In the modern world, not only production technologies are subject to changes, but also materials. Metal pipes are not popular due to the complexity of installation, heavy weight and susceptibility to rot. They were replaced by low-density polyethylene or HDPE.

This material has many advantages: plasticity, increased strength, unpretentiousness, long service life. A water supply system in a dacha made from HDPE pipes will last up to 50 years, and you can assemble it yourself.

Advantages of polymers

Pipes and connectors are made from durable, thick material.

Its popularity lies in its low cost and ease of installation compared to others. To manufacture systems you do not need to have special education, knowledge or skills. The connection of the pipe with the fitting is done manually, since there is a factory thread, you need to be careful and follow the assembly sequence.

Advantages of HDPE pipes:

- not subject to rotting and external influences;

- environmentally friendly;

- light;

- resistant to deformation;

- resistant to changes in water pressure;

- high maintainability;

- little heat dissipation.

Polypropylene water pipes for a summer cottage

Plastic pipelines made from “food grade” polypropylene are rightly considered by most experts to be the most technologically advanced and affordable for the construction of water pipelines in apartments, the private sector, country houses and cottages. Even the relatively high price of plastic pipes and components does not stop those who want to make good quality plumbing with their own hands.

Types of installation

Each method has its pros and cons.

Surface - for summer water supply

Connection using a split fitting

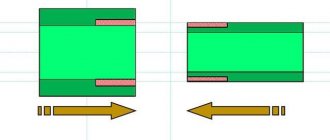

Ground installation is intended directly for summer cottages in order to timely water your garden, shrubs and trees. There is also an option for supplying water to auxiliary buildings: a sauna, a utility room, or a summer house.

The layout of the summer water supply system at the dacha repeats the layout of the underground one, but is as convenient as possible for repair, disassembly, and alteration if necessary. It can be dismantled for the winter or in case of redevelopment of your summer cottage.

If necessary, within half an hour you can easily change the junction and the location of the water supply on the site.

To avoid accidental damage to pipes located on the surface, it is necessary to provide stands or supports.

Many people install summer or, as they say, temporary water supply according to the principle of how they assembled it or cobbled it together from what was there, directly at the location.

It is preferable to draw up a diagram of the house’s water supply system in advance if the site is planned into zones. On the drawing, the first thing to note is the main consumers of water: the house, shower, trees, hedges, and the points where the taps will be located.

The pipes must be placed at an angle directed towards the consumer, since a drain valve is installed at the lowest point.

Capital system

Underground installation

A system designed for a home with year-round use will require much more time to think through the project and carry out excavation work. In this case, the principle of assembling a country water supply system from HDPE pipes must be changed, since additional compressor equipment, a hydroaccumulator and a closed arrangement method will be installed.

Which pipes to choose for water supply in the country

Just a decade and a half ago, no questions arose: there was no alternative to steel pipes. Today, metal is almost no longer used for country water supply: it is expensive, welding is required for installation, and modern pipes rust quickly. There is a much more practical alternative - plastic pipes. They are the best solution for country water supply: they definitely do not rust, some are also not afraid of frost. But plastic is different, as are the products made from it.

HDPE pipes

Most often, HDPE pipes - low-density polyethylene - are used for water supply in the country. They are attractive because they can be assembled without any additional devices. Fittings for assembling HDPE water pipes are threaded and are simply tightened by hand.

HDPE pipes for water supply systems are produced in coils or in sections (depending on the diameter)

Why are HDPE polyethylene pipes so good that they have almost replaced metal pipes? In addition to convenient installation, there are a number of advantages:

- If the operating rules are followed, the service life is 50 years. This figure has not yet been verified, but it is impressive.

- They do not rot, do not rust, and are resistant to chemical environments.

- Can be operated at temperatures down to -60°C.

- When the water in them freezes, they do not burst - they stretch, then after thawing they return to their previous size.

- Their inner surface is perfectly smooth. For water supply, this is important for two reasons: there is less pressure loss during transportation and deposits do not accumulate on the walls, they are simply carried away by the flow.

- With their help, it is very easy to make water supply in your dacha with your own hands, as well as make changes later.

