Metallurgy is a broad concept related to technology and science. This is a powerful industrial sector, the main task of which is the production and processing of metals. Metals are isolated from various ores, after which their physical and chemical properties are studied and modern high-tech alloys are produced.

- Fields of metallurgy

- Metallurgy technologies

- History of metallurgy

- Gases in metallurgy

- Specialty "Metallurgy"

In this material we will consider the main areas of activity of metallurgy, its features and technologies, as well as ways to master the specialty. "Metallurgy".

Fields of metallurgy

There are several areas in metallurgy:

- Black. It includes the production of metals such as cast iron, steel and iron. These are ferrous metals, the production of which requires a lot of materials, including coal;

- Colored. This is the extraction of various ores and the process of their further enrichment. Non-ferrous metals are processed in different ways to produce new alloys;

- Plasma. Metals are extracted from ores and then processed. For processing, powerful plasma reactors and furnaces are used, as well as plasma heating technology to give the melting process maximum intensity;

- Powder. The task of powder metallurgy is to obtain various powders from metals, which are used to make products. This industry also uses composite technologies, combining metals and non-metals.

Russian economy, figures and facts. Part 8 Metallurgy.

General information

Metallurgy is one of the most developed industries in the Russian economy.

In terms of importance for the Russian economy, the metallurgical industry ranks second after the oil and gas industry. Metallurgy is divided into ferrous and non-ferrous. In general, in the Russian Federation there are about 28,000 different organizations related to metallurgical production (including organizations related to the mining and processing of precious metals). According to statistics, 1 worker employed in steel production provides 25 jobs in related sectors of the economy. At the end of 2014, the metallurgical industry of the Russian Federation employed about 2.2% of all workers in the country, which in quantitative terms is 955 thousand people. It should be noted that the number of workers in this area is decreasing every year. This is primarily due to the automation of the industry and the reorganization of enterprises.

The average salary in the industry at the end of 2014 was just under 48 thousand rubles. This is almost 1.5 times more than the average salary in Russia. The highest salaries in the industry are received by employees of large metallurgical plants.

The share of the metallurgical industry in the country's GDP is 4.7%, while the share of metallurgical production in Russian industry is 12%. Metallurgical enterprises use about 20% of electricity from the general industrial level, and the share of the metallurgical industry in freight rail transportation is 18.8%.

At the end of 2014, enterprises in the metallurgical industry produced and shipped goods worth more than 4.32 trillion. rubles This is a record figure in recent Russian history. Compared to 2013, sales growth was 8.6%.

Several factors contributed to this. First of all, this is a reduction in the supply of Ukrainian-made metallurgical products. Over the past year, Ukrainian metallurgists have reduced production volumes by 38%. Thus, on the world metal market, demand exceeded supply and Russian metallurgists took advantage of this, securing new sales markets for themselves. The second factor is the devaluation of the ruble. By purchasing the raw materials necessary for production for rubles and receiving part of the proceeds in foreign currency, Russian metallurgists have significantly increased their profits. At the end of 2014, the profitability of metallurgical complex enterprises was 16.7%; the same figure for the industry in 2013 was 9.9%.

At the end of 2014, enterprises of the metallurgical industry exported products worth 31.78 billion US dollars. Of these, ferrous metallurgy accounted for 64.5% of exports, and non-ferrous metallurgy for 35.5%. The following products were exported most:

- Cast iron – 4,359 thousand tons;

- Semi-finished carbon steel – 13,511 thousand tons;

- Flat rolled carbon steel – 7,614 thousand tons;

- Unprocessed aluminum – 2,910 thousand tons;

- Ferroalloys – 912 thousand tons;

- Refined copper – 290 thousand tons;

- Unprocessed nickel – 238 thousand tons.

Ferrous metallurgy

Ferrous metallurgy is a branch of heavy industry that includes the production of cast iron, steel, rolled products, ferroalloys, as well as the extraction and beneficiation of iron ore and the production of refractories. The structure of the ferrous metallurgy of the Russian Federation includes more than 1.5 thousand enterprises, of which more than 70 are city-forming. This branch of the metallurgical industry employs 2/3 of the workers in Russian metallurgy.

