Design and electrical circuit of the grinder

Over the many years of existence of such a tool as an angle grinder, its appearance, as well as its internal structure, have remained virtually unchanged. To repair an angle grinder with your own hands, you need to know the structure of its mechanical part, as well as its electrical part.

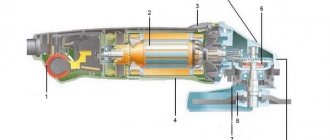

If you look at the figure below, you can see what parts the angle grinder consists of.

The figure below shows the electrical circuit of the angle grinder.

The electrical part of the angle grinder has the following elements:

The following figure shows the connection diagram for the angle grinder, namely its engine.

All components of an electric motor perform specific functions.

How to extend the service life of an angle grinder

- use the tool only for its intended purpose;

- during operation, do not neglect the main technical characteristics of the grinder indicated by the manufacturer;

- do not allow the power tool to become clogged;

- carry out timely lubrication of the mechanical elements of the device, and only high-quality lubricants should be used;

- Carry out maintenance in accordance with the technological maps for the equipment and in full.

If you follow all the rules and recommendations when working with an angle grinder, you can be sure that such a power tool will last much longer than its warranty period. During the Soviet era, angle grinders were made in Bulgaria. Therefore, the angle grinder began to be called the grinder. Currently, there are many companies producing angle grinders of various models. But the basic elements are the same. After familiarizing yourself with the device, possible breakdowns and diagnostics of the tool, you can repair an angle grinder of any modification with your own hands.

The main malfunctions of an angle grinder and their causes

According to statistics, most cases of angle grinder failure are associated with the electrical part of the device. Some damage may be minor, which allows you to repair the angle grinder yourself. But, for example, if the motor windings burn out, only a specialist can repair an angle grinder.

Grinder won't turn on

The reasons that the angle grinder does not turn on may be the following:

The angle grinder does not develop speed

The reasons why the angle grinder does not gain momentum can be different.

Although the brush is half worn out, it is still fully functional. In this case, a short contact wire prevents the spring from pressing the electrode to the collector. This situation may also be the reason why the angle grinder stopped working normally.

The electric motor is heating up

The reasons why the angle grinder is heating up may be the following.

Bulgarian sparkles

If you notice strong sparking when you turn on the angle grinder in the place where the collector is located, then the reasons for this trouble may be the following.

Prevention of breakage of an angle grinder

The service life of a grinding machine directly depends on the owner’s care for it. Each tool needs good care, then it will work properly for a long time. Any angle grinder will get warm during operation, but in order to postpone angle grinder repair for a long time, you must adhere to some rules in work:

- Do not overload the tool to avoid overheating and smoke.

- Do not forcefully press on it while working.

- Clean and lubricate the necessary parts inside the housing in a timely manner.

- If abnormal operation is noticeable, stop operation and inspect for problems.

- Replace wearing parts in a timely manner.

- If the grinder smokes, immediately stop working and do not turn it on again.

- Do not use the tool when processing wood-type materials.

- Hold the grinder firmly during operation so as not to drop or damage it.

By adhering to the listed simple recommendations and rules when working with a tool called an angle grinder, you can extend its service life longer than the warranty period.

Diagnostics of the electrical part of an angle grinder

As mentioned above, most often an angle grinder refuses to work due to breakdowns of the electrical part of the unit. To correctly diagnose the electrical circuits of a tool, electrical equipment repair technicians use a special device - a tester.

If you press the start button of the unit and it does not work, then in 90% of cases the cause of the breakdown is not so serious that you cannot repair the angle grinder yourself.

Experts advise adhering to the basic rule of repairing power tools: moving from simple to complex.

The first step is to check the electrical cable and the plug at its end. If it is collapsible, then unscrew it and check the reliability of the contacts. Otherwise, you will have to disassemble the angle grinder (remove the casing of the device) and “ring” the cable with a tester, and also make sure that the current is suitable for the contacts of the “Start” button. If the device shows a break, the cable should be replaced with a new one.

The situation when current flows to the button, but does not pass further (when in the on position), indicates a malfunction of the switch. The button cannot be repaired. It needs to be replaced with a new one, but first mark the contacts you are removing so that you can connect them correctly in the future. If the contacts are connected incorrectly, the motor winding may burn out.

If during the check it turns out that both the cable and the start button are in good condition, but no current is supplied to the brushes, then it is necessary to clean the contact plates of the brush holders. If this procedure is ineffective, it is recommended to replace the brushes. Next, if everything is fine with the brushes and current is flowing to them, you should check the rotor and stator for shorts and breaks.

Checking the motor armature

The electric motor rotor may have the following malfunctions: interturn short circuit and broken conductors at the lamella contacts. You can check the armature of an angle grinder with a multimeter: the device is switched to the resistance change mode, the value is set to 200 Ohms, and the resistance between two adjacent lamellas is measured using probes. Thus, it is necessary to check all pairs of lamellas. If the resistance values are the same, then the rotor winding is not damaged. Detection of other resistance values during “ringing”, as well as detection of an open circuit, indicates a malfunction in this coil. In this case, the angle grinder's anchor will need to be repaired.

Typically, conductor rupture occurs at the junction with the winding. Inspect the places where the coils are connected to the lamellas, make sure that the contacts are soldered securely.

