Water hammer in the heating system.

Residents of private houses and apartments in multi-storey buildings often hear dull or sharp, distinct knocks and knocks in heating pipelines. It would seem that this phenomenon need not be given special attention. In fact, the consequences of this phenomenon can not only destroy pipelines and radiators, but also cause injury to the residents themselves. Water hammer in a heating system causes most breakdowns and destruction of heating equipment. What to do, how to get rid of water hammer in the heating system? Resolving this issue is of great importance for the safety of equipment and communications of the heating complex. If in centralized heating it is difficult to take measures to localize this phenomenon, then water hammer in the heating system of a residential private house can be prevented.

What does water hammer mean?

Water hammer (water hammer) is a physical phenomenon characterized by a sharp increase in hydraulic pressure in a separate section of a fluid system, caused by a significant change in flow velocity.

In heating systems, the main type of coolant is water. Water is incompressible by definition, as are the vast majority of liquids. As the flow moves, obstacles may form in its path. Moreover, for a water hammer to occur, an obstacle must arise unexpectedly. When an obstacle appears, the fluid loses speed, the gradient of which tends to zero.

When the volume of liquid stops, the force of the pumping device that circulates the water continues to act on it. Under the influence of the pumping force, the hydraulic pressure of the fluid rises in the area. Pressure acts on the walls of pipelines and vessels.

Causes

There are several main reasons for the occurrence of water hammer in a heating system, among them the following can be distinguished:

- Sudden opening (closing) of shut-off valves;

- Presence of air pockets in the system;

- Sharp narrowing of the pipeline;

- Pipe bend;

- A sharp change in the operating mode of the pump - start or stop.

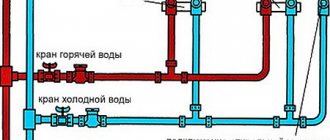

Abrupt manipulations with shut-off valves - opening or closing - lead to an instant change in pressure in the device area. When closing, the pressure on the valve and its connecting elements increases. In this case, seals of threaded connections, wafer gaskets, and, at high pressure, elements of the shut-off device are often damaged.

When opening quickly, there is a low pressure area in the area behind the valve. The liquid instantly rushes into it, acquiring greater speed. In this case, elements located after the reinforcement are subject to destruction. Areas with high hydraulic resistance are especially susceptible to water hammer - bends in pipelines, heating devices (radiators, convectors, etc.).

The presence of air pockets in the system is due to its incorrect configuration and installation errors. As a result of installation errors, the standard slope of communications is not observed, and “bags” and “dead zones” are formed. Air pockets often form in these areas.

The liquid stops in front of the plug, and the pressure begins to rise. The liquid gradually compresses the air volume and, when a certain pressure is reached, breaks through the obstacle. After this, it moves at high speed into a zone of low pressure, causing damage to system elements.

When the pipeline sharply narrows, the water also acquires high speed. The narrowing can be created during the construction of the network or as a result of the formation of durable deposits (scaling, etc.). Changes in the diameters of heating pipelines should occur smoothly along their length.

A common cause of water hammer is a change in the operating mode of the circulation pump. Water hammer occurs especially often when starting the pump (especially at high speed). In this case, the liquid acquires speed and moves along communications that previously had hydrostatic pressure. When starting, the water acquires a dynamic pressure component, which increases its speed.

When stopped, the pump becomes a natural obstacle in the path of water. The pressure in front of it increases, and portions of the working medium are forced through the impeller.

Water hammer is a constant phenomenon in steam heating systems. They are due to the different phase states of steam and water. Therefore, the communications of steam complexes are made of metals with increased wall thickness.

The root causes of water hammer and the consequences of this phenomenon

An external manifestation of the fact that a water hammer has occurred in the water supply of the heating system will be heard knocks and clicks. They arise due to the appearance of obstacles to the free movement of water. It, like any other fluid, is almost incompressible and is characterized by certain quantities, namely mass and inertia. If an obstacle appears in its path, then due to the inability to move further freely (and an instant stop of water is impossible a priori), the pressure may increase sharply.

