Water is the source of life. A person needs it in almost all areas of his activity: in everyday life, industry, etc. Often, the required volumes of water are quite difficult to move manually. Therefore, for a long time, people have used water pumps to pump various liquids. In general, they are divided into two large categories: household and industrial. Their main difference is that the latter are designed to work with large volumes of liquid and have a higher service life.

These two categories are in turn divided into different subtypes. The article will discuss the most popular of them and provide brief characteristics.

Types of household pumps

The entire variety of pumping equipment can be divided into several types:

- drainage devices;

- fecal pumps.

How do they differ from each other? In terms of operating principles, there are no significant differences between them. And all because the main task for which they are purchased is pumping out liquid.

If we talk about drainage pumps , then depending on their model, these installations can pump small fragments of solid waste along with water. To prevent damage to the mechanical parts of this pumping equipment, a filter made of a mesh with small cells is installed on the lower section of the pipe. Filter products are made of material that is not subject to corrosion. If there is a filter, particles will not get inside the equipment.

A fecal pump for pumping water from a basement differs from a drainage pump in that it does not have such a filter. Its main purpose is related to pumping wastewater and soft inputs like paper. To ensure high efficiency of its operation, depending on the model, it can be equipped with a cutting mechanism, which crushes large particles during operation of the equipment.

According to such a criterion as the method of operation in a liquid medium , both types of pumping equipment are divided into:

- submersible;

- external.

When a submersible pump is used to pump water, it is completely submerged in wastewater. Pumps of the second type are immersed in the aquatic environment with their lower part, and the main one is located outside. Pumping out wastewater and groundwater is carried out by a small part of it, which is lowered into the aquatic environment.

In what cases are pumps used to pump water?

Situations when we need a special pump to pump out dirty water are usually typical:

- Pumping fecal water from septic tanks.

- Elimination of consequences of utility accidents.

- Pumping out drainage water.

- Maintenance of swimming pools and garden ponds.

- Watering plants with groundwater from surface sources.

- Used in fire fighting for drawing water from fire reservoirs.

- Application in various production processes, etc.

At the same time, the meaning of the word “dirty” water should not be misleading. A special pump may be required even if drinking water is pumped from a well or spring, since the sand content in this water will be so high.

Trade offers a huge selection of pumps for pumping out dirty water from different brands and manufacturers. Therefore, its acquisition should begin by studying information about them. Time will not be wasted on this; this way you will be able to choose the right pump correctly and then use it correctly.

Drainage pump for cesspool

Such pumps are quite often used in country houses. An example of such equipment is the well-known “Malysh” pump. It can be considered as a station that provides the rise of water from a variety of sources. In domestic conditions, such pumps are most often used for watering plants in the garden. Some use them to organize individual water supply in their private household.

It is worth saying that drainage pumps used for water supply or autonomous sewerage can work not only on the surface of the site, but also at the bottom of the cesspool.

Pump "Baby"

This device belongs to the group of submersible-type installations, which, when used, are located in a tank with waste water. After installation, a pipeline is connected to it, through which liquid is pumped out to the surface. When installing the device, the following requirements must be met: the lower part of the pump should not be located at the bottom, since water is drawn from below. In a tank with wastewater, there is a layer of sludge at the bottom, which can clog the intake part of the equipment. Special cooling of the electric motor parts of the submersible pump is not required, since the temperature reduction occurs due to the low temperature of the waste water.

Both types of septic tank drainage pumps can be equipped with switches. regulates the level of water pumped out by the pump When a certain level of wastewater is reached, the mechanism automatically disconnects the device from the electrical network. When the maximum level of wastewater is increased, the device turns on and begins to pump sewage. The “Malysh” pump has a number of design features. One of them is reliable waterproofing of the housing, which is due to the use of equipment in an aquatic environment.

If the seal of the housing is broken, water will penetrate into the electric motor, which will lead to its failure. To ensure long-term operation of the equipment, it is necessary to periodically remove it from the water and carefully inspect the body.