If you do not have a measuring device, you can check the rotor using a 12 V light bulb and a battery for this purpose. The power should be between 30-40 W. The test is done as follows: apply 12 V voltage from the battery to the plug of the angle grinder, connect a light bulb to the gap in one wire, and start rotating the angle grinder spindle. If the winding is in good condition, the light will burn evenly, without blinking. With an interturn short circuit, the degree of incandescence of the light bulb filament will change. In this case, repairing the angle grinder's anchor with your own hands will be difficult, since the armature winding scheme is quite complex, and the process itself requires special equipment and knowledge. Therefore, it is recommended to entrust this operation to specialists. But the best way out of the situation would be to replace the anchor on the angle grinder with a new one.

Care and proper operation of the grinder

To make the grinder work for a long time, follow the rules:

- Monitor the integrity of the insulation of the wire and plug. Don't remove your protection.

Lubricate and clean the entire tool. After turning off the grinder, wait until the circle stops rotating, then place it on the ground. When the engine stops, the tool, through the ventilation holes, sucks in, along with the air flow, particles of earth and other hard fractions that hit the motor windings. As a result, a break or short circuit occurs.

If you actively use an angle grinder, it means you are a good master. Understanding the structure of the tool and repairing it with your own hands will not be difficult for you. First, find the problem and determine which components need to be checked. Repair the angle grinder carefully, without haste, so that a minor breakdown does not turn into a major one. Vibration characterizes imbalance during rotation. It is necessary to disassemble and look at the gearbox, the bearings on the motor shaft, and their integrity. For starters, and if you want to figure it out on your own. The main thing is that you absolutely cannot use such a tool. Vibration occurs within reasonable limits with any hand-held power tool, especially with an angle grinder (angle grinder) and a grinder. Yes, and heating also takes place. I think the concept of “getting very hot” should be compared with the state when a hand applied to the body cannot be tolerated, and strong vibration means that it is not comfortable to work with the tool. The cause of vibration in an angle grinder may be an incorrectly fastened disk (a factory defect is also possible). When the bearings “sing their death song,” there will also be vibration and heating. The gear transmission of the gearbox, or rather poor engagement of the gear teeth (backlash), is another cause of heating and vibration. If a grinding machine (grinder) starts to vibrate, rumble and the head (gear part) gets hot, then unfortunately it is slowly coming to an end , repairs may help, but as practice has shown, this is already incurable! This happens due to the development of grooves by the gear keys on the shafts of the engine and gearbox! The shafts are not hardened and if used incorrectly or ineptly, there are jerks, clamps and impacts with the disks on the surface - time after time the keys knock out the groove, and over time they begin to hang out there, rattle, the gears running into each other heat up and vibrate! Replacing the bearings, keys and gearbox shaft will only slightly reduce the symptoms! , since the same problem occurs on the engine shaft (rotor) - the grinder has very high engine speeds, so repairs with improvised means are impossible, and replacing the rotor, gear shaft, keys, bearings and bushings will be very expensive, so get ready to buy a new grinding machine and improve your skills in working with an angle grinder - you need to work confidently, feeling the strength and load on the device, then it will last a long time! Source: crast.ru

The grinder gets very hot and the brushes burn. Another little-known breakdown.

Grinder without sparks - is this possible + recommendations from professionals For everyone, the angle grinder familiar in everyday life is used for dismantling work, as well as for cutting various materials.

Its scope of application is incredibly large, and this is a big plus, but the risk of injury is a significant drawback. But we know how to remove it and we will tell you what protection there is from grinder sparks.

Please note that the greatest danger is posed by sparks from the angle grinder, as well as the possibility of the disc getting pinched.

Why does the grinder heat up?

The electric motor overheats in the following cases:

- Incorrect operating mode. As a result of too high loads, the motor windings burn out.

- Destruction of armature bearings. The result is difficulty in operating the engine and, as a result, overheating.

- Clogged ventilation ducts through which air flows to the electric motor, acting as a cooler.

- Closing the turns of the stator and rotor windings.

The angle grinder gearbox overheats due to lack of lubrication or its poor quality.

Design and electrical circuit of the grinder

Over the many years of existence of such a tool as an angle grinder, its appearance, as well as its internal structure, have remained virtually unchanged. To repair an angle grinder with your own hands, you need to know the structure of its mechanical part, as well as its electrical part.

If you look at the figure below, you can see what parts the angle grinder consists of.

The figure below shows the electrical circuit of the angle grinder.

The electrical part of the angle grinder has the following elements:

The following figure shows the connection diagram for the angle grinder, namely its engine.

All components of an electric motor perform specific functions.

Do-it-yourself repair of grinder gearboxes

Should the gearbox of a new angle grinder heat up?

Grinder gearboxes operate under increased loads, so the housing of even new gearboxes heats up. However, in the presence of high-quality lubrication and the absence of technical malfunctions, the body temperature should not exceed the standard values presented in the technical documentation attached to the angle grinder. Usually it should be around 40°C.

What to lubricate: CV joint and other options

The best option for lubricating the gearbox is a brand from the manufacturer of the grinder itself. This lubricant is tested on the manufacturer's models, so it is best suited for use. The main disadvantage is its high cost.

Lubricant for Makita , 30 grams. Photo VseInstruments.ru

Users of grinders find options based on domestic oils, which are somewhat worse than branded ones, but much cheaper. CV joint lubricant has good adhesion. If we take it as a basis and add MS-20 liquid oil to obtain the desired consistency, then the use of such a lubricant in an angle grinder is fully consistent with the operating conditions of a bevel gear pair. More information about lubrication of grinder gearboxes can be found in the article at the link.

