Varieties, choice

According to their purpose, shovels are divided into:

- Bayonet. Used for digging up soil (vegetable garden, trenches, holes). During use, the working surface may become dull. Requires timely sharpening.

- Sovkovye. They are used for moving materials subject to flow, as well as work related to loading and unloading. Sharpened in rare cases.

- Sapper. Such a tool has found a narrow application for performing special tasks in combat situations.

Bayonet-type products differ from analogues in their shape. The working part is made in the form of a rectangle, or tapers at a certain angle. To sharpen edges of various shapes, the same methods are used, depending on the type of work. They do not have instructions in which the manufacturer indicates the base material. For the manufacture of tools the following can be used:

- steel with high carbon content;

- steel with the addition of stainless elements;

- alloy steels;

- titanium and alloys of various metals.

The handle is made from any type of wood, as well as some light metals. The working part is performed by hot stamping, and it is necessary to further treat the metal surface by hardening. During inspection, the presence of cracks, burrs and gouges is not allowed. The handle is securely fixed to the metal. If the shovel bends as a result of pressure, it is considered defective.

Features of choice

Tools can be different: scoop, bayonet, etc. (depending on their purpose). Bayonet ones are used for digging earth (trenches, vegetable gardens). Scoops are a tool for loading and unloading operations and moving bulk substances. There are sapper blades, but they are unlikely to be used in everyday life. Sharpening is only needed for bayonet tools; shovel tools do not need it.

Bayonet shovels differ in the shape of the blade. It can be rectangular or tapering at a certain degree. They sharpen approximately the same. The choice is determined by the area of application of the tool. The most difficult thing is the choice of material. This tool is not accompanied by instructions that indicate the parameters of the metal from which it is made. Typically used to make shovels:

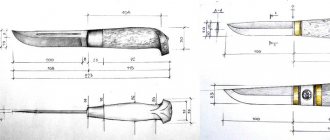

Figure 1. Sharpening of a shovel should be done with the side of the file.

- carbon steel;

- stainless steel;

- alloy steel;

- titanium;

- various alloys.

To understand the differences between shovel materials, you should briefly look at the manufacturing process. The shovel handle can be made from any material, from birch to hardened aluminum. The metal part of the shovel is made in different ways. The correct process is heating (not melting) high-quality metal to a soft state, and then stamping it on a special press. Incorrect - stamping sheet metal of a certain thickness.

Shovels often indicate that they are made of rail steel. This is not quite the correct name; steel has a different designation. This means that the tool is made from an old rail that has served its useful life. This is good material, but such an inscription does not give any guarantee of quality. This tool is called a pointed shovel.

Cracks, burrs, delaminations, scratches, cavities, dents and other damage are unacceptable. Metal thickness – 2 mm, cutting edge thickness – 0.5 mm. The surface of the shovel must be hardened, although when using some grades of steel, hardening is not necessary

An important condition is that the cutting edge should not have visible damage. The blade of the shovel should not bend from light pressure, and the connection with the handle should not wobble

A properly made shovel blade weighs approximately 1 kg.

What is the purpose of sharpening shovels?

If you have to exert maximum effort while digging the soil, this means that you need to sharpen the shovel. This manipulation will make it possible in the future to carry out work on pruning small plant roots and digging turf soil. It is recommended to adjust the working edge of new shovels, since when manufactured with a hot stamp the edges are not sharp.

The bayonet type, made from steel from old rails, must be constantly adjusted. However, some devices do not require sharpening throughout their service life.

Further care of shovels and their storage

To keep the edges of shovels (and other garden tools such as hoes, forks, etc.) sharp and prevent them from rusting, you should clean them after each use and allow them to dry before storing them in the shed. It is worth remembering that you should not sharpen shovels too often, as this reduces their service life. Tools should be stored in dry conditions, preferably on shelves or racks.

An excellent option is to store household equipment in a bucket with a mixture of sand and mineral oil.

If you do everything as described above, the purchased tools for working in the garden will last a very long time.

«>

Adblock detector

Sharpening tool

Sharpening a shovel involves using a high-quality tool. However, the speed of dressing the cutting edge depends on the skills of the worker. For quick sharpening, use the following devices:

- hand file with fine notch;

- angle grinder;

- hand-held sanding machine;

- industrial or benchtop sharpening machine.

