In modern conditions, metals of various types are used everywhere. Their scope of application covers almost all industries, so they have a high value in the market. All metals are conventionally divided into two types:

- black;

- colored.

The former belong to the category of alloys containing iron. The latter are created on the basis of rarer metals with unique properties. accepts ferrous scrap in Moscow on favorable terms. High prices and a wide range of services provide our clients with good profits from the sale of metals.

Key properties of ferrous metals

Iron and its alloys are the main metals on the market. In its pure form, the substance is extremely rare in nature. The earth's crust contains less than 6% of this substance. The main metal extraction is carried out by processing iron ore. It is the main source of iron.

Ferrous metals have a number of key properties and features that are achieved by changing the composition of the alloys. The main advantages are:

- high hardness;

- resistance to mechanical stress;

- increased strength;

- large volume of raw materials for production;

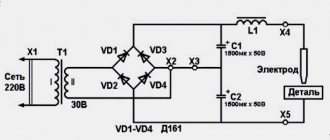

- excellent weldability;

- low cost (compared to non-ferrous metal) and so on.

Thanks to these features, ferrous metal is actively used in industrial and civil construction for the construction of structures with high load rates.

Introduction

Man's transition from the use of stone (Stone Age) to metal was long and complex. It did not occur as a result of a revolutionary leap in the development of society, but metals gradually entered into human use over a long period. The first metal that entered human everyday use was copper, which opened the era of metallurgy and gave the world its first alloy - bronze. According to archaeological data, the first information about copper smelting dates back to 6500–5700. BC. It was the basis of material culture for thousands of years, and the Copper Age gradually transitioned to the Bronze Age.

The next stage in metallurgy was the use of iron (Iron Age) and its beginning dates back to the second millennium BC. The production of pure iron and its alloys became possible thanks to the accumulated experience in the smelting of copper, bronze, gold and other low-melting metals and alloys. The development of iron production served as a powerful impetus for the development of productive forces and technical progress. In ancient times, eight metals were known to man - copper, gold, silver, tin, lead, iron, mercury and antimony. By the end of the 18th century. their number has increased to 20, and currently about 80 metals are produced and used.

The abundance of elements in the earth's crust varies - from a few percent to parts per million. The total content of the ten most common elements (oxygen - 47.00; silicon - 29.50; aluminum - 8.05; iron - 4.65, calcium - 2.96; sodium - 2.50; potassium - 2.50; magnesium – 1.87; titanium – 0.45; hydrogen – 0.15) makes up 99.63% of the mass of the earth’s crust, and all other elements account for only 0.37% of the total mass of the earth. An idea of the abundance of some well-known metals in the earth’s crust is given by their clarke values, i.e. arithmetic average content in the earth's crust, which are given below (%):

The most rarely found in nature are polonium and sea anemone, whose clarke is close to 10–15%.

The technical significance of a metal is determined by its prevalence in nature, the needs of the national economy and production capabilities. The last two factors determine the scale of production of individual types of metal. In metal production, about 95% of output (about 800 million tons) are cast iron and steel, which are alloys of iron with carbon and other alloying components. The annual production of main non-ferrous metals is at the level (million tons): aluminum 23–24; copper 10–11; nickel 0.5–0.7; lead 4–5; zinc 5–6; magnesium 0.2–0.3; tin 0.20–0.25; molybdenum 0.14–0.15; titanium is about 0.1.

Metallurgy, the largest branch of heavy industry, produces metals from ores and other types of metal-containing raw materials. Metallurgy is the central link in mining and metallurgical production, including geology, mining, beneficiation, metallurgy itself, foundry and metal processing using various methods (pressure, temperature, mechanical methods, etc.). Metallurgy is based on the principles of chemical technology, since during metallurgical processes, processed materials undergo various physical and chemical transformations. Therefore, metallurgy is closely related to physics, chemistry, and especially physical chemistry, which is the scientific basis of theoretical and practical metallurgy. In recent years, the connection between metallurgy and mathematics and computer technology has been increasing.