Sources:

https://kovka-svarka.net/kuznechnoe-delo/kak-razobrat-reduktor-bolgarki/ https://tractor-agro.ru/reduktor/pochemu-greetsya-reduktor-bolgarki.html https://kovka-svarka .net/kuznechnoe-delo/remont-reduktorov-bolgarok-svoimi-rukami/

The main malfunctions of an angle grinder and their causes

According to statistics, most cases of angle grinder failure are associated with the electrical part of the device. Some damage may be minor, which allows you to repair the angle grinder yourself. But, for example, if the motor windings burn out, only a specialist can repair an angle grinder.

Grinder won't turn on

The reasons that the angle grinder does not turn on may be the following:

The angle grinder does not develop speed

The reasons why the angle grinder does not gain momentum can be different.

Although the brush is half worn out, it is still fully functional. In this case, a short contact wire prevents the spring from pressing the electrode to the collector. This situation may also be the reason why the angle grinder stopped working normally.

The electric motor is heating up

The reasons why the angle grinder is heating up may be the following.

Bulgarian sparkles

If you notice strong sparking when you turn on the angle grinder in the place where the collector is located, then the reasons for this trouble may be the following.

Mechanical breakdowns and their elimination

Mechanical failures of angle grinders include the following.

- Worn motor armature bearings. Typically, when the bearings wear out, you may experience strong vibration while the machine is operating. In addition, grinding and other noises may be heard. Sooner or later, the bearing will collapse, and the spilled balls will fall on the gears of the gearbox. If this happens, then in addition to the bearing, the gears will also have to be replaced. Of course, it is better not to wait for this problem, but to replace it at the first sign of bearing failure. How to get to this part of the angle grinder was described above.

- Worn ball bearing or plain bearing of the gearbox. As in the previous case, when you turn on the device, vibration will be felt and noise will be heard that is unusual for the normal operation of an angle grinder. To prevent further damage to the gearbox, it is necessary to replace the faulty part.

- Reducer gear wear. Gears wear out quickly due to insufficient lubrication. For the same reason, the gearbox heats up. It is necessary to monitor the condition of the lubricant inside the gearbox and change it if necessary. How to disassemble the gearbox was described above. You need to use lubricant specially designed for angle grinder gearboxes, and you can buy it at points where this tool is sold. If for any reason the teeth of at least one gear are broken, then the entire set of gears (a pair) needs to be replaced.

Mechanical faults can also include a broken shaft lock. In order to replace the retainer, you will need to disassemble the gearbox and remove the large gear. Source: Tehnika.expert

Reasons for strong vibrations of the grinder

The source of this problem may be:

If your grinder stops working, if it makes noise, vibrates a lot or overheats, it is recommended to contact a service center, which will not only fix the current problem, but also diagnose all components of the tool.

The protection indicator indicates engine overload and battery overheating.

During operation, all components of the angle grinder heat up and if no measures are taken to protect the angle grinder from overheating, the tool may simply fail. What happens when overheating, that is, when the operating temperature of the angle grinder exceeds? Of course, all parts will be subject to linear expansion, the lubricant will lose its viscosity and simply leak out, thus increasing the friction force between the parts of the angle grinder. Not to mention the fact that it will be impossible to hold the instrument in your hands, and this can lead to sudden injury.

In most cases, the electric motor is prone to overheating, which can be protected in different ways. Modern designs of angle grinders provide an indicator that lights up when the temperature reaches 130 ºС; when the temperature rises to 160 ºС, the engine slows down, but when this value reaches 200 ºС, the power supply to the tool is turned off. There are models where temperature control is limited only by an overheating indicator. What is interesting is that some owners of grinders are dissatisfied with such automation and spontaneous stopping of work due to overheating. But it’s better to take an extra “smoke break” than to have the electric motor repaired.

Gearbox housing for grinder MAKITA GA5030

The most common cause of overheating is the gearbox housing of the angle grinder, inside which the gears rotate. Of course, the lubrication and ventilation of the gearbox itself removes a certain amount of heat generated as a result of friction of the parts. But the housing material from which the gearbox is made also plays an important role.

Angler impeller MAKITA 9565

Now they are increasingly making it from metal instead of plastic, and metal, as you know, removes heat better. Although it leads to a heavier overall weight of the tool, compared to the effect of heat removal, this can be tolerated. It should be noted that the term “metal” means a durable aluminum alloy, which has high thermal conductivity.

Grease the grinder to make it work better

Advice! Experts do not recommend using materials such as solid oil and lithol.

When deciding how to lubricate the angle grinder, pay special attention to silicone-based materials or silicone oil. Such lubricants are excellent for tools that operate in a spectrum of speeds from leisurely to huge and under all loads. They are highly resistant to oxidation, protect against corrosion, and are easily mixed with plastics and elastomers. The composition contains only silicone and lithium thickener, which makes them non-hazardous based on environmental concerns. The consistency is maintained at temperatures from 50 to 190 degrees Celsius.

One of the important components of the angle grinder is the gearbox. During operation of the tool, it gets very hot, since the gears rotate behind it, which leads to strong heating. It is for these reasons that the gearbox casing is made of metal, because it removes heat quite quickly. However, one casing is not enough to cope with high temperatures; proper lubrication is also important.

Anyone who is an expert when asked how to lubricate the gearbox of an angle grinder will answer that it is preferable to use a special lubricant for angle grinders. It is specially developed for the work and criteria in which such a tool is used. This lubricant has a specific blue color. Excellent, high-quality lubricant for the grinder gearbox has the following marking: MoS2 NLGI 5 ISOL-XBCHB 2 DIN 51825-KPF 2.4 K-20. Marking means:

- MoS2 – molybdenum disulfide acts as an additive;

- NLGI 3.2 – 2nd viscosity class;

- ISOL-XBCHB 5 – compliance with ISO standards;

- DIN 51825-KPF 5 K-20 is the most important point; it means that the lubricant complies with German DIN standards.

