The presence of traces of rust on the body of a car is not a pleasant sight. Moreover, this is your own car and you have to watch the unpleasant red phenomenon that spreads further over time. You can get rid of this using an effective method, which is also budget-friendly. Not many people prefer the galvanizing method, for some reason they underestimate it. Tested by some car enthusiasts, the rust goes away immediately, and for free. The secret lies in the use of a salt-type AA battery, orthophosphoric acid, or a car battery.

Treatment with salt batteries

It all starts with preparation. You will need:

- Salt batteries. For example, for a VAZ-2107, five salt batteries will be quite enough.

- Degreaser.

- Several types of sandpaper.

- Putty and a clean rag.

- Wires.

- Acid – phosphoric acid or soldering acid.

- Epoxy primer.

- Citric acid.

- Varnish, paint.

The area damaged by corrosion is thoroughly cleaned and galvanized with a battery. To do this, the top shell with the name is removed from the battery, and a wire is fixed to the body. The second end is connected to a car battery or car battery charger. The longer the wire, the better - it will be more convenient for you to work.

Then you need to apply voltage - the minus goes from the battery or charger to the body. We connect the light bulb in parallel so as not to damage the battery. After this, the battery is wrapped in a rag and soaked in acid. Slowly move this simple device around a protected area. You will hear a hissing sound and the iron will be covered with a light layer of zinc.

The process is long but effective. When the treatment is finished, you need to prepare a solution with citric acid and wipe the treated metal. Then degrease and dry, apply epoxy primer. Although it will cost 500-600 rubles per cylinder, it will hold up perfectly. Next, if necessary, putty is applied, primed and a base is applied. After this, the surface is covered with varnish or acrylic paint.

Read also: Replacing cells in a laptop battery

A couple of minutes solves the rust problem

To remove saffron milk caps you will need your own hands and a simple device. You can make it from improvised means:

- batteries;

- knife with a sharp blade;

- electrical insulating tape;

- regular table soda;

- to protect hands - gloves made of durable material.

The list is also complemented by a one-and-a-half cable and several hygienic cotton pads. Purchase phosphoric acid in advance. It is easy to find in radio parts stores.

Regarding batteries, you will need zinc salt cells. The zinc content can be checked easily, just hold a magnet, it should not be magnetic. Then you need to completely remove the cover from the battery with a knife. Next, we wrap the battery case with a wire in a spiral shape, securing it with electrical tape. A cotton pad must be attached to the negative side of the element with electrical insulating tape.

That's it, the device is ready. This takes on average two to three minutes. With this device we will get rid of rust stains and more. They can perfectly galvanize metal surfaces.

The galvanizing process is accelerated if you first throw pieces of zinc taken from disassembled batteries into the acid. Having completely dissolved in acid and been saturated with zinc, the reaction proceeds three to four times faster.

Other galvanizing methods

In addition to the processing method described above (galvanic), cold and thermal galvanizing is used. Let's look at them in more detail.

Cold galvanizing

Specialized stores sell finely dispersed zinc in cylinders. It is applied to the body like paint. It is far from the most reliable option, but it is the most affordable. It is used if you need to galvanize a budget car.

Thermal galvanization

It is almost impossible to implement it at home. At the factory it’s a different matter. The car body is dipped into molten zinc and rolled. Ford, Volvo, Porsche, etc. cars are subjected to this treatment.

Thus, cold and galvanic galvanizing can be done with your own hands at home, without the help of specialists. The event, although long, is low-cost. Absolutely every car enthusiast can hold it in his garage.

Error in the text? Select it with your mouse! And press: Ctrl + Enter

Is it difficult to check this yourself?

It is impossible to visually determine whether a machine or part of it is galvanized. But there are a few points that will help you figure this out:

- When purchasing a car, carefully inspect the body. 99% of the time you will find a couple of scratches. If the place where the paintwork was chipped simply darkened and there was no rust, the car or part of it was galvanized.

- Use the vehicle's VIN code, which contains technical characteristics, availability of protection and application method.

- Warranty card information. It says here about guarantees of anti-corrosion protection of the body. If a period of 5 to 10 years is indicated, this means cold galvanizing, 10-20 years - the galvanic method, more than 20 - the hot method.

- If the documents indicate that the car is galvanized, but the cost of the car is low, perhaps we are talking about either partial processing or the cold method.

If the machine has full anti-corrosion protection, the technical documentation indicates “full galvanization”.

Do-it-yourself galvanizing of a car body with video and photos

The article will talk about galvanizing a car body with your own hands. At the end of the article you will find a video on the same topic. Galvanizing a car body is quite a scrupulous matter. Therefore, we recommend that you initially practice on any other iron surface, and when you have already become proficient, you can safely start galvanizing the body of your car with your own hands.

To galvanize iron, we need soldering acid (zinc chlorine), you can buy it at a radio parts store, or you can do it yourself - throw pieces of zinc into hydrochloric acid until the reaction stops; zinc electrode; a glass of salted AA battery; a piece of fabric or cotton wool; the wire.

We connect the wire to the battery positive. Disconnect the positive terminal. The minus remains on the body.

We clean the metal so that there is not a drop of rust left on it.

We saturate the fabric with soldering acid.

We begin to move our fabric tip along the metal surface.

This is the reaction that takes place.

We continue to drive along the surface.

Anyone who has the patience can process the entire car body in this way. Afterwards everything is washed off with water. And for those who want to play it safe, they can wash it off with a light alkaline solution, for example, a solution of baking soda. Zinc can be obtained from salt batteries or from old Soviet carburetors. You can use a charger instead of a battery. Here at this place 2 years ago we had severe rust, which we cleaned and galvanized using this method.

