Characteristics of plastic products

The category of plastic pipes includes products made of polypropylene, polyethylene and polyvinyl chloride. Sewer pipes made from these materials have many similarities.

Preparing trenches for laying sewer pipes

Pipelines with standard sizes are available for sale. Their diameter is determined by GOSTs, that is, pipes can have sizes of 10, 50, 90, 110, 300 and 160 mm. There are also products of large diameters, but they are not suitable for private construction.

Basically, the connection of plastic pipes is made using a similar technology by inserting into a fitting or other pipeline. Fittings include tees, angles, crosses, bends, revisions, plugs.

All plastic products are light in weight, density 0.95-1.4 g/cm3, and differ in dielectric properties. Pipes have a slippery and smooth surface, which protects them from deposits.

PVC pipes are resistant to alkalis, acids and mineral oils. They are characterized by long-term operation, but at a temperature of 70 degrees their strength begins to lose. Therefore they are not suitable for industrial sewerage equipment. Also, PVC pipes are hard and slightly brittle and have low sound insulation.

Polyethylene pipes differ from PVC products in being more slippery and pliable. Polyethylene is characterized by better noise absorption, resistance to mechanical damage, and better chemical resistance to acids, biomass and alkalis. Polyethylene can be used to produce corrugated products intended for underground installation, resistant to pressure and soil displacement. But there is a risk of pipe deformation when pouring hot water.

installation of inspection wells

A more durable material for the production of pressure pipes is polypropylene. Its softening temperature reaches 140 ºС, melting temperature – 175 degrees. Polypropylene sewerage is resistant to boiling water, but at temperatures below 5 ºС the material becomes brittle. Because of this, pipelines need to be laid underground or thermally insulated. Polypropylene is highly resistant to wear, so it can be used for draining wastewater with a high content of solid abrasive elements.

Characteristics of products made of cast iron and other materials

Cast iron pipes can often be found in old buildings, but they are no longer recommended for new buildings. The only advantage of cast iron pipes over plastic ones is their high noise absorption. Otherwise, they are characterized by large mass, high cost, and complex installation. They can be used for laying under roads due to their high strength. If you have chosen these pipes, then it is better to choose products treated with an anti-corrosion compound.

When constructing a sewer system in cities and enterprises, ceramic, reinforced concrete and asbestos-cement pipelines can be used. But they are not used in domestic conditions.

Mostly, home owners refuse cast iron products due to difficult installation and large mass, preferring their plastic counterparts. Plastic pipelines can be laid independently without specialists. In addition, plastic is characterized by resistance to aggressive environmental influences and durability.

For laying internal sewerage, it is better to choose polyvinyl chloride products that are resistant to wastewater at different temperatures. The pipes withstand freezing and soil pressure, do not form cracks and there is no loss of shape. In addition, plastic structures are sealed and corrosion resistant.

The rules for laying sewers have one condition that must be strictly adhered to - avoid sudden changes in levels and turns. When laying sewerage, you must comply with the regulatory documentation SNiP P-G.3-62.

ensuring the correct slope angle of the sewer pipe

Asbestos cement pipes

Asbestos-cement pipes are durable, which is why sewer pipelines are made from them. Cement and asbestos fiber are not destroyed by rot, acids or corrosion.

Asbestos-cement pipes in a storm sewer system

Advantages:

- cheapness,

- durability,

- resistance to acids, alkalis, aggressive environments,

- strength,

- ease of installation,

- resistance to clogging.

Flaws:

- fragility, instability to mechanical stress,

- harm to people and the environment.

Given their low cost and durability, asbestos-cement pipes are not the best option. They are more difficult to transport and install than polyplastic - the weight is higher than that of polymers. Also, asbestos cement crumbles at the edges, which is why the tightness is compromised if the connections are incorrect or of poor quality. The most dangerous, especially for internal connections: the environmental damage of asbestos concrete. Asbestos releases carcinogens; it is dangerous to work with and live near it.

Selecting the diameter of the sewer pipeline

If you study SNiP 2.04.01-85, it describes in detail the calculation for choosing the size of pipes for sewerage. It turns out that the suitable diameter of the sewer pipe in a private house is 50 mm, to which plumbing equipment for the kitchen and bath can be installed. For the riser and toilet, structures with a diameter of more than 10 cm are chosen, since in such places a large water flow is created.

The toilet should be mounted to the riser via a separate pipeline. There is no need to connect products with a smaller size to its drain, otherwise the flow may block the cross-section of the pipeline and create a vacuum in the connected pipe. Because of this, the siphons of other equipment may become dry.