When this happens with fairly frequent frequency, and the system cannot, for one reason or another, provide the required safety margin, then there is a high probability that the need for heating repairs in the house will soon arise.

The specific root cause of water hammer may be:

- Failure or shutdown of the pump (circulation);

- The appearance of air bubbles in the communication system;

- Rapid closing of valves, resulting in a sudden stop of fluid flow.

By reviewing the figure below, you can understand the probable causes of water hammer, with the last cause from the list occurring most often. It is important to note that the use of ball valves to shut off pipes is strictly prohibited.

The amount by which the pressure level in the system increases determines the degree of probable damage. Accordingly, the cost and volume of upcoming heating repairs in an apartment or house are determined by the location of the burst and the length of the pipeline. If this happens at the beginning of a segment of long duration, then the intensity of the pressure increase will be somewhat less, but if it happens at the end, it will be greater.

Basic methods of protection

To protect materials, equipment and communications from water hammer, the following methods are used:

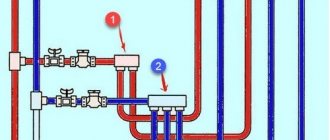

- Installation of thermostats with built-in shunt;

- Inserts made of plastic material;

- Installation of membrane devices;

- Control of pump operating modes based on data from the pressure sensor in the system;

- General preventive measures.

Temperature regulators with a built-in shunt are installed as shut-off valves. A shunt is a small-diameter tube that allows excess coolant to pass through when pressure increases.

Steel elements are most often subject to destruction from water hammer due to the rigidity of the structure and the lack of a shock-absorbing effect. To create a shock absorber, small sections of polymer pipes with good flexibility are often cut into place. During a water hammer, they compensate for the impact force by bending without being damaged.

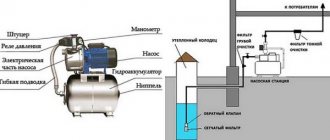

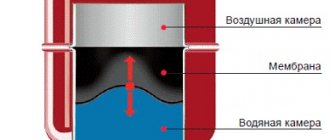

Hydraulic accumulators and expansion tanks also do a good job of increasing pressure, taking on the excess pressure. A membrane made of rubber or polymer bends and compresses the air in the air chamber. Water from the heating flows into the freed space, reducing the overall pressure in the system.

Circulation pumps are equipped with a pressure control system. The sensor monitors the water pressure in the network. When the value increases, it sends a command to reduce the pump speed. This system is applicable for pumps with variable speed control of the impeller rotation speed.

General preventive measures to prevent water hammer and their consequences:

- Perform smooth control of shut-off valves;

- Turn on the pumps at low speed;

- Check the functionality of air vents and safety valves;

- Promptly and regularly bleed air from the equipment;

- Regularly carry out visual inspections for the integrity of structural heating elements;

- Monitor the integrity of the membrane of the expansion chambers.

Water hammer is a common and dangerous phenomenon in heating networks. Timely prevention will save heating communications and equipment from damage and preserve their integrity and performance.

Water hammer in the heating system of a private house: causes and prevention.

An incorrectly designed heating system in most cases leads to incorrect operation. A characteristic sign of failure is changes in coolant pressure or water hammer.

If the liquid in the pipeline is distributed unevenly, an additional load is created on all components of the system - high pressure leads to depressurization of batteries, pipes and boiler breakdown. Therefore, it is important to know the causes of water hammer in order to prevent this phenomenon at the stage of installation of the heating system.

Why is this happening?

A sharp but short-term increase in pressure in the pipes is characterized by the appearance of characteristic clicks and knocks. Most owners simply do not pay attention to these sounds. Although this is the first alarm signal indicating a heating malfunction.

Extraneous sounds indicate inhibition of the coolant in the line - pressure prevents normal circulation and it slows down.

