Why is it necessary to build a well?

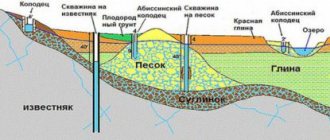

The arrangement of a hydraulic structure on private territory is carried out in accordance with regulatory documentation. Experienced employees of specialized companies are well aware of all the rules and standards. Professionals begin to equip the source with the simultaneous installation of pre-selected water supply equipment after completion of drilling work and before connecting the internal water supply system. With their help, Abyssinian tube wells, simple up to 50 m and 100-meter artesian water sources are created.

Common types of wells Source hotel-a.ru

Proper improvement of a well, regardless of its type, allows you to ensure:

- necessary conditions for connecting and performing maintenance of additionally installed equipment;

- protection of personal hydraulic structures, pipes and devices from freezing;

- the purity of an independent water source by excluding dust, dirt, rain and melt water from entering it.

In addition to the submersible pump, all equipment of an autonomous water supply system is installed near the well or in the house. To install devices near the source, a technical room of estimated area is first constructed. A special small room in the house will also not be superfluous. The room is created at the entrance of the water supply to the building. It is convenient to install and maintain a water supply pump and other equipment. A special room is also used to supply electrical power to technical devices and enter pipes into the water source.

Technical room for downhole equipment Source specteh-vrn.speczakaz.info

How to lower it correctly

Do-it-yourself installation of a pump in a well is carried out after studying the instructions with drawings for installing the pump and gaining practical experience using the videos below.

In accordance with the passport data for the excavation and the immersion depth, the downhole unit and materials are selected. When assembling the structure and installation work, two or three people are involved, sequentially, step by step, performing the following operations:

- We check the project package and lay out the submersible pump, pressure hose, control cable, cable and fasteners for assembly.

- We begin assembly by installing the check valve into the outlet on the pump using an adapter fitting. In this case, we take into account the direction of movement of the liquid, indicated by the arrow on the body.

- We cut the end of the pressure pipe at an angle of 90 degrees to the axis, put a plastic coupling with an O-ring on the hose and insert it into the body of the adapter fitting screwed into the valve. Tighten the coupling nut to secure the connection.

- Using a heat-shrinkable sleeve, we connect the control cable to the engine, and fill the entry point of the wires into the unit body with waterproofing glue.

- We insert a safety rope into the eyes on the device body, bend the threaded end into a loop and, using a special lock and a pressure washer, connect it to the main part of the rope.

- To prevent the cable and cable from touching the column when lowered into the shaft, we connect it together with the hose into a single strand using plastic clamps. A meter from the pump, we fix the ties every 20 cm, and then every meter to the top of the casing.

- Using a grinder, we cut off the casing pipe to the bottom of the caisson and install the head on the end. The cover serves to protect the well from debris, and it has holes for a pressure hose, cable and safety rope.

- We thread the hose, cable and cable into the holes on the head. We cut off the pressure pipe at the level of the lid and insert an angle fitting into it to connect to the water main laid in the trench to the house. We attach the safety cable to the casing carabiner. We lay the cable in a trench and lead it into the technical room.

- If the well is drilled no further than 5–7 meters from the house, the connection is simplified and a caisson is not installed. The pressure pipe is cut off at ground level and, together with the cable, is led through the head into the technical room in an insulated tray. To prevent the water from freezing in winter, a heating wire is inserted into the main hose, and a check valve is not installed on the pump. After injection, the liquid flows back, and the HDPE pipe remains dry.

Selection and installation of water supply equipment

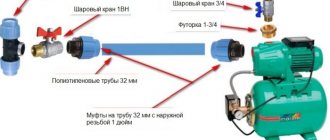

When installing an individual water supply, the following technical means are required:

- Submersible or surface mounted pump.

- Automation that protects the pumping unit from overloads and controls its operation.

- Hydraulic accumulator in closed or open type. The first type of device is a tank with a membrane. Its use allows you to ensure stable pressure in the utility network.

The type and method of placement of technical devices affects the nature of the arrangement of the water source. Installation of a tank with an open design is carried out at the highest point of the water supply. It is installed in the attic or under the ceiling of the last level of the house. Modern well equipment, which includes a membrane accumulator, can be installed in any convenient location.

