New types of metal welding

K-TIG (Keyhole TIG) is a high-tech version of TIG/GTAW welding. The word Keyhole translated from English means “keyhole” .

The method received this name due to technological features, which we will talk about a little later. This new welding process was developed and patented several years ago by the Australian Government Scientific and Industrial Research Organization (CSIRO). K-TIG is currently used in manufacturing in Australia, USA, UK, Norway, Sweden, Denmark, Taiwan, India, Malaysia, Argentina, China and several other countries.

This technology is already widely used in shipbuilding and tank manufacturing, cryogenics, oil and gas, power generation, water treatment, renewable energy, nuclear and defense products, and pipelines. In general, the range of applications is extensive. For example, GE (General Electric) has deployed the technology in several places and uses it to make the largest and most advanced gas turbines in the world.

The differences between K-TIG and conventional types of welding are truly impressive:

Single Pass Welds K-TIG makes very fast, single pass, fully penetrating welds up to 16mm in diameter in titanium, 13mm in stainless steel and 9mm in alloys.

Wide Range of Welding Materials The K-TIG process is well suited for low thermal conductivity materials such as stainless steels, nickel alloys, titanium alloys and indeed most corrosion resistant and exotic materials including 300 series stainless steel, duplex, super duplex, Hastelloy, Inconel, nimonic, zirconium and other materials.

Fast Welding Speeds Welds are produced at speeds up to 100 times faster than conventional TIG/GTAW welding and to a quality standard that meets the most stringent requirements of the nuclear, aerospace and defense industries.

Typical examples of K-TIG welding speeds: 12 mm austenitic stainless steel - speed 250 mm/min 8 mm C-Mn steel - speed 400 mm/min 3 mm ferritic stainless steel - speed 1000 mm/min All in one full pass, while Average speeds for the K-TIG welding process are indicated, which can be increased (in some cases significantly) if speed optimization is the goal.

And also K-TIG : - reduces energy and gas consumption by up to 95%; — wire consumption is reduced by more than 90% or completely eliminated; - does not require edge processing; — only one welding gas is used and its consumption is economical; — works in a very wide range of welding currents; — provides a safe and clean environment with low smoke levels for employees.

This list of technological features is due to the solution of the main tasks - a significant reduction in production costs and increased productivity .

How does K-TIG welding work?

K-TIG technology provides benefits previously available only to expensive laser or electron beam systems.

This simple process provides automatic, high quality deep welding, accessible to any small to medium sized welding machine.

The patented technology is based on extensive scientific research into the gas tungsten arc process and is the result of many innovations related to arc performance, weld pool stabilization, heat transfer reduction and welding process efficiency.

Essentially, the K-TIG option is a solution to the weld instability problems that are common with GTAW. In this case, self-induced effects are used to create a plasma jet. There is no hole, which makes the process much simpler than plasma arc welding.

A fundamental characteristic of the process is the deliberate increase in arc pressure until the crater at the bottom of the weld pool expands. At this point, the crater floor breaks through the root surface of the weld, forming a so-called “keyhole” and allowing the arc gases to escape. The most important thing is that the holes on the front and root surfaces of the weld are secured to the liquid surface of the weld pool. To help understand what this looks like, you can visualize the elastic properties of the film of a soap bubble, as shown in the image to the right.

The minimization of surface energy associated with the keyhole geometry and the relatively unimpeded escape of gases combine to create a very strong and quiet weld pool. In addition, surface tension prevents the molten metal in the weld pool from falling out from the surface of the weld root.

K-TIG welding process is unique because it does not rely on the very high energy density of lasers and plasmas, for example, resulting in a wider fusion zone on the face.

Main types of welding

Electric welding is divided into 2 main classes: non-arc and arc.

Non-arc welding is more often called contact welding. In resistance welding, electrodes that supply current are applied directly to the metal being welded. A short but very powerful current discharge (thousands of amperes) is supplied through the metal located between the brought electrodes. In this case, fusion occurs only between the applied electrodes. If the electrodes are located directly opposite each other, then the welded joint is a spot weld. Although spot welding is not the only type of contact welding, it is the most common. Therefore, the concepts of “spot welding” and “resistance welding” are often used as synonyms. Spot welding voltage is a few volts. Therefore, resistance welding is used primarily for fastening thin sheet metal. For example, in the automotive industry.