- 51825 indicates that the material corresponds to Type K grease.

The cost of such a mixture is very high, alas, there are more affordable lubricants with similar properties: KPF 5 K-20, where:

- K – intended for plain bearings;

- R – with extreme pressure additives;

- F. with hard filler;

- 4 – mixture corresponds to NLGI;

- K – highest operating temperature 120 degrees Celsius;

- 20 – low operating temperature.

Note! The introduction of special lubricants for angle grinders will provide the highest guarantee of reliable operation.

Increased attention should be paid to lubrication of angle grinders that are under warranty. It is not recommended to do this without the help of others; this work should be entrusted to special workshops. There, high quality and unique materials will be consumed with the right dose. You can apply the consistency incorrectly with your own hands, which will have a bad effect on the longevity of the tool.

Advice! It is recommended to take to special services not only grinders under warranty, but also those whose warranty period has already passed.

Various lithols and solid oils for lubricating gears and bearings are strictly prohibited. Also, opening the case on warranty instruments will be a prerequisite for refusal of service, and the introduction of “unauthorized” lubricant is generally a gross violation of the rules for operating an angle grinder. The only exceptions are external nodes, which, according to the annotation, need to be processed frequently.

The grinder, like other tools used in household and professional activities, requires constant maintenance. Operating efficiency and long service life are ensured by timely maintenance.

Grease for an angle grinder is the main component for servicing the device. To improve performance properties, you should choose the right composition.

The main modular unit of an angle grinder is the gearbox. It only bears the main part of the load during operation. It contains helical gears that transmit torque from the rotor to the operating element. Lubricating the grinder gear reduces the friction force in the gears. It also helps to reduce the temperature that appears during operation.

Where to change the lubricant? During operation, the lubricant coating scatters around the gearbox housing. After a short time, it begins to dry out and lumps form. Lumps of course accumulate particles of dust and metal formed during operation. If, when disassembling the grinder, lumps are found, then you need a new lubricant for the grinder gearbox.

There are situations when it is necessary to replace parts of an angle grinder gearbox, or, in other words, the rotor bearing. In this case, you need to disassemble the device. Accordingly, the lubricating layer will be removed. Instead, new material is applied.

During long periods of operation, the grinder's gearbox heats up. Accordingly, the coating used also begins to heat up. When heated, the lubricant becomes watery and may leak. When finished, there is not enough left inside. You can see this if you look at the gears. They should have a thick layer. Thus, if the volume of lubricant coating is small, you need to change it.

The lubricating coating for gearboxes is characterized by the following qualities:

- viscosity no more than 800 Pas;

- drop falling temperature of at least 120°C;

- tensile strength of at least 120 Pa;

- absence of mechanical impurities;

- corrosion resistance;

- highest melting point;

- water repellency.

It is necessary to choose a lubricant that does not contribute to the appearance of notches in areas of contacting parts.

When choosing coatings for yourself, you should be guided by the condition that the lubricant coating for the bearing parts of the gearbox differs from the lubricating coating of the motor bearings.

Types of lubricants

Many people are interested in the question: how to lubricate the gearbox of an angle grinder so as not to destroy the tool and increase its efficiency. The following types of lubricants are possible:

- the brand of lubricant products corresponds to the brand of the tool manufacturer;

- composition for CV joints;

- grease and lithol.

Probably tool manufacturers always advise using a suitable lubricant for maintenance in order to avoid negative consequences during operation. When using a composition from another manufacturer, the tool is not subject to warranty repair.

Many people will think that lubricating the gearbox with the manufacturer’s compound is very expensive. After all, the price of such materials is quite high. Already today, there is a Russian automobile industry that does not produce lubricants.

When choosing solid oil, also called lithol, as a lubricant, you run the risk of causing the instrument to quickly break down. This is justified by the fact that these substances do not imply use at elevated temperatures and high friction. Therefore, after some time there are problems during the operation of the tool.

Thus, a good lubricant option for angle grinders is considered to be one that corresponds to the brand of the tool manufacturer.

Lubrication is carried out in special workshops or without the help of others. When performing lubrication on your own, do not forget that a lubricant that does not match the brand of the tool will cause the tool to break. The process of processing with new lubricants involves the complete removal of the old lubricant layer. The parts and walls of the case are not made to contain remnants of the old coating.

Stages of lubrication of an angle machine gearbox:

- disassemble the grinder;

- wash the sides and cavities of the gearbox using kerosene or a solution of kerosene and gasoline;

- dry the washed parts;

- mix new lubricant;

- coat bearings and cavities;

- assemble the tool.

When applying, the question arises: how much lubrication is required? Applying a mass of lubricant will cause excess volume to flow out during operation. If the content is low, the operation of the gearbox will be difficult and will lead to rapid wear. As follows, such a volume of material is placed in the housing so that the gear teeth are hidden under the surface of the applied layer. The approximate content of the coating on angle grinder gearboxes is less than ½ the volume of the entire gearbox.

The grinder's lubrication, specifically its richness, is checked in idle mode during a test run for a short period of time. After starting, the gearbox begins to heat up. If some of the lubricant leaks out when the gearbox is warmed up, then you need to disassemble the tool again and remove the excess.