Read also: How to set the tightening torque on a torque wrench

We have been using the car in this condition for 2 years now and the rust has not reappeared. So feel free to try, don’t forget to practice before you work on the car.

Do-it-yourself galvanizing of a car video

Is there galvanization or not - how to find out in practice

Before galvanizing a passenger car with your own hands, it is advisable to determine whether the procedure was done initially. If information about a new car can be found in documents (although not always), then with a used car the situation is much more complicated.

If you have documents indicating the technical characteristics of the machine, you should carefully read all the information. In the absence of the words “galvanizing” or “galvanizing”, we can confidently say that the metal was not processed. Only the expression “full galvanization” means the presence of high-quality anti-corrosion protection. Most manufacturers of economy-class cars use partial galvanization, so many body parts are still susceptible to rust.

It is impossible to determine for yourself whether galvanizing has been performed. You will have to contact a specialized center, because in simple auto repair shops such a technique is not practiced due to its high cost and complexity. The cost of research is high, so it is not always advisable. It is better to look for information about galvanizing a specific model on the Internet, although you cannot be 100% sure.

galvanizing with battery Video

Chief Mechanic – Cleaning and galvanizing bugs on cars, removing pockets of corrosion! Galvanizing cars with his hands. Tsinkar.

Mechanics Blog - This Device Will Protect Your Car From Corrosion. How to galvanize a car with a battery. Struggle.

Greetings to you friends, subscribers and viewers who have come to visit me again! This video will cover exactly that.

Zincari solution 5%, a sprayer attached to it from a window cleaner, the solution can be made more powerful by crumbling it.

The best way to remove rust is to not interrupt the oxidation process. We will apply it using a physical-chemical method.

Galvanizing the body with your own hands using a salt battery. Mitsubishi Lancer CEDIA WAGON GDI (MITSUBISHI LANCER CEDIA WAGON) Group.

practical manual galvanizing of a damaged area of a car body. The description is on the channel.

Zinc from old batteries for galvanizing metal at home! How to shop on AliExpress with double.

In this episode of Technical Environment, its host Gennady Emelkin tells and shows how to use...

Greetings to you friends, subscribers and viewers who have come to visit me again! Thanks to your trust, one.

how to protect iron from corrosion forever. The most reliable way is to apply zinc to the surface of the iron.

I'm trying to galvanize with Hydrochloric acid instead of Sulfuric acid like last year, the straightened and puttied one has rotted.

Subscribe to my VK group https://vk.com/public120461485 Instagram https://www.instagram.com/nik86_youtube/

How the galvanizing technology with the Tsinkovatel-1 device has shown itself. Galvanized body part in use.

How to make flux for tinning and soldering ferrous and non-ferrous metals from hydrochloric acid or a cleaning agent.

Dear friends, I made a short video to prove that galvanic galvanization is electrochemical.

Electrochemical coating of the hammer with a layer of zinc.

As promised, I’m showing the elements that I galvanized about half a year ago. As you can see, not an ounce of rust.

I decided to make another video on galvanizing a car with my own hands, almost a video tutorial, only now straight.

Read also: Homemade sandblasting from a gas cylinder

The “home” method of galvanizing metal allows you to prevent the formation of corrosion on the car body and thereby reduce service costs. Galvanization can also be used for various metal products to further protect them from rust. It must be said right away that this method is very simple and does not require large financial costs.

This method involves the use of phosphoric acid with zinc dissolved in it, and will also require zinc (salt) batteries. You can use both small finger batteries and large batteries - it all depends on the amount of work being done.

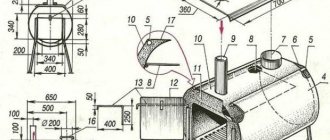

If you need to galvanize a large area, it is better to take large zinc batteries. First you need to print them out and remove all excess braiding. If desired, you can use only the battery case, removing the graphite rod and soot, but in principle you can leave the “insides” in place.

On the body of the “bare” battery, on one side you need to secure a cotton pad with an elastic band, and on the reverse side (also with an elastic band) - the power wire. You can use a car battery as a power source.

How does galvanizing of a surface occur?

The negative from the battery must be connected directly to the part of the body (or part) that you are going to galvanize. We connect the wire that goes to the zinc body of the battery to the positive terminal of the battery. Please note that the negative terminal should never be disconnected, because the desired effect will not be obtained.

Before starting galvanizing, it is advisable to clean the surface to be treated from traces of rust, if any. You need to take orthophosphoric acid with zinc dissolved in it into a syringe and soak a cotton pad that is placed on the battery body. After this, you just need to move the zinc battery over the entire area of the surface being treated.

The most important thing is not to stop. If you keep the battery in one place for a long time, then burns appear, and if you move the battery continuously over the surface, you get an even layer of zinc. You will see the result almost from the first seconds.

Although some call this method of galvanizing “artisanal,” it is truly a proven, simplest, and most importantly, effective way to combat corrosion. To learn how to properly perform galvanizing, watch the video.

Is there galvanization or not - how to find out in practice

Before galvanizing a passenger car with your own hands, it is advisable to determine whether the procedure was done initially. If information about a new car can be found in documents (although not always), then with a used car the situation is much more complicated.

If you have documents indicating the technical characteristics of the machine, you should carefully read all the information. In the absence of the words “galvanizing” or “galvanizing”, we can confidently say that the metal was not processed. Only the expression “full galvanization” means the presence of high-quality anti-corrosion protection. Most manufacturers of economy-class cars use partial galvanization, so many body parts are still susceptible to rust.

It is impossible to determine for yourself whether galvanizing has been performed. You will have to contact a specialized center, because in simple auto repair shops such a technique is not practiced due to its high cost and complexity. The cost of research is high, so it is not always advisable. It is better to look for information about galvanizing a specific model on the Internet, although you cannot be 100% sure.