Fecal pumps for cesspool

To pump wastewater, household pumps designed for sewage, fecal type, can be used. Regarding the location, they can be installed outside or inside the container itself.

Installation of an automatic water pumping system

What to do if the area is flat and has no slope? It is clear that there is simply nowhere to put the drainage pipe. There is a simple way to drain the basement in this case - to equip an automatic water pumping system.

What is needed for this:

1. Organization of a pit inside the basement. A hole is dug about 500x500 mm in size and at least 500 mm deep. The walls are reinforced, for example, with brickwork - the main thing is that they do not crumble over time. Gravel 100 mm thick is poured onto the bottom.

2. A special drainage pump with an automatic switching system when the water reaches a certain level.

The pump is installed in a pit. The connected hose is routed as far as possible from the house. When the primer level increases, water will first appear in the pit. At a certain point, which one depends on the pump settings, for example, when the upper edge of the pit is reached, pumping will begin and excess moisture will be removed. Naturally, the water will soon begin to accumulate again. As accumulation occurs, the pump will turn on and pump it out. This will continue until the primer level drops. If its increase is the result of snow melting, then the period of operation of the pumping system is March-May.

Conclusion: a fairly simple and reliable system. Of the costs, in fact, the only cost is the purchase of a pump - the price starts from 5,000 rubles. for simple options and up to 20,000 rubles. for samples with increased resource. The main disadvantage is that it does not eliminate the problem as a whole, but only provides a temporary solution, which depends on the service life of the pump.

Submersible products

Using such equipment, you can pump out wastewater from a basement or cellar with minimal time. Such pumps have one feature. The thing is that the parts of the devices must be made of materials that are resistant to chemicals . They must also be resistant to corrosion. When using such equipment in septic tanks, you should understand that the composition of sewage is constantly changing, and these changes often have an extremely negative impact on the equipment itself.

Modern detergents contain aggressive chemical compounds. Most often they contain chlorine, various acids and alkalis . These substances negatively affect the efficiency of pumping equipment, shortening its service life and reducing durability. Therefore, it is necessary to focus on these points when choosing a sewage pump. The higher the reliability of the unit and the greater the power, the longer its service life will be.

How to prevent water penetration

To get rid of water in the basement, homeowners can be advised to use several modern methods aimed at combating liquid penetration. The first of them involves the creation of a ring drainage, which is placed at the level of the base of the foundation around the walls and helps to ensure that liquid is retained by the drainage system. The second is the use of waterproofing applied to the floor and walls. The waterproofing layer will become a serious obstacle to water penetration.

Semi-submersible pump

This type of fecal pumps for a cesspool has its own characteristics. The main differences in the design are that only part of the unit is located in wastewater. It is the one that provides wastewater intake that is immersed. An electric motor is located on a special float. As the level of wastewater rises, so does the device.

As for indicators such as power and performance, they are insignificant for devices of this type. However, for a country house or country mansion such equipment will be the best choice. Having made a choice in its favor, you should be aware of its slight drawback - its design does not include a grinding mechanism, so it is not able to crush large waste.

Review of popular models

The market in this segment is represented by products of domestic and foreign manufacturers. There are adherents of both. The choice is an individual matter. “Whirlwind” and “Malysh”, produced by Russian factories, are popular due to their availability and maintainability.

Wilo Drain, Grundfos, Karcher, Makita are world-famous brands that do not need to be introduced. They have won the trust of consumers due to their reliability and durability, as well as high power performance. When purchasing, the main thing is to make sure that the package includes everything that is specified in the instructions.

As a rule, the characteristics depend on the type of design and method of operation. This is also taken into account when choosing. This is necessary so that high power does not cause an error if the pump is not designed for pumping dirt. Performance is not the main criterion taken into account when choosing a model.

Household Aquario ASP 1.5C-60-75 (920 W)

Submersible motor for water from a well from a famous Italian manufacturer. Structurally, it consists of a single-phase electric motor and a pump made of durable polymer material, combined in a single stainless steel housing. Throughput – 3.6 cubic meters per hour.