The main reasons for the slowdown are:

- shutting off valves that control the flow of water or antifreeze;

- the presence of an air barrier - a plug (it must be removed when the system is first filled with coolant by opening special taps);

- emergency stop or shutdown of the circulation pump.

The most common is the first reason. Nowadays, ball valves are more often used, which shut off pipes abruptly. Old-style cranes with a screw structure were devoid of this drawback, which was dangerous for the system.

If there is air in the pipes, any manipulation with the ball valve will only aggravate the situation. There is a strong collision of the working fluid with the plug. In this case, the pressure can reach several atmospheres! And this is detrimental to all components of the heating system. After all, any collision of the working fluid with an obstacle causes expansion of the pipes. If the load is too high, the consequences can be dire for the owners.

As soon as the first clicks in the system have been noted, the owners should think about its correct installation. Sometimes the cause of the problem may be incorrect selection of pipe diameters.

The liquid circulates through the circuit at a certain speed, and the narrowing of the pipes leads to a slowdown and increase in pressure.

Unloading the coolant into different registers, which is carried out at the point where the pipeline narrows, will help eliminate such a gross error in this engineering communication.

What are the dangers of pressure surges?

In fact, excess pressure has no restrictions. Several tens of atmospheres can easily turn into a large value. The situation is aggravated if the heating main has a significant length.

For example, tens of meters of pipes are laid in warm floors. And installing a thermostat will partially help solve the problem with pressure drops in such a design - it will not allow the floor to overheat. But at the same time, the thermostat will not help eliminate errors made during installation - incorrect pipe diameter, lack of slope. The fact is that after the thermostat valve is closed, the water continues to move by inertia for some time, creating a load on the pipes.

To protect heating from such one-time or regular water hammer, it is necessary to neutralize their force or impact.

The inertia of water and constant loads on any system lead to wear of threaded, rigid connections and the entire pipeline as a whole.

The most common consequences:

- release of hot coolant into residential premises;

- failure of the main components - boiler, pump, expansion tank;

- thermal burns and injuries to residents.

Basic methods of protection

Installation of an automatic system capable of regulating pressure without human control. In particular, the use of pumps with automatic operation control. Automation allows you to smoothly increase the speed of the pumping equipment and also gradually reduce it when this unit is turned off. Expensive boilers always have pumps that operate in automatic mode.

Reconstruction of an existing system, taking into account the basic installation rules:

- If the system has a thermostat, it is necessary to replace the rigid section of the circuit in front of it with elastic plastic or reinforced heat-resistant rubber. Such an insert tends to stretch and partially compensate for the pressure. The length of a homemade shock absorber is from 20 to 40 cm, depending on the line - the longer it is, the larger the section of plastic pipe.

- A shunt is inserted into the thermostatic valve in the direction of liquid movement - a tube with a cross-section of 0.2-0.4 millimeters. This insert reduces the volume of water in case of increased pressure in the system. And during normal heating operation, it does not in any way affect its proper functioning. When connecting to central heating, this method cannot be used - the tube will very quickly become clogged with rust. Autonomous systems allow you to use the shunt without restrictions (there are lines made of new high-quality pipes here, and the coolant is clean).

- You can also use a thermostat with a spring that prevents the valve from closing completely if there is excess load. Installation of such a device is carried out taking into account the arrow on the body, which shows the direction of movement of water or antifreeze. It should be noted that not all thermostat models have such protection against water hammer.

- A reserve tank or hydraulic accumulator must be installed. This compensating device allows you to successfully cope with the expansion of the coolant as pressure increases. Its rubber membrane or bulb stretches towards the air chamber, allowing a certain volume of liquid to be pushed into the second working compartment (its quantity depends on the parameters of the reserve tank - they are determined based on the volumes of the system itself and the boiler).

- The shut-off valves in the system must be continuously adjustable - such taps have a relatively short period of shut-off of the coolant.

All of the listed technical conditions work perfectly in a comprehensive manner - protection of heating from destruction will be ensured with high quality and for a long time.

Water hammer in the heating system - causes and precautions.