The technological process for producing cast iron and steel involves the use of iron ore and coking coal. Therefore, in order to reduce the cost of delivering these necessary raw materials, metallurgical plants were built in areas rich in these minerals. In Russia there are three main bases of ferrous metallurgy:

- Ural;

- Central;

- Siberian.

The Ural base is the oldest and largest in Russia. Now about half of all ferrous metallurgy products in the country are produced here. The Ural metallurgical base is connected with Kuzbass coal and Ural iron ore deposits. The centers of metallurgy in the Urals are Magnitogorsk, Chelyabinsk, Nizhny Tagil, and Yekaterinburg. The largest enterprises are the Magnitogorsk Iron and Steel Works, the Chelyabinsk Iron and Steel Works, the Chusovsky Metallurgical Plant, etc.

Since the iron ore deposits in the Urals are practically exhausted, the Siberian one is being built to replace the Ural metallurgical base. At the moment, this base is at the stage of formation and is represented by only two large metallurgical enterprises - the Kuznetsk Metallurgical Plant and the West Siberian Metallurgical Plant in Novokuznetsk.

The Central Metallurgical Base uses its own iron ore deposits, which are located in the Kursk and Belgorod regions. Ore mining here is very cheap and is mined by open pit mining. There is no coal here, but due to its convenient geographical location, enterprises are supplied with coal from three basins - Donetsk, Pechora and Kuznetsk. The largest enterprises are the Cherepovets Iron and Steel Works, the Novolipetsk Iron and Steel Works, and metallurgical plants in Tula and Stary Oskol.

The development of metallurgy in Russia was greatly facilitated by the presence of large deposits of iron ore. Russia ranks third in the world in terms of iron ore reserves, behind Australia and Brazil. The explored reserves of iron ore in Russia are about 25 billion tons, which in terms of pure iron is 14 billion tons.

The annual production of iron ore condensate in the Russian Federation over the past 5 years has been approximately 100 million tons. According to this indicator, the Russian Federation ranks 5th in the world, trailing leader China by almost 15 times. About a quarter of the iron ore mined in Russia is exported. In 2014, 23 million tons were exported, in 2013 and 2012 – 25.7 and 25.5 million tons, respectively.

The main indicator of the performance of ferrous metallurgy is the amount of steel produced. In total, according to the results of 2014, 1,662 million tons were produced in the world. The undisputed leader in steel production is Asia, where 1,132 million tons were produced. The EU produced 169.2 million tons, North America – 121.2 million tons, and South America – 45.2 million tons. The CIS countries decreased steel production compared to 2013 by 2.8%, mainly due to Ukraine, to 105.3 million tons.

The world leader in steel production is China; it is almost 8 times ahead of its closest competitors, the Japanese. And the United States of America closes the top three, 10 times behind the Chinese.

Compared to 2013, global steel production growth was 1.2%. Production growth in China slowed down slightly and amounted to only 0.9% compared to 2013. And the greatest growth was demonstrated by: Poland - 8.4% (from 8 million tons to 8.6) and South Korea - 7.5% (from 66.1 million tons to 71), such an increase in production allowed the Koreans to displace Russia from 5th place. And the largest decline in steel production at the end of 2014 was observed in Ukraine - (-17.1%) to 27.2 million tons.

Steel production growth in the Russian Federation in 2014 was 2.2%, which is 1% more than global growth, and this is the seventh highest growth rate among all countries in the world. The confident growth of metallurgical production in the Russian Federation in the context of the crisis and anti-Russian sanctions allows us to hope in 2015 for repeating or exceeding the record for steel production in the country, which was recorded in 2007 - 72.4 million tons.

Pig iron production is also the most important indicator of the metallurgical industry. In 2014, the world produced 1.18 billion tons of pig iron. As in steel production, Asia occupies a leading position - 911 million tons of cast iron produced. EU countries produced - 95.1 million tons, North America - 41.1 million tons, South America - 30.6 million tons. Pig iron production in the CIS countries amounted to 79.55 million tons.

China also occupies the leading position by a large margin. The Japanese, who are in second place, are 9 times behind, and the Indians, who are in third place, are more than 13 times behind.

Global growth in iron production was almost the same as steel production – 1.3%. The growth of pig iron production in China was also lower than the global one and amounted to 1%. And the greatest growth was achieved by South Korea - 12.5%, the largest decline compared to 2013 was recorded in Ukraine - (-15%).