It is allowed to pump water with a sand content of up to 180 grams per 1 cubic meter. meter. Liquid is taken from the middle of the body, which is favorable for working in the presence of bottom turbidity. The kit includes a 45 meter cable and a launch module.

Suitable for a dacha or a cottage - you can build a water supply system from artesian wells or wells, and also organize watering of the area from a surface water intake.

Borehole pump VORTEX SN-50 (750 W)

Another model of the Russian brand VIHR continues the list of the best well pumps. It is distinguished by double power, 2 times increased productivity, but also a higher price compared to Whirlwind CH-60V. Includes electrical cord and capacitor block.

The product consists of a single-phase asynchronous electric motor connected by a shaft to a screw made of brass. The use of non-ferrous metal in the design increases wear resistance, but at the same time makes the device heavier. Due to the sleeve-like shape of the housing, it is better to place the pump in a well with a diameter of 100 mm or more with clean water. There is no dry-running protection. The model has European and Russian quality certificates.

Recommended for domestic wells or wells up to 50 m deep in the water supply system of a small house or irrigation of a personal plot.

Pedrollo 4BLOCKm 2/10 (550 W) for lifting water from a depth of up to 40 meters

Product from an Italian manufacturer with a centrifugal pump. Household version of the industrial deep well pump 4SR. Designed to work with clean water, but allows the presence of suspended solid particles of 150 grams per 1 cubic meter. meter. Pumping such liquid is possible thanks to a pump with floating wheels made of LEXAN 141-R material and bearings of a special design.

To connect the pipe, an outlet with a diameter of 2" is provided to ensure a flow rate of 3.6 cubic meters per hour at a pressure of 65 meters and a depth of up to 40 meters. The electric motor of the 4BLOCKm model is powered from a 220 V household network; the 4BLOCK modification is intended for a three-phase 380 V network.

Recommended for lifting water from deep wells when high flow rates are required. Suitable for organizing water supply schemes for one- and two-story houses, and for working as part of irrigation systems.

CALIBER NPTS-3.8/80-550 (550 W) for lifting water 60 meters

Mid-price centrifugal pump made in China under a Russian brand. Designed for use when completely immersed in water with a vertical position. The submersible well pump can operate at depths of up to 80 meters. The pump is designed for clean water, the diameter of particles of mechanical impurities is no more than 0.5 mm. The motor and pump mechanism are connected by a shaft and housed in a single stainless steel housing.

Service life (according to the passport) – 3 years. Provides water flow up to 3.8 cubic meters per hour (63 liters per minute). The AC asynchronous motor is protected from overheating by a built-in relay. The kit includes an electrical cable 20 meters long with a plug.

Suitable for lowering groundwater levels, for collecting clean water from wells, boreholes, and open reservoirs.

UNIPUMP MINI ECO-2 (550 W) for a well 20 meters deep

The smallest pump in the review with a diameter of 3 inches for shallow wells. Lightweight but powerful, provides water flow up to 3 cubic meters per hour. The baby vortex pump maintains a pressure of 65 m when drawing from a depth of up to 20 meters. Thermal protection is built into the housing and turns off the motor in emergency modes. The impeller is made of polycarbonate, ensuring a long service life.

Floating wheels increase reliability when small mechanical impurities get into the water. Can be used as part of an automated local water supply system.

It is recommended for organizing water supply in low-rise buildings, cottages, dachas, for arranging a watering system for vegetable gardens, garden plots, and filling small reservoirs with water.

Grundfos SQE 1-65 (1020 W) for artesian well and other sources

A powerful German model, designed to operate at depths of up to 150 m, rightfully takes its place in the list of the best submersible pumps for wells. The multi-stage pump can be installed in working condition both vertically and horizontally.

The single-phase electric motor is equipped with a soft start device, protection against overheating and dry running. The speed control function will help you choose the optimal mode for flow, pressure or power consumption.

Recommended for supplying deep water to low-rise buildings, cottages, and for operation as part of small water pumping stations. The smart pump can be used to operate irrigation systems.

