01/21/2019 Author: VT-METALL

Issues discussed in the material:

- What is grinding of metal surfaces

- What are the main types of grinding of metal surfaces

- How to prepare metal for grinding

- Where can I order metal surface grinding?

Today there are countless methods of metal processing, characterized by the use of various types of equipment. One of the most common finishing methods is sanding. The operation itself is the process of removing part of the surface layer to achieve the optimal degree of roughness and give the part an exact size. We will talk about how metal surfaces are grinded in this article.

What is grinding of metal surfaces

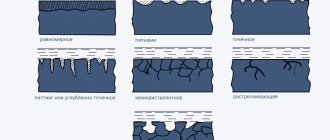

In the process of creating the required part, the material is subjected to various influences, which do not go unnoticed for the product - various defects inevitably form, such as scratches, slag residues and traces of heat treatment. Therefore, in order to ultimately obtain a perfectly smooth and beautiful metal surface, the part undergoes a grinding process.

Flat grinding of metal is not carried out on surfaces that have defects such as deep scratches or scratches - in this case they cannot be removed in this way.

The grinding process itself involves cutting the surface of a product using an abrasive tool, most often a grinding wheel consisting of many abrasive grains. When the wheel rotates, the edges of the cutting grains remove small chips from the surface of the workpiece.

The grinding process itself has some features that must be remembered when carrying out it:

- The cutting speed must be high.

- Grinding occurs with metal shavings of a special type.

- The shape of the cutting grains of the circle should be multidirectional.

- The temperature at the point of contact with the surface is high.

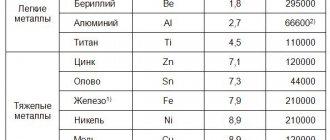

Metal surfaces subjected to grinding are classified according to the degree of difficulty in processing. Thus, the inner and outer regions of the cylinder and flat surfaces are considered simple. Helical or involute - refer to complex surfaces.

The essence and features of the process

Metal grinding is the processing of metal and alloys using abrasive materials, which allows you to correct uneven metal surfaces and smooth out roughness. For this purpose, special industrial and manual equipment is used.

Process Features:

- During grinding, using special equipment, the metal surface is brought to a certain degree of roughness.

- This is the final stage, which is not used to correct serious defects or remove a large layer of material.

- For faster and more efficient grinding, the metal is initially heated.

During the final stage of work, many features are taken into account.

Main types of grinding of metal surfaces

A wide variety of technologies are used for the grinding process, and in this article we will look at the most common of them. Let's talk:

- about cylindrical grinding of metal;

- about changes in the roughness of internal surfaces;

- about gear grinding;

- about the essence of centerless technology;

- about grinding flat surfaces.

Technologies are also classified depending on the type of material used when grinding the metal surface. Today, the process has been significantly simplified through the use of special machines, for example, CNC. Their use significantly reduces labor costs and maximizes the quality of the final product.

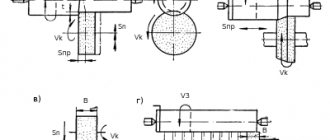

- External cylindrical grinding.

To use this technology, special equipment is required. The following features of this type of grinding are distinguished:

- The part is processed using an abrasive wheel rotating at high speed.

- To maximize the efficiency of the grinding process, the workpiece itself rotates in the opposite direction simultaneously with the wheel.

- To change the depth of penetration of the tool and ensure the ability to process the part along its entire length, the feed can be carried out both longitudinally and transversely.

Due to the fact that at the moment of rotation the entire surface of the metal workpiece is processed, which ensures the necessary uniformity, this method is often used for processing cylindrical parts.

- Internal grinding.

If it is necessary to process a cylindrical workpiece from the inside, then this technology is used. It differs from the previous method in that the abrasive wheel grinds the part from the inside of the cylinder.

The features of this technology are:

- obtaining transverse and longitudinal feed by the tool and workpiece;

- what basically rotates is the abrasive wheel.

For maximum processing efficiency, coolant is supplied to the grinding zone.

- Gear grinding.

This method is used for grinding gears, which are components of a wide variety of mechanisms. Due to the complex shape of the surface being processed, special grinding equipment is required in this case.

When using this grinding method:

- the profile of the ring gear is processed;

- the circle is changed to the size of the tooth involute;

- special machines are required.

Since in the vast majority of cases the teeth are hardened, the grinding process becomes much more complicated.

- Centerless grinding.

With this kind of grinding, the workpiece is not fixed in the centers. The peculiarity of this technology is that the part is processed using two rotating grinding wheels, between which it is placed. To prevent the workpiece from falling through or jamming due to displacement, there is a stainless steel knife in the center.

Such equipment, due to the use of two abrasive wheels at once, greatly speeds up the grinding process. On sale you will find a huge number of machines, the basis of which is the principle of centerless grinding.

- Sanding flat surfaces.

Flat housing parts made of various metals are most often subjected to this treatment. Features of this grinding:

- The part is placed on a special table, which ensures reliable magnetic or mechanical fastening.

- The abrasive wheel performs the main rotation, and the part or tool performs the reciprocating rotation.