In construction, electric arc welding has become much more widespread. In electric arc welding, there is a small gap between the current source (electrode) and the metal being welded, which is filled with an electric arc. It is a mistake to assume that this is an air gap. This is a gap of ionized gas that conducts current. Arc welding, as we imagine it today, is impossible without gas. The gas can simply be supplied from a separate cylinder, or it can be formed as a result of burning of the electrode coating.

The most common technologies in construction are the following:

- MMA (in the domestic classification - manual arc welding, or MMA)

- TIG (argon arc)

- MIG-MAG (semi-automatic, wire).

The popularity of this type of welding is predetermined precisely by the absence of the need to carry a gas cylinder with you. The coating of the electrode is the “frozen” gas cloud. As soon as the electrode touches the metal and the resulting short circuit current melts the metal of the electrode, the coating around it will also melt. The resulting gas cloud will provide a conductive ionized environment for the arc and protect the molten metal from oxygen.

Electrodes are selected according to the type of metal and diameter. The type of metal is important, since during operation the metal of the electrode rod flows drop by drop into the metal being welded and fuses with it. For a strong connection, the metal of the electrode rod and the metal being welded must be identical. The packaging of electrodes always indicates which metals these electrodes are suitable for.

Once you have decided on the type of electrode, you need to decide on its thickness. Newbie question: why do we need electrodes of different diameters? It's simple. The thicker the electrode, the greater the current that can melt it. The same goes for the edges of the metal being welded. Therefore, the thickness of the electrode is selected to match the thickness of the metal being welded. For ferrous metals it is recommended:

MMA technology allows you to work with most common metals, with the exception of aluminum and alloys based on it. Although theoretically this is also possible with an assistant, if you ensure that the cleaned aluminum surfaces do not have time to be covered with a film before melting. But it is more correct, of course, to simply use welding technologies suitable for this.

Promising types of welding

⇐ PreviousPage 4 of 4Arc welding with coated electrodes is by far the most popular, cheapest and most widespread. What are the trends in the development of welding production in the future? The twentieth century was characterized by a transition from the machine-technical to the scientific-technical revolution. What does the use of high technology as the basis for the existence of industry mean? And at the beginning of the third millennium, the main basis for the existence of industry changed to the use of high-tech processes. In everything - from household appliances to welding work.

As paradoxical as it may sound, welding processes in terms of the breadth of application and the gross volume of the final product occupy half (!) of all production work. About 2/3 of all rolled metal is used for the manufacture of structures and structures installed using this type of technology. This process is used everywhere - from high-rise construction and installation of all production facilities to work in outer space and on the ocean floor, being the only possible way to obtain permanent connections.

Until now, arc and contact types of welding are its main methods. High-quality welding electrodes are used in 40% of all types of such work, and their share will never decrease, despite any scientific achievements and innovative developments.

What are the main trends in this manufacturing sector? In the near future, the leading positions will be occupied by semi-automatic and automatic devices, the main technical solutions for which will be aimed at reducing their weight and size characteristics. For this purpose, new converters with an increased number of electric current phases, increased efficiency and power factor will be used. It is possible to use converters based on completely different principles than those currently used.

The second thing that modernization funds are aimed at is improving the quality of direct fusion on site. Synergetic control, automatic regulation of contact data using a computer to obtain fused objects of complex geometric shapes is the basis of scientific and technical planning. And now many industries use high-tech automatic machines, fully remote-controlled, which monitor the quality of the fusion process in different vectors, both at the time of welding and immediately after it (gas and oil pipelines, nuclear industry facilities and many others). In this case, conventional high-quality welding electrodes of various types are used.

Laser welding is still a fairly expensive and technically intensive process. But, perhaps, over time, it will also firmly enter into production and become widely used and cheap, like arc welding with coated electrodes today.

⇐ Previous4

Site search:

New technologies in welding

Modern civilization owes a lot to the welding process. Without welding elements, we would not have received transport, huge buildings, technological structures, mobile phones, etc. Despite the fact that this physical process has been used for many centuries, it does not stop its progress. Scientists from many countries continue to research and improve welding mechanisms, apply new techniques and make revolutionary discoveries in this area.

New technologies make it possible to achieve more perfect results using minimal resources. Developments that appear every year make it possible to weld materials that previously remained beyond the boundaries of this technology.