The best deep well pump BELAMOS TF-100 (1300 W)

- height of water rise – up to 100 meters;

- productivity – 4 cubic meters per hour;

- built-in check valve;

- overheat protection.

The most powerful device in the review consists of a 1300-watt single-phase electric motor and a multi-stage pump with floating wheels. Specially shaped blades provide good throughput while sparing energy consumption. Supplied with a double-insulated electric cable 80 m long. The best deep-well pump for a well in the top.

Designed for long-term continuous operation, but dry running is strictly prohibited. The product does not require special maintenance. If it is necessary to clean the pump part, the design provides easy access to the pump mechanism. The body is made of corrosion-resistant steel.

Recommended for lifting water from deep mine wells, from other bodies of water, including surface water, for water supply to houses and as part of an irrigation system.

The best pump for a well in the budget category VORTEX CH-60V (370 W)

- productivity – 25 l/min;

- electrical power – 370 W;

- lifts water 60 meters;

- own weight – 10 kg;

- the most inexpensive in the review.

The best well pump from a Russian brand is made in China. Inexpensive pump with vertical installation and immersion depth up to 35 meters. Screw-type technological part. The body is made of stainless steel, which improves heat exchange with the pumped water, prevents the engine from overheating and increases service life.

Thermal protection switches off the pump in case of overload or dry running. The lower temperature limit of operation is practically the point at which water begins to freeze. Designed to work only with clean liquid without mechanical impurities. Pumping acids and alkalis is not allowed.

Recommended for artesian wells and wells. Suitable for pumping water from open reservoirs for watering vegetable gardens or orchards.

The best submersible pump for the Aquarius well BTsPE 0.5-50U

- productivity – 3.6 cubic meters per hour;

- engine soft start system;

- lifts water up to 75 m;

- immersion depth – 50 m;

- power supply from a household network 220 volts.

The rating of submersible pumps for wells is headed by a model produced in Ukraine. It is a centrifugal pump with a vertical installation for pumping clean water from narrow wells (from 110 cm in diameter) or from any other fresh source (river, lake) for domestic needs.

The built-in thermal relay protects the motor from overload. Optionally, protection against dry operation is installed. The pump sleeve and shaft are made of stainless steel, the impeller is made of durable thermoplastic.

Suitable for creating an automated water supply system for a country house or cottage.

Surface-type unit for pumping out wastewater

Installation of such pumps is carried out indoors, which are reliably protected from moisture and frost. The best option for placing this equipment is premises located in close proximity to the cesspool.

Such pumps have certain advantages:

- mobility. Such pumps can be used not only for pumping wastewater, but also for other purposes;

- Compared to submersible pumps, these units have lower power. Therefore, using them for domestic purposes, you can save electricity;

- a mechanism for grinding small waste, as well as large, medium-sized fecal matter;

- acceptable cost.

What is a basement pump?

This is not specifically specialized equipment that serves exactly this purpose. A conventional drainage, sewage or surface pump is optimal for pumping out water. They can be used not only to drain the basement, but also for many other purposes:

- for pumping water out of trenches and pits during construction;

- for draining swimming pools, pumping water from various reservoirs;

- for watering garden and vegetable crops from lakes, barrels, etc.;

- when replacing water in decorative ponds and reservoirs.

Technical features of using different types of pumps for draining basements.

Surface pumps for the basement.

In this case, the pump itself is on the surface, and the supply hose is lowered into the basement, into its deepest place. The problem in this case may arise as follows - blockage of the suction hole with various debris in the water. We recommend making sure that there will be no problems with this or using an additional mesh. In this case, the entire process should be monitored, since not all surface pumps have dry-running protection, and if water stops being sucked in, the equipment may simply fail.

Sewage pumps for the basement.

This option is more preferable, since most models are equipped with a float, and when the water level drops to critical, it automatically turns off. Almost all models have the following feature - the suction hole is reliably protected from large inclusions, this is important if debris, leaves, etc. get into the basement. Some models of fecal pumps are equipped with a chopper blade, which is an additional insurance against blockage. Such equipment is always a problem-free solution.

