Tying the wellhead located in the basement of the house

The water well piping scheme includes options for seasonal and permanent installation - it all depends on the type and capacity of the well, and its location. The dacha option, which involves the use of water intake only in certain months, is most often done by hand, and is limited to installing a surface pump and connecting a hose to supply water upward. Tying a well that is used all year round requires a completely different approach - this is what we will discuss in our article.

How to equip a well in a country house

You will need to buy equipment for constructing a water well, which will make the operation of the hydraulic structure convenient.

Well pump piping

The arrangement begins with the purchase of a pump. They are selected according to the depth of the source, technical parameters depend on the budget. They produce surface and submersible models.

The first ones are installed on the ground next to the source. These pumps suck in liquid; the distance to the surface is important for them, so they are often mounted on a raft floating inside the well.

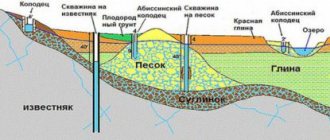

The equipment is placed near the mouth. In this case, the distance from the mouth to the water surface should be no more than 8 - 10 meters; from a greater depth, the surface pump will not lift liquid. Used for the Abyssinian well.

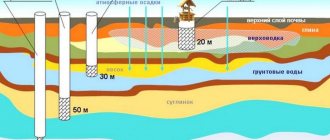

The submersible type works from the bottom of the well, located in the water column. The principle of operation is to push the liquid to the surface. They are installed in sources deeper than 10 meters - artesian and sand wells.

Install the hoses, check valve and filters according to the diagram in the picture below.

Surface pump connection diagram:

When purchasing equipment for arrangement, you need to calculate its characteristics. Correctly calculated data will quickly fill the water supply system at home. After all, a one-story house with two residents costs less than a two-family cottage with a large garden and a bathhouse.

Before going to the store, write down:

- Static water level.

- Dynamic level.

- Water yield indicator - well flow rate.

- Diameter of casing pipes.

Drillers record these indicators in the well passport, which is issued upon completion of the work. If you do not have such data, then take measurements yourself. We wrote about how to determine the water level in a well in the article about flow rate.

Surface pumps

To raise water from an Abyssinian well. Installed on the surface. Used for hydraulic structures no deeper than 8 meters. Surface electric pumps are reliable and easy to repair.

Centrifugal surface

The centrifugal model will pump water if air is trapped during suction. Dirty water will damage this model. Change filters regularly.

Among the surface ones, centrifugal ones are the noisiest.

Self-priming models

The pumps are clones of centrifugal ones, but with increased characteristics of the depth of moisture rise. The addition of an ejector increases the suction depth to 25 meters.

Surface - vortex

The most powerful design, yet the quietest. A serious disadvantage is that they only require clean water. This is the most sensitive model to liquid quality.

All types of surface pumps are installed the same way. The equipment is fixed on a smooth and level surface. This could be a thick piece of board or a stable raft (if the pump will operate inside the well). The main thing is that the equipment does not dangle on the work surface, but is securely fixed.

Submersible pumps

The principle is clear from the name - they work suspended inside the water column in a well or well. These pumps have built-in filters.

Advantages of submersible models:

- Silence. Operation underwater is silent.

- Temperature changes are not scary. At depth, the temperature does not change in winter and summer.

- The liquid pumped by the submersible device naturally cools the mechanism. The pump operates without the risk of overheating.

- Submersible pumps are more productive than surface pumps and operate at a depth of 100 meters.

Flaws:

- Installing a submersible pump is more difficult than installing a surface pump.

- For greater depths, helpers are needed.

- Power supply is routed over long distances.

- Submersible equipment is pulled out for preventive purposes. Pulling out even 20 meters of a bundle of cable, metal cable and watering hose with a pump at the end is not easy.

Submersible pumps are similar and look like an elongated metal cylinder 500 - 2.5 centimeters. But the operating principle and purpose are different.

Vibration type

The vibration model is sold in stores. The price attracts summer residents. Such pumps consume little electricity and weigh less than other submersible models. They are lowered into the well on a synthetic cord, the rest - only on a metal cable.

The disadvantage of the model is the strong noise and vibrations that the pump creates in the water column. These vibrations silt up the well. Used in wells of 10 meters or more.

Centrifugal - submersible

Wells are often equipped with a centrifugal type. These pumps operate at great depths without damaging the pipe walls.