Main innovative directions

All developments in this area are aimed at improving the main indicators of the process at the lowest cost:

- reduction of corrosion and warping of metals during operation;

- increasing the speed of the welding process;

- facilitating the cleaning of joints or ensuring that there is no such need;

- minimal consumption of materials;

- facilitated and simplified process management;

- the ability to join the thinnest sheets of metal of various grades.

Portable devices

These types of welding machines have made it possible to bring welding to a new – household – level. If before the invention of portable devices, such work was carried out mainly by highly qualified professionals, then portable technology made it possible to use them at home.

Modern welding machines

Firstly, such devices are very light in weight, making them easy to transport. Secondly, the manufacturers provided them with a complete ready-to-use kit, not forgetting about the electrode supply system (wire weighing up to 10 kg).

The main improvement can be considered that a digital control system is built into the device. On the display, everyone can indicate the basic welding parameters: the diameter of the wire being laid, the type of gas, etc. Based on the entered data, the portable device independently adjusts and performs welding at a level sufficient for non-production welds.

Improved burners

The gas torch is considered the most primitive element during welding, but even small changes to this element have significantly improved the quality of the work performed. Modern burner designs are made not only from new materials, but also have a different outlet diameter, which is capable of working with non-standard temperatures and creating the required pressure.

The gas burners proposed by scientists have become gearless and highly dynamic; with their help, even during a long process at the highest temperatures, you can get a perfectly even flame in which torches, flashes and pops will not appear. Because of such innovations, the welder's work does not require frequent stops, which allows more work to be completed in the same time.

Units have been developed with numerous nozzles that are used to connect large diameter pipes. The flame width when using linear burners can reach several meters. This technology is often used to join parts underwater or in the air, where there is an urgent need to dramatically reduce turnaround time.

Hybrid laser technology

This method was developed for the automotive industry, but has found application in other industrial sectors. A hybrid laser is used to produce high-quality seams when joining refractory steels when combined with carbon dioxide. This allows you to obtain ideal welds with precise control of the laser power within the range of 1.5 - 4.0 kW.

Another feature inherent in hybrid laser technology is the highest speed of the melting electrode and the work performed - from 40 to 450 m/hour. With the same performance, it is possible to process the thinnest sheets made of automotive steel, which became the reason for the financial support and improvement of this development by leading automobile corporations.

Twin arc welding

This technique was developed for large-sized structures, the manufacture of which involves thick sheets of hardening steel of grades such as 30KhGSA. The method is based on the fact that during double-arc exposure, two different types of wires containing alloying (heavy-duty) components are simultaneously used. The diameter of such electrodes is 5 mm.

To ensure stable arc burning during double-arc welding, a ceramic flux based on ANK-51A ceramics is required. It is with ceramic flux that this method shows the highest results and the formation of an ideal welded surface.

Gentle technique

For certain work, a new gentle technology has been developed, which is very highly effective, but has a low cost. During the process, special mixtures of protective gases are used: carbon dioxide combined with argon or a mixture of argon, carbon dioxide and oxygen. Compared to the traditional use of separated carbon dioxide, the resulting seam is smoother and more flawless.

Another positive point is the significant reduction in cost of the welding process: fewer wire electrodes are consumed for the same volume of connections made. The savings are about 20%, which is a significant amount on an industrial scale. Additionally, during the welding process, the transition to weldable parts becomes very gradual and smooth. Professional welders who were involved in the initial tests of the gentle technique emphasized that spattering of electrode metals with a multi-component gas mixture is significantly reduced.

Promising welding methods

Electron beam welding (EBW)

The essence of the electron beam welding process is to use the kinetic energy of electrons moving quickly in a deep vacuum. When electrons bombard the surface of a metal, their kinetic energy is converted into heat, which ensures the melting of the edges of the parts being welded.

Advantages of ELS:

1) The possibility of obtaining a narrow and deep penetration zone due to the high energy concentration in the electron beam, which makes it possible to weld any materials of large thickness.

2) Small leads (deformations) of the structure after welding due to a relatively small amount of heat input (10–15 times less than with DES) and rapid cooling of the weld metal.

3) The possibility of obtaining assemblies with fused seams, when one of the structural elements is inaccessible to the direct influence of the arc.

Disadvantages of ELS:

1) The need for labor-intensive adjustment of parts for welding (the gap between the welded edges should not exceed 0.15 mm, the non-parallelism of the ends with a metal thickness of up to 20 mm is within 0.5 mm, the cleanliness of the edges is Rz = 2.5 microns).

