The formation of openings in walls, partitions, panel structures and other structures may be required for a variety of purposes. But even a small-diameter installation passage can cause many problems during the creation process. Especially when it comes to solid building materials: brick or concrete. When working with soft surfaces, not everything is clear either. In such cases, traditional hand tools are used to drill holes. However, the work process itself requires skill and care, since the risk of deformation of the areas adjacent to the processing site increases. One way or another, each case involves its own drilling nuances, which should be examined separately.

In what cases are drilling operations used?

The areas of application of technical devices and equipment for creating holes by drilling are quite extensive. First of all, we are talking about repair and installation operations, during which builders create channels for laying communications. Moreover, the size of such holes can vary from 1 to 20 cm. Small passages are necessary for wiring cables of telephone lines, information networks, etc. Such work requires delicacy and high precision. Therefore, it is recommended to use an electric tool for drilling holes, which can be represented by a multi-function drill. Also, the need to create holes may be due to the laying of engineering and communication networks. This group of installation activities includes the installation of water, gas supply, and heating systems.

Types of drilling tools

As varied as the parameters of drilling operations are, the range of tools designed to implement them is equally wide. The classic and most common type of such means is the mentioned drill. By the way, it also suggests several subtypes. For example, there are traditional mechanical drills, corded and cordless versions that can perform tasks away from an outlet. There are also groups of special tools. They are designed to work with specific hardware. For example, a beginner in carpentry may have a question about what is the name of the tool for drilling cylindrical holes for the purpose of further inserting round tenons? For such operations, perkas are used - these are center drills that allow processing even across the fibers.

A separate group presents more powerful devices that work with concrete. Manufacturers offer both manual hammer drills and massive machines-like units for such tasks. The features of such equipment include increased productivity and the ability to form large niches in walls of any complexity. A tool for drilling holes in concrete can perform its tasks thanks to special equipment, which is most often represented by diamond cutting elements.

Wood working tool

In such work, a twist drill is most often used as part of a mechanical drill. With this set you can process not only wooden workpieces, but also plastic and thin metal. Depending on the requirements for the hole parameters, the appropriate drill size is selected.

There are also several types of work items in this category. For example, to obtain large-diameter niches, spoon attachments are used, while for small gaps it is more profitable to use screw or auger devices. Regardless of the type, the tool for drilling holes in wood provides a special cutting pattern. The fact is that the cutting edges process the fibers of the material in such a way that the resulting particles with sawdust are discharged along the screw grooves and do not interfere with the further process.

Advice from the experts

When carrying out work, I advise professionals to pay attention to the following features. They are divided into three categories:

- preliminary (preparatory) stage;

- stage of work;

- compliance with safety regulations.

At the first stage you need:

- select the necessary equipment (machine, electric or hand drill), depending on existing capabilities;

- based on standards and reference literature, determine cutting modes and acceptable types of drills for future operations;

- choose a marking tool (if this is not available, make it yourself);

- select a drill fixation device.

The preliminary stage should end with checking the reliability of the fastening of the drill and the workpiece. If a drill lock is used, its reliability should be checked.

Work on drilling holes must be carried out in strict sequence with the drawn up technological map or technical process. Particular attention should be paid to:

- the drill must be brought to the location of the future hole only after it has reached the specified rotation speed;

- The drill should be removed only while it is rotating (preferably at minimum speed if it is possible to change the rotation speed);

- monitor the cutting process (for example, if the cutting edge does not perform a drilling operation, therefore, the drill material is softer than the workpiece material);

- for drilling non-through holes, it is necessary to provide a clamp or mark that allows you to determine the depth of the passage in the material;

- When working on CNC-equipped machines, it is necessary to control the sequence of operations performed.

An important element when carrying out drilling work is compliance with safety regulations. It requires compliance with the following rules:

- ensuring reliable fastening of all structural elements;

- organizing conditions for removing the resulting chips;

- compliance with the temperature regime (preventing overheating of the drill and workpiece);

- use of special clothing and protective equipment (hands, eyes, open areas of the body);

- there should be no loose elements hanging on the clothing;

- long hair should be tucked into a headdress (this will prevent it from getting wrapped around the rotating elements of the machine).