Closed hydraulic accumulator Source 3agorod.ru

Surface mounted pump for shallow water source

Surface-mounted pumping units are easier to install, easier to maintain and cost less than submersible devices. Manufacturers produce 3-in-1 units. The equipment includes a pump, automation and a tank with a membrane with a volume of 20 to 60 liters. Devices combined into one installation are a profitable and rational option. Such equipment is called a pumping station. Its installation requires less space than when installing individual devices.

There are two hoses coming from the surface pump. One of them is the suction tube. She descends into the water source. The use of a surface-mounted pump simplifies the maintenance of the device and the installation of a water well in a private house. Moreover, a small diameter hose is connected to the equipment. This makes it possible to equip Abyssinian well structures with surface pumps, which do not include submersible devices.

Surface pumping unit Source ozone.ru

A station or a separate pump on the surface has one drawback - the equipment is not designed to lift water from deep wells. The overwhelming majority of manufactured models have a limit of 10 m. Therefore, water supply pumping stations and individual surface-mounted units are usually installed near the mouth of an underground water source. For installation in a residential building, more powerful equipment is needed that can overcome the resistance of the pipeline from the source to the building.

Submersible pump for deep water source

If the well is more than 10 m deep, then the water is raised using a submersible pumping unit. When selecting this type of equipment, its height in the casing is taken into account. Only specialists can correctly determine the value. If you make a mistake, the water pressure in the building will be weak or completely absent.

Submersible pumping devices Source variant-a.ru

See also: Catalog of companies that specialize in engineering systems and related work

Installation of a deep-well pumping unit begins with connecting a hose for supplying aqueous media. With modern models this process is simplified as much as possible. The device itself is held in the borehole by a cable.

When selecting equipment for a well at a dacha after drilling, it is better to mount a closed-structure hydraulic accumulator together with a deep unit. If necessary, it can be placed together with the automation at a significant distance from the water source. The ideal option for installing a membrane tank is a special room in a residential building. It may be on the first floor. It is also often installed in the basement.

What equipment is needed for a well?

To organize a water supply point in a country house, you will need pumping equipment, pipelines, sensors, automation and other elements. The characteristics of the system components will depend on the type of source, as well as on the equipment connection diagram.

- For tightness and to insulate the mouth of the system, a caisson is installed. To construct a well with a caisson, plastic, aluminum or concrete are used to avoid corrosion. A caisson is a tightly closing neck, usually up to 2 meters high and 1 meter in diameter, insulated with foam plastic or other insulation materials.

- The wellhead is equipped with a special head to block access of dirt to the source. A pump is suspended from the head. The plastic element of the head can withstand weight up to 200 kg, and cast iron up to 500 kg.

- A well pump is needed to lift water from the depths and deliver it to the water supply system. Pumping equipment is selected according to pressure power and volume. The pressure force maintains the operation of the system and ensures that the well is filled with water.

- An electrical cable connects the pump to the automation system, which regulates its operation. The length and cross-section of the cable depend on the characteristics of the equipment.

- The water supply system uses special casing pipes. They are not afraid of corrosion, are airtight, and can withstand heavy loads. The manufacturing material is most often plastic or asbestos cement.

- It’s good when a hydraulic accumulator is provided in the well connection diagram. It protects the system from water hammer and ensures uninterrupted pressure when water is supplied.

Methods for protecting an underground water source from precipitation and atmospheric influences

The well and water supply equipment must be protected from the negative effects of rain, snow, sunlight, wind, hail and even fallen branches. To do this, a ground or underground structure is built around the mouth of the water source.

Construction of a protective structure for a water source Source forum.guns.ru

Ground pavilion

Installing a structure in the form of a compact pavilion over an underground water source is the most simplified way to protect the water intake structure. To reduce heat loss, the building is covered with a little earth. A pavilion in this design will resemble a free-standing cellar.

This protection option is rarely implemented in dacha and cottage areas. More often it can be seen above wells that are used on an industrial scale. A pavilion is rarely installed, because the structure clutters the site and has to be additionally insulated.

Ground protective pavilion over a water source Source skvazhiny.ru

Well-caisson underground

When deciding how to design a water well in a dacha beautifully, most site owners choose a well in the form of a caisson. The protective structure does not clutter the area. Underground placement allows you to hide the structure. An exceptionally small hatch remains on the surface. It is located in the same plane with the ground.