If, after a short period of idling, signs of noise or rattling appear, then the volume of the applied layer must be increased.

If you want to use a good lubricant composition for an angle grinder gearbox, but you don’t have the ability to purchase it, then you should make it yourself using CV joint lubricant. We should not forget that the material used must have good adhesion.

The composition must adhere firmly to the rubbing elements. The composition for CV joints is characterized by increased adhesion and the ability to operate under high temperature loads.

To produce the consistency, a composition for the CV joint and MS-20 oil are taken to enhance the required viscosity and density. Using a homemade mixer, the composition is mixed with a small supply of oil (drop by drop).

And besides, always get material from the consistency of lubricants Tsiatim-221 and TAD-17. The main component is Tsiatim.

Foreign-made gearbox lubricants are more expensive than Russian ones. Among foreign brands, the Bosch brand is widely known. It is used to lubricate tools of the same brand, as well as other models of grinders. The coating has good performance properties.

Among Russian manufacturers, products called “Metal Plaque Electra” are known. Lubricants of this brand are used for most components of electronic tools.

Operating an angle grinder without a lubricant coating will initially lead to minor problems during operation, and then to failure of the tool. Lubricated gearboxes will extend the life of the tool and increase productivity. The master himself decides which lubricant is suitable for the existing device.

The angle grinder works in extreme conditions and under heavy load. This is why repeated lubrication of the grinder gearbox is necessary, because the moving components of power tools are subject to the highest lubrication requirements. Otherwise, if there is a lack of lubricant, excessive wear occurs and the service life of the power tool is reduced.

The angle grinder gearbox is designed in such a way that the grease of a pair of gears moves to the walls of the housing under the influence of centrifugal force. A sign of “draining” of the gearbox is excessive noise during operation of the grinder. When the gearbox housing is opened, the problem becomes trivial. All the factory grease is on the housing walls, the helical gears are virtually dry.

We check the degree of wear of a pair of gears and damage to the teeth. We replace gears as needed.

We clean the surface of the gears from mechanical dust. Lubricate the sealed bearings of the motor rotor and the working shaft of the gearbox with watery engine oil. We actively rotate the rotor to ensure uniform penetration of the lubricant inside the bearing. Remove excess watery grease with a clean rag. If this is not done, it will mix with the gear grease and make it more watery. Watery lubricant will not adhere well to the gear teeth.

If the factory grease for the grinder in the gearbox is of normal quality, apply it thickly to the teeth of both gears. If there are signs of aging of the lubricant, wash the gearbox with kerosene or other penetrating liquid and replace the lubricant.

Regarding the question of how to lubricate the gearbox of an angle grinder, no matter what kind of high-temperature grease is suitable, for example, for lubricating CV joints and wheel bearings of a car. At the same time, remember to apply it to the shaft support bearing.

We assemble the gearbox, carefully tightening the fasteners. If you leave free play in the gear pair, the gearbox may jam.

Also, to service the angle grinder, you need to lubricate the second rotor bearing and check the condition of the motor brushes.

Based on the intensity of use, a similar function (lubricating the grinder gearbox and checking the condition of moving parts) needs to be created frequently. This will extend the life of your power tool.

13, total, now

Source

Diagnostics of the electrical part of an angle grinder

As mentioned above, most often an angle grinder refuses to work due to breakdowns of the electrical part of the unit. To correctly diagnose the electrical circuits of a tool, electrical equipment repair technicians use a special device - a tester.

If you press the start button of the unit and it does not work, then in 90% of cases the cause of the breakdown is not so serious that you cannot repair the angle grinder yourself.

Experts advise adhering to the basic rule of repairing power tools: moving from simple to complex.

The first step is to check the electrical cable and the plug at its end. If it is collapsible, then unscrew it and check the reliability of the contacts. Otherwise, you will have to disassemble the angle grinder (remove the casing of the device) and “ring” the cable with a tester, and also make sure that the current is suitable for the contacts of the “Start” button. If the device shows a break, the cable should be replaced with a new one.

The situation when current flows to the button, but does not pass further (when in the on position), indicates a malfunction of the switch. The button cannot be repaired. It needs to be replaced with a new one, but first mark the contacts you are removing so that you can connect them correctly in the future. If the contacts are connected incorrectly, the motor winding may burn out.

If during the check it turns out that both the cable and the start button are in good condition, but no current is supplied to the brushes, then it is necessary to clean the contact plates of the brush holders. If this procedure is ineffective, it is recommended to replace the brushes. Next, if everything is fine with the brushes and current is flowing to them, you should check the rotor and stator for shorts and breaks.

Checking the motor armature

The electric motor rotor may have the following malfunctions: interturn short circuit and broken conductors at the lamella contacts. You can check the armature of an angle grinder with a multimeter: the device is switched to the resistance change mode, the value is set to 200 Ohms, and the resistance between two adjacent lamellas is measured using probes. Thus, it is necessary to check all pairs of lamellas. If the resistance values are the same, then the rotor winding is not damaged. Detection of other resistance values during “ringing”, as well as detection of an open circuit, indicates a malfunction in this coil. In this case, the angle grinder's anchor will need to be repaired.

Typically, conductor rupture occurs at the junction with the winding. Inspect the places where the coils are connected to the lamellas, make sure that the contacts are soldered securely.

