Submersible pumps are the main part of such an important structure as a sewage pumping station (SPS). KNS pumps lift and pump:

- silt;

- storm drains;

- industrial waters;

- domestic wastewater.

It is about them, their design, installation features, as well as the methodology for calculating suitable equipment that will be discussed in our article.

Sump station located on the site

General information

Depending on the complexity of the design and operational characteristics, sewage pumping stations can be divided into three main categories: simple, medium complexity and complex. It makes no sense to use complex water pumping stations for a private home, since such expensive installations are characterized by high productivity, significantly exceeding the volume of wastewater accumulating in a private building. SPS of complex category are equipped with industrial enterprises, during the course of their activities a large amount of wastewater is generated.

To service private homes, it is advisable to use household pumping stations, which are characterized by their compact dimensions and affordable cost. When choosing a specific modification of a water pumping station for a home, the expected volume of wastewater, the degree of its contamination, as well as the type of contaminants that are present in such waters are taken into account. In addition, it is necessary to take into account the topography of the area where the station will be installed, as well as the depth of the sewer pipes.

Household mini pump station

Control cabinet

The control cabinet is located outside the housing and is located on the ground surface next to the pump station. This arrangement is economical and convenient to use.

The SPS control cabinet, as standard, controls the operation of the SPS and provides protection for the electrical equipment of pumping units. Optionally, it can be equipped with a dispatch and remote control system via wired and wireless communication channels.

The control cabinet may be equipped with a switchboard for automatic transfer of a reserve (ATS) to switch the power supply to reserve lines in the absence of voltage at the main input, overloads, or short circuits. This allows you to quickly restore the operation of the pumping station and protect process equipment from overloads.

A modern control system provides control of all operating parameters of the pumping station:

- liquid level in the receiving tank;

- operation of electric motors and their tightness;

- power consumption;

- winding and bearing temperature;

- waste liquid consumption;

- number of starts per hour, etc.

Monitoring operating parameters over time allows for timely monitoring of possible malfunctions in the operation of the station. A signal is sent to the control panel not only in the event of an emergency, but also warning of the critical condition of equipment components.

The control cabinet housing can be made with anti-vandal protection.

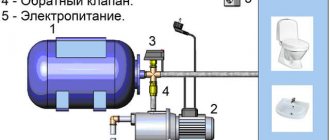

Device diagram

Different types of pumping stations for sewage differ from each other in design, but regardless of the modification, their main elements are a pump and a sealed tank into which waste products are collected. The reservoir with which the sewage pumping station is equipped can be made of concrete, plastic or metal. The task of the pump that is equipped with the sewerage station is to raise wastewater to a certain level, after which it flows into the storage tank by gravity. Once the tank is filled, the wastewater is pumped out and transported to a disposal site.

Middle class pumping station device

Often, the design of a household pumping station includes two pumps, the second of which is a backup and is used in cases where the main one fails. Sump stations serving industrial and municipal enterprises with large volumes of wastewater are required to be equipped with several pumps. Pumping equipment for pumping stations can be of various types. Thus, domestic sewage pumping stations, as a rule, are equipped with pumps with a cutting mechanism, with the help of which fecal matter and other impurities contained in wastewater are crushed. Such pumps are not installed at industrial stations, since solid inclusions contained in wastewater from industrial enterprises, if they get into the cutting mechanism of the pump, can lead to its breakdown.

Construction and connection of a small-sized pump station located indoors

In private homes, mini water pumping stations are often installed, the pumps of which are connected directly to the toilets. Such an aesthetically designed water pumping station (a real mini-system equipped with a pump with a cutting mechanism and a small storage tank) is usually installed directly in the bathroom.

Serial models of sewage pumping stations are equipped with polymer tanks that are buried in the ground, while the neck of such a tank for sewage pumping stations is located on the surface, which facilitates routine inspections, maintenance and repair of the tank, if the need arises. The neck of the storage tank before the start of operation of the pumping station is closed with a lid, which can be made of polymer material or metal. The connection of such a tank to the sewer system through which wastewater enters it is carried out using pipes. To ensure that wastewater flows into the storage tank evenly, a special baffle is provided in its design, and a water trench wall is responsible for ensuring that no turbulence occurs in the liquid medium.

KNS are divided according to their layout into horizontal (left) and vertical (right)

Sewage pumping stations for a private home are equipped with control devices and automatic control mechanisms. Additional elements that are supplied to industrial sewage pumping stations and installations for servicing a home sewer system include:

- a source that provides backup power supply to the equipment included in the pumping station;

- pressure gauges, pressure sensors, shut-off valve elements;

- equipment that provides cleaning of pumps and connecting pipes.

According to the design, SPS are available with submersible pumps, dry version and multi-section

Pumping station valve control diagram

Let's consider the circuit of a pump valve, which is controlled through a gearbox by a small-sized asynchronous electric motor. When voltage is applied to the circuit, the green lamp begins to glow fully. It signals the closed position of the plug. The pumping unit is started by the RU level relay. One of the RU contacts gives a command to start the electric motor M1 of the pump unit, and the second closes the circuit of the relay coil RP1, which controls the operation of the plug motor M2.

