Crankshaft ratchet

Today it acts as an integral element of various mechanisms and machines. The ratchet mechanism is widely used in the construction of turnstiles, jacks, winch mechanisms and many others. It has also found application in crankshafts.

The ratchet is an intermittent motion mechanism consisting of several components. Its main purpose is the ability to convert reciprocating movements into intermittent rotation exclusively in one direction. In other words, the ratchet prevents the rotation of the axis that occurs against the specified direction.

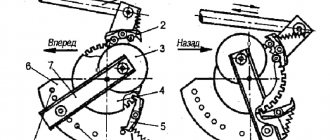

The mechanism of the ratchet device is represented by a gear wheel, the teeth of which are not symmetrical. They are equipped with a stop on one side. Reverse rotation is prevented by a pawl that is pressed against the gear. The dog can be pressed in two ways: most often the dog is pressed against the gear using a spring or a rubber ring, but there is another option - pressing by its own weight.

The pawl is connected to the rocker arm, which makes swinging movements near the center of the ratchet wheel, by a movable joint. It is necessary to grip the ratchet wheel that grips the rocker arm when moving the lever from side to side.

At the moment when the wheel moves in the opposite direction, the pawl easily jumps off several teeth of the wheel. In the crankshaft, this simple but quite important mechanism acts as a means of instant stopping.

Another purpose of the mechanism is to prevent shaft rotation. This is how the ratchet used in the winch design stops the reverse rotation of the drum when lifting the load.

If it is necessary to alternately rotate the shaft from right to left, the teeth are made rectangular and the pawl is reversible. Flipping the pawl allows you to change the direction of rotation of the ratchet.

The required rotation of the ratchet determines the number of teeth. To what fraction of the circle the ratchet is supposed to rotate, the number of teeth is designed. A 60 degree turn requires 6 teeth (one sixth of a circle), a 30 degree turn requires 12 teeth (one twelfth of a full turn). The minimum number of teeth is 6.

When designing, this feature is taken into account; the larger the ratchet, the larger the lever should be. Therefore, the ratchet is made as small as possible. The tooth height is calculated in 0.35-0.4 step sizes. The profile is traditionally rectangular, flat or radial. Designing the mechanism with two levers makes it more stable, preventing distortion during operation. Beveling the end of the tooth makes the stop more reliable.

The crankshaft ratchet allows the crank handle to be attached. With its help, rotational motion is transmitted in the direction from the handle to the crankshaft for starting. The shaft is also automatically disconnected from the handle as soon as possible after the engine starts running.

Source

Ratchet

Ratchet mechanism

(ratchet) - a gear mechanism

of intermittent motion

, designed to convert reciprocating rotational motion into intermittent rotational motion in one direction. Simply put, a ratchet allows the axle to rotate in one direction and does not allow it to rotate in the other. Ratchets are used quite widely - for example, in turnstiles, wrenches, winding mechanisms, jacks, etc.

The ratchet usually has the shape of a gear with asymmetrical teeth that have a stop on one side. Wheel movement in the opposite direction is limited by a pawl

, which is pressed against the wheel by a spring or under its own weight.

Manual drum winch - varieties

A hand winch with a drum is a classic of the genre. In addition to the common element - the pulley on which the cable is wound, the devices have different types of drive.

Single speed gear drive

A large, main gear is firmly attached to the drum. The entire load falls on it, and on the fastening. Therefore, the reliability of the elements must be at the proper level. In mesh with the main one, there is a small driving gear.

The ratio of the number of teeth is the value of the gear ratio. In other words, gain. The drive gear is integral with the drive shaft. Since we are talking about a hand tool, a handle is attached to the shaft for rotation.

The length of the lever also affects the degree of reinforcement. The larger the handle arm, the less effort you need to apply.

With the help of such devices, you can single-handedly lift several centners of cargo or move a car weighing 2-3 tons. At the same time, the rotation speed of the drum is quite high.

Multi-speed gear drive

The design consists of two or more pairs of gears, each of which has a gain of tens of times. With sequential engagement, these coefficients add up, multiplying the force.