As a result of this, the optimal choice would be pipes with a diameter of 50 mm for horizontal surfaces that go to the kitchen or bathroom, and for the riser and toilet - 110 mm.

For individual drain points (shower, bidet, sink) you can use smaller pipe diameters of 22-40 mm. Here rubber cuffs or couplings with a transitional size are used.

For apartment buildings (with 5 floors), pipes with a diameter of 100 mm are suitable, and in buildings with more floors, pipelines larger than 150 mm should be laid.

Pipes connecting several risers with access to the sewer well can be up to 20 cm in size.

Features of sewerage installation

In addition to choosing the appropriate pipe size, you should consider the details of laying the sewer system. The diameter of the horizontal pipeline cannot be larger than the drainage riser. Installation of horizontal connections is carried out with oblique angles and tees. Right angles are allowed only when connecting the riser to a horizontal section.

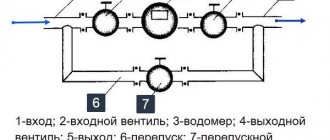

At sewer bends, revisions are installed - openings with covers for cleaning pipes.

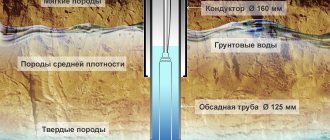

First, a system design is created, which takes into account the following factors:

- soil composition;

- mechanical loads on the sewer system;

- soil freezing depth;

- depth of groundwater.

The project reflects the placement of all drain points in the house, on the territory, the location of the water intake point, and the septic tank. The turning points, sewer pipe installation lines, and inspection installation are also indicated.

At this stage, the material used, the need for thermal insulation, drainage system and the number of adapters are determined. For bends and adapters, a slope of 45ºC must be created; from the pipe to the septic tank the slope must be at least 2 cm per linear meter. If the sewerage system is laid above the freezing point of the soil, it is insulated and the connections are sealed with sealant or silicone.

laying sewer pipes at the foundation stage

Do-it-yourself installation of sewer pipes begins after marking the system on the territory, calculating the installation depth, selecting pipes of the required diameter, and a cleaning facility.

Preparatory work involves digging a pit for a septic tank or cesspool, after which a trench is dug for pipe installation. They need to be dug 20 cm lower than the planned level of laying sewer elements.

Plastic is resistant to low temperatures, but to prevent water from freezing in such pipes, they are wrapped with thermal insulation and covered with a dry mixture of cement and sand in a ratio of 1/3.

laying a drain pipe to a sewer septic tank

In order for the sewer system to work properly, the slope of the pipes specified in the project must be observed. The depth of the trench on a flat surface near the house should be less than near the treatment plant. With a natural slope from the building to the septic tank, a trench is dug with a uniform depth along the entire length of the pipes.

On a steep slope, it is better to divide the sewer system into compartments with different levels, where drop-off or distribution wells are installed.

The bottom of the trench is compacted and covered with a crushed stone or sand layer. Pipes can be laid in a trench to any depth. When the groundwater level is high and the soil is deeply frozen, a buried trench is dug into which the pipeline is laid high. When the water level is low, it is placed near the bottom or in the center of the trench.

Before laying pipes in trenches, you should check the inside for cleanliness. Laying of the pipeline begins from the drain points in the house, after which the sewer is installed towards the treatment plant and connected to the remaining branches of the street drain.

You should remember to install pipes using an O-ring or silicone grease, installing them in areas of turns and branches of auditors. After carefully laying the pipes, they are carefully wrapped with thermal insulation. Inspection wells, auditors and a ventilation pipe are installed near the house. If the pipeline is long, it will be necessary to create 1 or 2 ventilation pipes.

Before backfilling the system, a control drain should be performed, which will reflect the quality of the pipe installation.

At the end of all work, the sewer pipes are first filled with a mixture of sand and cement to a depth of 15 cm, and then with soil. Inspection wells and revisions are installed 20 cm above the ground level.

Additionally, you can familiarize yourself with video instructions on laying a sewer system, which you can do yourself if you follow the appropriate rules.

Work on installation of sewerage systems performed by specialists of our company >>>

Laying external sewerage, at the dacha

External sewage system at the dacha

- this is part of the pipeline system located outside the house, designed to drain wastewater from buildings into a treatment system or into a centralized sewer system.

external sewerage in a dacha is carried out underground, usually at a depth of 0.6 to 1 meter. Underground pipelines are laid at a slight slope towards the sewerage receiver from 3 to 1 cm per linear line. meter, depending on the length.