A machine with two circles located on the same axis has become widespread. However, they differ in the size of the abrasive material. With the help of such a device it is possible to perform coarse and fine editing of the cutting edge. However, when using tools of complex shape, it is recommended to use portable, manually operated machines.

In the absence of electrically driven devices, you can straighten the working edge using files and sandpaper, but the process will take a lot of time. Using a grinder is possible if you have a metal processing disc.

Sharpening a shovel with a file

How to sharpen a shovel with a grinder?

Thanks to modern power tools, the process of sharpening agricultural tools has become significantly easier. For these purposes, you can use a grinder or a regular grinder.

Using such devices, you can sharpen a shovel blade in 1-2 minutes. But at the same time, this must be done extremely carefully, since if sharpened incorrectly, the metal can overheat. And this in turn will lead to a change in the structure of the metal, that is, the metal becomes soft.

When sharpening a shovel with a grinder, you need to monitor the temperature - it is unacceptable for the metal to overheat.

This quality is unacceptable for a cutting edge, as it will bend and quickly become dull.

In this case, you will have to process the surface of the shovel quite often, which can lead to its rapid abrasion. It is possible that you will not be able to work with such a shovel even for one season.

Since the rotation speed of the disc on a grinder is quite high, it will be quite difficult to achieve a uniform edge thickness. Consequently, the cut of the shovel will be of poor quality, which will make further work more difficult.

In addition, burrs and chips that are created due to the high processing speed can lead to injuries.

How to sharpen?

But if you decide to sharpen a shovel with a grinder, you need to do it extremely carefully. We fasten the shovel in a vice, and hold the sharpening tool so that the disk rotates towards the handle. Only the front part is processed, and the processing direction should be from bottom to top. We sharpen the back part of the working element only with shovels.

In order not to get too thin an edge of the surface being processed, do not press too hard on the grinder.

Preparatory stage

Before starting manipulations with processing the edge of the tool, you need to make sure that the handle is securely fastened. If only the metal part is available, then it can be clamped in a bench vice. To prevent injuries, it is necessary to provide the technician with personal protective equipment, which includes goggles and gloves, as well as overalls.

The power tool should be inspected for defects; wires and power cables should be intact without damage or kinks. It is forbidden to use grinding wheels with chips or gouges on the working surface.

The metal part of the shovel must first be cleaned of soil and dirt. Rinse the working edge with running water and wipe with a dry cloth. It is recommended to beat off the edges of the tool. Such manipulations will further speed up the process of sharpening the shovel. However, beating requires high skill of the master.

Why are shovels sharpened and how to do it?

Surely someone asked the question: “why are shovels sharpened?” It should be noted here that the sharper the iron cutting part of the shovel, the easier it will be to use the tool for its intended purpose. Therefore, it is necessary to sharpen at a certain frequency to make work in the garden or garden more comfortable and convenient.

In addition, you need to know that tool sharpening has certain features. They lie in the physics of the process, which is determined by the quality of the product material. Shovels today are made from iron of varying qualities. More expensive models are made of high-quality alloy steel, which holds its edge longer, but cheap products become dull much more often. The physics of sharpening, as well as the chemical composition of the alloy used to produce the iron part of the shovel, also determine the method of sharpening that is most effective in each specific case.

The quality and physics of sharpening is determined not only by the quality of the product and the person’s experience, but also by the chosen technique. Today, in order to give the shovel the desired sharpness, the following tools are used:

- file;

- grinder or angle grinder;

- sandpaper with a sanding machine.

Let's consider each method in detail in terms of the features and physics of the sharpening process.

File

Using a file is the most traditional and standard method. The advantages of using this tool include:

- a file is always at hand;

- it is small in size;

- affordable price;

- ease of use;

- excellent sharpening quality.

As a result of using a file, it is possible to obtain an excellent quality working edge of the shovel. In addition, during the sharpening process it is possible to constantly control the thickness of the metal layer that is removed. Thus, we will obtain a uniform thickness of the metal in the lateral and frontal planes. In this case, you can obtain the most optimal physics in the operation of gardening tools.

Separately, it is worth noting that during the use of a file, the metal does not heat up, as a result of which its physical and mechanical properties do not change. When using other sharpening methods, these parameters cannot always be kept unchanged and, as a result, the shovel may begin to become dull much more often.

