To choose a good electric pump for a summer house or country house, you need to understand the tasks it must perform. It is used to maintain the irrigation system of garden plants and green spaces, to pump water into the water supply system, to ensure the operation of the boiler room or to drain septic tanks.

Below are the design features of pumping systems. Having familiarized ourselves with the characteristics of different options, we will consider the types of Karcher pumps for a summer house and a private home.

What is a submersible well pump, its advantages and scope of application

Unlike wells, wells have a low depth of up to 15 meters if concrete rings are used in their construction, and also a depth of up to 25 meters or more in the designs of plastic wells with walls made of high-strength corrugated polyethylene pipes (Corsis).

For water intake from wells with a distance of the water surface from the surface of less than 9 meters, surface water pumps or pumping stations of a centrifugal operating principle with automation are widely used, which are characterized by budgetary cost and ease of operation. If the static level of the water supply source is more than 9 meters, or it drops to a greater depth during water intake (dynamic level), it is necessary to use a submersible electric pump in the well.

The main difference between submersible types and surface ones is the water cooling of the electric motor; if the unit is not immersed in liquid, it quickly fails (the winding burns out) when there is no built-in overheating protection or automatic shutdown when idling.

The main parameter of submersible types is high pressure characteristics, which allow water to be supplied over long distances when the source is located remotely from the house.

Centrifugal electric pumps specially designed for water intake from wells are equipped with float switches that prevent their operation when the water level in the source drops to certain limits.

Fig. 2 Scheme of home water supply with water intake from a well using a Gilex electric pump

A submersible well pump for individual water supply systems for domestic use can perform the following functions:

- Collect water to supply a private home from depths of more than 9 meters, ensuring supply volumes within a wide range.

- To supply water to the surface for irrigation, it can be used to fill barrels, tanks and various containers with water, which, after warming up in the air, is used to water the garden. If drip irrigation is organized on the site, you can use a submersible electric pump to fill a large-volume tank and turn it off with a float switch installed on the walls of the tank when filling.

- A submersible well pump can be used to fill swimming pools, artificial reservoirs, ponds or pump water out of them.

- In critical situations when underground basements, garages, cellars and other premises are flooded during the spring flood, you can use an electric pump to pump out the water if it is not very dirty, or install a homemade filter on its suction pipe to prevent dirt particles from entering the working mechanism.

- Using a submersible electric pump, you can immediately fill the heating system with coolant directly from a well or barrel, with a pressure of about 1.5 bar necessary for its operation, or use it to fill an expansion tank located in the attic of the house.

- Some types of submersible pumps (vibrating, screw) are effectively used to combat siltation of water supplies - to do this, the unit is released into the well a short distance from the bottom and the turbid liquid is pumped out with its help.

Wells collect water from shallow water layers (overflow), and are designed to use mechanical means of supply using a gate and a bucket. If you plan to draw water from the site to constantly supply a residential building using an electric pump, it is much easier and cheaper to drill a shallow Abyssinian well (many people drill it with their own hands) and use it as a water source. The use of a well is justified only if there is no or frequent loss of electricity on the site.

Rice. 3 Submersible pump for water supply to a house from a well at the source

The best surface stations with an ejector

Rating:

- Calpeda NGXM 3 pumps liquid from depths of up to 9.5 m.

- A machine with a remote ejector – Pedrolo JDWm 2/30 creates a pressure of up to 81 m and a lifting height of 45 m.

- Unipump DP 750 unit has a lift height of up to 20 m and a head of up to 40 m.

Installations operating on the surface are characterized by a low water intake depth. This figure rarely exceeds 8-9 meters. An ejector is used to lift water from great depths. These devices come in two types:

- integrated device;

- external ejector.

The operation of the ejector is based on liquid recirculation. When rising, part of the water is returned back through a narrow nozzle.

When it enters the mixer, a vacuum cavity is formed, which causes water from a low-pressure source to rise from the suction chamber into the supply pipe.

The use of a built-in ejector device allows you to increase the suction depth to 3-5 meters, and the remote element helps to lift water from a depth of 30-50 meters. In the second case, the design becomes somewhat more complicated.

Advantages:

- work with partially contaminated liquids;

- do not react to the presence of air in the sucked water.

An additional advantage of the external ejector is the low noise level during operation.

Flaws:

A common disadvantage of structures of any type is low efficiency, since part of the energy is spent on auxiliary work.

Devices with a built-in liquid return structure create additional noise when turned on and require a separate room.

What are the types and types of submersible well pumps?