The Russian metallurgical industry currently produces 78 elements of the D.I. Periodic Table. Mendeleev, as well as various types of fertilizers, building materials, sulfuric acid and sulfur, cement and many other types of products. Metallurgy in Russia is a highly developed branch of material production. Of particular importance for the development of mining in Russia were the works of M.B. Lomonosov, D.I. Mendeleev, as well as major specialists in the production of ferrous metals P.P. Anosova, D.K. Chernova, N.N. Beketova, I.P. Bardin and many others. An invaluable contribution to the development of the domestic non-ferrous metallurgy was made by A.A. Baykov, NS. Kurnakov, P.P. Fedotiev, V.A. Vanyukov, A.I. Belyaev, I. F. Khudyakov, AN Volsky and others.

Types and alloys of ferrous metals

Adding third-party substances to the composition of iron allows you to change the properties and characteristics of the metal. The development of modern industry has ensured the creation of a number of alloys that are classified as ferrous metals. The main ones are:

- Steel. The most common type of ferrous metal, which is used almost everywhere. To create the alloy, about 99% iron and from 0.02 to 2.14% carbon are used. The addition of substances of another type significantly changes the properties of the metal, allowing it to achieve protection against corrosion, increased strength, resistance to high temperatures, and so on. The most famous steel grades are 3A, 5A and 12A. They are in high demand on the market because they can be used for secondary production.

- Cast iron. The second representative of iron alloys. In cast iron, the percentage of carbon content is higher than in steel (from 3 to 5%). This metal is also widely used in various fields of production and industry. However, it has a large mass, which limits its use in certain conditions. Most often, cast iron is melted into steel at the end of its service life. You need to know how much cast iron costs per 1 kg for scrap, go to the appropriate section of the site.

Further classification of ferrous metal depends on the presence of specific substances in the alloy. Stainless steel and galvanization are in high demand on the market.

Non-ferrous metallurgy, black, white, green

Let's start with something simple.

Non-ferrous metallurgy includes all metals and alloys that do not contain iron or in which iron is not the main component. Gold medallions, famous copper pipes, beautiful bronze statues, silver cutlery, aluminum profiles, tin soldiers - all of these are different colors, so why invent a name? Colored.

Pouring zinc into molds

Historical background: In the beginning there was gold and silver. They made all sorts of crap out of them, mostly decorations. It was so long ago, around the Stone Age. Then they discovered copper - a metal that turned the course of history, launched the first technological revolution and opened the doors to the Bronze Age. Bronze could be used to make many useful things, especially tools for labor and killing. This is where life started to turn around. There was no time to be bored. There was an Iron Age on the nose.

Ferrous metallurgy . This is all about iron and alloys based on it.

There are more than 3,500 steel grades in the world. Each brand has its own chemical composition, which affects its strength, ductility, heat resistance and other characteristics. Your vehicle likely uses up to 40-45 different grades of steel to make your ride as safe as possible and keep you alive during a collision. In most modern films where the main character is trying to escape from captivity, the bars on the windows of his prison are most likely made of Hadfield steel - a cunning bastard, the more you saw it, the stronger it becomes.

Why is ferrous metallurgy black? Who knows... Maybe because black is style and elegance?

Pouring cast iron into the converter

Interesting insert: Scrap metal is a scarce commodity. So don't kick the rusty trough in your yard. Take a closer look, it smells like the Klondike. You won't find good scrap metal during the day. Melt down the scrap - here you have steel, but go find the ore, mine it, enrich it, process it, smelt the steel. The benefit is obvious.

Scrap metal is a valuable commodity. It is imported and exported. For example, the steel structures of the World Trade Center (about 400 thousand tons) were sold to India and China back in the 2000s, and who knows what was smelted from them now.

Before we knew it, we were on the threshold of White Metallurgy . It must be said that White metallurgy is woven from contradictions.

Let's start with the fact that this term is relatively new. Appeared in 2010. It is used only in the vast expanses of our country and is not at all about metals and their color. White metallurgy is the Japanese philosophy of Kaizen, which reached Russian soil, adapted, acquired modern technologies and took root at a number of production sites in Russia. Simply put, it is a system for continuously improving the quality of what you do and how you do it.

