The metallurgical complex occupies third position in the structure of industrial production and belongs to the basic sectors of the industry. Ferrous metallurgy plays an important role in the development of the economy of any country.

Its industry composition includes organizational and technological activities for the production of steel, cast iron and rolled products. In addition, it includes:

- mining, ore dressing;

- obtaining nonmetallic and auxiliary raw materials for this industry;

- secondary redistribution;

- production of refractories;

- metal products for industrial purposes;

- coking of coal.

Ferrous metallurgy products have found application in most areas of the economy. Its main consumers are the engineering and metalworking industries, construction, and railway transport. It is also interconnected with the light and chemical industries.

Ferrous metallurgy is a dynamically developing industry. But this is a complex production sector and Russia has quite strong competitors in Japan, Ukraine, and Brazil. It manages to maintain one of the leading positions, while standing out due to its low cost. In the field of iron ore mining, as well as iron smelting and coke production, it achieved the greatest success. This is facilitated by the constant improvement of technological processes, the development of strategic plans and the improvement of crisis management.

Story

The history of metallurgical production in our country goes back five thousand years. This is precisely the age of the first bronze objects found in the European part of Russia. Closer to the beginning of the 5th century AD, iron knives, axes, plows, sickles and other objects of labor and household use began to appear among the Slavic tribes.

The basis of metallurgy in the Moscow state until the 17th century was limonite, the so-called “swamp iron”. There were no explored reserves lying at a depth of several hundred meters underground at that time, and swamps were located everywhere. Just like the forest, which in those days played the role of metallurgical fuel.

The centers of iron production of that time were the following cities:

- Novgorod.

- Ustyug Iron.

- Rimov.

- Tula.

- Tikhvin.

- Olonets.

- Nut.

However, a significant amount of metal was purchased from Sweden and Germany. And the extraction and production of non-ferrous metals was practically absent until the 17th century (small copper sources in Pechora and the Olonets region did not satisfy the country’s needs).

The situation changed radically under Peter the Great, who decided to transfer exploration, mining and processing of ores into private hands. Although the first attempts to create domestic metallurgy by Ivan III and Ivan IV the Terrible were made earlier. In this regard, mention should be made of the Dutchman Vinius and a whole galaxy of famous Russian industrialists:

- Demidovs.

- Batashevs.

- Arekhovs.

- Krasilnikov.

- Mosolov.

Largely thanks to them, the Tula blast furnace and ironworks arose, and enterprises opened in the Urals. With the development of metallurgical production, Russia not only got rid of imports, but also became the largest producer and exporter of iron and cast iron.

As evidenced by the following indicators:

- 1725 1,165 thousand pounds of pig iron were smelted, which corresponds to more than 19 thousand tons.

- 1740 Russia produces 30 thousand tons more pig iron than the UK.

- In 1750, there were 72 iron factories and 29 copper smelters operating in the Russian Empire.

- 1767 83 thousand tons of cast iron.

- 1793 134 thousand tons of cast iron, 89,760 iron and steel.

- End of the 18th century. The country mines and processes: 2900 tons of copper, 1300 tons of lead, 28.7 tons of silver, 0.4 tons of gold.

In the early and mid-19th century, the growth rate of Russian metallurgy decreased significantly, which is explained by the establishment of state ownership of the largest enterprises, and as a consequence: the reluctance to update and improve equipment and establish new capitalist relations.

Metallurgy

Production of cast iron and steel on the territory of the Russian Empire in the 19th – early 20th centuries

| Years | Steel (thousand tons) | Cast iron (thousand tons) |

| 1830 | 178,72 | 108,8 |

| 1850 | 222,24 | 328,0 |

| 1870 | 350,40 | 221,20 |

| 1900 | 2865,60 | 2643,20 |

| 1913 | 4884,80 | 4803,20 |

Major political events at the beginning of the 20th century led to the liquidation of the mining industry and the shutdown of metallurgy enterprises. However, by the beginning of the Second World War, the USSR managed not only to restore, but also to significantly increase and modernize the industry. Domestic political and global economic problems of the late 20th and early 21st centuries significantly affected metal production. However, today the Russian Federation maintains high performance, remaining one of the world's largest exporters of this type of product.

general characteristics

The metallurgical complex belongs to the basic branches of the industry. This industry is engaged in the production of cast iron, steel and rolled products. In addition, it includes :

- mining, ore dressing;

- obtaining auxiliary and nonmetallic raw materials;

- secondary redistribution;

- production of refractories;

- coking of coal.