Before water intake from wells, household submersible electric pumps are used, which differ from industrial units in more modest technical characteristics. Since the depth of most wells does not exceed 15 meters, the pressure parameters are designed mainly to supply liquid in the horizontal direction and maintain the required pressure in the system.

The volume of supply by suction devices depends on their operating principle; most units are capable of delivering the required amount of water to a family of at least 3 people; the upper limit of household devices can reach the water supply of several families in a two- or three-story house.

Vibrating

Vibration pumps have been produced by domestic manufacturers since Soviet times, and since then they have not undergone significant design changes. All domestic models, their Chinese and Belarusian counterparts have absolutely the same design and technical characteristics.

The exception is the Ukrainian Aquarius with a two-valve system (there are also three-valve models) and higher pumping volumes. The vibration pump is placed vertically in the water source, suspended by a cable; its main components are:

- Frame. Consists of two halves connected to each other with bolts and nuts. In the upper body part there is an outlet pipe and eyelets for fastening a metal cable; if a device with an upper water intake is used, it contains inlet holes and a central screw for fastening the check valve. With a standard bottom fluid intake, the suction ports and valve are located at the bottom end of the lower half of the housing. To seal the connection between the two body parts, an elastic gasket is placed between them, which simultaneously reduces the resulting vibrations.

- Electrical part. In the vibration model, the main actuator is an electromagnetic coil with a copper wire winding. It is assembled from steel plates (electrical steel), installed in the upper or lower half of the body (depending on the location of the water intake holes) and filled with epoxy compound; a massive steel anchor with a rod at the end is tightly adjacent to its ends.

- Pump part. The main element of the suction part of the electric pump is a check valve on the cover and an elastic piston located on the armature rod; the working chamber is separated from the electrical part by an elastic damper membrane.

Rice. 4 Submersible pump for water supply vibration

The principle of operation of the vibration pump is quite simple: when an alternating voltage with a frequency of 50 hertz is applied to the winding of the coil, the armature located at a small distance from its ends begins to perform reciprocating movements with the same frequency. Vibrations through the rod are transmitted to the piston disk, which, during the return movement, draws liquid into the working chamber through the inlet holes and an open check valve.

During forward movement, the liquid inside the working chamber pushes the elastic disk of the check valve in the same direction, and it closes the intake holes. Since the outlet of water to the source is blocked, it enters the outlet pipe under pressure and is supplied outside.

Vibrating devices are designed for pumping small volumes of liquid; in terms of performance, these are pumps for irrigation and household needs, their maximum limit is 1.5 cubic meters per hour with a liquid lifting height (pressure) of up to 80 meters.

Vibration pumps are mainly used in everyday life for the following household needs - watering, filling an expansion tank or pouring coolant into heating systems, filling and pumping water from swimming pools and artificial ponds. Thanks to their design, pumps can work with contaminated liquids with small particles; they are often used for drainage work, draining gray waste into sewers, cleaning well and borehole sources from silting, and pumping wells.

The main disadvantage of vibration pumps follows from their name - vibrations of the housing during prolonged use in water intake sources lead to silting and faster destruction of concrete rings of wells, and violation of the tightness of the casing in wells. Vibration pumps have a coefficient of efficiency (efficiency) of 30 - 40%, an average service life of about 5 years, although they can work longer after repair or replacement of the housing mounting bolts with stainless ones before commissioning.

This type of electric pumps has a good price (20 - 25 USD) and is produced by a wide range of domestic and foreign manufacturers; the popular brands Malysh, Rucheek, Aquarius, Zubr, Vikhr are widely represented on the construction market.

Rice. 5 Submersible pump for water supply, vibrating - device

Screw

Screw (screw) units operate on the same principle as a household meat grinder - liquid is supplied to the pressure pipe using screw blades or a serpentine auger. Industrial units have a simple design - a working screw is attached to the shaft of an electric motor placed in a sealed housing, drawing liquid through the end inlet hole, and water is pushed out through a side pipe in the housing.

Household samples are structurally arranged a little differently - water intake occurs through a mesh diaphragm placed on the side wall of the electric pump, while the electric motor is located at the bottom, and the shaft with a fixed auger is in the upper half of the housing.

The water entering the screw auger, as it rotates, is pushed into the outlet pipe located in the top cover of the device; there are also lugs by which the electric pump is suspended when lowered into the well. In many household models, the screw does not adhere to the walls of the case, but is located in a plastic cage, rotating inside which it pushes out water.

The efficiency of household screw pumps reaches up to 50%, they can work with viscous liquids (oil pumping in the oil and gas industry), therefore, for domestic use, many believe that screw models can pump water and sand without damage. This opinion is incorrect, sand scratches the screw and the plastic cage, leading to their rapid wear; if necessary, you can purchase a rubber cage that is less susceptible to abrasion in the retail chain.