In the Russian Federation, pig iron production increased by 2.9%. In 2014, the 2007 figure was almost achieved. In 2015 it is planned to exceed it.

Also, based on the results of 2014, the production of finished rolled ferrous metals and coated flat products in Russia increased. During the year, 61.2 million tons of finished ferrous products and 5.8 million tons of coated flat products were produced. The increase in production compared to 2013 was 3.3% and 6.9%, respectively.

The Russian ferrous metallurgy industry is based on 6 large vertically and horizontally integrated holdings, which account for more than 93% of all products produced.

- PJSC Severstal;

- "EVRAZ";

- OJSC Novolipetsk Metallurgical Plant (NLMK);

- OJSC Magnitogorsk Iron and Steel Works (MMK);

- OJSC "Metalloinvest";

- OAO Mechel.

EVRAZ is a vertically integrated metallurgical and mining company founded in 1992. The company has assets in Russia, the USA, Canada, the Czech Republic, Kazakhstan and other countries. In 2014, the company's total revenue exceeded $13 billion. In Russia, EVRAZ owns two large metallurgical plants - the West Siberian Metallurgical Plant (ZSMK) and the Nizhny Tagil Metallurgical Plant (N in both enterprises is 100%).

ZSMK is the fifth largest metallurgical plant in Russia, located in Novokuznetsk. This is the easternmost of all Russian metallurgical plants. The plant includes coke-chemical, agglomerate, steel-smelting, rolling steel production, and a blast furnace shop. ZSMK produces more than 100 profiles of various rolled products. The West Siberian Metallurgical Plant is the general supplier of rail products to JSC Russian Railways. At the end of 2014, the plant produced 5.9 million tons of pig iron and 7.5 million tons of steel. The company employs more than 22.5 thousand employees.

NTMK is a metallurgical plant founded in 1940. The main types of products are construction metal products (I-beams, channels, angles). At the end of 2014, the company produced 4.8 million tons of cast iron, 4.2 million tons of steel and more than 2.8 tons of various rolled metal products.

Severstal is one of the main steel producers in Russia. The leading enterprise is Cherepovets Metallurgical Plant (CherMK). At the end of 2014, the total production of steel by Severstal PJSC was 11.3 million tons, cast iron - 9.1 million. Compared to 2013, these figures increased by 6% and 4%, respectively. The total turnover of the company, including the mining industry, at the end of 2014 amounted to 8.3 billion US dollars. In total, the company employs about 60,000 people.

OJSC Novolipetsk Metallurgical Plant is a public company that includes the third largest metallurgical plant in Russia. OJSC NLMK has assets not only in Russia, but also in Europe and the USA; the company's foreign factories produce rolled metal and small volumes of finished steel. At the end of 2014, foreign enterprises of NLMK OJSC produced 0.7 million tons of steel, while in Russia 15.2 million tons of steel and 12.14 million tons of cast iron were produced. The company's Russian enterprises employ 56.4 thousand employees.

OJSC Magnitogorsk Iron and Steel Works is the largest metallurgical plant in Russia. The company's assets represent a metallurgical complex with a full production cycle. The company supplies products to the domestic Russian market, as well as to European and Asian countries. At the end of 2014, MMK's production indicators reached record results; 13 million tons of steel and 10.3 million tons of cast iron were produced. The company's total revenue for the past year was just over $7.9 billion. More than 56,000 people work at the enterprises included in MMK's structure.

OJSC Metalloinvest is a large Russian mining and metallurgical holding. The company includes two large metallurgical enterprises - the Oskol Electrometallurgical Plant and the Ural Steel Plant. The company owns the largest iron ore reserves in the world. The number of employees of OJSC Metalloinvest exceeds 62 thousand people. The total turnover for 2014 is 6.36 billion US dollars, steel production - 4.5 million tons, cast iron - 2.3 million tons.

Mechel OJSC is a large Russian metallurgical and mining company. Mechel's assets are located not only in Russia, but also in neighboring countries. Russian metallurgical enterprises included in the structure, Beloretsk Metallurgical Plant, Izhstal. The turnover of Mechel OJSC in 2014 amounted to 6.4 billion US dollars. The company has about 80 thousand employees. In 2014, the company's enterprises produced 4.3 million tons of steel and 3.9 million tons of cast iron.