- HDPE pipes can be used to install summer and winter water supply systems.

- Convenient assembly methods: welding or compression (threaded) fittings.

There are some disadvantages, but they are few:

- do not tolerate heat well (except for cross-linked polyethylene pipes) and are therefore used only for transporting cold media;

- Compared to metal, they have lower strength - you cannot walk on them.

HDPE pipes can be welded with a special apparatus, or they can be connected using compression fittings. For country water supply, pieces of pipe, tees, and adapters are connected using threaded connections. Although such a connection seems unreliable, it can withstand much more than the 2-4 atm that you can create at the maximum. See the video for the results of testing connections on threaded fittings. At the same time, see their design and installation principle.

HDPE pipes with blue lines are suitable for water supply. They are designed for cold water. If the lines are yellow, they cannot be used to supply water - they are intended for gas. They contain special additives that make the water unsuitable.

There are several gradations of working pressure:

- L - light, withstands up to 2.5 atm;

- SL - medium-light - up to 4 atm;

- C - medium - up to 8 atm;

- T - heavy from 10 and above.

For the installation of external (street) water supply in a dacha, class C and SL HDPE pipes with diameters of 32 mm, 40 mm and 50 mm are used. When choosing, you still need to decide on the density.

There are three more brands of polyethylene: PE 63, 80, 100. These numbers indicate density. The denser the material, the stronger the product, but also the higher the price. For example, one linear meter of 32 mm pipe made of PE 80 costs from $4 (and more depending on the wall thickness). The same diameter, but made of PE 100, starting from $7 per linear meter.

Is high density necessary when installing water supply on a chacha? I guess it's yes. Due to the higher density, the pipe walls are made thinner, which reduces their weight. If water at the dacha is obtained from a well or well, weight can be an important factor - there will be fewer problems with securing the pipe lowered down.

PVC pipes

For water supply in the country, they also use pipes made of PVC - polyvinyl chloride. They are cheaper than HDPE and are joined using cold welding - with glue. The seam turns out to be reliable - it can withstand pressure up to 12-16 atm, the service life is stated to be the same: 50 years.

PVC pipes have a low price, but they cannot be scratched

The characteristics are slightly worse than those of low-density polyethylene:

- Temperature range from -15°C to +45°C.

- It does not like freezing - elasticity decreases, the material becomes more brittle.

- Average sensitivity to ultraviolet radiation.

The remaining advantages of plastic pipes are inherent in PVC in full:

- Easy to install, bendable.

- Smoothness of the inner surface.

- Resistance to oxidation (does not rust) and chemical environments.

- Low flammable.

The disadvantages of a dacha plastic PVC water supply are as follows:

- The upper temperature limit is +45°C, briefly possible up to +65°C.

- Difficult to dispose of because when decomposed it releases volatile chlorides that are harmful to health and the environment.

- When scratches appear on the surface of the pipe, its strength is significantly reduced. Therefore, it is not advisable to use PVC pipes for open laying of water supply in a country house. When laying underground, a protective shell or installation in a sewer is required.

Since scratches and cracks greatly reduce reliability, threaded connections are not possible. When connecting to metal pipes or equipment inlets, this is a big problem. And if laying pipes around the site is a simple matter, then piping the equipment is a serious task. This drawback limits the use of this material for external water supply systems, therefore PVC is more often used for internal wiring, where the risk of scratches is minimal. Even more often they are used for laying sewers.

Watch the video to see how to connect PVC pipes. The connection is really reliable. This conclusion is based on personal experience: a cold water comb was collected in the apartment. It stood for about 10 years without any problems, until the entire wiring had to be redone due to redevelopment.

Polypropylene (PPR)

Another material that can be used when installing water pipes in a dacha with your own hands is polypropylene pipes. They also belong to the category of plastics. There are for cold (with blue stripes) and hot water supply, as well as for heating (with red stripes). They are connected using soldering and couplings - there are special soldering irons that are used to heat the plastic on two parts, then connect them. After a couple of minutes the connection becomes monolithic. You don’t even have to buy a soldering iron (it costs about 2-5 thousand rubles) - they rent it in the same stores that sell pipes and fittings for polypropylene water supply.