There are not many screw models on the construction market from leading foreign manufacturers of pumping equipment; the most widely represented are domestic brands Belamos, Vikhr, Unipump ECO VINT, and imported ones Aquatica, Werk, Vodotok, Sprut. Screw types of household electric pumps can supply water with a volume of up to 15 cubic meters per hour. at a pressure of about 100 m.

Possible reasons for the lack of water pressure in the mains

The lack of water pressure in your pipelines for high-rise apartments may be due to several reasons:

- Daily fluctuations in water pressure in the water supply due to the frequency of use of the resource by the residents of the house;

- Lack of design capacity of general-use pumping equipment from the service organization;

- Temporary deposits of rust and salts inside the pipeline that clog the body of the water riser:

- Clogged water filters in the water supply connection system:

In such cases, you should interview neighbors on the floor and residents of the upper and lower floors of an apartment building to find out what water pressure usually occurs in their apartments. This way you can identify the local cause of low pressure in your particular case. It will already be possible to make the right decision to eliminate these problems or settle on the option of purchasing a high-pressure water pump individually or for public use, having agreed on this issue with other residents of the entrance (riser) of the high-rise building.

In a private home, these reasons are of a similar type. But there may be various additional reasons for low water pressure in your pipeline:

- Large distance from the main water supply pump;

- Excessive elevation of the structure and location of the flow valves above the pump installation level;

- Inconsistency between the pressure data of the power plant and the specific layout of power and consumable units, etc.

Vortex

In vortex submersible pumps, water is taken in and expelled using a single impeller with blades, which is located in the upper part of a vertically suspended housing next to the outlet pipe. To reduce hydraulic losses, the design provides for a very small distance between the side edge of the vortex wheel disk and the working chamber - this makes it impossible for vortex devices to operate in an environment with sand particles.

A special feature of vortex types used in industry is the ability to pump liquids with a high content of gases; the efficiency of household units rarely exceeds 50%.

Vortex-type devices have good pressure characteristics (the height of liquid rise reaches 100 m) and average pumping volumes (about 5 m3/h).

Although vortex electric pumps are rarely used in everyday life, there are Belamos TM, Sprut, Vikhr, NeoClima, Pedrollo Davis models on the market.

Rice. 7 Vortex submersible pump for water supply - design and appearance

Centrifugal

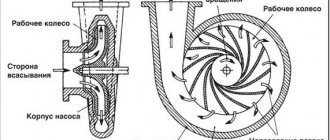

Centrifugal types are the undisputed leaders in household use among other types of electric pumps; almost all surface models have a centrifugal operating principle; they are part of household pumping stations.

Centrifugal devices have achieved such widespread popularity due to the following properties:

- Their efficiency factor (efficiency) is the highest of all analogues; in large-sized industrial units it reaches 92%, in household models it reaches 70%.

- Structurally, the working chamber is designed in such a way that the liquid enters the central part of the centrifugal wheel and is pushed out through the side pipe. This makes it possible to make multi-stage centrifugal devices in which the ejected liquid is fed to the axle of the next wheel, which further increases its pressure. Thanks to the use of several centrifugal wheels with separate working chambers (stages), it is possible to obtain pressure parameters in the system that are several times higher than those of other pumping equipment (in household models, the pressure does not exceed 300 m).

- Centrifugal types are capable of pumping liquid in large volumes at high pressure; for domestic use, this figure rarely exceeds 20 cubic meters per hour.

- Centrifugal-type units are less susceptible to the effects of small sand particles on the working mechanism; they are widely used in sand wells, choosing a model to work with the appropriate particle size specified in the passport.

- A significant advantage of centrifugal types is their high level of automation; the world's leading manufacturers of pumping equipment (Grundfos, Pedrollo, Speroni, Dab) equip their devices with units with frequency control of the impeller rotation speed. This innovation allows not only to significantly save energy when operating the electric pump (up to 50%), but also to significantly increase its service life.

If we list all the manufacturers of centrifugal pumps that present their products on the domestic market, the list will be quite lengthy, so we will limit ourselves to the leading global manufacturers listed above. Among the domestic brands, the most famous are Aquarius, Gilex Vodomet, Vikhr, Belamos, Caliber, Unipump.

Rice. 8 Centrifugal submersible pumps - design and materials using the example of Grundfos SBA

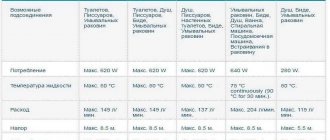

The best surface pumps for hot water

Rating:

- The CNS (G) line refers to multi-stage equipment. The fluid temperature ranges from 45°C (CNS) to 105°C (CNSG). The pressure indicator is in the range of 44-220 m, and the flow is 38 m3/h.