Sharpening with a file occurs according to the following scheme:

- blade fixation. It should be firmly fixed and not move. Many people use a bench vise for fixing. But here, be careful with the clamping force, otherwise you can damage the stamped blade;

- choose a file with a large notch;

- We process the front part of the edge with the tool.

As a result, you will carry out the first, rough processing of the shovel. Remember that this process should only be done on the face of the cutting part. The file is moved towards the handle from the edge of the blade.

After rough work with a file with a coarse notch, we arm ourselves with a file with a fine mesh and carry out a fine sharpening. At this stage, adjust the blade thickness to 0.5-0.6 mm. The angle of sharpening movements should be approximately 40-45 degrees. Maintaining this angle will allow you to avoid premature wear of the blade. Remember that the width of the processed edge should not be more than 5 mm. Make sure that the thickness of the blade is uniform along its entire length. Otherwise, thinner areas will dull faster, which will have a bad effect, so to speak, on the working potential of the shovel.

How to sharpen a shovel correctly

During operation, it is necessary to maintain a sharpening angle of up to 20°, while achieving a cutting edge thickness of no more than 0.5 mm. When using a power tool, do not apply excessive force, as this may result in metal defects or breakage of the grinding wheel.

To check the quality of work, you can use a sheet of paper or a wooden block. Use the edge of a shovel to cut off the edges; if you have to use force, then repeat the straightening process. There should be no dents, chips or burrs on the working surface. Even after sharpening, poor quality metal cannot be restored to its original sharpness.

Proper sharpening of a shovel

Sharpening with a file

Advantages of the method:

- High quality cutting edge. When using an electrically powered tool, the same result cannot be achieved. Use a file to regulate the thickness of the metal both on the working edge and on the side edges.

- There is no heating of the metal surface. When using a grinder and emery, overheating occurs, which leads to a change in the properties of the metal part of the shovel.

- Convenient to carry. The ability to straighten tools anywhere without having to find a power source.

When sharpening you must:

- Securely fasten the metal part. It is recommended to use a bench vice. It is forbidden to exceed the force when tightening the lips, as this may lead to deformation.

- Rough processing. First of all, editing is carried out with a file with a large notch. Move from front to back, reverse order is prohibited.

- Precise processing. The editing is carried out with a file with a fine notch, while achieving an edge thickness of no more than 0.5 mm.

- Removing sharp edges. A square profile file is used; with its help, edges sharpened at a smaller angle are removed.

Adjusting a shovel with a grinder

The disadvantages of this method are:

- The need for an electrical power source.

- As a result of critical heating of the metal, the technical characteristics of the edge decrease. This phenomenon leads to the fact that the edge quickly becomes dull in the future.

- The difference in the thickness of the edge of the shovel. High rotation speeds do not allow maintaining a thickness of 0.5 mm along the entire length of the tool edge.

- After processing, the metal must be additionally edited using a finely cut file. This will help avoid injury when transporting the shovel.

The only advantages include the speed of editing. When processing, the grinding wheel must be directed towards the holder. Only the front side of the instrument is sharpened.

Sharpening a shovel with a grinder

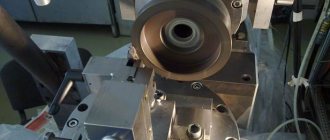

Sharpening with an emery machine

For high quality edges, it is necessary to use machines with adjustable speed of rotation of the sanding wheel, as well as a large weight of the abrasive. This will avoid vibration during processing. You can sharpen a shovel by following these instructions:

- Securely secure the workpiece. In this case, the master needs to press the working part of the shovel against the stop on the machine.

- Initially, it is recommended to remove a layer of metal no more than 0.3 mm thick. This smooths out cracks and dents on the edge of the shovel. Subsequently, the angle of the workpiece relative to the surface of the grinding wheel is changed. During operation, for cooling, the edges must be watered. Dark spots will appear on the edge, which, however, do not harm the characteristics of the metal.

- Final straightening is done using a hand file. Burrs and microcracks are removed. Areas with excessive edge sharpness are removed.

How to sharpen a sapper blade

You can sharpen a sapper blade just like a regular bayonet blade - in any of three main ways. It is recommended to first beat off the edges of the metal part, which will further help reduce the loss of time on straightening the edge using a tool. The movements are carried out along the front side, only burrs are removed from the back.