Pipe production

The pipe industry is a branch of ferrous metallurgy, which has been brought into the hotel segment of the market. In recent years, this branch of metallurgy has been on a high rise in the Russian Federation. Over 12 years, pipe companies have invested more than 360 billion rubles in the development of the industry, of which 35 billion rubles in 2014. The production capacity of Russian pipe manufacturers increased from 9 million tons in 2000 to 19 million tons. The production of pipes using electric welding (electric welded pipes) on average accounts for about 70% of all production, the remaining 30% comes from the production of seamless pipes.

The main factor in the development of pipe companies is the high demand for products in the domestic market. In 2014, pipe consumption in Russia increased by 6.8% compared to the previous year and amounted to 9.3 million tons. At the same time, the demand for large-diameter pipes, which are used in the construction of gas and oil pipelines, has sharply increased. Compared to 2013, the growth was 35.3%. This is primarily due to the start of construction of the Power of Siberia gas pipeline. In general, the sales of pipe products by industry are as follows:

- Pipeline transport and hydrocarbon production – 70%;

- Housing and communal services – 24%

- Mechanical engineering – 4%

- Energy – 2%

At the end of 2014, pipe imports to Russia decreased by 24.5% compared to 2013 and amounted to 561 thousand tons. In total, 11.5 million tons of pipes were produced in the Russian Federation last year, which is 12.2% more than in 2013. In general, experts predict an even greater increase in pipe production volumes; it is expected that by 2030 volumes will increase by 2.5 - 3 times. The main reason for the growth is the worn-out housing and communal services infrastructure (about 60% of fixed assets as of 2014) and the increasing construction of pipeline transport routes every year.

The leaders of the Russian pipe market are three companies, which produce about 80% of all products. This is the metallurgical group "ChPTZ", "United Metallurgical" (owns several enterprises specializing in the production of steel, rolled metal and cast iron, including the Chusovsky Metallurgical Plant and the Vyksa Metallurgical Plant. Also, the structure of "OMK" includes enterprises in the pipe rolling industry Almetyevsky Pipe and a valve production plant in Blagoveshchensk. The company's total revenue amounted to more than 312.1 billion rubles. The enterprises included in the OMK structure are mainly focused on the production of shaped metal products and pipes. OMK's share in the Russian pipe market is 24%.

ChPTZ is an industrial group that unites Chelyabinsk Pipe Rolling OJSC. The company produces all types of steel pipes available on the Russian market, including welded pipes with a diameter of 508 - 1422 mm. At the end of 2014, the company's revenue amounted to 128.12 billion rubles. About 18 thousand people work at ChPTZ enterprises. The company's share in the Russian pipe market is 21%.

Pipe Metallurgical Company is the largest Russian company in the field of pipe production. Since 2009, TMK has occupied a leading position, not only in Russia, but also in the world. At the end of 2014, the company produced 4.4 million tons of pipe products. The company's assets are located in Russia, Europe, North America and the CIS countries. In the Russian Federation, the company's structure includes: Volzhsky, Seversky and Sinarsky pipe plants, as well as the Taganrog Metallurgical Plant. The company's revenue in 2014 amounted to 6 billion US dollars, with more than 45 thousand employees. The TMK company occupies 26% of the Russian pipe market.

Non-ferrous metallurgy

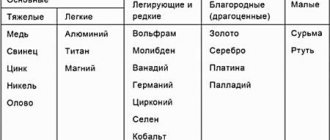

Non-ferrous metallurgy is a branch of the metallurgical industry, which includes the extraction and enrichment of non-ferrous metal ores, as well as the smelting of non-ferrous metals and their alloys. In total, there are more than 90 types of different metals in nature, and 6 of them are most widely used in industry. These are aluminum, nickel, copper, zinc, lead and tin.

Aluminum

Aluminum is one of the most popular metals in the world, its consumption is increasing every year. This metal is used in many industries and the national economy. Aluminum distribution by industry:

- Construction – 32%;

- Consumer goods – 25%;

- Electrical engineering – 23%;

- Mechanical engineering – 11%;

- Others – 9%.