Often the cause of failure of heating equipment is the formation of water hammer in the system. What is water hammer and how can you prevent it?

How to deal with water hammer

To protect water and heat supply systems from the effects of water hammer, a number of measures are used. Some of them are indicative of universal use, while some are used for pipelines for a specific purpose.

Smooth overlap

You need to get rid of the temptation to quickly cope with such a simple task as opening or closing a valve. This needs to be done slowly and smoothly. If the valve is tight, then it is allowed to move its handle with small jerks. This is customary at industrial enterprises, but it is indicative of implementation in everyday life.

To avoid water hammer, it is recommended to close the ball valve smoothly

Water hammer still occurs. But it breaks down into several smaller ones. The energy that affects the pipes once when the valve is suddenly closed is divided into portions that do not create strong pressure drops. And therefore - not dangerous.

Depreciation

By manually controlling the movement of fluid flows, they can be smoothly closed or opened. But thermostats, which automatically control the operation of the heating system, are not capable of this.

To soften the water hammer in the system, shock-absorbing devices are installed in it. Before installing the thermostat valve, part of the rigid pipeline is replaced with an elastic one. The materials used for this are either heat-resistant rubber or reinforced plastic.

Since these materials can stretch, at the moment of a water hammer they will absorb its force. By briefly increasing in diameter, the shock absorber will act as a damper and relieve pressure before the valve closes.

For most systems, installing a piece of elastic pipe of about 20–30 cm is sufficient. For long pipes, you can increase it by another 10 cm.

Bypass surgery

The method involves manual modification of thermal valves. To implement it, knowledge of their design is required, otherwise the device can only be damaged.

The shunt is a thin tube with a diameter of 0.2 - 0.4 mm. It is inserted into the valve in the direction of fluid flow. During operation, it does not in any way affect the performance of the system, but with a sharp increase in pressure it will help bleed it into the pipeline behind the valve.

Note: Such measures will only help in systems consisting of new pipelines, and preferably not made of metal. The presence of rust negates all efforts and tricks, as it will quickly clog the hole.

Instead of installing a tube, it is often enough to drill a hole of the appropriate diameter.

Protected thermostats

The industry produces thermostats equipped with a water hammer protection device. They have a spring mechanism installed between the valve and the thermal head. You can find out about the availability of this device when purchasing a thermostat from its technical documentation.

When the pressure is exceeded, the spring stretches and prevents the valve from closing completely. The same process occurs as with shunting - excess pressure is released into the pipeline behind the valve. When the water hammer stops, the spring will completely close the valve.

Important: Thermostats equipped with a water hammer protection system are installed into the system strictly in one direction, indicated by the arrow on the housing.

Compensators

One of the compensating devices used in heating systems (it is also suitable for water supply) to protect against water hammer is a hydraulic accumulator. It is a reservoir divided into two parts by a flexible membrane made of rubber or caoutchouc.

At the bottom of the tank, connected to the system, there is water. The top contains air under pressure. A product of a similar design is part of an automatic pumping station and is used there to turn off the pump when the nominal pressure in the system is reached.

As part of the heating system, the compensator is connected to places where water hammer may occur. At this moment, the increasing fluid pressure presses on the accumulator membrane. The air above it is compressed, the membrane moves towards it. Due to the increase in the volume occupied by the liquid, the pressure in it drops.

As soon as the impact of the water hammer ends, the membrane returns to its place. The use of hydraulic accumulators simultaneously allows you to remove excess fluid from the system.

To create a shock-absorbing effect in water supply systems, special dampers are used in addition to hydraulic accumulators.

Compensator device

Safety valves

Once upon a time, doctors performed bloodletting on patients with high blood pressure. Less fluid means less pressure. Safety valves work on the same principle.

They are placed in the most dangerous places subject to water hammer. They work either as independent devices, or from a command from a controller that controls the operation of the system and has information about the pressure in it at given points.

As soon as the pressure at the installation site of the safety valve exceeds the threshold level, it will open and throw excess liquid out. Naturally, this happens where they will not cause harm or discomfort to anyone.

