Casing pipes are necessary when it is necessary to equip a well on the territory of a personal plot and provide it with an uninterrupted supply of water.

To build a well in your summer cottage with your own hands, steel casing pipes are used. They are also the best option if you need to organize a well that has great depth.

However, some other materials are also suitable for constructing a well. For example, wood, plastic, cast iron and asbestos cement. However, the installation of steel casing pipes differs from other options in its ease of connection and acceptable strength characteristics

.

What type of products to choose

If you need a well casing, it can be made from various types of pipes:

- asbestos-cement;

- plastic;

- steel, etc.

They are distinguished not only by price, but also by performance characteristics. Below is a detailed description of each type of product.

Asbestos cement pipes

This type of materials has been successfully used for many years, since they are characterized by the following positive qualities:

- neutrality;

- resistance to corrosion;

- resistance to chemicals.

Advice. It is advisable to be extremely careful when installing these pipes as they are quite fragile and may break or crumble. It is also necessary to provide for compaction of the well walls.

Pipe in a well

However, in addition to the positive properties, there are also negative ones, which led to a decline in the popularity of this material:

- high requirements for tightness and neatness of joints;

- impossibility of installation in sandy soil;

- the impossibility of equipping wells whose depth exceeds one hundred meters;

- high price of material.

Advice. When choosing asbestos-cement pipes, please note that not all models are designed for contact with drinking water!

Steel pipes

These models have increased resistance to virtually any load.

However, this positive characteristic is offset by negative ones:

- susceptibility to corrosion;

- high iron content in water;

- the need to install a filter to combat iron and rust;

- the likelihood of pump failure as a result of rust getting into it;

- metallic taste of water;

- difficulty of installation.

Steel models

Note that the installation of a casing pipe in a well in this case is carried out only on two types of soil:

- sandy;

- limestone

Advice. When installing a steel pipe, be sure to install an additional filter to clean the liquid from high iron content.

Plastic models

This type is considered the most optimal today because:

- reliable;

- easy to install;

- durable;

- inexpensive.

However, if you are interested in how to install a casing pipe in a well if a plastic product is selected, then please note that they are only suitable for shallow sources.

Plastic product with thread

The following types of products are most often used for installation:

- from unplasticized polyvinyl chloride;

- polypropylene;

- polyethylene.

- uPVC casing pipes

Purpose and scope of casing pipe for a well

Well casing

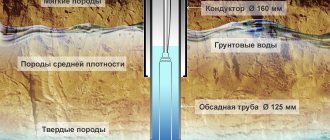

First of all, you need to decide what a casing pipe is and for what purpose it is used. This is a special column equipped with a reinforced casing, the main task of which is to strengthen the internal structure of the hydraulic structure. As a rule, more than one functional element is installed in a deep well shaft. They are connected to each other, and the seams are treated with sealant to obtain a single casing.

The thickness of the walls of the casing rings should be determined by the type and characteristic features of the structure, as well as the material used to manufacture the column walls.

Products made of concrete and metal are characterized by large wall thickness, diameter and length, in comparison with parts made of plastic. To create a tight connection between the elements, the end of one pipe always has a coupling. The second end is equipped with a ring that protects the thread from damage.

The pipe protects the well from soil pressure and contamination

Source casings are required to perform the following tasks:

- Protect the water pump or pumping system installed in the shaft from possible contamination and mechanical damage.

- Ensure the integrity of the water intake point throughout its entire service life. The products are characterized by increased strength, resistance to deformation and damage.

- Protect the well from high soil pressure.

- Prevent the seepage of sewage or groundwater into the well, which threatens to pollute the water and infect it with pathogens.

It is necessary to give preference to the threaded connection method, otherwise it is almost impossible to achieve reliable sealing of the casing pipes.

Connection Features

Installation of pipes involves a strong and reliable connection of all parts.

There are three main connection methods:

- by welding;

- bells;

- threads or fittings.

If we are talking about asbestos-cement pipes, then in this case only couplings are used.