In addition to the high performance qualities of the metal, which include high strength with relatively low weight, the production of aluminum is much more environmentally friendly than other non-ferrous metals. Also, aluminum is highly recyclable and now more than 20% of aluminum is made from scrap.

Russia ranks second in the world in terms of aluminum production, second to China, which produces 45% of all aluminum in the world. In 2014, Russia produced 3.6 million tons of aluminum, which is 6.8% of the world volume. At the same time, Russia is the world's main exporter of aluminum; in 2014, 82.7% of aluminum produced was exported, which amounted to about 16% of all world exports.

The global aluminum industry is highly concentrated, with the top 6 companies accounting for 40% of global production. And the world leader is the Chinese company Hongqiao Group, which in 2014 managed to bypass Russian Aluminum (RUSAL). This Russian company provides 100% of the production of primary aluminum in the Russian Federation.

RUSAL, after the takeover of the Siberian-Ural Aluminum Company, actually became a monopolist in the production of primary aluminum. RUSAL's structure includes 12 aluminum smelters in the Russian Federation, including the Bratsk Aluminum Smelter, which produces 30% of all Russian aluminum. In addition to aluminum production, the company is involved in alumina production and bauxite mining. RUSAL's assets are located in Russia, Europe, Africa and Australia. The company's total turnover in 2014 amounted to 9.35 billion US dollars. The company employs more than 60,000 employees.

Nickel

Over the past twelve years, global nickel production has increased almost 1.5 times, from 1.35 million tons in 2002 to almost 2 million tons in 2014. Primary nickel is used for alloying steels (about 67% of all nickel produced), as well as in electroplating, casting and production of nickel alloys.

World nickel reserves are estimated at 75 million tons. Of these, about 70% are concentrated in 5 countries. Russia ranks 4th on this list, its reserves amount to 6.1 million tons.

In 2014, due to Indonesia's ban on the export of nickel ores, the price of nickel increased. The average annual price was US$16,867 per ton, which is 12% higher than in 2013. And the maximum price in 2014 reached 21,000 US dollars per ton. All these fluctuations allowed nickel producing companies to finish the year with good financial performance.

At the end of 2014, Russia produced 285 thousand tons of nickel. 238.5 thousand tons of nickel were exported, which made it possible to satisfy 12% of global needs.

The leading enterprise in the industry in Russia is Norilsk Nickel. This company occupies 96% of the Russian nickel production market. Norilsk Nickel's assets are located in Russia, Finland, Australia and Africa. The company is a world leader in nickel and palladium production. In 2014, 274 thousand tons of nickel were produced. Total revenue amounted to 11.9 billion US dollars.

Copper

Copper is a metal that has been used by humans since ancient times. Currently, in the global structure of copper consumption, 30% is used in construction, 30% for equipment production, 13% in the transport industry, and the remaining 27% is distributed among other sectors of the economy.

In the copper market, Russia provides about 4.7% of global production. In total, in 2014, Russian companies produced 892 thousand tons of copper. And the leader in copper production in the world is Chile. This country has the largest copper reserves and its average annual production is about 30% of the world. In 2014, 18.9 million tons of copper were produced, of which 5.8 million tons were smelted in Chile.

Unlike aluminum and nickel, copper production in Russia is not monopolized, but is carried out by three large ones, MMC Norilsk Nickel and Russian Copper Company. The industry leader is, which in 2014 produced 380 thousand tons of copper, accounting for 42.5% of the total. The company is part of the structure of OJSC Ural Mining and Metallurgical Company.

The second place is occupied by MMC Norilsk Nickel; in 2014, this company produced 355 thousand tons of copper, almost 40% of all Russian copper. The Russian Copper Company produced 157 thousand tons of copper in 2014. But the structure of the Russian copper market may change as early as 2015. In connection with the opening of RMK, the Mikheevsky mining and processing plant, the company's management announced plans to produce more than 300 thousand tons of copper per year.

Zinc, blue, tin

For the needs of its domestic market, Russia imports zinc and tin. At the end of 2014, the Russian economy's need for zinc amounted to 229 thousand tons. 221 thousand tons were produced, of which 13.7 thousand tons or 6.2% were exported. The resulting deficit was covered by imports. The largest zinc producer in Russia is Chelyabinsk Zinc Plant OJSC, which is part of the UMMC group; it produces about 60% of all Russian zinc.