Polypropylene pipes have essentially one drawback - expensive fittings. For example, a linear meter of a pipe for cold water supply 32 mm in diameter (wall thickness 3 mm) costs about $2, a coupling for connecting two sections of the same diameter costs $1.2. Since the PPR pipe does not bend, everything is assembled using couplings, angles, etc. As a result, the water supply will not be very cheap, but reliable. After all, not only household water pipes are assembled from this material, but also industrial routes.

Polypropylene pipes for country water supply - a good, reliable option

You can read about drip irrigation systems and how to make them yourself in this article.

How to choose

Manufacturers make several types of HDPE pipes to choose from. The first difference is what the water with different color stripes will be used for.

For use in drinking water supply systems from wells and boreholes, HDPE pipes with a blue stripe should be used.

To make gas pipes, additives are used that change the composition of water. Pipes with yellow markings can also be used for country water supply, but their cost is noticeably higher. These pipes are designed for high pressure gas and have increased strength and a higher price.

HDPE pipes without markings cannot be used for drinking water supply. These are technical products made from recycled polyethylene. They can release toxic substances into the water.

For underground installation, two types of polyethylene are used:

- HDPE PE 100 according to GOST 18599-2001. The diameter of the products is 20 to 1200 mm, the appearance is a black pipe with a longitudinal blue stripe along the entire length.

- HDPE PE PROSAFE is produced in accordance with GOST 18599-2001, TU 2248-012-54432486-2013, PAS 1075, they are provided with an additional mineral protective shell up to 2 mm thick.

A pipe with a diameter of 40 mm is suitable for connecting the house. For other consumers, 20 mm or 25 mm is sufficient.

Irrigation systems for the garden

Watering a garden using plastic pipes can be done in various ways. The choice of a specific option depends on the climate, soil type, skills of the dacha owner and his personal preferences. We list the most common methods of irrigating a summer cottage:

- Subsoil irrigation . Perforated drainage pipes are laid in the soil, supplying water to the planted plants. They are constantly located in certain places, which is very favorable for irrigating perennial plants.

- Surface watering . This is the simplest type of irrigation and does not require the use of pipelines. Water is supplied to the plants through dug and open grooves.

- Sprinkler irrigation. Water enters the beds through a pipeline, where it is sprayed using various spray devices.

Irrigation by sprinkling is one of the most common options - Drip irrigation . Plastic pipes for watering the garden are laid in such a way that water flows by drip directly to the roots of the planted plants. This is the most economical method of irrigation, which uses a minimum of water to obtain maximum effect.

Advice: First decide on an irrigation system, and only then purchase pipes. Not all types of plastic piping are suitable for every irrigation system.

Let's take a closer look at the types of plastic pipes used for watering the site, their characteristics, installation features, advantages and disadvantages.

Connecting elements - couplings and fittings

HDPE compression fitting

Couplings of 2 different types are used as HDPE connectors:

- Compression ones, which are screwed onto the pipe pieces being connected. The elements are sealed due to rubber sealing rings. Assembly is carried out manually, since the use of gas keys can lead to overtightening and mechanical damage.

- Diffusion couplings. Designed for high-temperature welding with a special soldering iron. Without the use of additional seals, it is of higher quality compared to compression.

Types of fittings:

- Docking joints are used to connect pipes of the same diameter;

- transitional, for connecting pipes of different sizes;

- plug, disconnecting an unnecessary branch.

If necessary, purchase watering heads, drip hoses, and watering guns for a more comfortable arrangement.

Work order

Before installation, the length of the water supply pipeline from HDPE pipes to be laid is checked directly on site. To do this, it is necessary to transfer the diagram to the ground by marking with the placement of control pegs and pulling a cord that follows the contour of the future pipeline.

Only after this the excavation work begins. They measure the length again and begin shopping based on the measurements and calculations made.

The algorithm for performing the work is extremely simple:

- The trenches are dug at a slope at the connection point; the angle should not be large for its further exit into the horizontal plane.