- The WILO Yonos household unit has a “wet” rotor, provides a delivery height of up to 7 m and independent adjustment of the power level.

- A device with a dry rotor WILO VeroTwin with the index DR-E works with liquids with temperatures up to 120°C at high pressure (up to 16 bar).

To pump hot water, so-called circulation pumps are used. A closed loop will be required for the hot water supply and heating system.

The main requirement for device parts is resistance to temperature fluctuations. Therefore, many assembly units are made of cast iron, and insulation elements are made of ceramics or special elastic materials.

To pump liquid, a combination is used: a powerful motor - a winged rotor.

Installations with a “wet” rotor differ in the method of cooling the component parts. Here the moving liquid itself acts as a cooler.

The progressive design with a “dry” rotor is distinguished by an isolated power part from a moving pressure mechanism. This design is more expensive.

Depending on the operating conditions, pumping stations of different types act as working machines:

- centrifugal type models;

- centrifugal-vortex units;

- multi-stage installations.

Advantages:

- Installations with a “wet” rotor are characterized by smooth pressure control, less noise, and reliable operation.

- Units with a “dry” rotor have high performance and efficiency of up to 80%.

Flaws:

- Inexpensive models have an efficiency of no more than 50%.

- Expensive devices require periodic maintenance.

How to choose the right one and what to look for when buying a pump

When deciding which pump is best to install in a well, the following factors must be taken into account:

- Price. The cost of equipment is the main indicator when choosing a suitable model; the minimum price for Grundfos wells is 300 USD; domestic Gilex with similar parameters can be purchased several times cheaper (80 USD).

- Material of manufacture. Basically, well pump bodies are made of stainless steel or high-strength polymers, and their impellers are also made of high-quality plastic - this reduces the weight of the device. When purchasing, you should pay attention to the Chinese manufacturer - the fact is that in their products, the Chinese use sputtered aluminum - a mix - instead of copper windings. This leads to the fact that during operation, due to the higher resistance of aluminum, losses in the winding increase, heating of the housing increases, and efficiency decreases. Some Russian manufacturers are closely associated with Chinese companies; for example, equipment under the Vikhr brand is manufactured at Chinese enterprises and has an aluminum electric motor winding.

- Purpose of the pump. The main areas of use of pumping equipment in a suburban area are provision of permanent or temporary water supply and irrigation. When used for gardening purposes, it is better to choose a vibration electric pump - its cost is lower than all analogues, it is unpretentious to the quality of the working fluid, and temporary use for a short period will not cause significant damage to the well or well. In some cases, vibration models can be used for temporary water supply, but for permanent water supply, special submersible centrifugal pumps with a float switch for wells are used.

- Source parameters. The model must be selected in accordance with the flow rate of the source - the supply volume of the pumping unit should not exceed the natural replenishment of the reservoir with water. All models of submersible electric pumps indicate the depth of immersion under the water surface. Since the submersible pump is located in a well or borehole at a minimum distance of about 0.5 m from the bottom, the thickness of the water layer above it should not exceed the parameter specified in the technical passport.

- Pressure The pressure indicator for direct water supply is determined by calculation using simple formulas; it depends on the length of the horizontal and vertical sections of the water main and losses in the line; the part that goes to maintaining pressure in the system is also taken into account.

- Particle size. All models of submersible pumps are designed to draw clean drinking water; if the liquid contains fine sand, a modification is selected that allows operation with a certain particle size specified in the technical data sheet.

Fig.9 Submersible pump for water supply Gilex - technical characteristics

- Temperature. The manufacturer supplies the domestic market with installations for pumping water with standard parameters: working fluid temperature up to +35 C., ambient temperature up to +40 C. - it is clear that such a water temperature cannot be in a natural water supply source and any pumping equipment is suitable for these parameters.

- Model. For wells, special models of pumps with a float switch have been developed that turn off the power supply to the device when the water level in the well drops below the suction filter or at a certain mark (the depth of operation of the float can be adjusted). This device duplicates the dry running relay in the system, which can be installed at the request of the consumer. Well models from leading manufacturers (Grundfos) are equipped with a float water intake - this allows you to supply clean, unclouded water from the surface of the source, and not from the bottom area with a high content of sand particles, and there is no need to clean the water at home from sand.

- Other options. Less important factors that you should pay attention to when choosing a device are the length of the power cord, the presence of a built-in check valve, weight and overall dimensions, the length of the warranty period, the availability and location of the nearest technical service centers.