If you do not have a measuring device, you can check the rotor using a 12 V light bulb and a battery for this purpose. The power should be between 30-40 W. The test is done as follows: apply 12 V voltage from the battery to the plug of the angle grinder, connect a light bulb to the gap in one wire, and start rotating the angle grinder spindle. If the winding is in good condition, the light will burn evenly, without blinking. With an interturn short circuit, the degree of incandescence of the light bulb filament will change. In this case, repairing the angle grinder's anchor with your own hands will be difficult, since the armature winding scheme is quite complex, and the process itself requires special equipment and knowledge. Therefore, it is recommended to entrust this operation to specialists. But the best way out of the situation would be to replace the anchor on the angle grinder with a new one.

Why does the grinder spark strongly in the area of the brushes?

During normal operation, a small, uniform spark is observed inside the housing. If it is too strong, the brushes must be replaced. The problem occurs in the following situations:

- Damage to the armature winding - an interturn short circuit has occurred or a section of the winding has broken.

- Loss of contact between the winding and the collector plates.

- Violation of insulation between the collector lamellas.

- Severely worn grinder bearings, which cause the armature of the angle grinder to beat, causing the brushes to spark and burn.

- Using brushes whose characteristics do not correspond to the speed and voltage in the network.

- Motor overheating due to continuous operation for too long.

The grinder is warming itself. We find out the reason and repair it ourselves.

To come in

Already registered? Sign in here.

There are currently 0 users on the page

There are no users viewing this page.

Industrial gearboxes are one of the most commonly used equipment. However, their active use can lead to wear of parts and subsequently disrupt the technical characteristics of the unit. The main signs of problems with the gearbox are extraneous noise, vibration, oil leakage, heating or freezing of the housing. How to fix all problems with minimal costs?

Rice. 1 — Main problems of industrial gearboxes

If, when inspecting the gearbox, we noticed that oil is leaking from it, the input shaft does not rotate, and it itself makes sounds that are unusual for it - this is a clear sign of problems. We identify the 6 most common root causes of gearbox problems and offer methods to combat them.

Why does the gearbox get hot?

You can accurately determine the heating of the gearbox using a special thermal imaging ; if you do not have one, then the heating can be determined by touch.

Rice. 2 — Checking the gearbox with a thermal imager

The root causes of gearbox heating may be:

Problem:

Solution:

Gearbox surfaces must be clean

Why does the gearbox howl?

If you hear a loud noise or a sharp knock coming from the gearbox, the root cause may be the following:

Problem:

Solution:

— bearings are not adjusted or damaged

adjustment and replacement of the worm pair

Rice. 3 - Damaged worm gear teeth

Why is the gearbox humming?

If, in operating condition, the gearbox makes sounds similar to a hum while vibrating, the problem may lie in increasing the permissible vibration level. a vibrometer - will help you accurately determine the vibration indicator .

Rice. 4 — Determining the vibration level with a vibrometer

Causes of increased vibration levels and their solutions:

Problem:

Solution:

— misalignment of gear and unit shafts

tighten foundation bolts

Why does the gearbox freeze?

The gearbox freezes if you fill it with oil that is not intended for low ambient temperatures. To solve this problem, it is necessary to fill in a special oil, which is universal and suitable for both the summer and winter seasons (for example, TRANSOL-200A oil).

Why is oil leaking?

If you find traces of oil on or around the gearbox, we advise you to immediately inspect the gearbox and take all necessary actions. Oil can flow through the seals and along the plane of contact of the bearing caps to the housing or through the seals. To solve the problem you will need:

Solution:

— the drainage vent is clogged with debris

replace the faulty cuff

Why does the gearbox output shaft not rotate when the engine is turned on?

The output shafts of the gearbox must always rotate freely. If this does not happen, then the reason lies in the following:

Problem:

Solution:

- extra viscous oil is filled

Rice. 5 — Installing the key on the gearbox shafts

Detection of one of the above problems is the first signal that your gearbox may soon fail. Further operation of a faulty gearbox can lead to breakdown of its individual mechanisms or lead to a stop in the operation of the entire unit. Therefore, it is very important to do maintenance on the gearbox at least once a month, and also inspect it for oil leaks each time before use.

If you have any difficulties with servicing or repairing the gearbox, we advise you to immediately seek help from specialists. Our company can also help you with this. To use our services, follow the link and leave us a request.

Engineering Department Specialist

An angle grinder (“grinder”, angle grinder) is an electric tool necessary for manual cutting, cleaning and grinding of various materials. Depending on the type of wheel used, it is used to work with metal, stone, and concrete. There are models for domestic and professional use. The range of circle diameters is 115-230 mm. Like other tools, “grinders” do not work, get very hot or make noise for various reasons - due to non-compliance with operating rules, too intense loads, and natural wear of parts of components.

The gearbox is broken, causes and common malfunctions

Increased vibration, the presence of an uncharacteristic sound during operation, strong heating of the case, jamming of the gearbox during operation of the angle grinder require immediate intervention to determine the causes of the appearance of these factors and eliminate them. As the practice of operating angle grinders shows, the most common gearbox malfunctions are caused by the following reasons:

- wear of bearings with the appearance of critical play;

- bearings can, as they say, “crumble” due to shock loads during “hard” operation of the angle grinder;

- increased wear of a bevel gear pair, tooth breakage;

- untimely replacement of the gearbox lubricant or the presence of low-quality lubricant in it.

Bearing wear (Lepse)

In the following video, the author completely disassembles a Lepse brand grinder made in Russia (electrical machine-building plant in Kirov) in order to determine the absence of spindle rotation with a normally operating electric motor. In this case, a complete analysis of all disassembled parts is performed. Even high-quality Soviet bearings after 10 years of operation have slight wear, determined manually by the amount of play. For a detailed description of actions in such cases, see the article at the link “Replacing bearings in an angle grinder gearbox.” In the case of the Lepse model grinder, play in the front rotor bearing requires replacing it. After replacing a defective bearing with a new one, it must be lubricated , just like all other bearings of the angle grinder.