Drainage pumps for the basement.

As a rule, basements and cellars in Russia are filled with melt water in the spring, or groundwater comes too close. That is, the water level simply rises in this room, without much debris or pollution. In this case, the optimal and most cost-effective solution would be to use a drainage pump. Most of these models are designed for pumping dirty water, with inclusions of a certain diameter, so there should be no problems. Any correct drainage system, like its fecal counterpart, is equipped with a float for automatic shutdown and thermal protection. The choice of a specific model depends on technical tasks and personal preferences.

In most cases, we recommend using a drainage pump for this task, as it is the best option in terms of price and technical requirements.

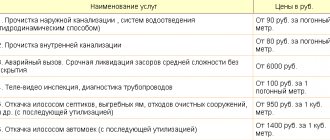

Features of basement pumps, what determines the price

We recommend paying attention to the following parameters of this equipment (we are talking about fecal or drainage pumps).

- Pressure is measured in meters. This indicator indicates to what height the pump can supply liquid. That is, when purchasing, you should take into account the depth of the basement and the drainage level. Naturally, the price of models with a high pressure indicator is higher.

- Productivity - in cubic meters per hour. The volume that the pump can pump out per hour. Different models have different performance, with larger ones costing more.

- Power - in kW. This is actually the device's power consumption. The higher the pressure and productivity, the more electricity is consumed.

- Case material. There are several options here - plastic housing, cast iron, stainless steel and intermediate models, including, for example, parts made of both plastic and stainless steel. The budget option itself is a plastic case. Stainless steel also has a longer service life, and in the event of accidental impacts, the case will not crack or break.

- Availability of pump protection systems - from overheating, automatic shutdown when the water level drops. All this will allow the equipment to operate for many years without unnecessary problems.

The higher the pressure, productivity and power, the higher the cost of the equipment; additional options in the form of a stainless steel body and protection options also increase the price of the product.

Grundfos sololift pump

The main advantage of these pumps, which are distinguished by their high price, is that they can be installed in various parts of the house. This is especially important for those owners whose plumbing fixtures are located below the drainage point. Pumps can be installed on any plumbing product. To place it in the bathroom or kitchen near the sink, you can use a regular pump. But for the toilet room, you should choose a model equipped with a cutting mechanism that will crush large particles, including paper. The presence of such a grinder allows the use of smaller diameter pipes for the sewerage system, which will reduce the cost of installing a wastewater disposal system.

Advantages of Grundfos sololift pumps

- Installation of such equipment can be carried out in any room in the house, regardless of in which part of the building the outlet pipe of the sewerage system is located;

- These devices are distinguished by their versatility of use. Their installation can be carried out on a separate device, or they can pump out wastewater coming from all plumbing fixtures located in the bathroom;

- this equipment can be equipped with a waste shredder, which allows the use of small diameter pipes for sewage;

- This equipment is characterized by high reliability and long service life;

- pumps from this manufacturer are distinguished by their aesthetic appearance and harmonize well with any interior;

- during operation it creates a small noise level, therefore, using it in the house, the owner will not encounter discomfort;

- The design of these devices includes an aerodynamic relay, which provides the ability to pump out wastewater automatically. When the set level is reached, the device turns off;

- the installation is equipped with an automatic system that turns off the pump if the electric motor overheats;

- Installation of such pumps is simple and convenient.

Harsh chemicals should not be poured down the drain . Otherwise, the performance and durability of the equipment may be affected.

Submersible pumps with centrifugal mechanism

When you need to choose a submersible mud pump, you must also take into account the design features. The principle of operation is different in different models. It is important to understand the operating principle of equipment for removing dirty water. The main difference is constructive. Modifications with different suction principles have been developed.

The suction principle is based on the capture of liquid by blades mounted on a wheel. This design ensures high performance and no risk of damaging mechanical components with abrasive particles. The working chamber can be made of metal or durable polymer materials.