The advantage of a caisson is also that it is easier to insulate compared to a ground-based building. Moreover, the structure is dug in below the soil freezing level. Therefore, the underground part of the protective structure is located in the zone of positive temperatures, which allows the heat from the soil to slightly warm the caisson. In this case, the structure must be well waterproofed in order to eliminate the negative impact of ground and flood water on the technical devices of the underground source.

A caisson well can be erected directly on private property when the well is being installed. The structure is also available in finished form. It is manufactured in factories of different shapes and sizes.

Ready-made underground caisson made of plastic Source userapi.com

Well arrangement diagram

It is better to initially take into account the required water supply option in the project. Productivity, equipment life, optimal performance, and water quality will depend on the correctness of the chosen water supply system. Let's consider possible options for constructing standard wells on the site.

For example, a water well at a dacha in the summer may look like an Abyssinian-type tube well. The depth of the water pipe can reach 12 meters. At the same time, for a water supply system of this type, a narrow pipe is sufficient. Abyssinian-type wells are usually not contaminated by high waters, and surface debris does not fall into them.

If a private house needs water from a winter well, then an artesian version is installed.

Estimates for an artesian well are usually prepared by collective farms, since this is an expensive pleasure. Such a well needs to be drilled from 50 to 200 meters deep. The arrangement is complicated by the fact that after drilling an artesian well, you can get a self-flow. In a self-flowing well, water will rise outward without a pump. The water is under constant pressure and flows out. Construction of such a well is usually more expensive, since additional costs are required. There are two ways to arrange this:

- Make a well with a caisson.

- Equip with a summer faucet. In this case, water will constantly flow from the mouth.

For one private property, it is easier to equip a sand well. The service life of these wells is shorter than that of the previous option, since silting occurs quite quickly, but unlike an artesian well, self-flowing practically does not happen here.

A caisson for a well is a sealed reservoir that protects the water source from contamination and freezing. Modern caissons have the following advantages:

- save space inside the house;

- do not need thermal insulation;

- are not subject to corrosive processes;

- They have a molded body made of high-quality plastic.

For equipment in a private home, cylindrical containers with a diameter of approximately 100 cm and a height of 200 cm are recommended. The summer option is convenient for watering. To prevent this summer option from freezing in winter, a slope is made from the self-flowing well, where water will constantly flow. Your spring on the site will not freeze, since the water temperature is about plus five degrees.

It is absolutely impossible to shut off the water in such a well for the winter. The pipes will burst, water will flow all over the area, and you will end up with a swamp. If you entrust the construction of a well to unqualified drillers, you can easily end up with a pond on a plot with a vegetable garden. Therefore, it is important here to weigh the pros and cons, and without experience, it is better to understand the theory of the process of drilling various types of wells with your own hands.

Installation of a steel coffer chamber

When installing a steel caisson chamber, work occurs according to the following algorithm.

Step 1. We dig a pit, the dimensions of which exceed the geometric dimensions of the caisson chamber by at least 30 centimeters in cross section. The upper part of the caisson, namely its neck, should “look out” from the ground by at least 15 cm. This will avoid contamination of the internal volume with spring melt water or heavy rain.

Digging a pit for a caisson

Step 2. We install a hole in the bottom of the caisson tank for the well casing pipe. The location of the nozzle is selected taking into account the placement of equipment in the internal volume of the caisson. The pipe is a sleeve about 15 cm long. When making a caisson yourself, pipes for water supply pipelines and, if necessary, for supplying a power electrical line are welded into the side of the structure.

Step 3. Cut the casing pipe at the well to ground level.

Step 4. We lay beams on top of the pit, and install the caisson body on them so that the pipe sleeve fits onto the casing pipe.

Step 5. Using a winch or assistants, remove the support bars and lower the caisson into the pit.

Metal caisson in a pit

Installation of a plastic caisson

When installing a plastic caisson, we proceed according to the following scheme:

- We dig a pit and place a compacted sand cushion at its bottom.

- The caisson can be placed on a finished concrete slab with a hole for the pipe

- At the bottom of the caisson chamber we mark and cut a hole for the casing pipe.

- On the side of the container we make holes for the water supply pipelines and power supply cable.

Installation of a caisson chamber in a pit

- We seal the joint between the casing pipe and the bottom of the caisson tank. For this you can use regular PVC glue.

- A plastic caisson container does not need to be treated with an anti-corrosion compound. In the pit it can be fixed to the ears of the concrete slab.

- Backfilling of a pit with a plastic caisson can be done with additional concreting. As a result, a protective barrier is formed that protects the equipment from ground movements.