Installation also requires compliance with certain requirements:

- the edge of the pipe should not reach the bottom by about 50 centimeters - this will ensure the free passage of water at any time;

- the diameter should not decrease when deepening, as this will lead to loss of water permeability;

- each link should be attached as firmly as possible, depending on the characteristics of the material - for example, at least four staples and strips of stainless steel.

Pump installation

Before installing the unit, prepare:

- pressure gauge;

- steel fixation unit;

- fittings - optionally - clamps;

- back pressure valve;

- valve for shutting off the water.

Selecting a suitable pump. Fastening at the right depth

Which pump to choose depends on the specific situation. Experts recommend centrifugal-type submersible models. They explain this preference by the natural vibrations that vibrating structures cause. This leads to soil destruction and equipment failure. Avoid vibration pumps when the well is installed on a sand base.

The power of the equipment depends on what kind of performance you expect. Remember, the greater the depth, the more powerful the pump will be required.

Read also: 5 ways to get into trouble with the law because of a well on your property

A separate selection criterion that also needs to be taken into account is the quality of drilling. There are special models of pumps that are used in wells dug without the help of professionals.

It is important to correctly calculate the depth of immersion. The device must be kept in water at all times. In this case, the device is mounted remotely from the bottom of the water intake. Otherwise there is a risk of clogging.

Standard pumps are fixed at a depth of 8-10 meters, injection pumps - 18-20 m, special ones - 35-40.

Surface pump

The main disadvantage of the models is their limited application. The device is only suitable for shallow wells. The advantage is ease of installation.

Work according to the scheme:

- mount the device in a stationary room or an individual caisson;

- connect a hose of the required size to the suction pipe;

- Secure the check valve on the other side of the hose. It will perform a protective function and prevent water from draining after the equipment is turned off;

- Place a protection filter on the valve - it will not allow debris fragments to penetrate inside;

- lower the hose into the well.

Submersible pump

Such structures are installed directly in wells. They do not require a caisson or permanent premises. The device is assembled, a water pipe and an electrical cord are connected to it, and the equipment is lowered into the well.

Note! In most models, water is supplied through plastic pipes. But there are also those that use a rubber hose.

The optimal immersion depth is 1.5-2 meters.

Submersible pump installation diagram:

- preparation of materials and equipment;

- immersing the device into the well;

- calculation of the operating point of the unit.

Arrangement of eyeliner

The power supply is provided by a separate line. It is equipped with an automatic power cut-off device. Don't forget about grounding. Before starting the equipment, the pump is filled with liquid. Observe the required pressure parameters.

After connecting the power, bleed the air by opening the valve. After a couple of minutes, the water supply starts. If this does not happen, turn off the device and add more water.

Turn on the device again. Set up the relay. By turning special screws, the required indicators are set.

If dismantling is necessary

If you are interested in the question of how to remove the casing from a well, then it is extremely important to understand why you should bother with this process at all.

There are at least two reasons:

- restore an abandoned source;

- repair the existing one.

Dismantling with cable

You have decided that replacing the casing pipe in a well is necessary, then in this case this process can be performed in several basic ways.

For example, hire professionals who know exactly how to remove the casing from the well.

In particular, they use special equipment:

- taps;

- overshots;

- pipe traps and other devices.

Of course, this method is the simplest, since you don’t have to do anything, but at the same time it is costly. Drillers rate their work highly.

Photo of pipe extraction

The second method is to do all the work yourself.

In this case, you need to perform the following sequence of actions:

- Secure the end of the pipe using:

- clamp;

- loops.

- Attach the clamp to the short arm of the long lever and gradually remove the pipe.

- Instead of a lever, a large jack, for example, from a large car or a railway jack, is perfect.

We manufacture new equipment

You can also make a special device with your own hands, for which you will need the following materials:

- channel ten;

- you need to make two racks from the channel;

- The racks should look like an upside down letter T.

- the height of the racks is about one meter, and the width is about sixty centimeters;

- a bearing is attached to the upper part, the internal diameter of which is four centimeters;

- an axis is threaded through the bearing, to which the handle and drum are attached;

- for dismantling, the edge of the pipe is secured with a cable;

- then simply twist the drum and remove the structure.