Using professional advice will allow you to perform the drilling operation efficiently and obtain holes with a high degree of accuracy in the places specified in the design documentation.

Perforation as a type of drilling

It has already been noted that in construction most often it is necessary to create holes with a diameter of several centimeters. Of course, there are exceptions. But perforation even requires working with a tool that provides an accuracy of about 0.25 mm. In such operations, drills are used, the diameter of which on average varies from 4 to 8 mm. Perforation itself is one of the ways to create small but complex holes in large quantities.

Usually a round one is used, but a rectangular processing pattern is also found. The target material is paper and cardboard sheets folded in bundles, and the tool for drilling holes of this type represents a separate group. Basically, special knives are used for such tasks, differing in size, shape of the cutters, perforation steps and other parameters. The drills used have a cutting edge on the outer edge. This makes it possible to make precise holes along the entire length of the channel.

Existing drill designs

Tool factories and companies offer for sale special drills for processing metals, wood, stone, glass and other materials. According to the external structural form, drilling tools can be divided into 9 groups:

- screw (spiral);

- feathers (feathers, perks);

- ring or crown;

- conical;

- centering;

- single-sided, single-edged;

- multi-edge;

- screw;

- special for deep drilling.

This division of drills does not apply to the type of material being processed, but determines only the external structural form and the types of work for which this tool is intended.

It should be noted that turning technology very often involves fixing the drill in a stationary position, and the workpiece itself is rotated. Using drilling tools of various designs and purposes, you can get a smooth through or blind hole, expand an existing one, or deepen it to the required level.

Spiral or screw

The working cutting part of such a tool is made in the form of two longitudinal edges, twisted in a spiral along the central axis. The drill itself consists of a cutting part, a connecting neck and a shank for fastening in a rotating drive.

This is the most common type of drill, which is used in industrial production, construction, repair and household work. The range of produced diameters is from 0.1 to 80 mm. The maximum length of the cutting part is 280 mm. They are mainly used for processing wood, metal and some other materials. The shape and method of sharpening the working tip depends on the area of application.

Feathered or feathered

The name of these drills is determined by their shape in the form of a flat blade, which on the working side has a sharp tip, sharpened for a cutting edge on both sides. To secure the blade in the drill chuck, a round or hexagonal shank is provided. Feather drills are used for drilling large and deep holes in wood and other not very hard materials. The diameter can be from 10 to 65 mm. The length of such a drill can be up to 40 cm.

Annular crowns

The core drilling tool has the shape of a hollow cylinder with a shank for mounting in an electric drive. On the working cutting side there are sharpened teeth, the number of which is determined by the diameter of the drill. To remove chips during drilling, inclined longitudinal grooves are machined on the outer side of the cylinder. Used to make holes in wood, plastic, metal and other materials.

Cone drills

These drills are designed and used for drilling thin sheet materials when another type of tool is not able to provide adequate quality and accuracy. When performing work with a cone drill, preliminary core drilling and centering preparation are not required.

The design of the drills is a flat or stepped cone with two sharpened cutting edges and a shank for fastening in an electric drive. The size of a cone drill is determined by the maximum diameter, which can range from 12 to 36 mm. Using drills of this type allows you to make new holes, as well as grind and expand existing ones. You can read more about them in this article.

Centering

Such drills represent a special group of high-precision tools made of high-speed steel. Centering drills are used to produce center holes with a diameter of 3.15 - 16 mm in particularly strong materials. They are a metal cylinder with a centering guide and two sharpened cutting edges. The presence of a guide shank ensures precise perpendicular direction of the tool when drilling. They are produced in accordance with the requirements of GOST 14952-75 or according to international standards DIN-333A, ISO 866. Read more about them (characteristics and application) here.

Single cut drills

They have only one cutting side, which ensures the highest accuracy when making holes.

Thermal drills or punches

This tool is used for chip-free drilling of metal by friction. This method is used to increase the area of threaded connections of thin workpieces or to install various bushings in them.