Tin is one of the few metals that Russia is forced to import in large quantities. At the end of 2014, the total demand of the Russian economy for tin amounted to 2.5 thousand tons. Of these, 1.9 thousand tons or 76% were imported. The main importers of this metal to Russia are the Netherlands and Malaysia.

Lead production in Russia is carried out mainly through the processing of secondary raw materials. Like aluminum, lead is easily recycled and today more than 55% of all lead in the world is produced through recycling. An interesting fact is that Russia ranks third in the world in terms of lead reserves - 9.2 million tons, but all the mined lead concentrate is exported. The largest Russian enterprises producing lead from recycled materials are UMMC and JSC Ryaztsvetmet. Both plants have production capacity to produce about 30 thousand tons of lead per year.

Metallurgy technologies

In metallurgy, special metal extraction technologies are used:

- pyrometallurgy. All processes of melting, roasting and other technologies take place at high temperatures;

- hydrometallurgy. Metals are extracted from ore, and then solutions are separated from them using electrolysis;

- biotechnology. Metal can be extracted from ore using living microorganisms for biooxidation or biosorption reactions.

Every year, economic development requires new reserves of metals. It is known that natural resources are not limitless, therefore one of the main tasks of metallurgists, in addition to the development of the geological exploration industry, is the reuse of this or that metal.

There are several metals that have long been widely used in various branches of human activity. These are steel (its annual consumption is more than 90%), lead, as well as copper and aluminum. Among rare metals, the mining of platinum, tellurium, osmium and gold should be noted.

It is impossible to imagine the construction industry without the use of iron and steel. They are highly wear-resistant and it is almost impossible to find a replacement for them. As for durable aluminum, it is this aluminum that, due to its low density, is used in the construction of aircraft.

One of the main properties of copper is its high degree of thermal conductivity, which is why it is widely used for the manufacture of electrical cables. Gold is actively used for the production of jewelry. It is also used to make electrical connections that are not subject to oxidation reactions.

Previously, pure metals were used in the metallurgical industry, but over time, high-tech alloys confidently displaced them from the production sphere. Alloys have special qualities that pure metals do not have. The most popular of them are stainless steel, carbon steel, nickel and copper alloys.

State total

Currently, Russia occupies a leading position in iron ore and nickel reserves. The country produces more than 70 different metals and elements. Metallurgical production is of great economic importance.

The metallurgy industry is one of the most dynamically developing industries. Despite high competition from large developing countries, Russia manages to maintain leadership due to low production costs.

To maintain positions, strategic, anti-crisis plans are being developed. Metallurgy serves as a source of foreign exchange earnings for the country. It ensures Russia's stable position in the world market.

The metallurgical complex has its own problems. Production growth at most enterprises occurs only with the creation of new production capacities. Most of them were created more than 50 years ago, but they have already exhausted their reserves.

History of metallurgy

Metallurgy began to develop back in the Stone Age. There are several historical milestones in its development. According to archaeological excavations, our ancient ancestors already in the 6th century. BC. actively used iron that fell to Earth as part of meteorites. People gradually mastered the processing of silver and tin.

During the Bronze Age (5500 years ago), people learned to extract tin and copper from rocks, from which they accidentally came up with bronze. During the Iron Age (1200 years ago), iron began to be extracted from ore. Its main miners are considered to be the ancient Romans, who excelled in the art of forging, and a quarter of the inventions of metalworking and mining technologies belong to the Chinese.

Regardless of where in the world metallurgy developed, all people used the classic cheese-making method, which was used to smelt copper and lead.

This was followed by an era called the cementation stage. Iron began to be hardened, it turned into a metal much stronger than bronze. However, the process of people mastering this technology took about a thousand years.

During the Middle Ages, the height of smelting furnaces was already three meters, and they worked using energy obtained through water. These furnaces were called stukofen and became an incentive for ferrous metallurgy to enter the next stage of development. During the Renaissance, new types of stoves appeared, which were called blauofens. After them, huge blast furnaces appeared. They worked 24 hours a day, producing up to one and a half thousand tons of cast iron of excellent quality.