2) The comparative complexity of the equipment used (welding chambers and large-sized installations).

Diffusion welding

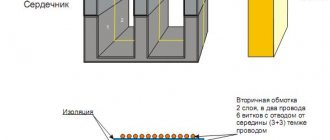

The essence of the diffusion welding (DS) process is the formation of a permanent connection of parts in the solid state due to the mutual diffusion of atoms through the contact surface as a result of pressure and heating for a certain time. The connection is formed as a result of the development of physical contact and activation of contact surfaces due to their plastic deformation and interaction, leading to the formation of chemical bonds between atoms (Fig. 1.19).

The factors determining the DS process are temperature, pressure and time. The combination of these factors ensures a high-quality connection. It is recommended to weld titanium alloys at a temperature 15–30°C below the polymorphic transformation temperature (below 900–1000°C). Welding pressure is 0.4–2.0 MPa, welding time is 0.5–3 hours.

Rice. 1.19. Diffusion welding installation diagram:

1 – top plate; 2 – vacuum chamber; 3 – bottom plate;

4 – heater; 5 – table; 6 – vacuum system; 7 – product

The quality of surface preparation and the environment are important to obtain a quality connection. Diffusion welding can be carried out in a vacuum, in an environment of inert gases, in salt baths (preferably in a vacuum).

Advantages of DS

· high quality of connection, mechanical properties of the material in the welding zone are close to the properties of the base material;

· low distortion of the structure due to the absence of residual stresses in the welds;

· elimination of vacuum annealing of the structure after welding;

· improvement of working conditions for welders (no gas emissions, dust, etc.).

Of particular interest is the complex process of pneumothermal molding - diffusion welding of titanium structures (PTF/DS), which is being intensively developed by a number of aerospace companies. The complex PTF/DS process is based on the identical conditions and modes of superplastic molding and diffusion welding (comparable temperature, power and time parameters, the need to use vacuum or neutral gases).

According to the 1st scheme (Fig. 1.20, a

) pre-prepared elements are placed into the equipment. Forming is carried out by gas supply. At the final stage, welding pressure is created.

The method can be successfully used to compensate for the thinning of the sheet in the most deformable areas or to connect the sheet with fittings, brackets and other structural elements.

According to the 2nd scheme (Fig. 1.20, b

) an anti-welding coating is applied to the sheet locally (in places of deformation).

Collect two leaves. Create a welding pressure R

f by welding the sheets in places where there is no coating. then argon is fed between the sheets and the bottom sheet is formed according to the profile of the tool.

The method is used for the manufacture of integrally rigid structures - panels, in the form of sheets, reinforced with stiffening elements (example: a panel with frames and stringers).

Rice. 1.20. Basic schemes for implementing the complex PTF/DS process

According to the 3rd scheme (Fig. 1.20, in

) an anti-welding coating is applied to the sheet on both sides. Collect a package of three sheets. Create welding pressure. The middle sheet is welded to the sheathing sheets. When gas is supplied, a three-layer aggregate structure is formed between the sheets. The shape of the filler is determined by the pattern of the applied anti-welding coating.

Using this method, various types of fillers can be obtained: corrugated, cellular, wafer or combined. The shape of the product is not necessarily flat (example: multi-layer panels). Additional elements can be placed in the equipment.

Main types of welding and areas of their use (14 photos)

Manual arc welding (MAW)

Used in almost all industries, technology and construction. This method is suitable for joining steel, cast iron or non-ferrous metals. Almost every owner of a summer house or suburban area now has a compact welding machine for carrying out basic welding work. The operating principle of arc welding is based on the creation of an electric arc between the electrode and the parts being welded. The resulting short circuit current heats the metal rod and the edges of the parts to the melting temperature for their mutual diffusion.

When carrying out welding work at home, fairly small, compact and light inverters are used, the cost of which ranges around $200.

The main advantages of the RDS: an easy process of learning the simplest welding techniques, the compactness of the devices, which allows work to be carried out in small, cramped spaces, the versatility of the RDS, which is ensured by the presence of a large selection of electrodes of different brands and characteristics, a relatively low price for the devices and consumables - electrodes. Disadvantages include the inconvenience and sometimes impossibility of welding thin materials (less than 2 mm). Welding critical load-bearing elements requires highly qualified workers, since the strength of the entire structure depends on the quality of the formed seam. During welding, harmful substances are released and good ventilation is necessary.