Multi-edge

Designed specifically to increase the processing speed of workpieces and for this purpose they have 4 working cutting edges. The shank for fastening can be cylindrical, conical, in the form of a 4- or 6-tagon. The main disadvantage of the design is the complex sharpening technology and the high cost of the tool.

Screw

Designed specifically for drilling soft materials that produce large amounts of coarse chips. The very deep discharge grooves are very good at removing generated waste from the material processing area.

Special tool for deep drilling

When talking about this group of drills, first of all, they mention cannon and rifle tools. These drills are indispensable when it is necessary to drill holes of great depth and large diameters. At the same time, it is necessary to ensure the ability to process very hard materials with high precision, removal of generated chips, and active cooling of the material and tool in the drilling zone.

To this end, most designs have one cutting edge, at least two screw channels for removing chips, and a channel inside the drill for supplying coolant.

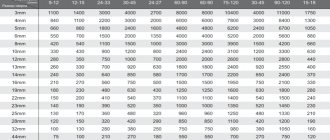

Table of drill diameters of different types

| Tool type | Screw | Feather | Koronchatoye | Centering | Auger |

| Min. diameter | 0.25 mm | 6 mm | 12 mm | 0.5 mm | 6 mm |

| Max. Diameter | 80 mm | 65 mm | 160 mm | 10 mm | 60 mm |

Metal tool

Creating holes in metal workpieces can also be done with punches. Typically, such a tool is used when working with sheet soft material. For thick workpieces, special machines or electric drills are often used. Often there is a need to expand existing holes or only the upper parts. Such recesses may be required for further screwing in bolts, screws and screws with masking heads. For this, either special drills with appropriate attachments or a countersinking tool are used.

A special feature of working with metal is the use of a machine vice that holds the workpiece. For wood, such equipment is not necessary. So, the workpiece is secured between the jaws by rotating a special screw. If a tool for drilling holes in metal in the form of a machine is used in combination with a vice, the locking device can be fixed directly to the working platform. But that is not all. Some models of drilling machines are equipped with locking mechanisms with convenient devices for adjusting the position of the workpiece.

Marking metal before drilling

Before you start drilling metal using different methods, be sure to mark the hole. Using a punch, mark the place on the surface of the product where the slot will be made. In addition to the center punch, a marker can be used. However, this is less convenient, since you will have to constantly monitor the location of the drill at the selected point. The punch makes a small depression at the drilling site. To do this, it is hit with a hammer. The resulting outline will be convenient for further work.

Precision can be increased by pre-drilling. Notches are made on the surface of the workpiece with a chisel, designed to guide the tool towards the hole.

We recommend articles on metalworking

- Steel grades: classification and interpretation

- Aluminum grades and areas of their application

- Defects in metal products: causes and search methods

If it is necessary to produce several holes in workpieces, a template is used. Thus, several sheets of metal are drilled at once, which are connected with a clamp.

A jig is used to make precise holes that must be angled. This is a small strip with templates for holes located on it. Such devices are used in various industries.

Currently, several types of conductors are used, for example:

- universal;

- fastened;

- turning;

- sliding;

- overhead.

Concrete drilling tool

In the processing of concrete and brick walls, equipment is used in the form of electric, hydraulic and other drilling rigs with an impact effect. As already noted, the entry level of this group is a hammer drill. But also modern electric drills in some modifications have the option of connecting impact. Another thing is that the power of such models will be enough only for one-time operations with thin walls. Diamond drilling of holes in concrete is most in demand. The tool for performing such activities is, in essence, a machine to which an electric motor is connected.

The features of such units include three points. Firstly, it is a highly durable design with a housing that ensures reliable installation of the equipment where work is performed. Secondly, there is a power drive, which determines the ability of rather large cutting elements to perform complex drilling operations. Thirdly, these are crowns and drills, which themselves are high-strength diamond parts that require cooling during operation.

Diamond Drilling Technology

There are several types of drilling machines that implement diamond cutting technology. The most common type is the electromagnetic drill. It is equipped with two engines. Direct processing is carried out under the influence of about 3 thousand beats per minute. In this case, the second motor rotates the diamond drill itself, the speed of which is adjusted by the user in accordance with the requirements for the result. Depending on the bit used and the force potential available to the machine, the operator can expect to obtain a hole in the range of 30-160 mm.

