When performing various types of household work, the need to cut metal often arises. This process itself does not cause difficulties. But to perform it you need to have a specialized tool. The simplest is the usual “grandfather’s” hacksaw for metal. She will cope with the task, but the investment of time and effort can unpleasantly surprise a modern person. Fortunately, many other tools for mechanical cutting of metal are now available.

Metal scissors

Metal scissors are also effective for cutting. Depending on the type and thickness of the material, the following types of tools are distinguished:

- ordinary hand scissors (used for sheet steel with a thickness of 0.4 - 1.1 mm);

- chair scissors (they have large dimensions and are suitable for steel up to 2.5 mm);

- power shears (for steel up to 5.0 mm);

- lever or swing shears (for long material with a thickness of up to 3.0 mm);

- guillotine (have inclined knives, suitable for thick steels up to 32 mm).

Mechanical methods

The classification of mechanical cutting methods is usually based on the answer to the question: how to cut metal? Cutting with a hacksaw and metal scissors

Cutting with scissors: a) cutting the sheet into strips; b) cutting with leaf scissors. Cutting out a round shape: c) incorrectly; d) correct

At home, metal is usually cut with an ordinary hacksaw. This process is quite labor-intensive. It is greatly simplified if you have a mechanical hacksaw at your disposal.

Unlike hacksaws, there are quite a few types of metal scissors:

- Hand shears allow you to cut relatively thin sheet metal. They allow you to do this quickly and accurately, following the cutting line correctly. There are several types of hand scissors: finger, power, chair, lever, for curved cutting.

- Spline shears carry out both straight and curved cutting. They allow you to cut metal in confined spaces while maintaining high quality cuts. Powered by an electric motor.

- Guillotine shears can cut metal with high precision. The main advantages are the absence of defects, high cutting accuracy, and preservation of the outer coating of the material being cut.

Types of guillotine shears:

Hand scissors can cut relatively thin sheets of metal.

- Hand scissors. The main disadvantage is that the force developed is not enough for cutting if the metal is very strong.

- Mechanical scissors. They are driven by an electric motor, so the productivity is significantly higher than that of manual guillotines.

- Hydraulic driven shears. Provide very high accuracy of work. In addition, they can be equipped with a CNC, which allows them to significantly increase their productivity by storing typical cut parameters in memory.

Reciprocating and circular saws, angle grinders

Reciprocating saws are similar in principle to jigsaws. Outwardly, they look like an electric drill, only instead of a drill there is a forward saw, 10 to 35 cm long, performing a reciprocating movement. The saw is usually powered from the mains, but cordless versions are also available.

Reciprocating saws are used for precise and fast cutting of metal.

Different types of saw blades are used for different types of work. They are easy to change, like drill bits in an electric drill. The fastening system is reliable and rational. Knowing what you have to work with, you can choose the right file. For example, the greater the curvature of the cut, the narrower the canvas should be.

Working with a reciprocating saw requires skill, a steady hand and a good eye.

It is easier to work with circular saws. Their cutting discs are usually made of hard, high-alloy alloy or special high-speed steel. The saws are designed for cutting a variety of metal profiles made from a wide variety of metals and alloys; they provide a narrow cut and a small amount of chips.

To choose the right saw, you should pay special attention to the sawing wheel, in particular its diameter. The larger it is, the greater the capabilities of the tool. After cutting, additional processing is usually required to remove sharp edges. The disadvantages include the rather large dimensions and fairly high cost.

A circular saw can be used to cut copper, aluminum and other non-ferrous metals.

Most consumers do not even suspect that the “grinder” is an angle grinder. The fact is that this miracle of technology comes from Bulgaria, and our people don’t like long names. In most cases, a grinder equipped with a disc for cutting steel perfectly replaces a circular saw for metal, although, judging by the name, it was originally intended for grinding.