For laying underground sewerage pipelines, only thick-walled pipes with high ring rigidity are used. Namely, PVC pipes with a wall thickness of at least 3.6 mm, brown or red in color; in some cases, when laying sewers at great depths, corrugated pipes that can withstand higher loads can be used.

Attention!

For underground installation, you can use only thick-walled PVC pipes with a wall thickness of at least 3.6 mm or even more reinforced corrugated pipes. PVC pipes for underground installation are usually available in brown or red color.

» rel=»lightbox» href=»assets/cache/directresize-wm/wm_vodosnabgenie_dachi_kiriyanovo_7.jpg»> Laying underground sewerage pipes in a dacha is in most cases done manually, without the use of any construction equipment.

The process of laying an underground sewer pipeline occurs as follows:

First of all, a trench of the required length and depth is developed onto the base of which sand is poured and leveled at the required slope, thereby creating a solid and level foundation for the subsequent laying of the sewer pipeline. Next, the sewer pipes are connected through rubber seals and laid on the prepared base.

Laying external sewerage pipes

includes connecting the sewer pipeline to the sewer receiver. This connection must be absolutely sealed, otherwise there is a high probability of flooding the sewerage receiver with groundwater.

» rel=»lightbox» href=»assets/cache/directresize-wm/wm_podkluchenie_topas.jpg»> Treatment stations for deep biological treatment of the “Topas” type and other polypropylene containers are connected to the supply pipelines by means of a socket connection, the connecting socket is welded into the sidewall of the installed container.

The connection of the pipeline with the fiberglass sewage receiver is also completely sealed - the connecting pipe is inserted at the factory. The socket-pipe connections themselves are made through special rubber seals. They ensure complete tightness of the pipeline sewer system.

Our

carries out installation of external sewage systems at the dacha in various designs, adhering to one very important principle - we ensure complete tightness of the entire sewer system.

Underground sewerage installation at the dacha

is carried out, depending on various conditions, at a depth of 0.6 to 1.5 meters on a flat, pre-prepared surface. Namely, on a compacted, water-spilled sand cushion. Backfilling of the trench is carried out only after checking the required slope of the pipeline being laid.

When installing long-distance sewers

inspection and, if necessary, rotary and distribution wells are installed.

Ceramic pipes

This is the most ancient material of all, which is gradually being used less and less.

Old ceramic sewer pipes

Advantages:

- neutrality to chemicals,

- smooth inner surface,

- resistance to temperature changes,

- easy installation.

Flaws:

- fragility,

- short length of one pipe.

Ceramic products used to be excellent for sewerage. But now many other materials that are lighter or stronger have similar properties.

Installation of internal sewerage, in the country

» rel=»lightbox» href=»assets/cache/directresize-wm/wm_vodosnabgenie_dachi_kiriyanovo_5.jpg»> The installation of internal sewerage is the installation of sewer pipelines throughout the house with outlets to the necessary plumbing fixtures.

Laying of all internal sewerage pipes

performed at a slight slope (from 1 to 3 cm per 1 linear meter) towards the main riser.

Internal sewage system

at the dacha can be done both open and hidden. When laying in a hidden way, pipes are laid in places invisible to the eye, between ceilings, under the floor, in wall cladding.

For laying internal sewerage, thin-walled pipes of domestic production are used, usually they are gray in color. Depending on the configuration of the system, pipes vary in diameter from 30 to 110 mm.

We

We install various sewer systems intended for use specifically in the country. We carry out installation of external and internal sewage systems in various designs, including turnkey ones.

Call our team and order perfect and high-quality sewer systems designed to work specifically in your country house!

Almost all sewer systems that are created to ensure the normal functioning of residential, industrial, administrative buildings, social and cultural facilities are equipped with sewer systems. They are complexes of engineering structures, which, as a rule, consist of above-ground and underground parts. One of the Russian companies that successfully design and implement modern sewerage systems of any degree of complexity is Flotenk.

To order and calculate treatment facilities, send a request to E-mail: or call toll-free. Or fill out .

Aboveground and underground sewerage from Flotenk

One of the main specializations is the development of complexes of sewer systems, consisting, as a rule, of above-ground and underground parts. By contacting this company, you can either buy ready-made standard systems that have proven themselves in practice, or order specialized ones that best meet the specifics and needs of each specific client. manufactures almost all elements of these engineering complexes on its own production base from such modern material as fiberglass.

Topology of sewer systems

Almost any modern sewer system consists of those sections that are located above the surface of the earth, and those that are laid directly into the ground or into cavities specially prepared for this purpose in it. In addition, it includes underground sewage tanks, which are intended to accumulate wastewater and purify it from impurities in accordance with accepted sanitary and hygienic standards.

