Many owners of country houses are interested in whether it is possible to make a septic tank on clay. The main problem with constructing a treatment plant on this type of soil is that pre-treated wastewater, after passing through the septic tank, is discharged into the ground, and the clay does not allow and filter water well. However, even on clay soil, an autonomous treatment plant can work effectively and for a long time if it is properly designed. In our article we will look at different types of septic tanks that can be made on clay soil, as well as the features of their design and choice.

Features of clays and loams

A septic tank for clay soil should have some design differences from conventional devices. To understand how a septic tank works in clay, you need to remember how conventional treatment plants work: first, the wastewater enters the sump, being divided into light and heavy fractions, and then the purified water enters the soil, where final purification occurs. To organize soil cleaning, filter wells are used, the design of which includes perforated walls and a drainage bottom. But the performance of such a system depends on several factors: laying depth, wall area, soil water level and the type of soil prevailing in the area.

The last indicator must be considered in more detail, since the efficiency of the entire structure depends on it. For example, one square meter of sandy soil can absorb about 90 liters of liquid per day.

In sandy loam soils this volume is reduced to 50 liters; loamy soils can process no more than 25 liters. In the case of dense clay soil, the situation is even worse: the soil can absorb more than 5 liters of water per day. That is why a septic tank on clay is constructed somewhat differently than conventional structures. You also need to know what to do if your septic tank stinks. There are many drugs and remedies to solve this problem.

Advantages of MAPLE septic tanks for clay

Autonomous sewage system for a dacha KLEN has a number of advantages over analogues:

- Simple maintenance that is done every 1-2 years. It is enough to clear the container of sludge. Many gardeners pump out the contents of the container with a fecal pump into a compost pit, subsequently using it as a basis for fertilizers;

- long service life. After installing a septic tank, you will not have to worry about sewerage for several decades. The MAPLE septic tank will serve you for 40-50 years;

- ease of installation. If you wish, you can install it yourself. True, in some cases it makes sense to turn to specialists. High groundwater levels and clay soil require very careful and sealed installation;

- everything is seasonal. Preservation is not necessary, the septic tank can be used all year round;

By choosing MAPLE, you choose the safety and comfort of your loved ones!

Filtration in clay soil

As a rule, the layer of clay soil rarely has a thickness of more than 2-3 meters. This can be noticed when constructing a well: under the upper layers of the earth’s surface you will find sandy loam soils, or even clean sand, which has an excellent water absorption rate. In this case, the well will work much better than it could work in homogeneous soil: the water column will create high pressure.

When choosing a suitable solution, you should first study in detail the types of soil located on the site. You can find out from the old residents of the area, neighbors who have recently carried out construction work, or order a geological survey. The latter option will have maximum accuracy, and there is a point in studying the geology of the site: making a septic tank in clay is much easier and cheaper than purchasing a ready-made biological treatment station, which is only good for the most difficult situations.

Structurally, a septic tank on clay soil can be made in any way: you can install a plastic, brick, reinforced concrete or concrete system. Clay soil does not affect the choice of material at all, so this issue rests entirely on the shoulders of the homeowner, and depends on personal preferences and the amount of finance allocated for construction. Quite often, concrete rings for sewerage are installed with your own hands, which allows you to reduce costs.

Calculation of the number of filtration wells on the site

The number of wells is determined by the amount of water consumed during the day. One septic tank is usually equipped with 2-4 wells. Meanwhile, the volume of the septic tank itself should be three times the daily water consumption. For example, if one person consumes up to 250 liters of water per day, then a family of 4 people will need a septic tank with a volume of more than 3 m3.

The amount of load per 1 m2 of a filtration well is calculated taking into account the type of soil (for sand - 80 liters, for sandy loam - no more than 40). If the distance from groundwater to the well bottom exceeds a distance of 2 m, then the load can be increased by 20 percent. It is also possible to provide for an increase in load at dachas, when wells are usually used only in summer.

Watering

If there is good fertile black soil on the site, you can reuse water purified by a septic tank to water the plants.

To implement such a project, you will need to make the following design: the filter well must be replaced with a sealed tank to which a drainage pump is connected. This pump will supply purified liquid to the irrigation system. This septic tank design is well suited for summer cottages, but it is not practical to use it in country houses where people permanently live. Another disadvantage is the low degree of purification, as a result of which the treated wastewater has a characteristic sewer smell. To avoid this problem, you will have to use a septic tank with aeration.

Types of septic tanks for country houses

You can build various types of septic tanks at your dacha with your own hands. All types of containers for the sewer system can be divided according to different criteria. According to the principle of operation, septic tanks built by yourself can be classified into:

If there is a well with drinking water on the site, then the septic tank should be located at least 30 meters from it.