Today, many people use it specifically as a saw, and not for grinding, although a modern grinder can cut, clean, polish, etc. Moreover, almost all materials can be cut and sanded. The main thing is that you don’t need to buy different tools. For different materials and work, only different consumables are purchased, and only one machine itself is needed.

Electric metal shears

An excellent metal cutting effect is achieved using electric scissors. There are more than 10 varieties of this tool, but they are united by the ability to cope with almost any material, as well as the ability to carry out shape cutting. Electric metal shears can be considered a specialized tool for these purposes.

Thus, there are a lot of devices that can cope with the task in question. Which device to choose depends on the frequency with which you have to cut metal, the thickness of the material and your budget.

Professional and industrial metal cutting tools

Professional metal cutting tools are used to process workpieces in industrial conditions.

Tools and machines for mechanical cutting

Mechanical cutting has the following advantages:

- the edges of the cuts are smooth;

- technologies are economical;

- processing accuracy is high.

The main disadvantage is that only straight cuts can be made mechanically.

- Grinders are most often used for cutting long products of small and medium diameters. Using grinders, fittings, corners, as well as square and round tubes are made. The method is characterized by low productivity, but the amount of waste tends to a minimum.

Photo No. 1: cutting metal with a grinder

Consumables for processing metal with a grinder are abrasive and diamond wheels.

- Circular saws. They can be used to make cuts at an angle. The advantages of the method are high accuracy and quality. Disadvantages: limited cutting depth, large amount of waste.

Photo No. 2: cutting metal with a circular saw

- Guillotines. The blanks are divided into parts using the chopping method. This processing method is considered the most productive and cheapest, but is not intended for the manufacture of parts with complex configurations.

Photo No. 3: cutting metal using a guillotine

- Band saw machines are designed for cutting any metals and alloys. The method is characterized by low waste. The edges of the cuts are as smooth as possible. There are restrictions on the size of the workpieces.

Photo No. 4: cutting metal on a band saw

Waterjet cutting

The metal is cut on special equipment using a solution (water + abrasive sand), which is supplied under high pressure through a narrow nozzle. The innovative technology is designed for cutting metal up to 30 cm thick. The resulting parts do not require additional processing. In this case, the metal does not deform, since there is no thermal effect.

Photo No. 5: waterjet cutting of metal

This processing method is very expensive and is not suitable for metals that are susceptible to corrosion.

Hot cutting technologies

- Laser. The blanks are processed on special machines. When exposed to a laser beam, part of the metal evaporates. The remaining molten material is blown out with a gas mixture.

Photo No. 6: laser cutting of metal

Using laser cutting, high-precision parts of any configuration are produced that do not require additional processing. However, the method has disadvantages:

- limitation on metal thickness - laser machines can process workpieces up to 20 mm thick;

- high cost - prices for machines and their operation are kept at a high level;

- Limitation on metal types - laser processing is not suitable for stainless steel, aluminum and other highly reflective alloys.

- Gas. The workpieces are processed on special machines. The cutting technology is based on intensive melting of the metal. It occurs under the influence of a directed flow of a gas-oxygen mixture.

Photo No. 7: gas cutting of metal

The method is suitable for rough cutting of metals and alloys with low thermal conductivity. In areas of processing under the influence of high temperatures, scale and sagging are formed. The resulting parts require additional processing.

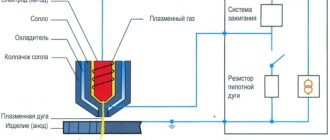

- Plasma. The metal is cut by a mixture of gases supplied under high pressure. As a result, the material melts and burns out, and residues and scale are completely blown away.

Photo No. 8: plasma cutting of metal

Plasma cutting has the following advantages:

- profitability - the amount of waste tends to a minimum, the resulting parts do not require additional processing;

- productivity - plasma cutting is faster than laser, waterjet and mechanical cutting by 4, 8 and 10 times, respectively;

- versatility - the technology is suitable for processing any conductive metals with a thickness from 1 mm to 15 cm.