The other side of the coin is a proportional reduction in speed. Having such a winch, you can slowly vertically lift loads of more than a ton, but if you have to work with two bags of cement, the lifting time will stretch for tens of minutes.

Therefore, manufacturers have provided the opportunity to use each pair of gears separately. By fixing the handle on a straight pair, we get medium force at high speed. By transferring it to the second pair, we lose speed, but double our strength.

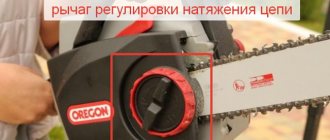

A mandatory element of all manual winches is a stopper, or “pawl”

It works on the principle of a ratchet mechanism. After the force on the handle stops, the teeth of the sprocket rest against the stopper, preventing the cable from unwinding under the weight of the load. This improves safety, but the mechanism has a disadvantage.

It works perfectly when going up, but is completely useless when going down. During reverse rotation, the pawl is simply thrown to the side, releasing the ratchet.

Worm drive

To increase the force, a worm mechanism is used. The principle of calculating the transmission pair, compared to flat gears, is somewhat different, but the technique is the same. A small-diameter helical gear rotates the main gear mounted on the drum.

The advantage of the design is the high gain. Another plus is that the design is self-locking. That is, if you do not apply force to the handle, the machine will stop. This increases safety and comfort.

The handle can be rotated in any direction, lifting and lowering the load - without fear of it falling off.

A serious design flaw is the high friction in the worm pair. The mechanism needs constant lubrication, otherwise wear will be simply catastrophic. When working “dry,” the pair may simply jam.

Considering the mechanics of the process, there are restrictions on the weight with which you can work. But the tool turns out to be compact and is often used in the home.

Planetary reductor

With outstanding compactness (the gear mechanism is actually located inside the drum), the number of gear pairs can reach up to ten. The gain with this design can reach hundreds of times. The only drawback is the high cost of the product, so it is rarely used in everyday life.

Scope of application

Industrial units with components of engineering structures and the operation of small fittings for tools are based on ratchets. This speaks to the versatility of the device and its flexibility in terms of technical integration. For example, the simplest ratcheting mechanism for helmets allows adjustment of the head strap through a wheel that transmits movement to the fixation system.

In instruments, this device serves as a means of setting certain operating parameters. In the design of the pruning shears, in particular, the ratchet allows you to clearly fix the cutting step within a given range. If we talk about more responsible areas, then machine-tool production equipment will come to the fore. Cross-planing units are equipped with external ratchet wheels that can withstand heavy physical loads. In cylindrical grinding machines, this device is used to provide radial feeds - installation is carried out in combination with piston drives. In addition, ratchets are used in winch systems, jacks, starter and winding mechanisms.

Features of operation

The ratchet mechanism makes the tool easy to use:

- Place the blades of the pruning shears where you want to make the cut.

- Press the handles all the way.

- Let go.

- Press until the branch is completely cut off.

The thicker it is, the more pressings you will have to do. Some models are capable of cutting through a branch with a diameter of up to 5 cm in steps. In order for the tool to last as long as possible, it must be properly cared for:

- Before first use, carefully read the instructions and follow them exactly;

- Clean the blades thoroughly after each use;

- regularly lubricate the ratchet with special machine oil;

- sharpen blades in a timely manner;

- treat them with a disinfectant before each use.

WHAT IS A FLYWHEEL NEEDED IN AN ICE? (10 POINTS).

Dear readers of my channel, in this article I will tell you why a flywheel is needed in a D.V.S. In fact, this is a multifunctional part that has many purposes, without which no engine can operate. Many motorists don't even know about it. So:

1. A flywheel is needed to start the engine - all flywheels have a ring gear that comes into contact with the starter bendix and which gives it initial rotation.

2. To mount the clutch - a clutch basket is mounted on most flywheels, except for automatic transmissions.

3. To balance the engine - there are drillings on the flywheel, thanks to which the crankshaft imbalance is eliminated.

4. The flywheel is used to move the pistons from the top and bottom dead centers.

5. To install the crankshaft position sensor - informs the controller about the valve timing.

6. The flywheel is used to set the ignition timing (there are marks on it - early, late).

7. The flywheel serves to remove heat from the Ferado disk. (flywheel + pressure plate).

8. The flywheel is used to jam the engine (for example, there is a special hole where a pry bar is inserted and the engine is wedged by the ring gear, after which you can unscrew the ratchet, gears, and flywheel).