Advice. If you are dismantling a long pipe, then in this case you can play it safe with a special clamp that will help hold the pipe when intercepting the cable fastening. To dismantle a plastic pipe, it is recommended to use a crimp clamp.

How to construct a well yourself

To properly equip a well yourself, study the recommendations of professionals. Select the caisson and electric pump model in advance. Draw up a layout plan, decide on a location, and work consistently.

Sealing a well string (installation of a well head or a well cover with an adapter)

There are two types of heads:

- with a removable or hinged lid;

- with coupling adapter.

Borehole heads provide sealing of the equipment and protect the pump, which is located inside the caisson. Its installation does not require welding - all metal elements of the structure are galvanized, so they are not afraid of moisture. Mounting the header is easy:

- Make a small pit next to the casing. Height - 1.5 meters;

- dig a trench for water pipes;

- make a hole in the wall of the column using a hammer drill;

- assemble the adapter assembly;

- screw it onto the mounting rod and lower it into the well shaft. Insert the adapter into the side hole of the column;

- secure the position of the device with a union nut.

Installation of caisson

The caisson installation process includes several stages:

- excavation work - choose a location for installation. To install the pipes, trenches are made, a hole is dug - there will be a container in it. Strengthen the soil from subsidence. The voids are filled up;

- installation itself - form a drainage layer, make a base. Provide warmth and waterproofing;

- install pumps, connect them to the pipeline, and adjust equipment;

- install the roof and hatch.

Excavation

Plan this work for the warm season. In summer, groundwater flows lower. To dig a hole, rent special equipment. If the pit is small, use a shovel.

Which method to choose depends not only on the size of the pit, but also on the composition of the soil. If the ground contains a lot of clay or rocks, order an excavator. Sandy soil is soft and can be dug with a shovel.

Well casing device

If you plan to do the installation yourself, you need to study the design of the structure:

- initial filter - made in the form of a mesh product, installed to retain large fractions;

- gravel cushion at the bottom of a hydraulic structure - prevents groundwater from penetrating into the well;

- cap - prevents precipitation and dirt from getting inside.

Installing a filter is not enough to equip a well. To do this, it is necessary to correctly assemble (if it is not solid) and fix the column.

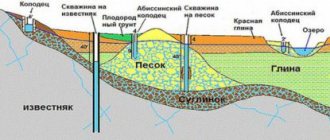

Advantages of hydraulic drilling over driving an Abyssinian well

There are clear advantages of hydraulic drilling technology over driving a needle into a well.

Firstly, the process is simpler - no gigantic physical effort is required to hammer steel pipes with a headstock.

Secondly, the soil is constantly washed out to the surface, that is, the driller clearly understands whether he is passing through clay or sand.

Thirdly, it is clearly determined that the pipe has reached the aquifer - this layer absorbs water, which is supplied to the pipe to flush the well, and the driller sees that the water has stopped coming to the surface.

The only disadvantages of hydrodrilling include the need to have a reserve of several hundred liters of water, and the difficulty of working in cold weather - the water in the hoses freezes.

The video describes the process of hydraulic drilling, but we are looking at a simplified process - a well in sand.

Made of steel and asbestos cement

More recently, steel was used when casing was required for a self-contained well. Its durability is more than 40 years. The thickness of its wall is 5 millimeters. But the main thing is that steel feels great even on moving soils, unlike PVC. The main disadvantage is that it rusts. Therefore, additional filtration is required to purify water. In addition, the price of steel is quite high. But, despite this, it has one undeniable advantage, unlike HDPE: for example, it is indispensable when drilling on limestone soil inside the casing.

Asbestos-cement casings have been used for a long time. They are durable and have good safety. However, they also have their drawbacks. The main one is that asbestos cement fibers contain chrysotile. It promotes the accumulation of harmful substances in the human body. Without careful water filtration, they can cause health problems. In addition, this material is difficult to install.