At the end of the 19th and beginning of the 20th centuries, new metal production technologies appeared. We are talking about the Bessemer, Thomas and, finally, open-hearth methods. They helped people increase production volumes many times over, producing metals from six tons per hour. 50 years later, non-stop steel casting and the oxygen blowing method appeared. At the present stage, scientists are actively developing various technologies for ore enrichment and steel production in electric furnaces.

Aluminum production

The aluminum industry occupies one of the leading and unique positions in non-ferrous metallurgy. This fact is explained by the fact that higher quality raw materials (bauxite, nepheline) are used for metal production. The central territories where bauxite production is carried out are considered to be Boksitogorsk, Severouralsk and the Severo-Onezhskoye deposit.

Nepheline deposits are located in Kirovsk on the Kola Peninsula and in Goryachegorsk, which is located in Eastern Siberia. The difference between the minerals is that nephelines have a more complex composition. Main stages of the aluminum industry:

- alumina production;

- production of metal aluminum.

Such activities can occur both in one area and in different territories. Enterprises producing alumina try to locate as close as possible to the deposits, since this production is considered more material-intensive.

Aluminum plants are located closer to sources of mass and cheap electricity. Russia is second only to the People's Republic of China in the production of this metal. Comparative table of aluminum production in thousands of tons by countries for 2012 and 2021.

| Place | A country | 2012 | 2016 |

| 1 | China | 21500 | 31000 |

| 2 | Russia | 3950 | 3580 |

| 3 | Canada | 2900 | 3250 |

| 4 | India | 1700 | 2750 |

| 5 | UAE | 1800 | 2400 |

Areas where limestone and cheap fuel are found along with aluminum raw materials are considered optimal for the production of alumina. Such areas include Achinsk-Krasnoyarsk in Siberia and Severouralsko-Krasnoturinsky in the Urals. Enterprises for processing metals and alloys are located closer to consumers and are usually located in large industrial centers.

Gases in metallurgy

Pyrometallurgy is an industry that involves constant gas formation. Gases must be removed regularly from ovens along with dust. They are technological and fuel.

The formation of process gases occurs during complex processes. They consist of carbon dioxide, water vapor, carbon monoxide and sulfur dioxide. Also, during some processes in metallurgy, the release of chlorine gas and other chlorides is observed. When fuel burns, carbon dioxide and water vapor are released. The temperature of the gases released during reactions ranges from 800 to 1300C, but sometimes it can be higher.

Nowadays, any metallurgical production uses complex gas processing technologies:

- using sulfur oxide;

- high temperatures;

- dehydration process, etc.

The meaning and composition of the industry basis

The metallurgical complex consists of enterprises and plants throughout the country that produce various types of metals. For its efficient operation, about 25% of fuel and energy are used, and it accounts for up to 30% of transport traffic.

The two main directions of development of the complex are ferrous and non-ferrous metallurgy, which together represent up to 90% of all metals. The production complex consists of a number of industrial processes:

- mining, beneficiation, agglomeration and other types of ore preparation;

- activities for processing cast iron and steel;

- rolled metals and pipes;

- production of alloys;

- processing of residues from production activities.

The metallurgical industry differs from others in its rather complex production process and disproportionate scale of the work cycle. Thus, in order to obtain some types of products, it is necessary to perform 15–18 processing operations.

In addition, the metallurgy field has a well-established logistics system not only with other factories and enterprises in Russia, but also in the countries of the former Soviet Union. The complex is also distinguished by the fact that its production involves the largest number of labor resources. Now there is no larger production in the world than metallurgy.

Refining

Crude metals contain various impurities that affect the physical and chemical properties of metals, and also contain important expensive elements, such as gold or silver. Therefore, one of the most important stages of metal processing is refining, that is, cleaning. Refining is carried out in three ways:

- electrolytic - used for deep cleaning of non-ferrous metals;

- chemical, which is also called refining, is used for deep purification of gold;

- pyrometallurgical - used in the production of high-purity metals and is divided into fractional, segregation, and oxidative refining.

Ore

Ore is a mineral mined from the depths of the earth. This is a rock from which, at the given level of technological development, it is economically feasible to extract metals. For example, it is currently advisable to process ores if their metal content is:

- iron – 20 – 60%;

- copper – 1 – 3%;

- nickel – 0.3 – 1.0%;

- molybdenum – 0.005 – 0.02%.