Electric pumps designed for drawing water from wells should not be used in wells, even if they meet the parameters. The fact is that well pumps are designed to draw water from shallow depths (their maximum pressure rarely exceeds 50 meters), and if you use a well pump with high pressure characteristics at low pressure, thereby increasing the volume of water supply, its efficiency will be unacceptably low.

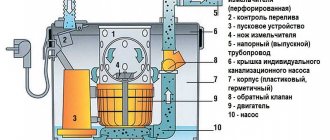

The best surface fecal pumps

Rating:

- A universal representative - Grundfos Liftaway B flows up to 100 l/min, temperature range from 50 to 70°C.

- The powerful representative Wilo DrainLift Box has a flow rate of 300 l/min and a power of no more than 600 W.

- The productive pump for cold wastewater DAB Fecalift 200 is capable of pumping out up to 70 l/min, motor power up to 65 W.

A type of group of devices for pumping dirty water are sewage stations. They differ from simpler models:

- powerful engine;

- the presence of a grinding device or filter element;

- equipped with float switches.

The models have limitations in use for a number of indicators:

- low suction height – from 1 m;

- inefficient pump operation at low power;

- frequent breakdowns due to high load.

Submersible pump for water supply - connection diagram

The well pump is lowered into the source strictly in its center to avoid the float touching the walls; it is tied to a rigid transverse pipe, angle, or metal profile inserted into the punched hole in the walls along with the pressure pipe of the water supply. The second option - hanging the pump on a transverse support located on top of the well walls - is simpler, but to connect to a water supply line located underground, you will still have to go down into the well. The calculated point for installing the pump from the surface of the earth is the depth of soil freezing in winter; the entire water supply system is deepened to a distance of about 0.5 below this mark.

To supply water to the house, pipes made of low-density polyethylene (HDPE), specially designed for use in water supply systems, are usually used. The pressure pipe is connected to the electric pump with a plastic fitting; its further connection to the water supply line is also made using an adapter corner plastic coupling; when supplied to the house using HDPE fittings, the line is easily connected to the internal water supply system.

Pumping equipment is connected according to a standard scheme using a pressure switch, pressure gauge, hydraulic accumulator (allows you to maintain pressure in the system), using special fitting plumbing fixtures (five-inlet fitting). Unlike downhole types, the dry-running relay can be excluded from the control automation - the submersible unit is protected from winding burnout by a float switch.

Rice. 10 Connection diagrams for a well electric pump

Centrifugal pump - universal equipment

Devices of this type are used in almost all areas - both industrial and household. The operating principle is based on the creation of centrifugal force inside the body, due to which water moves and pressure is created. The blades and wheels of the working part, rotating, draw in the liquid, press it against the wall, and then push it out into the outlet hole. Depending on the design and purpose, devices are divided into many groups. They can be surface and submersible, cantilever, horizontal, vertical, monoblock, single- and multi-stage.

All structural elements are made of high-strength materials, the parts practically do not wear out. The pumps are expected to run continuously. Therefore, they are designed to be easy and fast to service. The devices can operate at high temperatures and in chemically aggressive environments; the characteristics depend on the features of the specific model. Some of them can withstand up to 350 degrees.

The advantages of centrifugal pumps include reliability, durability, reliability, reasonable price, the ability to be equipped with the necessary automation, and high efficiency. However, like any other device, pumps of this type have their own disadvantages. So, to start the device, the housing must be filled with water, since due to the low centrifugal force, water is not sucked into the pipe. If air enters the inlet pipe, the pump may stop. In addition, if the resistance in the electrical network changes, this may affect the stability of the device.

Surface centrifugal pumps are mobile, easy to dismantle and transport, but are poorly suited for stationary installation

Centrifugal cantilever pumps are widely used. They are used for pumping clean and dirty water containing impurities and small solid particles. For water supply systems of houses and cottages, single-stage horizontal cantilever pumps are used. Multistage horizontal pumps are a design that operates as several identical, series-connected, single-stage devices. Thanks to this, they are able to provide powerful pressure in the system.

Centrifugal water pumps are purchased for homes, cottages, watering and irrigation systems. They are installed in water supply systems powered by wells. Submersible and semi-submersible models are used. The former are easier to install, and the latter are easier to maintain. To install a semi-submersible model in a well, special conditions are required. This is labor-intensive work, therefore, despite the obvious advantages, owners of private houses often opt for submersible models. They can be installed in wells where there were deviations from the vertical when installing the casing. The disadvantages of the structures include high sensitivity to sand and dirt.