The downside of the model is regular maintenance, which again means lifting a heavy ligament from the depths and a high price.

Screw pumps

The screw type model is less common than the centrifugal one. However, the helical type operates in contaminated environments where other submersible models would fail.

The downside is a shorter service life. Parts with increased friction in screw equipment wear out faster. Their unpretentiousness has made these pumps popular for operating industrial wells.

Vortex models

The advantages of the vortex type are high productivity and price. Among the submersible ones, some vortex pumps pump a mixture of gas and liquid. A short service life and the ability to pump only clean water are a minus.

When installing submersible models, you need to pay attention to the diameter of the casing pipe and pump housing. The gap size is indicated in the technical data sheet of each model. Check these values to ensure the pump does not get stuck or overheat.

We wrote earlier about how to remove a stuck pump from a well.

Place the equipment at the correct depth - lower than 30 centimeters than the dynamic level, but no closer than 1 meter to the bottom.

The submersible pump is lowered on a bundle of watering hose or plastic pipe, cable and electric cable. Fasten all three elements 25 centimeters from the pump with plastic ties, and repeat further every meter.

The bundle of a submersible pump consisting of a hose, a cable and an electric cable must have a cable in a taut state.

Video - instructions for installing a submersible pump in a well, 8.14 minutes long:

Arrangement of the head

The wellhead piping reliably secures the submersible pump in the shaft and prevents it from falling to the bottom. It is more difficult to steal an electric pump from a wellhead equipped with a head. It is convenient to connect equipment through the head, keep the hydraulic structure clean, and prevent it from freezing in cold weather.

To equip a well on the water, they put heads made of the following materials:

- Cast iron head - long service life. Cast iron is heavy and can withstand weights of up to 500 kilograms. The disadvantages of cast iron heads are fragility upon impact and price.

- Steel heads are second only to cast iron in their ability to support weight. The golden mean in terms of strength and price. Cast iron and steel are used to construct artesian water supply sources.

- Plastic - cheap heads, installed on sand wells.

Head selection:

- The weight of the equipment that will be suspended from the head. The mass of the equipment will consist of a submersible pump and a bundle - a cable, a hose and an electric cable. The deeper the well, the heavier the mass of suspended hoses, pipes and cables that the head holds.

- The diameter of the casing pipe coincides with the size of the head. The instructions for the head indicate what size pipes it is intended for.

- If the material of the pipe and the head is the same, then the joint is secured by welding.

Video instructions for installing the head on a well, 2.43 minutes long:

Hydraulic accumulator for well

Installing a hydraulic accumulator will solve the following:

- Maintains stable pressure. This will provide constant pressure in the tap, protect the pump from repeated switching on or off - and this is the service life.

- Constant supply of water. Useful in case of sudden power outage.

- Protection against water hammer, which occurs during voltage surges.

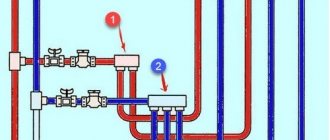

Hydraulic accumulators painted blue are installed for cold water supply. Red hydraulic accumulators can withstand pressure more.

When purchasing hydraulic accumulators, you can choose between membrane and balloon types.

Piping diagram for a well with a hydraulic accumulator:

Balloon type hydraulic accumulators

The hydraulic tank is in the form of a thick-walled tank with a rubber bulb inside. The space between the bulb and the walls of the tank is filled with air under pressure. Water from the well is pumped into the rubber bulb, compressing the air inside the tank.

When the pressure in the water supply system inside the house drops, compressed air from the tank pushes water from the bulb into the system. The balloon type is reliable, since the bulb is replaced if it wears out.

Membrane accumulators

The space in the membrane accumulator tank is divided into two parts. A membrane is installed in the partition. In one half there is liquid, in the second there is air, which displaces water when the pressure in the pipes inside the house drops.

The membrane cannot be replaced. If it wears out, the entire tank is replaced. Wear of the tank occurs due to contact with liquid, which is not present in the balloon type.

Accumulator volume

To properly arrange the water supply system, you need to calculate the volume of the accumulator in order to buy a tank according to size.

Water flow is the basis for the volume of the accumulator.

- If the number of water intake points is no more than three, and the productivity of the well pump is 2 cubic meters per hour, then a tank of up to 35 liters is sufficient.