Compliance with the instructions and safety requirements will help keep the tool in working condition for a long time and will reduce the effort when digging up soil on a personal plot.

Sharpening methods

Shovel handle

The shape and principles of sharpening for bayonet equipment with a rectangular or tapering blade do not differ and do not depend on the method of sharpening. When processing, there is no need to shorten the tool blade, but it can be narrowed.

Using a file

Sharpening with a file

This type of sharpening is the most time-consuming and tedious, but has advantages:

- mobility (the file can be easily brought to the country house or to the field);

- does not require electricity;

- metal overheating is excluded;

- It's easy to control the force and get optimal sharpness.

Only the outer edge should be sharpened. First, rough sharpening is done with a coarse file, then using a small tool or an abrasive stone the edge is brought to the desired shape.

Sharpening a shovel using an angle grinder (“grinder”)

Sharpening a shovel using an angle grinder

This method has an undoubted advantage - speed of work. But only a qualified craftsman can achieve the level of sharpening provided by a file, since it is difficult to sharpen a shovel efficiently using this method. You should use a regular metal disk, the direction of movement is from bottom to top. After machine sharpening, minor flaws will have to be removed with a file.

Important! When sharpening with an angle grinder, a lot of heat is generated. Care should be taken not to overheat the shovel and not to damage the structure of the metal. Otherwise, it will become soft and dull or deformed during use.

How to sharpen a bayonet shovel on an emery machine

The best option for the relationship between quality and speed is an electric sander (preferably with a heavy grinding wheel). Sharpening is done as usual, but you won’t be able to move the tool, so during the process you will have to move the shovel, observing the direction from the edge up. It is great if the sharpening machine has an adjustable rotation speed, since this is how it is more convenient to sharpen a bayonet shovel.

We use power tools

How to sharpen a shovel quickly and without extra effort? To do this, you can use a grinder or a grinder.

You need to work with the grinder carefully. There are many reasons for this:

- The rotating disk of the tool can cause serious injury.

- When sharpening is too intense, the metal overheats, causing it to significantly lose strength.

- At high disk rotation speeds, it is very difficult to control the uniform sharpening of the shovel tip. With a high degree of probability, the cut will be uneven, with burrs and chips.

How to sharpen a shovel with a grinder? This must be done from bottom to top, being careful not to press too hard with the tool so as not to thin the edge. For safety reasons, be sure to protect your eyes with goggles and wear gloves.

A special sanding machine is much more efficient. It allows you to regulate the speed of rotation of the disk and makes it possible to select the optimal mode. In addition, modern machines are usually equipped with clamps that allow you to firmly secure the tool being sharpened and prevent it from oscillating during the sharpening process. To ensure uniform surface treatment of the shovel, it is recommended to use heavy abrasive wheels.

But no matter how hard a person tries to sharpen a shovel correctly on a machine, it is still a rough tool that will probably leave minor imperfections, and they will have to be corrected with a fine-cut file. At the same time, you should understand that even the most careful sharpening will not save a low-quality shovel from rapid breakdown. Therefore, when choosing a tool for working in the country, you should not skimp.

A shovel is an indispensable tool for solving a large number of problems, especially in agriculture. But with frequent use, it can become dull, and therefore the work process will slow down significantly and become more complicated. It is still possible to solve this problem, but to do this you need to sharpen the shovel. And we will look at how to do this correctly in this article.

Shovel sharpening options

Before you begin the sharpening process itself, you also need to clean the surface of the shovel from any soil stuck to it, as this may complicate further sharpening.

To sharpen a shovel, you can use one of the following tools:

- File;

- Bulgarian;

- Emery machine;

Types of shovels and features of their choice

The effectiveness of straightening garden tools largely depends on the material from which it is made. There are 3 classes of shovels: gardening, construction, loading and unloading. All of them, according to the shape of the blade, are divided into 2 main types: bayonet and scoop.

- copal pointed;

- digging rectangular;

- selection;

- selection faceted;

- mortar

- sand scoops;

- scoop grains;

- coal;

- metallurgical;

- snow removal

A special type of shovel is sapper shovel. They are similar to a garden bayonet, but have a unique blade shape that allows this tool to be used as a bayonet and shovel. This equipment has standard blade and handle dimensions, which are strictly observed during the production of the product. Therefore, a mining shovel can be used as a tool for measuring distances.