Of course, such high performance characteristics also determine the corresponding investments that diamond drilling of holes in concrete requires. A tool whose price is 100-150 thousand rubles can be classified as entry-level. The middle and most common segment is represented by installations with a power of about 2.4 kW, capable of forming holes of about 40-250 mm. Such equipment can be purchased for 200-250 thousand.

How to drill metal correctly

Regardless of whether drilling is performed with a drill or on a machine, the main thing is to choose the right rotation speed. In most cases, the optimal speed is in the range of 1800–2500 rpm, but in practice completely different values can be selected depending on the sharpening accuracy and the properties of the material.

For efficient and fast drilling, you cannot do without the ability to correctly match the rotation speed and feed force. It is easy to feel how the drill cuts into the metal, continuously releasing chips, and itself begins to penetrate into the bottom of the hole without significant effort. The speed is usually quite low - about 300-500 rpm.

The best indicator that the drilling process is technologically correct and the drill is sharpened correctly is the uniform output of chips from both spiral flutes. The quality of the chips is also a significant indicator:

- when drilling steel, solid chips are released in the form of long spirals;

- cast iron, hardened steel and other brittle materials form a scattering of needles;

- aluminum is drilled to form short curls;

- When drilling stainless steel, dust and small flakes can be produced.

Correct chips when drilling metal

If the drill does not cut into the metal, but rubs against it with a characteristic squeak, or an atypical type of chip is formed at the exit, it is better to stop and correct the sharpening, otherwise there is a risk of the metal releasing from overheating or breaking the working part.

Be sure to follow safety precautions! You should drill without gloves, protecting your eyes with locksmith goggles.

Before you start drilling, you need to mark all the holes that need to be made in the part. The center of each hole should be marked with a center punch. First, a small hole 2–3 mm deep is drilled, and a few drops of machine oil are added into it. You need to learn to let the drill do its job: first press the tool firmly, and when the edges cut into the metal, release the pressure and just press lightly, maintaining a uniform rotation speed.

Other coolants can be used instead of oil. So, when drilling stainless steel, the drill must be moistened with oleic acid. Its fumes are harmful, so you need to wear a respirator when working. Kerosene and soapy water are also good for cooling - a liter of household bar.

Particular attention is required at the moment the drill comes out when drilling through holes. Quite often in such cases, the thin bottom breaks through with the formation of large burrs, which fall into the spiral grooves and pull the drill forward. At the exit from the part, you need to loosen the pressure and slightly increase the speed.

Drilling metal with a crown

It is better to drill holes of large diameter in several stages, gradually increasing the diameter of the drill. This will not only reduce the stress on the tool, but will also extend the life of the sharpening and ensure a clean finish. Holes with a diameter of over 13 mm are best drilled using crowns. It is recommended to use grease instead of oil, this will reduce splashes. The bit must be periodically allowed to cool down, and during operation, carefully ensure that the teeth are immersed evenly, in other words, keep the spindle strictly perpendicular to the surface of the part.

Drilling instructions

Work begins with preliminary marking of the work area where drilling will be carried out. Depending on the tool, marking the cutting point can be done with a pencil, marker or using a core. Next comes the preparation. At this stage, you should check the integrity of the housing and the reliability of fixation of the working element. And if we are talking about an electric model, then it is necessary to evaluate the quality of the network connection. When the hole drilling tool is ready for use, the operation can begin. Experts do not recommend applying excessive force to provide mechanical impact on the workpiece. Especially when it comes to wood.

Metal drilling devices

Various methods of drilling metal involve the use of cutting fluids. In most cases, they are used to reduce friction and equalize the temperature of the surface being processed and the tool. Good quality coolant will not cause corrosion, it is completely safe to use, it has no odor, and fully performs its function.

As a lubricant for drilling metal workpieces at home, you can take:

- Technical Vaseline - used primarily for drilling soft materials.

- Soap solution - used for aluminum parts.

- Turpentine with alcohol is used for silumin.