- With 4 - 8 water intake points and a pumping equipment capacity of 4 cubic meters per hour, buy hydraulic accumulators of 50 - 100 liters.

- Buy tanks larger than 150 liters for a home where there are more than 8 water intake points, and the pump pumps water from 4.5 cubic meters per hour.

Water intake point is the point of connection to the water supply. The washing machine, toilet and faucet are water intake points.

Sometimes, instead of a hydraulic accumulator, a water tank equipped with a float is installed. When the float drops below the level, the pump is turned on and the tank is filled. The method does not provide drinking water. Oxidation of the iron tank requires frequent replacement and cleaning.

Pipes for piping and installation

The casing pipe is installed into the well during drilling. The trunk is reinforced with 125 mm plastic or metal pipes.

For piping the well, plastic pipes with a diameter of 32 mm are used.

HDPE pipes are sold in coils, and you can buy a piece along the length of the water supply without joints.

Pump and filter system

Performance is the main indicator that should be relied on when choosing pumping equipment. This is the amount of water that the device can pump per hour of operation. There are also additional conditions:

- The maximum performance of the electric pump should be equal to the flow rate of the well.

- The power should be sufficient for normal supply of water through the system in sufficient quantities.

The pumping station can be mounted in a caisson. An effective method of supplying water is to install a deep-well pump, which is immersed in the casing. When choosing a pumping station, it is necessary to install a hydraulic accumulator and a filtration system.

The advantage is that all the equipment is located outside the residential building, but if maintenance is required, no access problems arise. Regular inspection of the storage tank, pump and filter is required. A check valve is installed nearby.

Construction of a summer well

Summer installation of a water well is used at dachas for watering the garden.

The summer version of well construction is done without a caisson or adapter:

- The equipment is mounted inside the barrel.

- Manual control of water supply.

- It works in the summer, but the pump is removed for the winter.

The cord from the pump is plugged into the outlet, and water begins to flow from the pipe.

Main features of the harness

If you want to leave the upper outlet of the well outside, then you can only use it in the summer. If you connect a water supply to the head during the warm season, you can use the source until the first cold weather. If it is necessary to supply water to the house all year round, the pipeline should be made permanent. To do this, it is laid below the frost line. This indicates that the well entrance should be located at a depth of 2 m.

It is necessary to protect the water source not only from freezing, but also from debris. Among other things, the equipment must be periodically maintained and the well cleaned. Therefore, free access to the system must be provided.

Winter option for well construction

The most time-consuming part in installing a water well is protecting the equipment from freezing. Russia is a northern country. Our winters are long and cold. If the hydraulic structure is not protected, it will only work in the summer. It needs to be preserved for the winter by draining the pipes.

Ground premises

If the plot size is large, then a separate building can be built above the well. This could be a modular structure, an insulated container, or a beautifully decorated house that will become an element of landscape design.

The disadvantage of this method is heating the room. An unheated building will be useless at sub-zero temperatures - the water in the pipes will freeze.

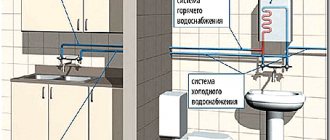

Placing a well in the house

Installing a well inside the house will solve all heating issues. You can place the piping elements close to the source, which is economical: fewer pipes and cables are required. The disadvantages of this method are equipment prevention. The pump will need to be repaired - you will have to pull the entire bunch out of the well and into the house.

A well drilled close to the foundation can damage it. This type of strapping should be planned before the construction of the house, when all calculations of the strength of the structure can be made. We do not recommend drilling a deep well in a finished house.

Pit construction

The underground version of the piping does not disturb the landscape with additional buildings. Sufficient depth is a guarantee of maintaining a temperature comfortable for equipment operation.

There is no need to heat the underground room.

The pit looks like an underground garden cellar, with the wellhead at the bottom. When building a pit, strengthen the walls against crumbling to make it airtight.

The pits are made of concrete, poured through formwork. The brickwork version is less airtight and is used for sandy soil.

Arrangement with a caisson

For houses with water supply from a well, a caisson works well in winter. The advantage of the structure is its tightness. Installed if groundwater passes at a depth of up to 3 meters, and when clay soils are located at the same depth. This retains moisture near the caisson, protects the well from contamination, and protects the equipment.

A caisson for a well is a sealed structure to protect equipment from low temperatures. Containers for caissons are made of plastic or metal.