Plasma cutting is used for both serial and individual production.

Sheet cutting machines

Metal products manufacturing enterprises use a variety of tools designed to cut parts from sheet materials.

- Guillotine shears are a wide-cut machine in which sheet blanks are cut in a straight line. The drive of the machines is electric, hydraulic and pneumatic. Industrial equipment cuts steel sheets up to 6 mm thick.

When cutting strips (rolled sheet material), rollers are installed from which the strip is unwinded. Additionally, they are equipped with roller measuring devices that allow for high-performance cutting.

- Manual guillotines are more common in small workshops. They can cut sheets up to 2 mm thick. The length of the cut is relatively short. If it is necessary to separate over a long distance, cut in parts, gradually moving the workpiece along the cutting edges. To make it easier for the operator to do the work, tables are installed around the machine, on the surface of which roller tables are installed. It is easy to move semi-finished products along them.

- Circular saws equipped with metal blades are used to make long cuts on sheets more than 2 mm thick. The speed of the process is low. To reduce the load on the tool, cooling is carried out using lubricant cooling materials (coolants).

- A jigsaw is used to cut workpieces with a thickness of more than 1.5 mm. With a smaller thickness, the process is accompanied by strong vibration. The quality is noticeably reduced.

- Jig punching presses are used in fairly large industries. They produce complex parts from sheet materials according to a given program. The shape of the cutting line can be very diverse. Holes of various shapes are made in the workpieces. Modern machines perform over 5,000 strokes per minute, which guarantees high productivity in cutting parts.

Thermal methods of metal cutting

There are two types of cutting of metal products using high-temperature technologies: gas-electric and gas. In both cases, the metal is heated by an oxygen flame.

Gas cutting

There are three technologies for gas cutting of metal sheets:

- Oxygen. Cutting the material and removing the formed oxides occurs under the influence of a hot stream of oxygen.

- Oxygen-flux. For cutting, a special powder is used, which has abrasive, thermal and chemical effects. Thanks to these properties of the flux, the cutting process is easier and faster.

- Oxygen-spear. To obtain a high temperature, a lance-tube is used, through which an oxygen stream is blown during the combustion process.

The advantages of these gas cutting technologies include low cost and the ability to process large-diameter materials. Disadvantages of the listed thermal cutting methods:

- deformation, high metal consumption;

- additional processing of parts is required;

- low accuracy;

- low speed and large cutting thickness.

Gas-electric cutting

To heat the metal for gas-electric cutting, a source of electricity is used. Melts are removed from the cut area using a gas jet. There are two gas-electric cutting technologies:

- air-arc – cutting of metal products is carried out with compressed air, which is also blown out of the melting zone;

- oxygen-arc - cutting the material and removing oxides occurs under the influence of an incoming stream of oxygen, which is heated in the arc flame.

Typically, these gas-electric cutting technologies are used to correct defects after welding work. The main disadvantage is the saturation of the surface with carbon in an amount that exceeds its concentration in the metal sheet, which is due to the combustion of carbon electrodes.

Plasma cutting

The most economical, fast and efficient technology for cutting metal products is plasma jet cutting. This is an ionized gas, which, using a plasma torch, is converted into a plasma jet and melts the metal.

Compared to gas cutting tools, which use expensive gases, plasma cutting is affordable. It is characterized by high cutting speed, safety, environmental friendliness and versatility. A plasma jet can efficiently and accurately cut parts of any shape.

The disadvantages of plasma cutting include:

- high noise level;

- complexity of equipment installation and maintenance;

- limited angle of deviation of the cutting element from perpendicularity;

- You cannot cut parts with a thickness of more than 100 mm;

- high price.

In addition to the above methods, thermal cutting of metal products can be carried out using a laser (laser cutting), electric discharge (electrical discharge machining), ultra-low temperatures (cryogenic cutting), as well as a mixture of water and abrasive material (water jet cutting).