We offer an overview of centrifugal monoblock water pumps that are perfect for the garden:

Recent Entries

5 working ways to use tar in the garden 7 indoor plants that help you get married even in adulthood Indoor plants that can bloom in trouble

Submersible pump calculation

When purchasing a submersible pump, its main indicators are the lift height and the volume of pumped liquid. The volume of water that the pump must pump is associated with two parameters - the flow rate of the source and the needs of the consumer. The volumetric parameters of the pump should not exceed the speed of the natural inflow of water in the well, otherwise the dynamic level will drop to critical and the float switch will turn off the pump, stopping the water supply. You need to understand that too much excess of water supplied by the pump before consumption is ineffective and economically unprofitable - the operation of a powerful device will lead to frequent water hammer, a decrease in the time between on-off cycles and the service life of the device, and unnecessary waste of electricity.

Calculation of a well pump for irrigation

It is rare that anyone uses expensive submersible well electric pumps designed to ensure a constant water supply only for irrigation; they usually choose budget vibrating units that have the same characteristics. Since the choice is limited, it makes no sense to calculate the parameters of a vibration pump when choosing a suitable model if their characteristics are the same.

Best Surface Multistage Pumps

Rating:

- Lowara HM is designed to handle liquids without contamination. It has a head of 60 m, a flow of up to 7.2 m3/hour.

- Metabo P 6000 has 5 working stages. Provides delivery up to 55 meters at a pressure of 5.5 bar. Suction height up to 8 meters.

- Wilo WJ 20 EM – 2-stage station. Provides a supply of 38 meters with a pressure of up to 6 bar.

The use of a multistage pump is justified if the distance to the aquifer surface does not exceed 8-9 meters. Due to the use of several stages in the design, the water pressure is significantly increased when compared with standard pumps.

Multistage devices are created on the basis of centrifugal mini-stations. This allows you to create good pressure, while keeping the noise level and energy consumption low.

- Supply – up to 7.5 m3/hour.

- Pressure – up to 60 meters.

- Developed pressure up to 6 bar.

- The operating temperature of the pumped liquid is up to 40°C.

Advantages:

Multistage stations are reliable devices that do not require regular maintenance. Other advantages stand out:

- smooth supply, without sudden pressure drops;

- simplicity of design combined with low price;

- working with slightly contaminated liquids.

Flaws:

Multistage pumps have certain disadvantages that limit their scope of application:

- low efficiency;

- limitation on self-absorption of water;

- rapid overheating with low fluid supply.

Calculation of a well pump for water supply at home

When calculating a well electric pump for constant water supply to an individual house, the main results of the calculations obtained are the height of the water column and the volume of pumped liquid. The initial data is the estimated or calculated volumes of water consumption using tables or using online calculators.

Consumption volume

There are two main methods for calculating the volume of water consumed: the first is to calculate the water consumption of each resident, the second is to calculate the total water consumption of plumbing fixtures. In both cases, tables or online calculators are used. The indicator of average daily water consumption by one person is more significant in calculating the ability of a source to maintain a static water level with constant water consumption with a certain volume.

The main task of the electric pump is to sufficiently fill the main with water while simultaneously turning on the maximum number of plumbing fixtures that can be used by residents, taking into account working household appliances (washing machines and dishwashers).

Therefore, when tables are used to calculate and add up the water consumption of all plumbing fixtures, this is not entirely true - for convenience, an individual residential building may contain several sanitary units, an excessive number of showers and bathtubs, which the owners rarely use. If this plumbing is taken into account when calculating total water consumption, the result will be excessive capacity parameters of the purchased pump - this will lead to excessive energy consumption and unjustified financial costs.

To calculate the maximum volume of water consumption per unit of time for a family of three living in an individual residential building, you can use an online calculator or make simple calculations manually. If we take the three sources with the highest water consumption and add a small volume from household appliances (the tables indicate values that should not be taken into account - water consumption by appliances does not occur on a constant basis), then as a result of simple manual calculations we obtain the peak water consumption per family of 3 people - 2.5 cubic meters/hour. The indicator was obtained using the most water-intensive plumbing equipment - the bathroom; in the absence of such amenities, a water supply of 2 cubic meters per hour is quite sufficient.

Rice. 13 Table of water consumption for plumbing fixtures

If we use some online calculators, we will get slightly more water consumption by entering the data of the dishwasher, washing machine, toilet, bidet, which are expressed in units corresponding to other plumbing fixtures, and according to the compilers, consume water continuously.