Semi-automatic welding (PAS)

A type of arc welding during which electrode wire and shielding gas (carbon dioxide or argon) are supplied to the working area. The function of the shielding gas is to insulate the hot metal being welded from the environment. Allows you to connect both ferrous and non-ferrous metals.

In addition, PAS allows you to weld both thin (0.5 mm) sheets and critical load-bearing structures with a part thickness of 30 mm. The cost of a compact semi-automatic welding machine is up to $350.

The main advantages of PAS are manifested in comfortable and safe working conditions for the welder, the ability to weld thin material with a spatial configuration. The weld does not depend on subjective reasons and is generally of high quality. Among the disadvantages, one can note the low mobility of the device, due to the need to transport a gas cylinder, but this problem is solved by using wire with special additives, fluxes.

Prospects for the development of welding and welding technologies

An important scientific and technical problem is the creation of economical, reliable and durable welded structures that could work on land, under water and in space, with large temperature differences, in aggressive environments and with intense radiation. More than half of the gross national product of industrialized countries is generated by welding and related technologies. The welding industry employs about 5 million people, the majority of whom (70%-80%) perform electric arc processes.

Fusion welding is the basis of welding production.

The technique and technology of this process is constantly being improved. Arc welding equipment ranks first in the welding equipment market. The production of equipment for welding with flux-cored and solid wire is increasing, while the share of equipment for manual arc welding with coated electrodes is decreasing. In industrialized countries, the share of metal deposited by manual arc welding has decreased by almost 3 times and amounts to 20-30%; in other countries this decrease is less intense.

The production of resistance welding equipment ranks second. At the same time, the share of equipment for gas welding and cutting is decreasing. In world practice, inverter power supplies have recently begun to be widely used, which have great capabilities for automatically controlling welding processes.

The areas of application of laser technologies, in particular high-power diode welding lasers with high efficiency, are expanding. Electron beam welding is widely used, with which metals up to 200-300 mm thick can be welded in one pass. For the development of heavy engineering, electroslag welding is of great importance in the manufacture of large, thick-walled products. Contact welding (roller, spot and relief) is developing successfully.

Thanks to the development of electronic technology and instrument making, ultrasonic, diffusion, press and other types of welding have emerged. Ensuring high-quality connections in difficult conditions requires improved techniques and means of preparation for repair welding.

An integral part of welding production is surfacing, for which 8-10% of electrodes and solid wire are used, as well as 30% of flux-cored wire of the total volume of welding materials and almost all sintered and flux-cored tapes. Technologies for applying special and protective coatings using plasma-arc, electron-beam, gas-thermal and dynamic spraying methods are being updated. Bonding technologies are of particular importance. A significant number of adhesive compositions have been created that make it possible to connect similar and dissimilar materials.

The problem of welding new materials based on iron, copper, nickel, aluminum, titanium, etc. remains relevant. A solution to improve the weldability of promising aluminum and titanium alloys was found at the Institute of Electric Welding named after. E.O.Paton. New technologies have been created that make it possible to obtain welded joints with a thickness of 1.5-1000 mm. To obtain permanent connections from dissimilar materials (steel - titanium, copper - aluminum, steel - aluminum, etc.), the following processes will be preferable: magnetic pulse welding, explosion welding, diffusion welding, soldering, gluing, mechanical connections.

New technologies have been introduced into production for welding polymers and composites based on them, welding pipes made of thermoplastics, which are used in the construction of gas and water pipelines, as well as other communications. Promising are the connections of these materials using ultrasonic welding, friction welding and high-frequency currents.

The capabilities of underwater welding and cutting, which are used at depths of several tens of meters, have increased significantly. In this case, welding with fusible and infusible electrodes and laser radiation are used. New mechanized welding and cutting methods are being developed, as well as equipment that could be used at kilometer depths to lay gas and oil pipelines along the ocean floor.

The most outstanding achievements of welding technology can be considered developments in the field of joining biological tissues. Laser welding of biological tissues refers to seamless methods of joining tissues without puncturing them and using suture and staple material.

Rice. 1. Welding of biological tissues

Welding and related technologies will continue to develop intensively, as they are key to the leading sectors of modern industry.