9. The flywheel is used to crank the engine when setting the ignition timing (you can’t adjust it to the marks with a starter). See photo above.

10. The flywheel is used to transmit torque to the transmission.

In this article you have received comprehensive knowledge on the purpose of the flywheel in an internal combustion engine. I hope that with the help of these questions you have increased your knowledge and become an advanced motorist, and have also become head and shoulders above any other motorist. In one of the following articles, I will tell you in detail about the most terrible phenomenon - “ENGINE DIVERSION” (what causes it and how to deal with it).

Dear readers of my channel, like (thumbs up), subscribe, write in the comments (we will answer).

Source

How does a ratchet mechanism work?

The spread of the ratchet mechanism can be associated with a fairly simple mechanism and operating principle, which ensures a long service life. The ratchet as a part is in many ways reminiscent of a ratchet element, since a corresponding sound occurs during operation. The features of the operating principle include the following points:

- The main part is represented by a hook, lever or drive. The trigger element activates the entire system.

- At the beginning of operation, the pawl is engaged with the wheel, but after activating the mechanism, the main element performs axial rotation. In this case, the latch moves a small distance relative to its original location.

- Traction can be represented by various mechanisms. You can often find a mechanism that provides force adjustment.

- At the moment of axial rotation, the dog slides along the surface. Due to intermittent movement, in some cases it is not possible to use the mechanism in question, as a strong hum occurs.

- The pawl, which is necessary to ensure the functionality of the device, at the moment the axial rotation stops, falls into a special groove, due to which the main part is fixed.

Operating principle

As the toothed part moves in the forward direction, the pawl slides along the tops of the teeth. When the dog jumps from one tooth to another, you can often hear the characteristic sound of a rattle. Anyone who has ridden a modern bicycle has heard this sound while coasting.

Example of a ratchet mechanism

When changing the direction of movement of a rack or gear, the pawl rests on the steep slope of the tooth and does not allow the part to rotate freely in this direction.

As engineers say, the uniqueness of freewheel ratchet mechanisms compared to other MSKh lies in the closure of the mechanical diode under the action of tangential forces (Latin tangens - tangent), i.e. acting tangentially to the ratchet. The rest of the MSKh (ball, roller, crack type) operate on the principle of frictional wedge closure.

Below is an example of how a linear ratchet works with a rack instead of a gear.

An example of the operation of a linear ratchet mechanism with a rack

Ratchet mechanism for lashing straps

Samson LLC products are delivered to all regions of Russia and neighboring countries. When placing an order with us, you can choose the most convenient way for you to receive the goods.

- Pickup.

- Delivery by transport company.

- Courier delivery service.

Transportation of finished products is carried out by leading Russian forwarding companies, which are ready to offer various delivery methods and convenient terms and transportation schemes.

For small consignments of goods, the most popular service is that of transport companies for the delivery of groupage cargo. Our company delivers goods to the TK terminal free of charge, in this case the buyer is responsible for paying for the service of transporting goods between terminals and delivery to the door (if necessary).

To send large cargo or large consignments of goods, it is possible to charter special vehicles or containers.

The order is dispatched after receipt of payment to the company's bank account within the time period agreed with the recipient. Cargo is delivered to the transport company’s terminal 2 times a week – Tuesday and Thursday.

You can get more detailed information from our managers or on the official websites of TC.