Lack of gear clutch (Interskol), gearbox is noisy/clatters

When the Interskol model grinder is operating in the next video, there is a rattling noise , characteristic of a gear pair failure. The assumption was confirmed after opening the gearbox housing, where a breakdown of the drive small gear . Further disassembly of the angle grinder made it possible to determine the probable cause of the gear failure. Increased play in the front rotor bearing could cause increased forces in a pair of bevel gears, which led to failure of one of them.

Backlash (CROWN, Bosch)

Increased play not only of the rotor, but also of the spindle can cause an emergency.

The CROWN model grinder from the following video had increased spindle play . The author drew attention to the strong end runout of the working tool. Working in such conditions can lead to the destruction of , for example, a cutting wheel, which will create an unsafe situation for the person working with the angle grinder and the people around him. The author replaced the bearing using a puller.

In the next video, the spindle play is noticeably larger . This is due to the wear of both bearing units - the ball bearing located in the housing cover and the plain bearing located in the gear housing. Lack of lubrication - this is the conclusion the author draws by analyzing the defects. It should be noted the method by which the plain bearing is removed from the housing. A calibrated rod (in this case, a drill guide) creates pressure on the grease, which tightly fills the cavity of the inner diameter of the sliding sleeve. After loading, the lubricant penetrates into the gap between the bushing and the body and squeezes the bushing out of the seat.

angle grinder

Any chopper consists of the following parts:

- The rotor is the part of an electric motor that rotates during operation and is controlled by speed, also called an armature;

- Collector. The place on the rotor where the winding control wires are located;

- Brushes. Parts that serve as current conductors from the cable to the collector winding;

- Gearbox. The mechanism, which acts as a drive from the rotating rotor to the rotating disk, consists of a spindle, a bearing, two gears (a large and a gear shaft);

- Stator. The part of the engine in which the rotor operates;

- Impellers for cooling the impeller;

- Start button;

- Motorized network cable;

- Profiled sheeting;

- Grinding machine body;

- Additional handle.

READ Replacing the Bearing on the Grinder Interskol

All these details can be divided into two parts:

- Electric;

- Mechanical.

Causes of the defect: it gets very hot

Based on the experience of our service engineers, we can identify the following reasons:

- Untimely prevention and cleaning of the device

- Lack of protection against power outages

- Replacing Consumable Accessories

- Not carefully studying the user manual or ignoring the manufacturer's advice.

- Not careful use

Bring your equipment to our service centers or call the technicians to your home and we will repair it and provide a guarantee. Afterwards, the faulty device will work at 100 percent (full). Addresses of Umedia services in all districts of St. Petersburg.

How to disassemble an angle grinder for diagnostics

In order to diagnose the electrical part of the angle grinder, as well as eliminate mechanical breakdowns of the device, you will need to disassemble it. Disassembly is carried out according to the following algorithm.

- Using a wrench, remove the disk or other attachment from the spindle of the unit.

- Unscrew the handle.

- Remove the protective cover.

- Open the special windows located on the sides of the angle grinder casing and remove the electric brushes, having first disconnected the terminals.

- Unscrew the gear housing from the angle grinder motor housing.

- Pull the gear housing lightly and remove it from the housing. In this case, the gear unit will be removed along with the rotor.

- After removing the armature, the motor stator will remain in the casing, which can also be easily removed for diagnostics after unscrewing the fasteners.

- To disassemble the gearbox, unscrew the screws holding the cover. After removing the cover, you will see the gears of the gearbox.

- To remove the anchor from the angle grinder, you will need to unscrew the nut located inside the gearbox.

- In order to remove the bearing from the armature, it is recommended to use a special puller. Otherwise, the shaft may be damaged.

Types of breakdowns in grinders

Typical minor damage

In the event of a malfunction, it is first necessary to eliminate elementary breakdowns:

- The grinder does not turn on. The angle grinder suddenly became faulty - it stopped turning on. In this case, you need to check the serviceability of the socket, then the plug and the power cord; perhaps the drive simply does not work due to the fact that no current flows into the product.

- The cable and plug are intact, but the drive does not work. You need to check the start button. It is easier to repair an angle grinder switch by purchasing a new button and replacing it. Since it is rarely repairable - mainly, the plastic switch rod inside breaks. If you want to experiment, you can disassemble it, numbering the contacts, and put everything back in its place so that after assembly there is no short circuit.

- The above parts are unharmed, but the angle grinder does not want to work - which means it’s time to check the brushes. Perhaps it's time to change them in the grinder. Brushes constantly heat up from work, so they wear out quickly and need to be replaced more often than other parts, and in pairs.

Major faults

Having ruled out all minor damage, you need to figure out why the tool does not want to turn on and how to repair it. Most likely, the malfunctions are serious and require additional knowledge. This happens if:

- the body is deformed;

- one of the bearings is jammed;

- the armature or stator does not work;

- the gear teeth of the gearbox are broken or worn out;

- the collector has failed;

- The control electronics sensor shows no signs of life.

If it is determined that the malfunction has occurred in the mechanical part of the angle grinder, then you need to pay attention to the condition of the large gear located on the shaft and the bushings. If the teeth are partially worn out or the shafts become wobbly, they must be replaced immediately.