Ferrous metallurgy products are widely distributed in various sectors of the economy. However, it is of greatest importance for the metalworking and engineering industries, railway transport, and construction. This industry is also closely related to the chemical and light industries.

Rice. 1. Mechanical engineering.

Iron, as a pure chemical metal, does not have high structural parameters. To provide it with increased strength and at the same time ductility, other elements are added to it. Cast iron is an alloy of iron and carbon produced in a blast furnace. Steel is also an alloy of iron and carbon, but with a different concentration, as well as with other elements. Steel is smelted in open hearth furnaces.

The Russian ferrous metallurgy has a rich history. At first, iron ores were smelted in cheese furnaces and furnaces. Factory production of iron became possible in the 17th century, when the first plant with a blast furnace was built in Tula.

By the beginning of the twentieth century, iron and steel industry was well developed in several countries: Germany, USA, Great Britain, Luxembourg and Belgium. However, over time, the share of these countries has decreased significantly. Currently, the overwhelming majority of metallurgical products are produced by developed countries, which specialize in the production of high-quality steel and complex types of rolled products, while developing countries produce low-grade steel and cast iron.

Rice. 2. Metallurgical plant in Luxembourg.

Role in the economy

Metallurgy has always been the basis of the economy, since without its products the work of such industries as mechanical engineering, agriculture, construction, transport, and energy is impossible. The role of this industry is also great in the formation of the defense complex, the exploration of outer space and the creation of conditions for the development of the most advanced technologies. Ultimately, it is the current state of the metallurgical complex that reflects the level of the country’s scientific and technical potential and determines the development of all sectors of the national economy.

Only on its basis is it possible to implement new “breakthrough” technologies that can bring our country to the most advanced frontiers of the world economy. Because it is here that today the absolute majority of materials are created, endowed with special physical and chemical properties, without which the material realization of any achievements of progress is impossible.

Ferrous metallurgy

One of the main industries providing heavy engineering and a number of other ministries:

- Steel.

- Cast iron.

- Ferroalloys.

- For rent.

Ferrous metallurgy provides up to 10% of the country's industrial production, with employment of 385.6 thousand people. At the same time, it is one of the largest components of the influx of foreign currency. Thus, in 2021, the export of ferrous metals brought $10.1 billion to the country’s budget.

Production Features

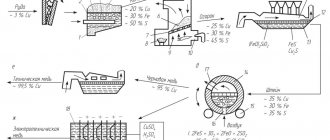

Ferrous metals are iron, manganese, chromium. Fossil ores of these metals are rich in the content of the desired component and can be mined in open pit and underground mines. The process of obtaining the final product itself includes a number of successive stages:

- Extraction and enrichment of iron, manganese and chrome ore, as well as non-metallic raw materials used in the production: refractory clays, fluxing limestones, molding materials.

- Pelleting is the formation of small volumes of raw materials with the properties necessary for blast furnace smelting.

- Smelting or manufacturing: carbon steel, cast iron.

- Production: rolled products, ferrous metal powders.

- Production of cast iron or steel pipes.

- Processing of scrap and waste ferrous metals for the purpose of their recycling.

Ferrous metallurgy

The technological cycle itself consists of the following productions:

- Cast iron and blast furnace.

- Electric steelmaking.

- Oxygen converter.

- Martenovskoe.

- Continuous casting.

- Rental.

Enterprises

The largest ferrous metallurgy enterprises:

- JSC United Metallurgical Company.

- OJSC "Pipe Metallurgical Company"

- OJSC "Holding"

- Mechel Group PJSC.