- A mixture of various oils is applied for processing steels (tool or alloy).

Sometimes a fairly universal lubricant composition is used, which is made from a mixture of laundry soap (200 g) and motor oil (20 g), followed by boiling to an emulsion.

There are industrial coolants. Their use makes it possible to increase the speed of work with different types of metal. Working with stainless steel is 30% faster. With cast iron the growth is even higher – 40%.

Ways to prevent drill overheating

A powerful and productive tool is usually equipped with automatic means of supplying water to the cutting head. This allows you to protect equipment from overheating and extend the service life of the same crowns. However, the tool for drilling holes does not always include such technological solutions in its design. This usually applies to machines that work with diamond elements, which quickly enter a high-heat stage. In other cases, for example, when working with a hammer drill, it is recommended to provide a separate container with cold water. The liquid can be used to wet the nozzle as the work progresses.

Tips for drilling different materials

When working with wood, you should use a mechanical hand tool in the form of a drill or a brace. Typically, the stop is pressed with the left palm, and the operator rotates the handle with the other hand. In this case, the direction of movement is clockwise. As the process is completed, the pressure should be reduced, which will allow the formation of the most even cut along the edges. Working with metal is greatly simplified through the use of automatic machines. In this case, the user only needs to correctly install the workpiece in a vice and adjust the unit to suitable drilling parameters. The main work with diamond drills occurs at the preparation stage. Reliable fixation and adjustment of the cutting elements is the main thing that a tool for drilling holes in concrete requires from the user.

The types of attachments for such equipment are very widely represented and differ in different ways. Therefore, it is important to decide on this part of the preparation. Diamond drills exist in sizes from 8 to 16 mm in diameter. Depending on the requirements for the hole, one or another nozzle is selected. Next, the characteristics of the drill are taken into account in terms of its ability to cut concrete. Manufacturers produce such elements specifically for working with concrete grades M250-M500.

Hole press

One of the common methods is punching using a special press. It happens like this:

- First, the workpiece is placed on the press table and grabbed by several clamps.

- The metal is then moved under the punching tool. At this stage, additional fastening of the material occurs using a clamping ring.

- At the last stage, penetration occurs using a punch.

The revolver can have several nozzles of different diameters, which allows you to quickly create holes of different diameters. Such equipment is usually not used for working with metal in domestic conditions.

If you plan to do the work at home, you should choose a universal tool. This will allow you to easily process metal without worrying about purchasing additional parts. The video presented will introduce you in detail to the technology of the process.

We also recommend reading:

Metal processing is one of the rather complex operations. Drilling may be required when repairing premises or your own car, as well as manufacturing various structures on a summer cottage. As with any other holes, we will need a hand drill, which can be supplemented with various additional devices. Although a drill is a very popular and in-demand tool, available in almost every home, it requires considerable experience in metal processing. In our article we will talk about metal drilling, drills and some of the features of this labor-intensive process.

Drilling holes in metal is a special technology that involves removing a certain layer of material due to the simultaneous rotational and translational movement of the drill. It is necessary to fix the drill in one position so that the drill does not move during operation. This is the main condition for the correct and safe performance of work. To ensure that the drill axis is in a fixed position, you can use one of the many devices, which will be discussed below.

When working with metal, drills made from R6M5 steel are used.

We will need the following tools for working with metal:

- Hand or electric drill

- Twist drill

- Hammer

- Kerner

- Safety glasses and gloves

It will be impossible to achieve success in the planned event without the appropriate drill. The choice of this element is a very important point, because different drills are selected based on the properties of the metal, as well as the diameter of the future hole. Drills are usually made from high-speed steel. The most common are products made from steel grade R6M5. In some cases, cobalt additives are used to increase the durability and wear resistance of the drill. In this case, the letter K appears in the product labeling. For very hard metals, drills are used that are equipped with a small solder on the tip, which ensures the required level of drilling of the material.

You should know that not all drills are capable of making exactly the holes that you need. Thus, the manufacturer usually indicates the relevant information in the instruction manual. For example, drilling a large diameter hole with a drill whose power is 700 W will not work. After all, this equipment is designed to create a hole with a maximum size of 13 mm in diameter.