Plastic caisson

Plastic caissons began to be used in the 2000s. Caissons are made from non-toxic plastics and fiberglass.

The advantage of plastic caissons is their tightness and lightness. A PVC caisson can be installed by 2-3 workers without lifting equipment.

The downside is that the walls of the caisson can be pushed through by soil and deformed. Pour concrete into the free space between the walls of the caisson and the boiler. This will insulate the caisson and protect it from deformation.

Metal caisson

The iron caisson will not be warped by the soil. Well-welded seams and metal coated with an anti-corrosion coating are a guarantee of tightness. If the metal caisson is not insulated, frost will form on the cold inner surface.

The disadvantage of an iron caisson is its weight. To install it in the pit you will need a crane.

Construction of a well in a well made of concrete rings

Winter well construction with concrete rings is done in areas where rainwater does not accumulate.

The disadvantage of constructing a well with a caisson made of concrete rings is the lack of tightness of the joints, through which liquid will fill the well and damage the equipment.

Harness with adapter

The adapter is placed inside the casing. This is a replacement for a warm room.

A well adapter is an adapter that secures the pump below the freezing point, and the caisson itself plays the role of a caisson.

The advantage of the invention is the protection of the well from groundwater and the price. However, there are disadvantages:

- The adapter is installed in structures with one column.

- Only a metal casing provides tightness. Plastic pipes do not maintain tight seals.

- The adapter is disassembled once a year and the connections are disconnected to prevent the nodes from merging.

Adapter installation video:

The well adapter should not be installed in areas with long, harsh winters.

Downhole adapter

With this device, you don’t have to install an expensive caisson, but pumping and other equipment will have to be placed in a separate shed or in the house. In addition to being cheap, the advantage of using an adapter is that the casing pipe can be completely hidden underground.

Installation is carried out as follows:

- The casing pipe is cut to ground level and dug about one and a half meters deep.

- Using a crown, a hole is cut in the pipe for mounting the adapter.

- The adapter is installed externally, and the deep pump is lowered into the well using the pressure pipe on which it is attached.

- The excess part of the support pipe is cut off, and a dovetail is installed in this place (this is the name of the second element of the adapter).

- The adapter is lowered into the well on a metal tube.

- The dug hole is filled with earth.

You can do the installation yourself. It is not necessary to resort to the services of specialists. If a caisson is used, it is better to make it closed. The entire structure must be as tight as possible.

Previous

Water pumps and pumping stationsSelection of membrane accumulator for water supply systems

Next

Water pumps and pumping stations Water intake unit: types and diagrams of water supply units

Requirements for the caisson

Scheme of arrangement of a protective chamber

The main requirement for constructing a water well caisson is the absolute tightness of the chamber. Otherwise, the high water will periodically flood the room, which will not have the best effect on the performance of the pumping equipment.

Otherwise, the caisson is selected according to the following criteria:

- It is desirable that the depth of the chamber be greater than the level of soil freezing in the region.

- The parameters should allow the equipment to be installed freely in the caisson, with indentations so that the technician can freely carry out maintenance and repair of the equipment.

- Material of manufacture. The most durable is considered to be a thick-walled polymer with stiffeners. Concrete and brick are in second place in terms of practicality, since they are capable of absorbing water, albeit slowly. This can be avoided by using external and internal sealing coating. Metal is the worst option for constructing a caisson. The material oxidizes and rusts over time. Even the use of protective anti-corrosion coatings does not help. Gradually, the composition retreats in places from the surface of the metal, and the box rusts.

For complete tightness, the caisson chamber is equipped with an upper hatch. For convenient descent there is a staircase.

Step-by-step description of tying using a pit

If you decide to use a pit as a tying technology, then first you need to decide on the method of its manufacture. At the next stage, a hole is prepared, the depth of which can reach 2 m, otherwise working inside will be extremely inconvenient. Crushed stone is poured into the bottom, after which you can proceed to making walls. If necessary, they can be waterproofed and then sprinkled with expanded clay or gravel around the perimeter.

If piping a well with your own hands is done using the technology of constructing a pit, then you should remember that it has an impressive disadvantage, expressed in low tightness. This prevents installation inside the equipment; another room must be prepared for this. The cover can be made of metal; an alternative solution is to use a concrete slab with a hatch. In each of these cases, thermal insulation will be needed. You can place the main cover area below the top ground line. There will be only a hatch outside.