- The bottom of the trench must be equipped with a sand cushion with additional waterproofing. This is done to smooth out any unevenness that will inevitably appear.

- HDPE pipes are cut directly when they are laid in a trench. Docking to the water intake point first, then laying along the site. We insulate pipes with pre-selected material. After completion of the work, connect the pumping station.

Compression connectors are installed in the following sequence:

- The couplings are disassembled, the clamping part and the gasket are removed.

- The gasket and clamp are installed in the reverse order on the tabs.

- The nodes are joined, the fitting is screwed on manually, without much effort.

If the elements are connected by soldering, then the following rules must be followed:

- The joints are cleaned, degreased, and dried.

- Work is allowed to be carried out at temperatures greater than +5C.

- Pipes with a diameter of 50 mm or more must be chamfered.

Types of HDPE pipes

These pipes are welded, and for domestic conditions and temporary water supply conditions they are assembled using plastic fittings.

Fittings and fittings for HDPE water supply

The fitting is disassembled in the photo below. Video montage at the end of the post.

At that stage, I decided to abandon the winter water supply and make do with the summer one: a tap in the house, a tap in the parking lot, a tap on the street. I figured that the water supply route should not pass under the parking lot and should not be damaged by construction equipment during further work on landscaping the site and building a house. Otherwise, the pipes would have to be laid immediately as expected. I also wanted to reduce the costs of temporary water supply while maintaining reliability.

My plumbing installation experience

I purchased everything and got to work. I was lucky with sandy soil and simply buried the pipe to a depth of 30-45 centimeters. Just in case, I laid a warning tape “Do not dig, below the cable!” almost under the very surface above the pipe. There was no other one at hand. It won’t save you from an excavator, but it will help you out if anything happens.

By the time I was about to build a water supply system, groundwater had accumulated in the well. I had to pump it out with a pump (we lower any pump for 700 rubles with a hose into the well for 1.5 hours - 2 rings are drained), and then put up a ladder and go down.

Since the water supply is summer, in the fall the water must be turned off and the remainder drained. As a result, I had to lay pipes with a slight slope towards the well . HDPE pipes make this easy. For 15 meters of pipe laid horizontally, the height difference was 15 centimeters.

In a well, pipes are attached to the wall using these or other clamps.

To build a winter water supply system, you need to know some details, which I will discuss below.

— The depth of the water supply must be greater than the depth of soil freezing.

— Additionally, pipe heating is introduced. There is indoor and outdoor.

— Additionally, they provide high-quality thermal insulation.

— In order not to pump groundwater out of the well in the fall and cut off the water supply for the winter, there are such interesting things as.

Output from the well

The pumping station must be located as close as possible to the well pipe. The pipe must pass inside through a special sleeve made of metal. It is designed to protect against destruction during seasonal fluctuations in ambient temperatures. The pipe is connected to the pumping station only after it has been fixed.

The HDPE pipe is inserted into the well immediately after the pressure regulating relay. Don't forget to include a prefabricated elbow. To do this, a coupling with an MRN thread is soldered onto a piece of pipe. It is installed on a tap to the relay. Then the head is attached to the well.

When laying a year-round system on the bends of the main highway, it is necessary to provide wells for maintenance and repair.

What to look for when choosing irrigation pipes

When choosing pipes for watering your site, pay attention to the following points:

- If your water supply system maintains high water pressure, then pipes are selected with thickened walls;

- Often it is quite enough to lay only the main branch of the pipeline, and from there lead the connection points for flexible hoses. This will ensure mobility of watering and save money that you could spend on purchasing plastic pipes;

- The diameter of the irrigation pipe at the dacha for laying main canals must be larger than that of the outlet canals. Only in this case will a uniform flow of incoming water be maintained in all outlet channels;

- Provide reliable plugs for the end sections of pipelines;

- Shut-off valves and connecting fittings must be designed for the water pressure in the system.

And one more tip - choose a type of pipe that you can install yourself. This will allow you not only to install an irrigation system relatively inexpensively, but also to repair the system yourself if any problems arise.