As the pressure decreases, the valve will close, returning to its original state.

Relief safety valve

What is water hammer in a heating system?

Regular increase in pressure in the heating system can lead to an unpleasant phenomenon - water hammer. It can cause the entire system to fail and cause serious injuries to all residents of the house.

Water hammer in a heating system is formed due to a sharp increase in pressure in a certain area, which leads to a decrease in the flow rate of the coolant, the role of which is often played by tap water. As is known, it does not have the property of being compressed like other working fluids. And if something impedes its progress, and the force of pressure still continues to act, this leads to the destruction of the walls of the radiators and other elements of the heating system. As a result of hydraulic shock, emergency depressurization of utility lines occurs.

What is the danger of water hammer

Any increase in pressure in the pipeline above the design value is dangerous both for the pipes themselves and for their connections. Shut-off valves may also be damaged.

This will not happen immediately, because initially all engineering systems, without exception, are carried out with a safety margin. But each water hammer methodically and mercilessly searches for a weak point in the pipeline, gradually preparing it for destruction. And at some point the patience of the pipes reaches a limit, and they burst.

An example of the consequences of water hammer

The consequences of breakthroughs are widely known. This is damaged furniture, wallpaper, carpets. Neighbors flooded with water, nervously demanding that everything be fixed as soon as possible, followed by payment of compensation for the damage caused.

If there was a water hammer in the heating system, then intangible victims are also possible. Hot coolant can cause serious burns to people who are unlucky enough to fall under its stream. And material losses from exposure to hot water are more serious than from cold water.

If the accident happened in severe frost (and breakdowns never happen), then stopping the heat supply will entail stopping the boiler with a complete freeze of the system.

It is easier to prevent losses than to compensate. To do this, you need to understand how to avoid them. So, water hammer in the water supply system, the reasons for its occurrence.

Reasons for appearance

Hydraulic formation can occur for a number of reasons:

- presence of air pockets in the system;

- sudden opening or closing of shut-off valves;

- narrowing of the lumen in the pipeline;

- incorrect design, resulting in bending of pipelines;

- a sudden change in pumping equipment settings, for example, starting or stopping the system too quickly;

- a worn out and old pipeline that has long been in need of replacement - for this reason, about 60% of all water hammers occur;

- the use of pipes of different calibers in the system, which is often associated with savings on the installation of the heating system.

What to do

How to prevent water hammer in the heating system? The following recommendations will help protect against such troubles:

- Pay attention to the quality of shut-off valves when installing a heating system, give preference to valves with smooth movement.

- Trust the design of utilities and installation of equipment and elements to professionals.

- To compensate for pressure in the system, use special devices, for example, hydraulic accumulators.

- Do not use flexible hoses or other unreliable elements.

By following these simple rules, you will significantly increase the service life of your heating equipment and prevent the formation of water hammer in the system.

Modernization and modification of the heating system

To begin with, I would like to remind you that the components must fully comply with the operating rules of the heating hydraulic system. When installing equipment, ball valves may not be suitable at all. All parts must be strong and wear-resistant.

Installation of special taps

In order to control the pressure of the fluid flow, electric pumps are installed that can control the fluid pressure and respond to its changes by adjusting the water supply to the system. With the help of such pumps, a smooth supply of liquid is automatically produced.

There are compensators that dampen hydraulic shock, they are called hydraulic accumulators. These are so-called barrels that absorb excess liquid when there is an excess in the system, thereby preventing high pressure from being pumped into the pipeline. In an emergency, this is an indispensable device for preventing water hammer.

Hydraulic accumulator device

Water hammer protection valves are installed in systems that are under pressure. The principle of its operation is to release excess pressure in the system itself into the external environment. To protect the system, you can use a corrugated pipe; it will act as a shock-absorbing mechanism in the event of a water hammer. This tube is made of flexible materials; if a problem occurs, it can stretch, thereby compensating for the pressure of the liquid.