Installation of a caisson made of reinforced concrete rings

Installing a caisson made of reinforced concrete rings is a good alternative to building a monolithic structure or a permanent caisson made of brick.

- After digging a pit, a monolithic concrete slab with metal reinforcement is poured at the bottom around the casing pipe.

- We lower the rings one on top of the other into the pit.

- Reinforced concrete rings can be connected to each other by twisted steel wire.

We lower the concrete ring into the pit

- After installing the caisson well, its surface must be waterproofed. The easiest way to do this is to use bitumen mastic.

- Backfilling of concrete rings can be done using clay to create a hydraulic lock around the structure.

Descent and installation of the pump

The most important step in the procedure for installing a water well and establishing an uninterrupted source of water supply is the installation of a well pump. The basic rule for competent selection of a pump suitable for the operational characteristics of a well is a preliminary study by AquaGeoComplex specialists of the passport of the water intake structure, which reflects:

- depth and design features of the well;

- water levels in statics and dynamics;

- flow rate (well productivity);

- horizontal difference (slope) of well heights;

- distance from the highest point of water intake to ground level.

The quality of the supplied water, its chemical composition, and functioning will ultimately depend on the correct choice of pump type (surface - for drawing water from depths of 7 to 8 m or submersible - for drawing water from great depths), as well as its manufacturer. the entire water supply system.

A significant advantage when installing deep-well pumps is the quiet operation of the entire water intake system, while the durability of its service is directly proportional to the competent determination of the initial loading depth of the pump (no higher than 3-5 meters from the dynamic level), since errors made when loading the pump in the final As a result, they can lead to a change in the chemical composition of the water supplied through the well and cause irreparable harm to human health.

Well caisson dimensions

The protective structure over the underground water source must allow the installation of all necessary auxiliary water supply equipment. The installation location of technical devices affects the dimensions of the caisson well. It is recommended to choose a protective structure where a person can “turn around” when performing work.

If it is decided to install the equipment in a caisson well, the distance from the front and side of the pumping station or accumulator to the walls of the structure must be at least 50 cm. When creating a well for drinking water in a private house, it is necessary to provide in advance in the building design a technical room with a minimum size of 80* 80 cm. It would be better, of course, if it were more spacious.

Choosing a location for installation

Before you connect the pumping unit to the well yourself, you need to choose the right location. It is recommended to install the equipment near the well. Most often, the equipment is protected with a caisson. The size of the recess must allow servicing of the mechanisms.

The walls of the pit are lined with brick or concrete. The pump is placed on a concrete foundation and secured with anchor bolts. The suction pipe is inserted into the well through an adapter. Installing the station in a caisson has a positive effect on the service life of the centrifugal pump.

Submersible equipment components can be placed at any distance from the well. The control module can be installed in the basement or boiler room. The room must be protected from moisture. Otherwise, the equipment will quickly fail.

There are the following station placement options:

- Away from the center of the room. This allows you to increase the amount of free space required for servicing the installation. The equipment must not come into contact with walls. This leads to vibration and extraneous sounds during operation of the equipment. Constant vibrations destroy the protective coating, causing damage to the metal.

- Accommodation in a separate building. Helps to avoid noise, but the owner cannot quickly access the equipment. Some people drill a mine at the pit formation stage, which is why the source remains in the basement. Installing a pumping station in a well using this method saves money, but repairing and replacing equipment components causes difficulties.

Video description

The creation of an Abyssinian well in a residential building is shown in the following video

If it is decided to use reinforced concrete rings during the construction of a protective structure, then their standard diameters are 90, 150 and 200 cm. Products with the smallest size are best used to create a caisson well in which a pump and membrane tank will not be mounted. Reinforced concrete rings with a diameter of 150 cm are suitable for protective structures where it is planned to locate medium-sized equipment. Two-meter products are an ideal option for creating a caisson, in which you can easily mount a large pumping station and even install a 200-liter membrane tank.

Manufacturers produce caisson wells of various sizes. The product range allows you to select a factory product to accommodate equipment of any size.

Important! The bottom of the protective structure must be at least 15 cm below the soil freezing level. This is a prerequisite for climatic regions with harsh winters. The ideal option is to install 1/3 of the structure in a non-freezing area.

The third lower part of the ketone must be located below the freezing point of the soil Source ksportal.ru

The upper part of the caisson well must be insulated.