Pressure

When calculating the pressure, the formula given above for organizing irrigation is used (H = Hv + Ng + Np + Nd), calculations are carried out using the same method, the main problem is calculating the hydraulic resistance, more precisely, that part of the pressure that will be needed to overcome areas of pipe resistance.

There are also tables taking into account the resistance of fittings, taps, bends, tees and other parts of plumbing fittings. Using online calculators, you can calculate the hydraulic resistance of a pipeline of a given length, depending on the material of its manufacture and diameter. If the line is made of hydraulically smooth HDPE pipes with a diameter of more than 1 inch and assembled in accordance with standard specifications, its hydraulic resistance can be taken equal to 20% of the entire length of the line.

For example, let’s calculate the pressure characteristics of a submersible pump installed at a depth of 10 m, the distance to the house is 50 meters, the length of the line in the house is 50 meters, the lift height from the basement to the second floor is 5 meters, the highest pressure in the system is 3 bar. Similar to the method discussed above, we get the result:

H = 10 + (5 + 5) + 5 + 115 x 20 / 100 + 30 = 78 (m.)

Based on the pressure characteristics graph, we determine a suitable electric pump; choosing a Gilex brand device to solve the tasks will not suit us (a supply volume of 2.5 m3/h corresponds to 41.6 l/m3), so we are not considering it. The corresponding model SQ-2-85 is in the Grundfos equipment line (Fig. 14, point 5), with which you can make a water supply system with the calculated parameters.

Rice. 14 Grundfos pressure characteristics

The best surface pumps for dirty water

Rating:

- Powerful model Pedrollo D20 . Capacity 20 m3/hour. Head height 27 m.

- Universal model Grunfos Unilift CC 9 A1 . Copes with a volume of 14 m3/hour. Head height 9 m.

- Budget model Grunfos Unilift CC 5 A1 . Capacity 6 m3/hour. Head height 5 m.

Pumps are most often used in the following cases:

- drainage of basements and pits;

- pumping muddy water from cellars and sewer basements during floods and natural disasters;

- drainage of fountains, artificial reservoirs and canals;

- pumping liquid from a drainage well or sump for processing garden plantings.

- All models are self-priming.

- The size of particles contaminating the liquid is limited by installing a filter and is in the range of 10-15 mm.

- Wide range of operating temperatures – from -10˚С to +90˚С.

When choosing a model, the conditions of upcoming operation are taken into account.

Advantages:

The advantages of the pumping device are related to the design:

- Screw pumps handle sludge masses regardless of their density.

- Membrane models work with large inclusions (up to 50 mm) with a concentration of such particles of no more than 50%.

Depending on the version, the drive of the devices is electric or gasoline.

Flaws:

- noise during operation;

- the need for proper placement of suction hoses;

- limited lift height.

Recommendations from experts

When organizing the installation of a water supply system with your own hands, the most important task is the correct choice of pumping equipment, which should not only perform the assigned tasks, but also work for a long time without breakdowns. When selecting it, the following expert recommendations may be useful:

- The leaders in performance are centrifugal types, which are optimally used for wells - all others have lower efficiency, lead to silting of the source (vibration-type pumps), can only work with clean water (vortex pumps), and their analogues also do not have a float switch.

- To draw water from wells, you should use only well units with low pressure characteristics and high pumping volumes - in this case, their efficiency will be maximum, unlike well pumps not intended for use in wells.

- Choosing the right manufacturer is the main task when purchasing a pump. Almost all Chinese models are supplied with aluminum windings, which have high resistance and large energy losses, leading to increased heating - this factor reduces the efficiency of the electric pump. It is better not to use domestic and Chinese budget models from unknown manufacturers - some of them have an engine shaft oil seal, which was obsolete half a century ago and can allow sand and water to pass through at high pressure (all modern models have a mechanical seal with ceramic, graphite rings or similar materials) .

- If, after calculations, a model from a Chinese manufacturer is considered, then it should be taken into account that its compliance with the parameters specified in the technical data sheet differs by 20% downwards - therefore, you should choose a model with a similar margin in terms of technical characteristics.

- To obtain the optimal price-quality ratio, it is better to use pumps from an Italian manufacturer (Pedrollo, Speroni, Dab) - they are cheaper than Grundfos, made of high-quality materials, and have high technical parameters.

- Pumps with a float intake from the upper water layer will help improve the quality of drinking water sucked from a well - in this case, the liquid will be free of sand, which is found in large quantities in the bottom area, and the installation of additional filters will not be necessary.