Hydrodrilling technology for an Abyssinian well from HDPE pipes

First you need to flush the hole in the ground to the desired aquifer. To do this, take a HDPE pipe with a diameter of 32 mm (for plastic pipes, the marking is the outer diameter), and a meter-long piece of steel pipe with an outer diameter of 25 mm is inserted into it with preload. At the end of the pipe, use a grinder to cut teeth - a crown for loosening the soil.

Next, we feed water into the HDPE pipe through a hose using any pump and begin “drilling” - holding on to the HDPE pipe, twisting it, we bite into the soil, which is washed out by water around our immersed HDPE pipe. No special effort is required to work. The verticality of the channel is ensured by a steel pipe, followed by HDPE like a thread behind a needle.

When our crown reaches the aquifer, water will stop coming to the surface around the HDPE pipe. You should go deep into the aquifer to the length of the filter of our Abyssinian well, remove the drilling HDPE and quickly insert another HDPE of the same diameter into the resulting hole in the ground - with a ready-made filter at the end. You need to insert the Abyssinian as soon as possible, because... there is a chance of the well walls collapsing. Since the hole in the ground when flushing turns out to be larger than the diameter of our HDPE, inserting another pipe - with a filter - usually works out without problems.

Correct selection of diameter

Regardless of what type will be used (PVC or any other), it is important to select the exact diameter of the pipe and the thickness of its walls. This determines how productive the well will be, that is, how much water it can produce daily. The smallest diameter that is suitable for the site must be calculated in advance. This way you can reduce financial costs and get the most optimal result.

First you need to calculate the peak water flow. For example, an ordinary water tap at maximum pressure uses about 0.7 cubic meters of water per hour. If you add to this additional household appliances and a bathroom, as well as watering the area, then the consumption will increase significantly. In this case, the maximum water consumption can increase to 8 cubic meters. m. per hour. This consumption is easy to calculate yourself, taking into account everything that can be used for water consumption. After this, you can purchase a pipe made of PVC or other material.

The location from which the water will be taken and the type of pump used also influences.

If we take the maximum water flow rate of 8 cubic meters per hour, then we will need a pump whose diameter should be 102 mm. Next, a simple calculation is made. We take the diameter of the pump, add to it an additional 4 mm for the gap between the pipe and the pump and a wall thickness of 8 mm. As a result, we get a diameter of 114 mm. If the required diameter is not available, then select the one that is closest. They all have a standard diameter - 89, 108 and 114 mm. But it’s better to always make a reserve, just in case.

Materials used for the production of inventory pipes

The traditional material for pipe production is steel, which has high performance characteristics. Today, steel inventory casing with a significant wall thickness is most often used when drilling wells for various purposes.

At the same time, it is worth noting the fact that recently the volume of use of pipes made of polymer materials has increased significantly, which in some characteristics are significantly superior to traditional steel.

On an industrial scale, the production of casing pipes made of uPVC (unplasticized polyvinyl chloride), HDPE (low-density polyethylene), and polypropylene has been established. In terms of strength characteristics, such pipes are practically not inferior to metal products.

Made of plastic

Systems of this type have several types, or rather two: low and high pressure polyethylene - HDPE, LDPE and unplasticized polyvinyl chloride - PVC. This is the most common option for casing wells today. This model can be with or without thread. HDPE models are always equipped with threads. It can be submerged to a depth of 30 meters and can withstand heavy loads - more than 5 tons.

PVC - unplasticized polyvinyl chloride models, have greater rigidity, therefore they are often compared with steel ones. They are the most durable and reliable, unlike HDPE. This material is one of the cheapest today, but despite this, it has better tightness than steel. However, they gained popularity due to the ease of installation and low weight. The main disadvantage of a composition such as HDPE is low strength and poor protection from mechanical damage.

The main advantages of plastic

A material such as HDPE has a number of useful characteristics, including:

- long service life - more than 50 years;

- chemical resistance;

- absolute resistance to corrosion;

- light weight;

- good tightness;

- low cost;

- easy to install.

The easiest way to install such casing systems is if they are threaded. This is the best option for wells of any type.