The most common breakdowns

Grinder malfunctions happen quite often. Everyone who works with this tool knows about this. What goes wrong most often?

The spindle lock button is broken.

Just one awkward press on the spindle lock button while the disk is rotating leads to its breakdown. Sometimes it can be broken if it is used to remove a jammed disk. To prevent this from happening, you need to use an open-end wrench inserted into special holes near the place where the disk is attached.

Broken gear teeth

It mainly occurs when jamming occurs. If you hear a rumble in the gearbox, this is a sign of just such a malfunction. When more than one tooth of a gear is broken, the grinder will not be able to cut the required material.

In order for the tool to continue working, it is necessary to change the gears, all of them, and even the bevel wheel. Before going to the store for spare parts, remember the manufacturer, model and power of the product.

The electric motor does not work.

This type of breakdown occurs with angle grinders that work in places where there is a lot of dust, and when they are given a rest, they are left on the ground. Dust that gets inside spoils the winding. Large loads, especially for a small power angle grinder, result in motor failure.

If the grinder is used for cutting materials that create a lot of dust, then it is recommended to cover the ventilation holes with something.

Bearing fell out

The weakest link, and not only among grinders, are the bearings. High rotation speeds quickly wear out the mechanism. The good news is that changing the bearing is easy. Replacing a worn out bearing on an angle grinder must be done on time to avoid a breakdown that cannot be fixed.

In what cases can you save an anchor and restore it yourself?

If damage to the armature is determined with guaranteed accuracy, the part must be removed from the electric motor. Disassembling the motor must be done with special care, after removing the brushes and disconnecting the power terminals. The rotor is removed along with the support bearings and the motor cooling impeller; they form a single whole with it.

If most of the wiring in the armature is damaged and the balancing is disrupted as a result of overheating, it is better to replace it entirely. An imbalance is indicated by increased vibration and an uneven hum when the mechanism operates.

How to rewind an anchor - step-by-step instructions

If the balancing of the armature is not disturbed, and the problem is only in damaged windings, then such an armature can be restored independently by rewinding the coils. Rewinding a rotor at home requires a lot of patience and accuracy.

The technician must have skills in working with a soldering iron and instruments for diagnosing electrical circuits. If you are unsure of your abilities, it is better to take the engine to a workshop for repairs or replace the entire armature yourself.

To rewind the anchor yourself you will need:

- wire for a new winding. A copper core with a diameter exactly matching the old conductor is used;

- dielectric paper for insulating the winding from the core;

- varnish for filling coils;

- soldering iron with tin-lead solder and rosin.

Before rewinding, it is important to count the number of turns of wire in the winding and wind the same amount of new conductor onto the coils.

The rewinding process consists of the following steps:

- Dismantling old windings. They must be carefully removed without damaging the metal body of the armature. If any burrs or damage are found on the body, they must be smoothed out with a file or sanded with emery. Sometimes, to completely clean the body of slag, craftsmen prefer to burn it with a torch.

- Preparing the collector for connecting a new wire. There is no need to remove the manifold. You should inspect the lamellas and measure the resistance of the contacts in relation to the housing with a megger or multimeter. It should be no more than 0.25 MOhm.

- Removing old wiring on the manifold. Carefully remove the remaining wires and cut grooves in the contacts. In the future, the ends of the coil wires will be inserted into the grooves.

- Installation of sleeves for anchors. The sleeves are made of dielectric material 0.3 mm thick, for example, electrical cardboard. Cut a certain number of sleeves and insert them into the grooves of the cleaned anchor.

- Rewinding reels. The end of the new conductor is soldered to the end of the lamella and wound in successive circular movements, counterclockwise. This laying is called “laying to the right.” Winding Repeat for all coils. Near the collector, tie the wires together with a thick thread of cotton fabric (it is prohibited to use nylon, as it melts when heated).

- Checking the winding quality. After laying all the windings, check with a multimeter for the absence of interturn short circuits and possible breaks.

- Finishing processing. Treat the finished coil with varnish or epoxy resin to secure the winding. In factory conditions, the impregnation is dried in special ovens. You can do this at home in the oven. As an option, use quick-drying varnishes for impregnation, applying the coating in several layers.

Why won't the grinder turn on?

Most angle grinder problems are related to the electrical part. The tool may not turn on for the following reasons:

- the cable is damaged or the plug is faulty;

- the start button is faulty;

- severe wear of the brushes or lack of contact between them and the cable;

- failure of the rotor or stator windings is the most serious reason why the grinder does not start.

It is advisable to solve problems with an electric motor in a specialized workshop that employs qualified specialists and has modern diagnostic equipment and repair tools.

Features of the asynchronous motor of the angle grinder

Almost all electrical appliances used in everyday life use an asynchronous electric motor. An important advantage of this type of motor is that when the load on it changes, the speed does not change. This means that if, for example, you cut stone for a long time and without stopping with a household grinder, there will be no noticeable external signs of engine overload. The disk rotation speed will be constant, the sound will be monophonic. Only the temperature will change, but this may not be noticed if your hands are wearing gloves.

If you are not careful, an advantage can turn into a disadvantage. Asynchronous motors are very sensitive to overheating; a significant increase in operating temperature entails melting of the insulation on the rotor windings. At first, the motor will work intermittently, and then - when an interturn short circuit occurs - the motor will stop completely. If you overheat the grinder's engine several times, it is most likely that the anchor will melt. In addition, the high temperature causes the contacts connecting the wires of the primary winding to the collector to become unsoldered, which leads to an interruption in the supply of electric current.