- storage tanks;

- septic tanks for deep biological treatment;

- septic tanks with a system for soil filtration.

It is customary to divide sewage tanks according to materials of manufacture:

- brick;

- monolithic and prefabricated septic tanks made of reinforced concrete;

- metal in the form of barrels;

- plastic modern PVC containers.

Based on their shape and installation, septic tanks can be divided into vertical and horizontal. There is a division by type of chamber (surface and underground). According to the principle of operation, septic tanks can be divided into:

- two-chamber septic tanks that process wastewater daily;

- storage septic tanks;

- septic tanks with soil treatment;

- with biological deep cleaning.

Filtration field

Sometimes even the densest soils demonstrate good absorption qualities. Of course, this does not always manifest itself, but if a soil analysis has shown that it can absorb at least a small amount of water, then you can take advantage of this and increase the absorption area. To implement this idea, filtration fields are used.

The structure is prepared as follows:

- first, the entire free area allocated for the structure is filled with crushed stone;

- then drains with holes of at least 2 cm in diameter are laid on it. The length of the pipeline in this case depends on the number of permanent residents: one person requires about 10 meters of pipe;

- then the pipeline is covered with at least a 10-centimeter layer of crushed stone;

- A layer of black soil is laid on top, on which moisture-loving plants can be planted.

This solution is quite convenient: in this case, little depends on the degree of wastewater treatment, because the smell will not be able to escape. In addition, if the depth of the pipes is more than 40 cm, then the sewer can be used even in winter, since the pipeline will not freeze. The disadvantage of the design is the impossibility of using it on soils that are completely impermeable to water.

Dumping into a ditch

In the case of soils that do not absorb moisture at all, you can dispose of wastewater directly onto the site or into a special ditch.

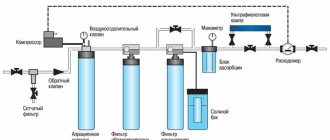

Naturally, such a system implies maximum wastewater purification (from 95%) and absence of odor. To implement the design, it is best to use energy-dependent septic tanks using aeration. Similar treatment plants operate on similar principles:

- the first tank constantly contains air, which supports the vital activity of aerobic bacteria that decompose organic substances entering the septic tank;

- Having passed the aeration stage, wastewater enters the next compartment, where the sludge sinks to the bottom and is transferred to the first container using a compressor;

- final purification is carried out in the third chamber, from which the purified water is pumped out and ends up in a ditch or large area from which it can evaporate.

Conclusion

As you can see from this article, a septic tank in clay soil is not a big problem. The main thing is to correctly understand the characteristics of the site and choose the most suitable design that best suits the specific situation.

Mechanical cleaning

It is also called the goldsmith method. To carry out this type of sludge removal, you need to prepare a fecal or drainage pump, a brush for cleaning the pit, a reservoir for pumping out liquid (you can dig an additional pit) and a hose of the required length (for immersing the pump).

Step-by-step instructions on what to do if a sealed cesspool or septic tank has silted up:

- A fecal or drainage pump is lowered into the tank containing waste. Pay attention to the type of device you are using. Depending on the type of equipment chosen, immersion can be made to the bottom of the pit or to the upper wastewater line. For better pumping results, we recommend purchasing a fecal pump with a grinder;

- A hose is pulled from the cesspool to the drain (additional pit) tank;

- When the pit is completely cleared of liquid waste, the process of mechanical cleaning of the bottom and walls of silt and fatty deposits begins. Depending on the level of siltation, brushes with metal tips, buckets, or hired workers are used for this;

Cleaning sludge with buckets - Remains of solid accumulations are removed from the bottom, after which the pit is filled with clean water. The first stage is repeated - pumping and recycling of water. To enhance the cleaning effect, you can add chemical reagents (nitrates or ammonium) to the pit.

If you don’t want to clean the sludge in the pit yourself, use the services of a vacuum cleaner. Most professional machines are equipped with suction pumps. This is a device designed to remove silt deposits.

Professional sludge sucker

How the process of pumping out a pit with a sludge sucker occurs can be seen in the video below: https://www.youtube.com/watch?v=5xsM09hkwvo

Advantages of mechanical cleaning:

- You can do it yourself;

- Suitable for cleaning concrete, metal and stone structures;

- Affordable and highly effective.

Disadvantages of this method:

- Will not help get rid of unpleasant odor;

- Manual cleaning is not acceptable for plastic and open cesspools;

- There is no long-term effect.