Disadvantage: prohibition on dry use. But this problem has been solved by manufacturers who install automatic switches (float or electronic) on mud pumps. Operational feature - pumping equipment must not look out of the water, cooling it from overheating.

Causes of flooding and pump selection

There can be several reasons for flooding of a basement or ground floor:

- seasonal flooding of underground buildings during spring floods;

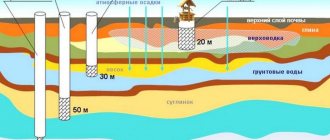

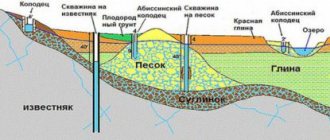

- close occurrence of groundwater;

- burst of water supply or sewerage.

It is the reasons for flooding of basements and basements that are an indicator of which pump to pump water from the basement to choose.

In the case of seasonal flooding, water can be pumped out from the basement once a year after the flood has passed and the water has settled below the level of underground buildings. That is, there is no need for the pumping device to be permanently located in an underground room.

In the case of close groundwater, the drainage system must operate continuously. Consequently, the pump is installed during construction in a special collection tank and is removed from there only for maintenance. In such situations, the drainage pump should work automatically: turn on when the water reaches a certain level and turn off after pumping it out without human intervention.

If the flooding of the basement occurred due to a break in the water supply or sewer system, the situation changes somewhat. In this case, of course, the pump is used once, but other nuances arise here. In case of a break in a cold water supply, any drainage pump will do.

Motorized pump

If hot water pipes rupture, the pump should be selected based on the temperature characteristics of the pumped medium.

If the cellar or basement is flooded with the contents of sewer pipes, a fecal pump will be required. The peculiarity of the fecal unit is that it is capable of pumping liquids interspersed with solid particles of large diameters or even grinding them.

Drainage arrangement

This method is good because it allows you to combat the root cause of flooding - high groundwater levels. The result of the work will be its reduction. Unfortunately, this method is not applicable in every case. To understand why, let's take a closer look.

A drainage system is essentially a drainage system through ditches or special drainage pipes. Deep ditches on a site are dangerous and do not enhance its appearance, so they are not used for domestic purposes. With their help, you can, for example, drain a swamp in order to organize a place for a vegetable garden. Let's consider a system of pipes. A drainage pipe is a pipe of large diameter, at least 100 mm, with a network of small holes across the entire surface, buried to the drainage depth, that is, below the basement floor level, with a slope away from the house and a free exit. Thus, the use of such a system is possible only in areas that have their own slope. It is this that will ensure the natural flow of water and its free exit at the end.

Conclusion: if you have the opportunity to make a drainage system around your home, then it is necessary to do so. Either alone or in combination with other basement drainage measures, it will give excellent results and eliminate the root cause of flooding.

Installing a waterproof barrier in the basement

There is a solution to the problem of basement flooding in houses on flat areas, which, although it does not eliminate the cause itself, like drainage, allows you to completely do without any temporary devices. We are talking about organizing a waterproof barrier inside the basement - essentially a “trough” over the entire surface of the walls and floor. How this is done will be discussed further.

Generally speaking, there is no need to make such a barrier along the entire height of the basement walls. It is enough to raise its level 100 mm above the highest groundwater level. Of course, you can simply make a barrier to the soil level - water simply cannot rise higher, but the high price of the materials used in this method requires corresponding savings, and this can only be achieved by avoiding overspending. Accordingly, the first thing that needs to be done is to determine the level of the primer and, thereby, determine the upper limit of waterproofing.

Next, you need to decide what exactly needs to be done to create a waterproof barrier. There are two options here:

- If the basement is a reinforced concrete monolith-trough, poured in one go, then it will be enough to treat it from the inside with impregnating waterproofing. This is a special mixture that penetrates into the pores and microcracks of concrete and contains additives that crystallize in water. The crystals formed clog all the pores in the concrete, thereby forming a waterproof barrier - what we need.