The heat insulator is usually used on the outside. Extruded polystyrene foam or other similar products that are resistant to humid environments are used as an insulating material. If the well is connected in a house for all-season living, there is no need to use an additional heat insulator. After all, such a structure must have a heating system.

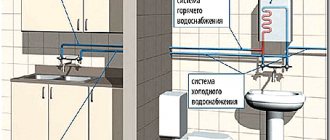

How to make plumbing in a private house with your own hands

Water supply can be organized using two types of pumps:

- surface models, which are not immersed in the water intake source, ensure the rise of water from a depth of 8-9 meters, which is why they are used in wells;

- submersible models are placed directly in a well or well, and their power allows you to raise water to a height of more than 200 meters.

Conducting from the well

A trench is dug from an existing or newly constructed well to the house, the bottom of which should be below the freezing mark of the soil in the given area. Next, a 32 mm pipe (copper, steel, polypropylene or metal-plastic) is laid at the bottom of the trench at a slight slope towards the source. The slope is necessary to prevent water from stagnating in the pipeline. The pipe is led into the basement through a hole in the foundation, which is insulated. Otherwise, in severe frosts, freezing may occur in this place.

The pipeline running from the well to the basement of a private house is laid in a trench dug taking into account the depth of soil freezing in the area

From the well

You can also supply water to your home from an autonomous source, which is usually a well or well. It is recommended to use water from open reservoirs only for technical purposes; it is not suitable for drinking or cooking.

Video: how to provide yourself with clean water

The laying of communications from the well, protected from freezing and the ingress of contaminated wastewater by a caisson (metal container), begins with assembling a bundle of cable, safety rope and water supply pipe covered with aluminum tape. Then a submersible pump is attached to them and lowered into the well. On the surface, the cord is wrapped in insulation, after which they begin to lay it at the bottom of a one and a half meter trench dug from the well to the house.

Installation diagram of water supply for a private house from a well drilled to the aquifer by a licensed company using a powerful rotary drilling rig

They bring the pipe and cable into the house, then install:

- a tank that will allow you to turn on the pump as needed;

- a control unit designed to protect the system from voltage surges in the network, as well as from overheating.

Sealing the casing

Dust, rain, melt water and condensate formed in the caisson well should not enter the underground source. Otherwise, harmful microscopic organisms will penetrate the well. To fix this, you will have to spend a lot of time and money. Therefore, even during the development of the project, protection of the casing is provided. A borehole head is used for this purpose. It is a special steel cover. The product has holes for communications. The steel cover is also equipped with a hook, which is designed for hanging the pump unit.

Supply from a well drilled in the house

Such shafts are usually installed in rooms with an area of at least 2 x 2 m. Most often they are located on the ground floor. A feature of the water supply system from a well in this case is the absence of an external pipeline. The question of how to get water from a well into the house does not arise at all for owners of a suburban area when using such a scheme. When installing inside a building, a special sealed cap must be placed on the shaft itself. This helps prevent indoor spills when the water level underground rises.

Deep wells in premises can only be drilled during the construction of a house or immediately before. In ready-made buildings, small wells are usually installed using a small drilling rig. Water supply from such mines is carried out accordingly using equipment that is not too powerful. These are mainly surface pumps.

The advantage of installing a well directly in the house is that freezing of pipes in this case is completely eliminated. In addition, the work when connecting such a well to the water supply system of the house is reduced in cost due to the absence of the need to install an external pipeline. Repairing the equipment of such a well, since it is carried out only indoors, can also become a more convenient procedure in the winter season.

Video description

See the video for installation of one of the heads

The selection of a special well cover is carried out taking into account the diameter of the casing pipe. The head package includes a rubber crimp collar. It is used to seal the casing. To enter the electrical cable and water pipe, the special cover also provides sealing elements.

Experts do not recommend cutting the casing to the level of the caisson well floor. Otherwise, it will be inconvenient to install a pumping unit with a head and the likelihood of contaminated water entering the well will increase if the protective structure is flooded. It is recommended to cut the casing at a distance of at least 25 cm from the caisson floor.

Two-stage technology: design features

When using this method of supplying water from a well to the house after the pumping equipment, an expansion tank with a float switch is installed in the caisson. After filling this container, the equipment de-energization system is activated.

After the expansion tank, another pressure-type pump is installed in such a network. After it, a second hydraulic accumulator is installed according to a similar scheme. This system allows you to accumulate more water during idle consumption in the house and release it as needed.