Read also: Cold and hot welding of cast iron

Drilling metal causes difficulties for many people, even experienced craftsmen. One reason is the physical complexity of the process itself. After all, it is necessary to hold a heavy drill at a right angle in a clearly fixed position for a long time. However, you can always use additional devices designed to make the whole process easier.

Drilling guides allow you to securely fix the drill bit

In hardware stores you can purchase the following mechanisms for perpendicular drilling of holes in metal products:

- 1. Drilling jigs

- 2. Drill guides

- 3. Drill stands

Conductors are extremely popular; it is with their help that specialists make holes in products. The mechanism itself is a kind of box, convenient to hold, in which guide bushings are located. Suitable for working with drills of various diameters. The bushings are made of very hard types of metal, much harder than the drill itself. Therefore, there is no need to worry that they will be damaged when working with a drill.

You just need to place the jig over the location of the future hole, previously marked with a center punch, and then turn on the drill. The drill will be firmly fixed by the bushings, so it will not move away from the given direction. The jig is considered especially useful when drilling cylindrical shapes, for example, pipes, since the tip of the drill constantly slides off the round shape of the pipe.

You can also purchase guides for a hand drill - this is a useful support mechanism where the drill is fixed by the neck to achieve immobility during operation. The sole, held by the free hand, is installed on the workpiece itself. In this state of affairs, the tool moves exclusively vertically, without the slightest deviation or distortion.

Today, universal designs are produced, equipped with a corner holder. Thanks to this, you can drill holes with a drill even at an angle. True, in the case of metal, drilling at an angle using guides is very difficult, since lateral overloads almost immediately break the drill. Therefore, you need to take care when purchasing a product made of solid metal.

Another device that simplifies the hole making process is called a stationary stand. At its core, this equipment is a somewhat simplified drilling machine, albeit with less functionality, but also significantly lower cost. The drill moves along the rod using a lever. Clamps or a vice are used to secure the workpiece. In terms of drilling quality, this unit is an order of magnitude higher than its other competitors. However, its price is also higher compared to jigs or guides.

The process of drilling holes in metal products differs significantly depending on the thickness of the workpiece. Deep holes are much more difficult to make compared to regular ones. For such cases, specialists use lathes, and it is the workpiece that must rotate, and not the drill itself on the machine. An important point is the removal of waste and chips from the part, as well as cooling the drill.

When drilling deep holes, timely removal of chips is important.

Naturally, it is unlikely that you will be able to use a lathe at home. The only way out is to purchase drill guides, which were described above. The length of the drill is important because the drill can only make holes two-thirds of its way. So you need to purchase a long drill, but strong enough that it will not break under the influence of enormous overloads.

If there are no guides, you can try to drill without this equipment if you are confident in your abilities. However, it is strictly forbidden to change the drilling angle, as this can completely damage both the drill and the workpiece.

In no case should we forget about cooling and chip removal. The easiest way is to use soapy water, in which you should first dip the tip of the drill. Some experts recommend coating the drill with vegetable oil or lard. This will significantly reduce the friction of the product on the metal and, as a result, will have a very positive effect on the cooling of the drill.

If we talk about extracting chips, then this must be done with regular frequency, periodically removing drilling waste. The easiest way is to turn the workpiece over so that the chips, under the influence of gravity, free the hole. If the product is very heavy, then improvised devices are used, including hooks or magnets. Otherwise, the chips can clog the grooves on the drill, which will subsequently lead to blocking of rotation, as well as to breakage of the drill.

Drilling a large hole in metal is even more difficult than making a deep hole. There are several approaches: either use a conical drill to make a large-diameter hole in the metal in several approaches, or use a special crown. The cost of cone drills is very high, while the efficiency is lower than that of a crown.

That is why experts say that it is more correct to drill metal using a crown. In the central part there is a drill, while at the edges there is a cutting surface with sharply sharpened teeth. Thanks to the drill, the crown is fixed in one position and does not move during operation. Drilling is carried out at low speeds of the drill, and everything must be done very carefully and carefully so as not to damage the crown.