Feeling conflicted? What is a natural habitat for a Japanese person is completely unnatural for a Russian person. It’s as if Emelya from our fairy tales suddenly got up from the stove, became a samurai and devoted his life to improving his use of an ax.

In addition, White metallurgy is not white at all, but very colorful and bright. The term itself was introduced into use by the ChTPZ group. And not only introduced, but also implemented at production sites: “Vysota 239”, “Eterno” ChTPZ, “Iron Ozone 32” and “Finish Center”. Take “Height 239” for example: only the robes worn by the workers are white, but the walls are painted bright red. They say it took 105 tons of paint to paint the workshop. There were even shortages in the region - the plant bought up all its supplies. ChelPipe managed to perform a Russian miracle and turn Emelya into a samurai. That case when it is better to see once than to read a hundred times.

Height 239 - workshop for the production of large diameter pipes

Let's move on. Just as relentlessly as decarbonization hit the Ferrous Metallurgy, we hit the Green Industry . Green metallurgy is an environmentally friendly production. An attempt to turn industry towards nature and reduce CO2 emissions. There’s nothing you can do about it: steel production doesn’t produce mountain air, which is a pity.

This is what metallurgy will look like in 2025

How to turn? The best way to make manufacturing pay for its emissions. No sooner said than done. Some countries have made increased commitments and have begun to actively develop emission control tools. There are two popular ones:

- Carbon tax . If you produce a “dirty” product with a large carbon footprint, you will pay a large tax;

- Emissions quota system . These are like gigabytes of the Internet that can be bought, used, transferred to another month or sold.

The Motherland said “it is necessary”, production answered “there is” and split into two camps. Some industries simply pick up and move to other countries. Where there is no carbon tax or it is lower. As a result, in the context of a particular country, emissions decreased, but in the context of the planet, they simply moved to another place. This effect is called “carbon leakage”.

More forward-thinking industries are investing in new green technologies. There are reasons for this. In 2021, the European Union adopted the Green Pact – zero greenhouse gas emissions by 2050. And 2050 is just around the corner.

Russia has a special path, but no one has canceled the climate agenda. We have not entered into any alliances, but we are very actively discussing everything.

Areas of application of ferrous metals

The availability and properties of the material have become the main reason for its demand in the market. Today, ferrous metal is widely used in the following industries:

- automotive industry;

- food industry;

- electrical engineering and thermal power engineering;

- industrial and civil construction;

- production of various types of products and others.

At the same time, a number of alloys with unique properties can be used in strict operating conditions. This applies to production under sudden temperature changes, in aggressive environments, and so on.

Origin of metal waste

Copper is scrap brass and bronze.

The most valuable is electrical :

- transformer buses;

- conductors;

- multi-strand cables.

Scrap metal is sold in the following form :

- not burnt;

- not oxidized;

- without enamel;

- without insulation.

They will also accept it with inclusions, but the acceptance price will decrease .

Tin is much more expensive than copper, but there is less of it.

Contain it:

- bearings;

- white tin food containers;

- solder;

- pipelines.

alloy of tin and lead – babbitt – is one of the most expensive.

Lead is taken in the form of:

- plates;

- cable braid;

- melted down

Taken from:

- batteries;

- typographic font;

- telephone cable.

Titanium sources :

- shut-off valves;

- pipelines.

Aluminum is more readily accepted :

- electrotechnical;

- profile;

- cable;

- food.

Depending on where the metal is mined , the acceptance price varies.

Zinc scrap and the alloy of this metal with aluminum and magnesium are valued three times more than just zinc waste. This alloy is called TsAM . It can be found in large quantities in the car.

Properties of non-ferrous metals

Tsvetmet has unique features that make it possible to use alloys for the production of devices and products with limited properties. Non-ferrous metals have a higher price in the market. This is largely due to limited resources. For the same reason, non-ferrous metal scrap is more often processed for recycling. The key properties of non-ferrous metals are:

- corrosion resistance;

- excellent electrical conductivity;

- high rate of ductility and flexibility;

- low weight (in relation to ferrous metal);

- the presence of unique properties, etc.