Video description

Details about the installation of the downhole adapter are described in the following video.

The downhole adapter is located below ground level. Therefore, when maintenance is required, which is carried out very rarely, excavation work must be carried out to gain access to the device.

An adapter is a special fitting consisting of an internal and external part. The external part is designed to connect the pipeline through which water will flow into the house. The internal part of the adapter is located in the well. It is designed to connect a pipe from a submersible pumping unit. When connecting both parts, hermetic seals are used.

Important! The borehole adapter is installed below the freezing point of the ground. Only a small part of the casing remains on the surface. It is closed with a special lid through which the power supply cable for the submersible pump is inserted.

Installation of downhole adapter Source svayburvod.rf

Preparation for installation

This approach will allow you to avoid mistakes when connecting the pump to the well and ensure trouble-free operation of the water supply structure for decades.

Miscalculations that should not be made when designing a source:

- incorrect determination of the depth of the aquifer in the area and the distance of suspension of the apparatus in the well. The submersible is not completely submerged and remains without cooling. When running dry, the electric motor overheats and fails;

- the cable is incorrectly selected and secured. A metal product rusts and may break over time, which will lead to the loss of the unit. Failure to secure the safety rope to the pump or casing cover can lead to the same result. Reliable fixation of the device is ensured by a stainless steel cable;

- wrong choice of pressure hose. The HDPE pipe product must withstand the pressure created by the pump. Using a hose with a smaller diameter than the outlet of the unit will lead to increased load on the engine, overheating of the windings and failure;

- incorrect choice of control wire when connecting a well pump. The cable must have the correct cross-section, depending on its length and the power of the device, so that the increased load does not cause overheating of the wires, followed by a short circuit. Its shell must have protective properties and prevent damage to the wire insulation;

- check valve not installed. Its absence will delay the flow of water into the house, pushing air out of the pipe after the next start, since when the engine is stopped, it will flow into the workings;

- Voltage and current stabilizer is not installed. To protect the electric motor of the unit from overheating, a motor automatic is used, which monitors the increase in current and responds to voltage surges. When the motor jams due to sand or silt getting into the working part, the protection is triggered and the pump is turned off;

- An automatic control system for the operation of the unit is not installed. Installing a cabinet with control and protective devices for autonomous water supply eliminates the operation of the device in emergency mode. Automation monitors emerging problems in the water supply design and warns of possible negative consequences by stopping the unit.

Self-installation of a well pump can only be performed after obtaining the necessary knowledge and practical skills in installation work.

Briefly about the main thing

Modern arrangement of a well in a country house or area with a cottage is carried out to protect the water source, equipment, and pipeline system from dirt, precipitation, dust, the negative effects of low temperatures, melt and rain water. To do this, the installation or construction of a protective structure is carried out. It can be above ground level or in the ground. One of the options is also to arrange a special technical room in the house. Regardless of the option, it is used for installing a pump, accumulator and automation.

Ratings 0

Hydraulic accumulator in the connection diagram of a well pump

The presence of a hydraulic accumulator in the water supply system of a private home prevents problems with water supply. The hydraulic tank prevents the pump from being overloaded. After filling the reservoir with water, the pump automatically turns off and resumes operation only when the liquid is consumed to a certain level. The volume of the hydraulic tank varies from 12 to 500 liters. When there is a power outage, there will always be a certain supply of water in the tank.

There are membrane and storage type hydraulic accumulators. In the first case, these are small-sized devices, with a check valve and a pressure gauge. They perform the task of ensuring pressure in the water supply system. Hydraulic storage accumulators have large-volume reservoirs; they are most often installed in the attics of houses, which requires reinforcement of structures and thermal insulation to protect against frost in winter.

The principle of operation of an expansion tank for water supply is to maintain pressure in the water supply system. The cylindrical container has two chambers, for air and for water. When filling the container with water, the air part decreases, and the pressure increases. An expansion tank of any type solves the following problems:

- maintains system pressure when the pump is turned off;

- protects equipment from water hammer;

- stores a reserve amount of water in case of problems with the electricity supply;

- protects system elements from rapid wear.

The expansion tank allows you not to turn on the pump every time when the need for water is insignificant and there is enough of it from the tank.

Now let's figure out how to choose an expansion tank for water supply. Everything will depend on other equipment included in the water supply scheme. You can always get comprehensive advice at special sales points.