- PJSC Severstal.

- Public.

Full cycle

In partial cycle metallurgy, the emphasis is on one type of product - cast iron, steel or rolled products. Conversion plants are a separate group specializing in the production of steel without smelting iron; it also includes pipe rolling plants.

The location of such production depends on proximity to sources of recyclable materials and consumers of finished products. In the case of machine-building plants, this is one person, since they are both consumers and sources of scrap metal.

For small metallurgy, which is part of mechanical engineering enterprises, as is clear from the location, the main reference point is consumers.

The production of ferroalloys and electric steel is also part of the ferrous metallurgy industry.

The first are alloys with alloying metals such as ferrosilicon and ferrochrome. They are produced at conversion plants (cast iron-steel, cast iron) or full-cycle plants.

They are important for the development of high-quality metallurgy. They are produced electrometallurgically at specialized plants, but this consumes a large amount of electricity - up to 9 thousand kWh is needed for 1 ton. The production of electric steel is most developed in areas where there is a necessary accumulation of scrap metal and energy sources.

In modern mechanical engineering, which requires metal of different grades, high quality, and limited quantities, the products of mini-factories are in particular demand. They do not require large capacities and are capable of promptly smelting a specific metal in small quantities.

Their advantage is a quick response to changes in market conditions, maximum satisfaction of consumer demands and high quality of the resulting steel, a feature of melting using the progressive electric arc method.

Production and use of cast iron and steel

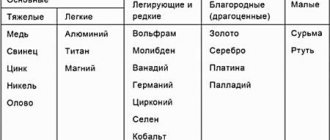

Non-ferrous metallurgy

An industry engaged in the extraction and production of non-ferrous metals and their alloys, including: light, heavy, precious, rare, refractory. Compared to ferrous metallurgy, its production volumes are 20 times less, although its share in GDP is 7.8%, which is reflected in the number of personnel, amounting to 193 thousand people.

However, in terms of exports, non-ferrous metallurgy is significantly ahead of ferrous metallurgy. In 2021, the industry delivered to the international market:

- Non-ferrous metals worth $11.2 billion.

- Precious metals – by 11.2 billion dollars (gold – 124 tons).

- Rentals - by 2.4 billion dollars.

Production Features

Non-ferrous metals include all metals except iron and its alloys. Their production technology represents a certain sequence, which includes:

- Mining and beneficiation of ores.

- Smelting and sometimes also refining of metal.

- Receiving redistribution.

- Production of rolled metal.

Non-ferrous metallurgy

Distinctive features of production in non-ferrous metallurgy are:

- The raw material “poverty” of ores, compensated by a wide variety of accompanying elements.

- Increased demand for raw materials, water and energy resources.

- The complexity and multi-stage nature of a large number of different technological cycles used in the processing of raw materials and in the process of obtaining the final product.

It is quite logical that such specific features required the creation of multidisciplinary associations, sometimes combining chemistry, metallurgy and energy.

Enterprises

The leaders of non-ferrous metallurgy today are:

- JSC RUSAL Sayanogorsk Aluminum.

- JSC "Electrozinc"

- OJSC Sredneuralsk Copper Smelter.

- Evraz Vanadium Tula LLC.

- LLC "Mednogorsk Copper and Sulfur Combine".

- LLC "Novoangarsk Concentrating Plant"

- PJSC MMC Norilsk Nickel.

- PJSC RUSAL Bratsk Aluminum Plant.

- PJSC "Chelyabinsk Zinc Plant".

Basic principles of placement

Due to their specific nature, metallurgical enterprises should be located in close proximity to:

- Places of occurrence and extraction of fossil ores.

- Sources and production of fuel: coal, coke.

- Water resources.

- Electric stations.

- Areas of consumption of finished products.

A developed transport infrastructure plays an important role in this. Production must be provided to one degree or another with: railway, road transport, water and fuel supply pipelines, as well as power lines.