Fig. 15 Well pumps for home water supply from leading manufacturers Grundfos, Pedrollo, Dab, Karcher

When choosing a device for water intake from a well, you should use centrifugal models with a float switch, specifically designed for these purposes - they are most suitable in terms of technical characteristics. The popular domestic unit Gilex Vodomet can be purchased for a price of about 100 USD; imported analogues will cost 3-5 times more.

A short video tutorial on pump selection

When choosing an electric water pump for your home, cottage or garden, first of all consider its intended purpose. There is no ideal equipment for “everything”. Consider what main tasks the device will perform, whether it will only work to pump clean water or whether there is a possibility that it will have to lift water with sand and dirt.

When selecting a specific model, be sure to take into account the most important technical parameters: power, performance, efficiency, maximum pressure. If during the calculations you have doubts about their correctness, consult a specialist. As for brands of household water pumps, the brands Wilo, DAB, Gilex, and Belamos have proven themselves well. The market leader is the Grundfos brand.

- Author: irina-jakuschenko

Rate this article:

- 5

- 4

- 3

- 2

- 1

(6 votes, average: 3.8 out of 5)

Share with your friends!

How to install a pump to increase water pressure in a private home

How to install a self-priming pump

Installation of this type of pump is quite simple. You don't need to purchase any complicated tools to install the equipment. You should follow these steps:

- determine the location for the accumulator and pump;

- install a hydraulic accumulator;

- install pipes to connect equipment to the water supply;

- hang a pump to increase water pressure from the wall;

- tie the pump and accumulator;

- check the operation of the pump in automatic mode.

A pump and hydraulic accumulator with a pressure switch are a variation of a pumping station for increasing pressure in a private house. In order to install it, you will have to think about where exactly the tank can be placed. Some owners of private houses, instead of a hydraulic accumulator with a membrane, install ordinary large plastic tanks (volume 200 l).

In such cases, the pressure switch replaces the float sensor, due to which the tank is filled with water when necessary. Such a tank should be located as high as possible (attic, top floor). It is necessary to think about its most suitable configuration in a timely manner.

To save space, you should choose a narrow flat tank; its shape can be arbitrary. The installation should be carried out in such a way that access to it or to the hydraulic accumulator is maintained (alternatively, it can be made so that it can be easily removed if necessary). This is important, as otherwise difficulties will arise during maintenance, repair or replacement of the device.

A store-bought hydraulic accumulator does not require any preparation for installation, but you will have to create holes in the tank through which water will flow in and out. It would be a good idea to install an additional shut-off valve, with which you can quickly drain the water in the event of an accident. The pipes that take and supply liquid to the water supply system are mounted to one water pipe.

Nowadays, it is most convenient to use plastic pipes for assembling a water supply system: they are easy to install and, what is very important, they are reliable. It makes sense to install check valves on the pipes: they will prevent air from the pump and water from entering the container when the equipment is turned off.

Now you can begin assembling and installing a suction pump to increase pressure in a private house, which was probably purchased disassembled.

If you decide to mount the pump to the wall, then do not forget about the markings for fasteners. After the device is installed, it is connected to the water supply. This is not difficult, but it is important to carefully monitor the direction of water movement in the device (there should be special marks on the body).

The liquid in the pump to increase water in a private house must move from the tank to the water collection points. In other words, the installation must be connected according to the following scheme: hydraulic accumulator - pump - consumer. The next stage is piping the pump.

Below is a diagram of connecting a pump to increase water pressure in a private house to the water supply system.

Installation is usually carried out as follows: the pipes at the beginning of the system are disconnected and a pump is connected to them (fittings are used for this).

It is important that the connections are tight. If a pump is “screwed on” to increase water pressure in a private house, then the threaded connection must contain the required amount of sealant (FUM tape, flax thread). Fittings are required to connect the device to plastic pipes.

It is important to check the operation of the system; to do this, fill the tank with the float with water. It is necessary to make sure that the container does not leak, and also check the operation of the sensor. In the absence of these problems, you can test the work yourself.

To do this, connect the device to the network (automatic mode), open the tap and observe its operation. If everything is correct, then the pump to increase water pressure in a private house should automatically turn on, and the liquid pressure should increase significantly.

Read material on the topic: How to increase water pressure

Installing a circulation pump to increase water pressure

The installation of circulation pumps for increasing pressure in a private house is carried out in the same way. They are cut into the water supply in a certain place. It is important to consider the direction of fluid movement. If the device is not positioned correctly, water will pass through the pump.

Connection diagram of the circulation pump to the water supply system:

But you will not notice an increase in pressure, since the device will not perform its task. Therefore, carefully study the instructions; they describe in detail the correct position of the pump to increase water pressure in a private home. If the pump connected to the network affected the water pressure, then it means that no errors were made during installation.