Sharpening is required only for those tools that are equipped with a bayonet-shaped blade. Shovels are used primarily for moving bulk materials, so the sharpness of the edge of the metal blade is not so important for them. The success of sharpening a blade largely depends on what material it is made of.

What are shovel blades made from?

The manufacturer of gardening and construction equipment does not always indicate what material it is made of. On shovels it is most often noted that they are made of rail steel (that is, from a rail that has served its purpose).

Table of steel alloys for shovel blades.

This material is not bad, but does not provide any guarantee of the quality of the canvas. In most cases, it is used to produce bayonet-type pointed digging shovels.

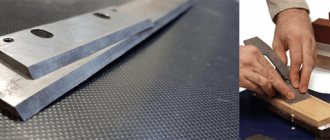

When choosing a tool, you need to pay attention to the thickness of the blade: it should be at least 2 mm. The optimal thickness of the cutting edge is 0.5 mm.

It is extremely important that there are no flaws on this part of the blade. It is recommended to choose shovels made from the following materials:

- carbon steel;

- stainless steel;

- alloy steel;

- alloys.

Sharpening a shovel with a file

Using a file has only a few disadvantages - it is a rather long and tedious process. But there are significantly more advantages. The file is small in size, which allows you to always have it at hand. Manual sharpening makes it possible to control the thickness of the metal layer being removed and sharpen the shovel exactly as much as necessary. With strong heating, a change in the physical and mechanical properties of the metal occurs, as a result of which it becomes softer and more brittle. But when working with a file, such strong heating does not occur.

How to sharpen a bayonet shovel with a file? First of all, it must be cleaned of adhering clods of dirt, plant debris, etc. and fix it motionless so that at the most inopportune moment it does not fall and cause injury.

Sharpening occurs along the front part of the cutting area of the shovel in the direction from the blade to the handle of the shovel. First, rough sharpening is done with a file with a large notch, then a tool with a fine notch is used to finish the blade.

When working, you must try to avoid the appearance of too thin areas on the edge of the shovel - they will quickly become dull.

Traditional file sharpening and its features

Many people do not trust the traditional “grandfather’s” method of sharpening, which has existed for hundreds of years. However, a hand file has many “advantages” in the process of processing garden tools. Let's take a closer look at why it is more profitable to use it.

- Excellent edge quality. You will not be able to achieve exactly the same levelness when using a power tool, especially if it has a high rotation speed of the wheel. You will be able to regulate the thickness of metal removal and make uniform processing not only of the cutting front part, but also of the side planes.

- There is no overheating of the metal. Perhaps this is one of the most important advantages, since an ordinary grinder or electric emery heats the metal surface to a temperature of +200 degrees or higher, changing the physical and mechanical properties of the material. With the slightest resistance, it will wear off or become dull, making it impossible to cultivate hard soil.

- You can take it with you on the road. You can adjust the shovel directly at the workplace if large-scale work is planned far from a source of electricity or a vice.

And the most important thing is that a file can be found in any owner’s workshop, so you don’t have to spend a lot of money on purchasing an electric emery or any other device. Let's take a step-by-step look at how to properly sharpen a shovel.

The first step is to fix the blade so that it does not move under significant physical impact. It is best to use cleats, but without fanaticism - do not tighten too much, so as not to deform the stamping - they are quite fragile.

Now you need to take a coarse file and run it along the inside of the edge. You cannot sharpen the back side of the shovel (the one on which the holder comes out); we only process the front side. It is preferable to sharpen towards the holder, that is, the file stroke begins in the direction from the edge to the holder.

Now you need to work with an ordinary, small file, with which you can adjust the blade to a thickness of at least 0.5 mm, and at an angle of no more than 40 degrees, so that the metal does not quickly wear off. Sharpening of the shovel should be carried out until the entire blade is no more than 0.5 mm thick at the very edge, and before that it should be processed with a fine-grained file.

Now we take a square file and run it several times along the very edge to remove thin sections that will become dull at the first contact with the ground. 5-10 wires will be enough, then run them several times at an angle of 40 degrees to remove possible chips.

We figured out how to sharpen a shovel with a file, now you can go and try out the acquired knowledge in practice. But there are other ways to process garden tools, which have their own advantages and disadvantages; let’s look at them in more detail.