Geography of location

Objects that use common resources for their needs and produce metal are called metallurgical bases. Their geography on the map:

- Ural. A characteristic feature of this territory is the absence of coal, so forest resources are used here as fuel. All enterprises are located near iron ore deposits. The following industrial complexes are located here: Chelyabinsk, Nizhny Tagil, Magnitogorsk, Orsko-Khalilovsky. They produce cast iron, steel and rolled products.

- Central regions of Russia. Ferrous metallurgy developed in these regions due to the presence of rich iron ore deposits. The Novooskolsk and Lipetsk metallurgical plants were built here. In addition, a number of factories are located in Moscow, Orel, and Tula.

- West Siberian territory. The development of metallurgy here occurs due to the presence of iron ore and coal from the Kuzbass basin. Despite the nearby Trans-Siberian Railway, there are difficulties in transporting finished products to consumers.

In Russia, the production of metallurgical products exceeds domestic needs, so it is export-oriented. This has its own difficulties due to the high competition in the global market.

Industry competitiveness

The formation of the competitiveness of the metallurgical complex occurs in the conditions of established commodity-money relations in the international market and within the country. Accordingly, its performance is significantly influenced by the following factors:

- For the entire industry of the country as a whole, as a supplier of exported products:

- General economic and political situation in the world.

- The current situation in the global metallurgical market.

- International legislation together with the legal norms of product importing countries.

- For an individual manufacturer:

- Production and economic potential.

- Level of technical equipment.

- The location of the enterprise in relation to the supply of necessary resources and the organization of sales of finished products or products.

- Degree of integration.

The conducted studies show that the industry, one of the first in the country to become:

- Restructure production capacity.

- Eliminate ineffective equipment.

- Build industry structures, specialize, and then unite into complete completed cycles.

- Increase production of the most profitable and best-selling products.

- Engage in cost reduction.

- Solve environmental issues.

- Improve the social conditions of your employees.

Overall, it has achieved a high level of competitiveness.

Mctallurgy

Although some indicators: electricity consumption per unit of production (20-30% more than in Germany and the USA); labor costs (2.5 times higher than in Germany, the USA and Japan) remain at a very low level. Which requires further work to update production capacity and optimize the structure.

General overview of the state of ferrous metallurgy in Russia

The Russian Federation is one of the world's largest producers of cast iron, steel and rolled metal products. This is largely due to the fact that the country has rich deposits of iron ore and coking coal, used as a fuel resource. The metallurgical industry in Russia is a system-forming and highly efficient industry.

History of the development of the metallurgical industry

Humanity learned to process iron ore at the dawn of its history. Archaeologists even distinguish such a historical era as the “Iron Age,” which refers to a time period when the main tools of production were iron products.

Development prospects

The main prospects for the development of Russian metallurgy are opening up by solving two main problems:

- Inconsistencies between the level of production and market requirements in terms of qualitative and quantitative indicators.

- Modernization, which must be carried out through the introduction of modern technologies of the highest scientific level.

- The most effective areas in this regard are:

- Further preferential use of blast-free smelting methods.

- Increased use of secondary resources. In light of the depletion of existing deposits and the difficulties of developing new ones, this direction is especially relevant!

- Increasing the share of alloys and other products of a high scientific and technological level.

- Introduction of energy-intensive but at the same time economical technologies.

- Resource and energy saving.

- Reducing environmental pollution.

All these areas are reflected in the development strategies of metallurgical production for 2014-2020 and for the future until 2030.

Author: Yuri Florinskikh All articles by this author

Latest articles by the author: The largest producers of milk and dairy products in the world Diamonds: properties, mining methods and applications

Production Features

Metallurgical production involves a cycle of technological processes that can be carried out either entirely at one enterprise or at different ones. Stages:

- iron smelting;

- steel production;

- rolling production.

Thus, at full-cycle enterprises, all of the above stages are carried out. If the plant produces only rolled products, then such production is called marginal.

At the moment, the world gives preference to the development of small-scale metallurgy, where the production of steel and rolled products takes place at machine-building plants, and this significantly reduces the costs of the final product. However, large full-cycle plants remain in operation.