrap metal baling presses. Taking into account the fact that adjacent models of baling presses in the line have slight differences in performance characteristics (most often this is the chamber volume with a difference in pressing force), confusion arises in the market, which is taken advantage of by unscrupulous suppliers. This is the reason that the client overpays significant amounts. Be careful.

This page presents presses suitable for obtaining a license and two models of mini presses for scrap metal.

Hydraulic press for baling scrap metal Y81F-125 (total force 2500 kN - press for license)

Hydraulic press for scrap metal scrap baling Y81-125 (the press is suitable for obtaining a license, total pressing 2500 kN) Pressing scrap ferrous metals up to 4 mm thick, scrap aluminum, copper into packages 300 x 300 mm or 250 x 250 mm (modification according to customer wishes ). It is also possible to press plastic vine-shaped shavings of non-ferrous metals with a length of at least 100 mm. Pressing principle: three-stage - the primary compaction of scrap metal occurs under the pressure of the lid, then through the side and main pressing cylinders. The edge of the lid is equipped with knives. The forces of the cylinders of the Y81-125 baling press comply with licensing requirements (total force from 2500 kN). You can buy a baling press for a license by contacting the offices of our organization.

| Hydraulic scrap press Y81-125 technical specifications | |

| Camera, mm | 1200 x 700 x 600 |

| Total pressing force, kN (ton) | 2500 (250) |

| Package size, mm | 250 x 250 |

| Electric drive, kW | 15 |

| Cycle, sec | 110 |

Depending on the configuration, the average price of a Y81-125 baling press is $27,000

Scrap press Y81-125 characteristics►

Hydraulic press for baling scrap metal Y81F-135. The press is great for both license and work.

The scrap press model Y1-135 with chamber dimensions of 1400 x 900 x 700 mm and a main cylinder pressing force of 135 tons is only $3,000 more expensive.

Please note that this is a scrap press with a three-stage pressing cycle, unlike the Q81-135 model (two-stage cycle - lid and longitudinal compression of the material inside the chamber, scrap press Q81-135►).

| Hydraulic scrap press Y81-135A technical specifications | |

| Camera, mm | 1400 x 900 x 700 |

| Main cylinder pressing force, kN (ton) | 1350 (135) |

| Package size, mm | 350 x 350 |

| Electric drive, kW | 22 |

| Cycle, sec | 120 |

Depending on the configuration, the average price of a Y81-135 baling press is $29,000.

Price reduction►.

Hydraulic press for baling scrap metal Y81F63-X (mini press for scrap metal)

The most affordable scrap press. The press is used in small enterprises with their own small production of scrap metal. The hydraulic press of this model takes up little space, has low power consumption of only 7.5 kW and excellent operating speed. The pressing cycle of a hydraulic scrap metal press is just over one minute.

| Hydraulic scrap press Y81-63 technical specifications► | |

| Camera, mm | 800 x 500 x 450 |

| Main cylinder pressing force, kN (tons) | 630 (63) |

| Package size, mm | 200 x 200 |

| Electric drive, kW | 7,5 |

| Cycle, sec | 70 |

The price of a new hydraulic scrap press Y81-63 with a 12-month warranty is about 1,300,000 rubles, incl. VAT.

Hydraulic press for baling scrap metal Y81F-100

The next affordable scrap press model is the Y81F-100 model. Main cylinder force 100 tons, power consumption 11 kW.

| Hydraulic scrap press Y81-100C technical specifications | |

| Camera, mm | 1000 x 700 x 550 |

| Main cylinder pressing force, kN (ton) | 1000 (100) |

| Package size, mm | 250 x 250 |

| Electric drive, kW | 11 |

| Cycle, sec | 70 |

The price of a new hydraulic scrap press Y81-100 with a 12-month warranty is about 1,500,000 rubles, incl. VAT.

Both models are excellent for packaging ferrous and non-ferrous scrap metal. But, of course, the package sizes of 200 x 200 mm and 250 x 250 mm are ideal for pressing and further sale of non-ferrous scrap, copper and aluminum.

Shipment of scrap metal baler Y81F-135

Exploitation

When operating a scrap metal baling press, the following features must be taken into account:

- it is necessary to carry out technical inspections and repairs in a timely manner;

- Before performing work, you should make sure that the protective system is working;

- if there is a danger of displacement of the slider as a result of a pressure difference, it is necessary to use rigid tubes instead of flexible ones;

- check the functionality of pressure relief valves;

- electrical systems must be protected from moisture and dust;

- during operation, it is prohibited to perform adjustments or lubrication of mechanical moving parts;

- in case of malfunction or detection of breakdowns, it is necessary to turn off the power and repair the equipment;

- monitor the condition of the working tool;

- the hydraulic system needs periodic cleaning (at least once every 3 months);

- Do not allow sand, dust, or other contaminants to get into the valves, which may cause them to not close tightly.

The performance of equipment is determined by their ability to compress metal. Typically this figure ranges from 30% to 60% of the initial density of scrap loaded into the bunker.

Demand for pressing equipment for recycling scrap metal

Scrap metal presses are used in many industrial fields: metallurgy, mechanical engineering, waste recycling and other industries. Metal, simply divided into measured fragments, is not sent to the plant, since it has insufficient density. Bunching machines are mandatory equipment for metal processing. They are equipped with a hydraulic drive.

Equipment of this type is widely used because:

Press machine for scrap metal

- allow you to use warehouse space more efficiently after receiving compact bars;

- transportation of rectangular briquettes is faster and easier than non-standard scrap;

- recycling of secondary raw materials is a profitable business.

The operating parameters and dimensions of metal palletizing presses are established by GOST 9860-98 standards. The standard regulates the productivity of the pressing stages and the chamber volume required for processing ferrous and non-ferrous scrap. Baling machines compress scrap of any kind, rolled products, sheets, pipes, profiles, rods, shavings, and other metal waste.

The quality of packaging equipment is determined by the density and uniformity of the resulting blocks. To obtain stable packages, scissors are built in.

Press equipment arrangement

The operating principle of the machines is simple. Raw materials are loaded into a steel box using a grab crane. The full box is rotated to pour the metal into the press chamber. The lid closes and the packaging process starts. Vertical and horizontal cylinders are automatically put into operation. At the end, the pressing punch pushes the finished compressed package onto the conveyor belt.

The efficiency of the equipment is assessed by the density of the resulting briquette. The standard figure varies from 30 to 60% (of the density of the feedstock). At least 60% are produced by modern machines. Technical characteristics, capabilities and price of equipment depend on the type of model.