By choosing a wheel with a suitable profile, you can process parts of the most complex shapes. To avoid overheating and warping when grinding metal surfaces, coolant should be supplied to the contact point between the workpiece and the tool.

Application area

Wet mechanical polishing is more effective than dry polishing, but requires more time and money. Dry methods are used for processing interior elements and facades, wet methods are used in shipbuilding, mechanical engineering, and the production of components for the chemical, pharmaceutical and food industries.

Machine machining is used for large parts with complex profiles. Wheels are used for polishing bodies of revolution. Enterprises install machines with regulators that allow changing rotation speeds.

Chemical polishing allows you to obtain parts covered with a shiny film that lasts throughout its entire service life. Precision instruments and parts for them, headlights, reflectors and other small parts that cannot be processed mechanically are subjected to electrochemical processing.

Treatment of metal surfaces before grinding

Grinding is the last stage of part processing. Before this, the following actions must be carried out:

- Rough turning of metal.

At this time, the workpiece acquires the required shape and size, taking into account the allowance. - Finish turning.

It is required in order to give the part the desired size. - Milling.

This technological process is necessary for mechanical removal of metal. Typically gears and housing parts are processed. - Heat treatment.

Through hardening, the surface hardness and strength of the part are increased, and through tempering and annealing, the fragility of the metal structure is reduced. Sometimes thermochemical treatment is also required, that is, certain chemicals are introduced into the surface layer.

When developing processing modes, it is necessary to take into account allowances for all operations of the technological process.

Processing parts before grinding

Polishing a metal surface can only begin after preparation has been completed. First of all, the part is cleaned of rust, scale, and drops remaining after welding. You can use metal brushes for this. After this, rough chips, dents and bumps are corrected. After rough processing of the metal, the milling process takes place. A layer of metal is mechanically removed from the workpiece.

When processing on industrial equipment is completed, it is necessary to harden the metal. Annealing increases the strength of the part. Metal is often enriched with various chemicals that improve its characteristics.

Before grinding, you need to check the part for visual defects and inspect it for irregularities.

Marking and characteristics of abrasive tools

For high-quality grinding of metal surfaces, an abrasive tool is used, represented by a combination of a large number of grains bound with a special lubricant.

The circle is characterized by the following parameters:

- Form.

Can be changed depending on the surface to be treated. - Size.

It depends on the dimensions of the surface intended for processing. - Material type.

The circle can be made from crumbs of various hardnesses. The most resistant to abrasion is the one made from diamond chips. - Grain size.

For finishing grinding, use a wheel with the finest grain. But keep in mind that the finer the grit of the tool, the more time it takes to process the workpiece. - Surface hardness.

Is one of the main parameters. Usually indicated on the label. - Mounting hole size.

It is kept in mind when a wheel is selected in accordance with the parameters of the machine.

Abrasive materials are manufactured in accordance with GOST and technical specifications.

The type of material used in the manufacture of the abrasive wheel is indicated in the marking. For example, electrocorundum is an artificial corundum based on aluminum oxide. There are the following types of circles on sale:

- 14A, 15A, 16A – normal.

- 22A, 23A and 24A – white.

- 32A and 33A – chromium.

- ES – spherocorundum.

Silicon carbide of two grades can also be used: black and green. Boron carbide is labeled as KB. Currently, the most popular circles are made of synthetic diamond, which are marked ACP and ASO, ARV and ARK.

Abrasives can be made from natural or artificial materials. Natural ones are less in demand due to their unstable physical and mechanical properties. Artificial ones can be used for a long time.

Advantages and disadvantages

Mechanical and chemical polishing is not suitable for large enterprises, since the process cannot be automated. The machines are expensive, and it is difficult to obtain a mirror surface. But there are also advantages. The use of chemicals makes it possible to process the material in a few minutes, with little manual labor. The surface quality does not depend on the configuration of the part. But it is necessary to take into account that most solutions are toxic and short-lived.

Electrochemical polishing is more effective, resulting in an electroplated surface that is more durable than the base material. Disadvantages include high energy costs, dependence of the result on the quality of the composition and its temperature.

The most effective and environmentally friendly method of polishing is ultrasonic. No toxic solutions are needed, the process is completely silent, and is suitable for particularly hard alloys for which other methods are ineffective. This greatly simplifies the technological process.

Grinding and polishing metal surfaces at home

The file leaves noticeable rough marks on the metal from the cut teeth. The metal surface becomes clean and smooth after grinding and polishing.

At home, you can sand the metal using emery cloth, after first treating the surface with a file. For greater convenience, we recommend wrapping the sandpaper around a wooden block or a wide file, while holding the ends of the sandpaper with the thumbs and forefingers of both hands. If you need to sand a convex cylindrical surface, wrap the sandpaper around it.

First, the surface of the workpiece is treated in different directions with coarse sandpaper, then finer sandpaper should be taken. Finishing sanding is done in one - longitudinal - direction and with the finest-grained sandpaper. Keep in mind that the part must be securely fastened.