As you can see, there are quite a lot of methods and technologies for cutting metal sheets. Each of them has its own advantages and disadvantages. For each case, a specific option is suitable. Where cutting with a plasma jet would be an unjustified waste of money, you can use a hacksaw, scissors or a saw. In some cases, the only effective method will be the use of thermal technologies. Which method is the most optimal and profitable depends on the volume and nature of the work, as well as the type and thickness of the metal.

Prospects for the development of the metal cutting industry

The listed methods are used in practice and are known to everyone. But scientists are developing new methods: for example, in Germany they have created an installation for cutting metal using an electromagnetic pulse, which works quickly, silently and leaves no traces. Ultrasonic cutting experiments are also being conducted. It is possible that in the foreseeable future they will become widespread.

Cutting width and maximum workpiece thickness (points):

| Type of cutting | Thickness | Width |

| Guillotine | 1 | 10 |

| LPS | 9 | 9 |

| Oxygen gas | 8 | 5 |

| Plasma | 6 | 6 |

| Laser | 3 | 10 |

| Waterjet | 9 | 8 |

When cutting metal 50 mm thick, the cutting width when using a water jet machine is 2 mm, and with an oxygen gas machine it is 20 mm. This saves 15 kg of metal per 1 meter of cut.

Cut quality and productivity (points):

| Type of cutting | Cut quality | Performance |

| Guillotine | 9 | 9 |

| LPS | 8 | 4 |

| Oxygen gas | 5 | 6 |

| Plasma | 7 | 9 |

| Laser | 9 | 7 |

| Waterjet | 10 | 5 |

Scissors

It is relatively easy to cut a smooth sheet with scissors, but with long cuts you have to find ways to install the material so as not to damage your hands or the workpiece. Complex configurations are difficult to produce; it is easier to move in a straight line. When using an angle grinder with cutting discs, the edge burns and unprotected metal remains on it.

Cutting a profiled sheet is much more difficult. The blades of scissors do not have enough grip angle, so craftsmen are forced to find ways to grip and cut metal.

Ideas to adapt existing tools to perform complex tinsmith work have been around for a long time. But not everyone is ready to purchase complex and expensive devices. It’s easier to use attachments for existing power tools.

Cutting type drill attachments

In addition to perforated attachments, devices are produced that cut sheet material. The attachment resembles small scissors. There is an active cutting plastic and a counter-edge.

A sheet of metal hits the counter-cutting edge, a cutting edge runs into it, which pinches the material being cut. The result is a cut over a short distance.

Consistently moving the scissors in the desired direction, cut off excess metal or divide the sheet surface into two different parts.

Such attachments are called “Steel Beaver”. They have several main advantages over other devices:

- The user receives a cut whose quality is comparable to cutting on an industrial machine; the edges are minimal; they do not even need to be removed after the work.

- It is easy to hold the tool in your hands; the presence of an additional handle helps to guide the device in the desired direction.

- During work, the cutting direction can be changed along a small radius, which is quite convenient for obtaining parts of complex configurations.

- The weight of the tool increases by about 30%, which makes working with the power tool slightly more difficult.

- No sparks are generated during operation. The tool, when cutting metal, does not even heat the cutting zone. Protective coatings are not damaged.

- It takes no more than half an hour to master the device. More time has to be spent not on the process itself, but on preparing the sheets. You need to get used to laying them out at your workplace in order to have easy access.

Video: cutting metal quickly - a super attachment for a drill!

The jigsaw is a brilliant tool

Available for home and professional use, the power of the tool directly depends on its purpose. Manual cutting with a professional jigsaw is not difficult, and the master will be able to cut a steel profile up to 10 mm, and an aluminum profile up to 20 mm.

The main factor when choosing is the power of the device; the service life, operating time and cutting depth depend on the value. The weight of the jigsaw is also of considerable importance, as it directly affects the complexity of the job.