Specific types of non-ferrous metals have specific applications. Many of them are widely used in pharmaceuticals, medicine, aircraft manufacturing and other industries.

Main types of non-ferrous metals

There are an order of magnitude more types of non-ferrous metals than ferrous metals. The addition of various substances to the alloy made it possible to diversify the structure and properties of the material. Today all non-ferrous metals are classified into groups:

- heavy (lead, copper, zinc);

- lightweight (aluminium, titanium, lithium);

- refractory (tungsten, vanadium);

- noble (silver, gold, platinum);

- radioactive (uranium, radium);

- scattered (indium, thallium, germanium);

- rare earths (cerium, scandium, yttrium).

Each type of non-ferrous metal has its own unique features and characteristics that determine its purpose.

Popular non-ferrous metals and their applications

Despite the fairly large number of well-known non-ferrous metals, only a few of them are in great demand on the market. Most in demand:

- Copper. Metal with anti-corrosion properties and effective electrical conductivity. Used for the manufacture of pipes, cables, wiring and other technical products.

- Brass. An alloy of copper and tin. The alloy was mainly used in the production of sanitary products.

- Aluminum. A fairly light metal that is widely used in aircraft construction. This industry is the main consumer of aluminum on the market, since it is lightweight and resistant to negative external factors.

- Lead. A heavy alloy that ranks fourth in production after copper, aluminum and zinc. Has good electrical conductivity properties. However, it is toxic and poisonous, which limits its scope of application.

- Zinc. It is actively used to create other alloys. In its pure form it is used in pharmaceuticals and a number of manufacturing industries.

Each of the non-ferrous metals has its own value on the secondary market. Since raw materials are limited in nature, recycling allows organizations to reduce costs by melting down old products. For this reason, the price of non-ferrous metal is increasing every year.

Sorting non-ferrous metal

Non-ferrous metals and alloys are divided into groups on several grounds:

- Heavy: copper, tin, mercury, lead, zinc.

- Lightweight: aluminum, beryllium, calcium, magnesium.

- Noble: gold, silver, platinum, palladium, radium, ruthenium, iridium, osmium.

- Rare: vanadium, tungsten, molybdenum, radium, tantalum, chromium, etc.

- Refractory: vanadium, tungsten, manganese, molybdenum, titanium, chromium.

There are much more metal alloys in various combinations and proportions . Then the resulting material acquires the necessary properties for use in sectors of the national economy.

Scrap metal from non-ferrous metals and alloys is also usually classified :

- By type of predominant metal: copper scrap and copper alloy scrap, aluminum, magnesium, titanium, lead, rare metal scrap, semiconductor, precious.

- According to physical indicators, scrap is divided into classes;

- According to the chemical composition - on the brand.

- In terms of quality - by variety.

In metallurgy they are sorted depending on:

- characteristic properties;

- meanings.

The scale of importance for the industrial production of common metals and alloys is built as follows:

- aluminum and aluminum alloys;

- copper and copper-nickel alloys;

- bronze and tin bronzes;

- magnesium;

- nickel;

- titanium;

- tin;

- lead;

- zinc.

At collection points they readily take any non-ferrous metal. The championship rightfully belongs to aluminum , or more precisely, to its alloys. In second place is copper.

Both are used more intensively than others in:

- industrial production;

- construction.

very common .

The electrical conductivity properties of silver are higher, but it is expensive. Therefore, in cables and wires to conduct current, conductors are made from another excellent conductor - copper.

It is actively used in:

- electrical engineering;

- pipe production.

Why is it necessary to pass ferrous and non-ferrous metals?

Over the past centuries, the amount of metals used to make various products has increased greatly. If waste disposal is not monitored, the volumes of old scrap will cause environmental damage. At the same time, some non-ferrous metals have toxic properties that harm the human body. Storing such products can lead to chronic illnesses among employees.

Also, metal recycling can significantly reduce the costs of enterprises and organizations by melting down old scrap. Selling scrap metal provides economic benefits for all parties, further helping to reduce the risk of environmental disaster. Ours will provide customers with transport and forklifts for quick removal of scrap. High prices and high-quality service at our reception points will provide favorable conditions for our clients.