As a rule, above-ground sewerage represents that part of the overall system that is located in buildings and structures, as well as in close proximity to the surface of the earth (for example, most of the stormwater communications). Underground sewerage is characterized by the fact that it is buried in the soil, and therefore all its elements are hidden from view. These include pipelines and specialized tanks.

Underground sewerage

Design and installation of underground sewerage, as a rule, is a more technically complex, time-consuming and expensive procedure. It requires mandatory consideration of factors such as the expected volume of wastewater discharge per unit of time, geography of the area, as well as climatic conditions. According to current rules and regulations, underground sewerage installation must be carried out below the freezing depth of the soil in winter. Almost all modern equipment used for wastewater treatment and included in sewer systems is designed specifically for underground installation.

Aboveground sewerage

This part of the sewer system requires careful calculation and design, since it is intended to collect all wastewater that must be treated and further discharged into the environment. Aboveground sewerage installation is a rather difficult task, the solution of which should only be carried out by true professionals in their field. For the manufacture of its components, materials such as plastic and fiberglass are now often used, which are characterized by strength, resistance to various types of mechanical and chemical influences, and also a relatively low price.

Many people ask themselves the question: is it possible to lay sewer pipes on the ground? Answer: yes, you can.

Before starting work, you just need to select the desired type of pipe. Previously, only asbestos or cast iron were used, but now plastic ones are increasingly used.

They have many advantages:

- cost relatively little;

- during installation, you can make much fewer joints on one line;

- resistant to temperatures ranging from -50 to +60 degrees Celsius;

- they are joined by gluing or cold welding;

- have a service life of more than fifty years;

- resistant to liquids with an acidity level greater than 10 pH;

- You can lay plastic pipes yourself even in difficult areas, for example, under an asphalt surface.

To lay a street underground sewer, orange or brown PVC pipes are required. There are two types - SN4 (3.0 mm wall) and SN8 (3.2 mm wall).

Each product is marked with markings, so choose carefully. Incorrectly placed pipes will lead to rapid failure.

Such pipes perfectly withstand the aggressive effects of the environment; they are smooth on the inside, which prevents blockages from appearing, and have a long service life. However, they are difficult to tolerate exposure to high temperatures. If liquids hotter than +40 degrees are drained into the sewer system, the service life will be significantly reduced.

Important point! Gray PVC pipes are often used for laying sewer systems inside buildings. They should not be used for street work. They are too soft and will not be able to withstand significant external loads. The thickness of their walls is only 2.7 mm.

Corrugated polypropylene products for sewerage are now on sale. These products are often used in industrial enterprises. They tolerate high temperatures well and are much stronger than conventional smooth pipes.

Even if you lay corrugated polypropylene pipes deeper than 2 m, the weight of the earth will not harm the product.

These products are perfect for laying underground sewers. Polyethylene is a fairly strong material, and the corrugated structure increases the strength against external influences several times more.

Important point!

Corrugated polyethylene pipes can be buried 15 m into the ground without fear of being crushed. They withstand temperature changes well (unlike orange PVC products, they do not deteriorate from hot liquids) and aggressive environmental influences.

In addition, these products have excellent throughput. Only their outer surface is corrugated. The inside of the product is smooth, which prevents blockages from appearing.

There are also more rarely used materials. For example, asbestos-cement pipes. They weigh less than cast iron, can withstand heavy loads and withstand aggressive environments well. But they are quite fragile, and their installation is much more difficult than the installation of polymer products.

PVC pipes cost less than other types. They are quite strong and have a long service life. But they do not withstand high temperatures well; too much hot water will quickly deteriorate them. PVC pipes are ideal for small private houses and cottages.

Corrugated polyethylene pipes cost more, but they are durable and reliable. The sewer system will last for several decades without any blockages.

Cast iron pipes

Cast iron pipes are divided into gray cast iron and ductile iron materials. Gray cast iron does not resist dynamic loads well: for example, cars passing over a sewer line. Malleable cast iron perfectly withstands any load and, unlike other ferrous metals, does not rust.

Old cast iron sewer pipes

Advantages:

- high strength,

- durability,

- resistance to low and high temperatures,

- simple installation,

- corrosion resistance.

Flaws:

- heavy weight,

- roughness of internal surfaces,

- instability to salts and saline solutions,

- high price.

To bring and install cast iron pipes you will need special equipment. The costs of the material itself add up to the costs of building a sewer system. However, after installation, the sewerage system does not guarantee a long period of flawless operation due to the possibility of silting.