As technology develops, these limits are gradually reduced and ores with a lower content of useful components are processed.

Ore consists of minerals containing useful metal and what is called gangue. Waste breed can be:

- siliceous, represented by quartz – SiO2;

- aluminous, containing a significant amount of alumina – Al2O3;

- magnesium, containing magnesium compounds.

Depending on the content of the mined metal, ores are rich and poor. Low-grade ores are enriched, that is, part of the waste rock is removed from the ore, resulting in a concentrate with a higher content of mined metal.

Ores are usually named for one or more metals they contain. For example, iron, manganese, copper, chromium-nickel, iron-vanadium, etc.

Depending on the degree of exploration, ore reserves are divided into several categories, designated by the letters of the Latin alphabet A, B, C.

Category A (commercial reserves) includes deposits for which exploratory drilling has been carried out using a dense pattern of wells and the shape of the ore body has been identified with sufficient accuracy. Approval of a deposit under category A is the basis for the start of construction of a metallurgical plant.

Category B (probable reserves) includes deposits drilled through a sparse pattern of wells, which makes it difficult to determine the exact shape of the ore body. If the deposit is classified as category B, then this can serve as a basis for design, but not for the construction of a metallurgical plant.

Category C (indicative reserves) includes deposits in which the shape of the ore body is known only in the most general terms, from natural outcrops or geophysical data. Ore reserves of category C can only be used for long-term planning of metallurgy development.

The sum of reserves (A + B + C) is called the total balance reserves of ores.

Black

Ferrous metallurgy is a branch of metallurgy that deals with the production of alloys from iron, manganese and chromium.

In nature, iron occurs in ore in the forms of carbonates, hydroxide and oxide. Therefore, the first stage of production in ferrous metallurgy is the liberation of iron from ore using a blast furnace at a temperature of more than +1000 C. If necessary, at this stage the properties of the metal are changed.

Ferrous metallurgy includes such areas as:

- extraction and enrichment of non-metallic raw materials;

- production of ferrous metals;

- production of steel and cast iron pipes;

- coke industry;

- secondary processing of raw materials.

Products produced at metallurgical plants are:

- main, that is, the final product, ready for use;

- by-product, that is, a product that is obtained during the production of the main product;

- by-products, that is, products remaining after the production of the main and by-products, which are used either as recyclable materials or as is.

Schematic diagrams of metal production

The metallurgical process is the production of metals, alloys, chemical compounds of metals, as well as metal-containing intermediate products.

The initial raw materials for the production of most metals are ores, for the processing of which a technological scheme for metallurgical processing is developed, i.e. sequence and optimal conditions of processes under which the highest technical and economic indicators in terms of cost and metal quality are achieved.

There are hundreds of different technological schemes for obtaining metals, but the fundamental essence of all schemes is the same - the separation of metal from waste rock and related elements. It is advisable to divide the entire complex of operations included in the technological schemes into four stages, in each of which a specific task is solved:

- the first stage is the production of ore concentrate by mechanical methods (crushing, grinding, enrichment);

- the second stage – obtaining a “chemical” concentrate (roasting, sintering-decomposition, dissolution, precipitation, smelting, etc.);

- third stage – obtaining a “rough” metal or its chemical compound (chlorination, rectification, extraction, sublimation);

- fourth stage – obtaining pure metal (chemical and physical cleaning methods).

At the first stage of the process, the ore mineral is separated from the gangue by beneficiation methods, as a result of which the ore is divided into two parts: a concentrate, which contains the bulk of the ore mineral, and tailings, consisting mainly of gangue.

At the second stage of the scheme, the remaining amount of waste rock is removed using chemical and metallurgical methods. The result of this stage is the production of either a chemical compound of a given metal or a metal alloy.

At the third stage, in some schemes a rough metal (contaminated with impurities) is obtained, in others a pure chemical compound of the metal is obtained, which is the starting material for obtaining pure metal at the last stage.

At the fourth stage, pure metal is obtained by reducing the corresponding chemical compound or by purifying the “rough” metal.

Obtaining metals is a difficult task, and it becomes significantly more difficult when processing poor or polymetallic raw materials. The most complex technological schemes are typical for the production of non-ferrous metals.