If you need to achieve a mirror finish, then polish the part after sanding. Surfaces that you have already carefully treated with a personal or velvety file can be polished without preliminary sanding. Rub the file with chalk. First treat the surface across the strokes on it. After the strokes along and across are the same, change the direction to 90°. Repeat this several times. Then polish such a treated surface, as well as the grinding surface, using special polishing pastes.

The most common brand of polishing pastes is GOI. They contain: fine abrasive powders (chromium oxide, iron oxide, etc.), soft plastic substances consisting of wax, stearin, kerosene and other materials.

We recommend articles on metalworking

- Steel grades: classification and interpretation

- Aluminum grades and areas of their application

- Defects in metal products: causes and search methods

GOI pastes come in coarse (almost black), medium (dark green) and fine (light green). First, the surface of the product is polished with a coarse paste. It makes it matte. Then it is polished with a medium-hard paste, and finished with a fine paste to a mirror shine.

To polish the surface of the workpiece, use a felt swab, cloth or linen rag.

By the way, you can prepare the polishing paste yourself. So, for polishing steel products the following composition is used (in parts by weight):

- chromium oxide – 80;

- stearin – 32;

- beeswax – 6;

- technical lard – 5;

- lead oxide – 3.

If you want to polish brass or nickel-plated surfaces or make them glossy, use the paste (in parts by weight):

- chromium oxide – 14;

- stearin – 5;

- technical lard – 1;

After polishing, wipe the part first with a rag soaked in kerosene, and then dry with a clean rag.

Creation proportions

A paste is most often applied to a metal polishing cloth. Most pastes contain 60% abrasive, 40% binder and 2% process activating additive.

Various compounds are used in chemical processing:

- 2/3 hydrochloric acid, 1/3 sulfuric acid and dye;

- 30 parts of phosphoric acid, 5 parts each of hydrochloric and nitric acid, 0.5 parts each of disodium acetic acid and sulfosalicylic acid, 1 part glycerin, 0.1 part benzyl alcohol;

- 20-30% phosphoric acid, 4% hydrochloric and 4-5% nitric acid, 1.5% methyl orange, the rest is water.

The first solution is heated to 70°C; three minutes are enough for processing. The temperature of the second mixture is 80°C, the processing time is 3 minutes. The third solution is heated to 25°C, the part is kept in it for 5-10 minutes.

Solutions for electrochemical polishing:

- 730 g phosphoric and 700 g sulfuric acid, 4-6 g triethanolamine, 1 g catapine;

- orthophosphoric and sulfuric acid in a ratio of 65% to 15%, 12% glycerin, 5% chromic anhydride, water.

Where can I order metal surface grinding?

If you need perfect polishing of a large number of metal products, contact the professionals. In the modern metal processing market, many enterprises will offer their services to you. But don’t rush to make a choice; first, thoroughly study the activities of the company you like, read reviews about its work. It is worth choosing trusted specialists, since metal grinding is a process that requires considerable experience and knowledge.

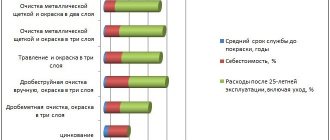

Disadvantages of traditional types of metal polishing

The first three of the listed methods for treating metal surfaces have a number of application limitations. The main limitation for a number of industrial enterprises is the impossibility of automation when using mechanical, chemical or electrochemical methods for processing the surfaces of products in large batches of mass production.

Difficulties in using traditional types of metal polishing have both economic and technological reasons. Economic difficulties are associated with the high cost of production robots and CNC machines. The technological reasons for the difficulties in using traditional types of metal finishing are associated with the difficulties of building a fully automated production process. The forced use of manual labor at the stage of polishing products, activating the surface or cleaning it does not allow for the smooth operation of industrial automated lines. Often, due to the use of outdated metal processing methods, the production line takes the form of a conveyor, which significantly increases the cost of production and ultimately negatively affects the competitiveness of the products produced.

Comparison of types of metal polishing

| Mechanical polishing | Chemical polishing | Electro-chemical polishing | Electrolytic plasma polishing | |

| Performance | Average | Low | Average | High |

| Geometry limitation | Simple profile | Complex profile | Complex profile | Complex profile |

| Change material | Susceptibility to foreign particle intrusion | Uneven processing, etching | Poor finishing of flat surfaces | It is possible to strengthen the material |

| Difficulty of processing | Average | Average | High | Average |

| Possibility of automation | No | No | Eat | Eat |

| Material costs | High | High | High | Low |

| Installation depreciation period | 25 years | 5 years | 20 years | 25 years |

| Occupied production pl. | Small | Average | Average | Average |

| Environmental friendliness | Low | Low | Low | High |

| Fire hazard | Low | High | Average | Low |

| Energy consumption | Average | Low | High | High |

| Worker qualifications | High | Average | Average | Average |

Widespread introduction into industry of more productive electrolytic-plasma polishing of metal will eventually make it possible to replace the toxic electrochemical processing method almost everywhere. Its advantages, in comparison with other methods of surface polishing, are high productivity and efficiency, compliance with the environmental cleanliness of the environment, high quality and speed of operations, and low cost.

The electrolyte-plasma method of surface polishing is environmentally friendly and meets sanitary standards; special treatment facilities are not required to clean the spent electrolyte.