After starting the pump and increasing the pressure in the water supply system to a normal level, the contact of the pressure switch RD, connected in series with the contact RU in the RP1 coil circuit, closes. Relay RP1 is pulled up, closes the normally open contact and supplies voltage to the contactor for opening the KO valve. The contactor starts the M2 electric motor to open the valve. The process of opening the valve is controlled by the limit switch VK2, as well as by a brightly burning red lamp. After the valve is completely opened, the contacts BK2 will open, the KO will turn off, and the valve control motor will stop. The red lamp will burn at full intensity, and the green lamp will go out completely. The valve closing circuit works in a similar way. For emergency shutdown of the control circuit, the VKA emergency switch is used. When the switch is triggered, both warning lamps go out.

How does KNS work?

The CNS has a fairly simple operating principle.

- Wastewater from the sewer system enters the receiving part of the installation, from where it is pumped into the pressure pipeline.

- Through a pressure pipeline, wastewater is transported to a distribution chamber, from where it is then pumped into the treatment plant system or into the central sewer system.

Scheme for treating wastewater from a private house using SPS

To ensure that wastewater does not return through the pipeline to the pump, the pumping station is equipped with a check valve. If the volume of wastewater in the sewer pipeline increases, an additional pump is turned on at the station. If the main and additional pumps for the pumping station cannot cope with pumping the volume of wastewater, then a device is automatically turned on, signaling the occurrence of an emergency situation.

The operating principle of industrial SPS provides for automatic control of such installations, which is provided by float-type sensors installed at different levels of the station's receiving tank. A CNS equipped with such sensors operates according to the following principle.

- When the level of wastewater entering the tank reaches the level of the lowest sensor, the pumping equipment remains turned off.

- When the tank is filled with wastewater to the level of the second sensor, the pump automatically turns on and begins pumping the wastewater.

- If the tank is filled with waste to the level of the third sensor, the backup pump is turned on.

- When the tank is filled to the fourth (topmost) sensor, a signal is triggered indicating that both pumps involved in the pumping station cannot cope with the volume of wastewater.

Scheme of automatic control of the operation of the pumping station

After the level of wastewater pumped out of the tank drops to the level of the lowest sensor, the system automatically turns off the pumping equipment. The next time the system is turned on, the backup pump is activated to pump wastewater out of the tank, which allows both pumping devices to operate in a gentle mode. The station’s operation can also be switched to manual control mode, which is necessary in cases where the pumping station is being maintained or repaired.

Download the standard project for sewer station TP 902-1-170.91:

TP 902-1-170.91 - Album 1 - Explanatory note (10.5 MB) TP 902-1-170.91 - Album 2 - Production technology. Internal water supply and sewerage. (7.6 MB)TP 902-1-170.91 - Album 3 - Above-ground part and general drawings of the underground part (25.7 MB)TP 902-1-170.91 - Album 4 - Products (7.8 MB)TP 902-1 -170.91 - Album 5 - Underground part (22.6 MB)TP 902-1-170.91 - Album 6 - Power electrical equipment. Technical control. (28.4 MB)TP 902-1-170.91 - Album 7 - Non-standard equipment (23.8 MB)TP 902-1-170.91 - Album 8 - Equipment specification (9.7 MB)TP 902-1-170.91 - Album 9 - List of requirements for materials (6.7 MB) TP 902-1-170.91 - Album 10 - Estimates. General part (17.6 MB) TP 902-1-170.91 - Album 11 - Estimates. Underground part (9.4 MB)| from 2,200 to 10,000 m3/hour |

Types of pumping equipment for pumping stations

The main and most important element of any sewerage pumping station is the pump, whose task is to pump out domestic and industrial wastewater, sludge and liquid media coming from storm sewers. The main types of pumps that are used to equip pumping stations are:

- submersible devices;

- console pumps;

- self-priming pumping equipment.

Submersible pumping equipment, classified as pressure-type devices, during operation is constantly in the liquid medium it pumps, therefore the body of devices of this type is made of materials that are resistant to the aggressive effects of substances contained in wastewater.

Submersible pumps for pumping stations

Among the advantages of submersible pumping equipment used to equip the pumping station are:

- no need for a specially designated place for installation, since such equipment is located in the medium it pumps;

- high reliability;

- ease of use;

- no need for frequent maintenance;

- ability to function effectively even at low temperatures;

- spontaneous cooling of internal elements of equipment, carried out by the liquid medium pumped by it;

- versatility, which lies in the fact that pumps of this type can also be installed on the surface of the earth.

Sewage pumping stations based on submersible pumps are the most popular and simplest in design

Using cantilever pumps located on the surface of the earth, industrial pumping stations are serviced. To install such pumping equipment, it is necessary to prepare a separate concrete site and correctly install pipes to it, so it is best to trust the implementation of such a responsible procedure to qualified specialists. The advantages of cantilever-type pumping equipment include:

- high reliability;

- ease of maintenance and repair (since the pump is located on the surface of the earth);

- the ability to change the performance of the device, which is carried out by replacing the electric motor and other structural elements.

Industrial pumping station based on cantilever pumps

Surface self-priming pumps, which can be used to pump even heavily contaminated media, are used to service pumping stations of industrial and municipal enterprises. If we talk about the advantages of pumps of this type, then these include:

- ease of maintenance, which is ensured by a retractable design;

- the possibility of pumping wastewater containing solid inclusions;

- ability to work even at sub-zero temperatures when equipped with a special heating element;

- maximum tightness of the housing, which is ensured by a double mechanical seal;

- ease of installation and dismantling.