- Any other case, including a reinforced concrete monolith poured several times, because even this option cannot be considered a full-fledged monolith, since each new pour over the existing concrete creates a highly permeable boundary between different layers; for water it is, in fact, almost a crack. Penetrating waterproofing, which clogs only microcracks and pores, will be powerless here. What can we say about all sorts of combined options, for example, walls made of concrete blocks or bricks, the floor is a monolith. In this case, it is necessary to make an additional inner layer of waterproofing materials. Coating or adhesive waterproofing is not suitable here, since it has an increased risk of peeling, especially under water pressure. It is necessary to use materials that have high adhesion to concrete and brick surfaces and create a high-strength layer that does not crack over time. This is exactly the option we will consider.

First, let's decide on the necessary materials and tools. We will need:

- Sand concrete mixture.

- Impregnation waterproofing.

- Reinforcing waterproofing.

- Mixer and kneading container.

- Brushes, rollers, brushes.

- Spatulas.

Let's get to work.

We have a basement with walls made of concrete blocks, the floor is a monolith, which was poured after the walls were built. When spring comes, the basement floods. By the way, this also happens in case of prolonged rains.

It is quite obvious that the main problem areas are the junction of the walls with the floor and the tile joints.

1. Pump out water from the basement. This can be done manually or using any suitable pump, such as a baby pump. Please note that they come in two types: with lower or upper water intake. It is clear that it is better to use with the lower one. By fixing it vertically, you can pump out almost all the water. In our case, there was no such pump, so pumping had to be done in two stages: pumping to the minimum possible level - approximately 30 mm, and manual residual pumping.

As the pump drains, it will emerge from under the water. Very important! It only cools down when it is in water, so you need to constantly water it to keep it from overheating. Next, we place the pump in a large bucket, where we scoop out the water with a suitable tool.

We sweep the remaining water into one puddle with a brush and pump it out in the same way. As a result, we get an almost dry room. The water, of course, will rise. If the work is done slowly and does not interfere, then you can move on to the next stage. Otherwise, the work will have to be postponed until a more suitable time.

2. We process the junctions of walls and floors, as well as seams. We mix the sand-concrete mixture and use a spatula to form skirting boards with a height and width of about 40–50 mm along the entire perimeter of the room. We putty the seams between the slabs with the same mixture. Leave to dry. The next day, when the baseboards are in place, we move on to the next stage - treatment with impregnating waterproofing. High humidity in the room will not hurt - the impregnation works in water, the main thing is that there are no puddles. We pump them out using the method described above.

3. Mix the waterproofing mixture with a mixer according to the attached instructions.

4. Use a brush to cover the entire surface to be treated with the resulting creamy mass.

Leave to dry. After the time specified according to the instructions, apply the second layer. After treatment, water will not flow through the surface of the concrete - these are the planes of the blocks and the entire floor. The seams and junctions remain. We will process them when the second layer of penetrating waterproofing dries.

5. If necessary, pump out the water again.

6. Mix the armoring solution according to the instructions.

7. Similar to penetrating waterproofing, apply the resulting solution with a brush to the entire surface to be treated. We pay special attention to the seams between the slabs and the junctions.

8. The first layer is the base layer. It is necessary to wait the required time for setting and apply the second layer. Before this stage, all flaws will be clearly visible, in the form of oozing microholes. The water leaves clearly visible marks; in the photo there is a whitish stripe. In this case, the location of the leak can be seen.

The result is puddles that need to be drained.

9. Mix the solution a little thicker and treat the leakage areas. Fill the floor with the next creamy mixture. It is convenient to distribute the finished mixture with a roller:

or with a flat brush:

As a result, we get a very durable, absolutely waterproof layer of waterproofing.

If after the second layer there are still holes with oozing water, then you need to repeat the procedure in the leakage areas as many times as necessary. Usually after the third layer there are no such places left.

So, the described methods for draining the basement will certainly allow you to get rid of unnecessary water and protect the internal basement from high humidity, but which option to use must be decided individually, based on specific cases and goals.