Shipping cost calculator:

Ratchet wheel calculation

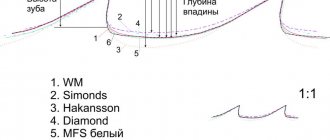

The relationship between the tooth width b and the module m is determined by the coefficient ψ=b/m, the values of which are given in Table 1. Larger values of the coefficient ψ are taken for those working with significant impact loads. The width of the pawl is taken to be 2-4 mm wider than the tooth of the ratchet wheel in order to compensate for possible installation inaccuracies. Using the equations given above, we obtain the expression for the wheel modulus:

If the number of teeth is unknown, but the diameter of the ratchet wheel is known, then it is more convenient to use the expression:

With a ratchet wheel module m≥6 mm, you can limit yourself to checking the tooth by bending. The fracture plane of the tooth (Fig. 1, b) is located at a distance h = m from the top of the tooth. The height of the design section of the tooth of the ratchet wheel with external gearing is taken to be a = 1.5m. Then the moment bending the tooth:

The moment of resistance to bending when considering the tooth as a beam fixed at one end:

The bending stress must satisfy the inequality:

Taking the permissible stresses [σ and ] = σ in /n for cast iron and [σ and ] = σ t /n for steels, where the values of n are indicated in Table 1, we obtain the expression for the modulus:

With internal gearing, the teeth of the ratchet wheel are much stronger, since in this case the height of the design section of the tooth is a = 3m. The module is determined from the expression:

How to make your own ratchet?

The design technique will depend on the requirements for the system in which it will be used. As a basis, you can take a shaft in the form of a piece of metal pipe, a cutout from a steel sheet and a piece of profile that will act as a “dog”. The main difficulty will be in adjusting the dimensions of these components, because only with optimal alignment can the stable operation of the ratchet mechanism be ensured. You should also make a supporting base with your own hands - a metal frame assembled from the same steel sheets is used for it. By welding, a shaft is attached to it on both sides, onto which a pre-processed disk with cut grooves sits. To install the pawl, a running clamp with a spring system should be provided. Installation is carried out using hardware or welding.

Rules for working with ratchet pruners

The basic rules for operating pruners with a ratcheting mechanism are to maintain the tool in working condition and correctly define the area of work.

Principles of working with ratchet pruners:

- Thoroughly clean the blades after each use of the tool.

- Regular lubrication of moving parts of the mechanism.

- Regular sharpening of knives.

- Treat the blades with a disinfectant before using the pruning shears.

- Control over the position of the protective lock.

Secateurs Mr Logo

Something to remember! This tool is effective when processing large branches and sanitary pruning. Using ratchet pruning shears with thin shanks will require additional effort and take longer than using other types of pruning shears.

Manufacturers often supplement the tool with a variety of functions and accessories, which you should find out about in advance.

Note! The key to high-quality and long service life of pruners is to study the instructions for the tool and follow them.

Backlash

Backlash is a gap, free movement of one part relative to another. In a rack or pinion ratchet mechanism, the maximum play is the distance from one tooth to the next.

In devices in which it is necessary to reduce the reverse movement to almost zero, instead of a gear or rack, a part with a smooth elastic surface with a high friction force, for example, made of rubber, can be used. In this case, during the reverse stroke, the pawl will “stumble” on the rubber, and when it is buried in the elastic material, the mechanism will jam.

Types of mechanism

There are a wide variety of friction ratchet mechanisms available on the market. They can be used to implement a wide variety of tasks. Among the features of the classification, we note the following points:

- The profiled surface is often made in the form of a drum or rack.

- The rack-and-pinion version is extremely rare, since the functionality of the device is significantly reduced. Drum friction ratchets are much more common due to their compactness and other properties.

- The base profile is also classified according to a large number of characteristics. The most common are radial, rectangular and flat designs. Radial ones are widely used because they are compact and easy to install.

In most cases, the tooth has a classic shape, which ensures reliable operation.

Features of the operation of bidirectional mechanisms

Many ratchet mechanisms are characterized by the fact that the rotation of the wheel or rack is carried out in only one direction. They also began to produce versions that can rotate in both directions. The key points are the following:

- Rotation is realized left and right. It is this moment that significantly increases the functionality of the device.

- The shape of the teeth is rectangular. Only this ensures uniform rotation of the wheel in both directions.

- A key feature is also how the locking pawl works. At the moment of rotation of the main element, it does not jump, but rises. Due to this, the device becomes more functional, but at the same time less reliable.

The scope of application of such an element has become very widespread today. A variety of materials can be used in its manufacture; in most cases, attention is paid to versions with increased corrosion resistance.