Drain-overflow system: technical features

The piping, also known as the drain-overflow system, is a structure consisting of pipes hermetically connected to each other. It is this that ensures the drainage of wastewater into the sewer system and also protects the bathtub from overflowing.

Diagram: bath drain device

The drain-overflow system must be equipped with a siphon, which prevents the appearance of an unpleasant odor in the bathroom. Water from the overflow hole enters the sewer using an auxiliary pipe. Most often, a corrugated tube is used, which can be stretched to the desired size and bent to the drain in any direction.

Advice! When choosing a drainage system, you need to pay attention to all the external parts that frame the bathtub openings. In a quality product they are made of stainless steel.

When buying a drainage system for a bathtub, you should definitely pay attention to the quality of the parts. It is also important to check the presence of seals and cuffs; the absence of one of them will certainly lead to a flood after the first filling of the bath. Seals are necessary to ensure the tightness of the structure and prevent leakage.

Siphon with drain-overflow system for the bathroom

At the moment there is a large selection of harnesses. From simple plastic siphons to chromed metal structures with special ornaments. Modern technologies make it possible to satisfy the requirements of the most capricious customers. Drain-overflow systems are divided into:

- a simple siphon equipped with a stopper;

- semi-automatic system;

- automatic drain-overflow system;

- filling machine.

Semi-automatic drain-overflow system

Each of these systems has its own advantages and disadvantages. And in order to decide which bathtub drain and overflow is better, it is necessary to consider each design in more detail.

What types are there?

There are not many varieties of this product based on the way it works. There are 3 types in total, which are completely different from each other:

- Mechanical systems;

- Semi-automatic;

- Automatic.

The name of each system is conditional. It reveals only the operating principle that occurs inside the equipment; automatic systems do not have any special features that allow control via a smartphone. To make it easier to navigate the store, it is important to know what the main differences between representatives are.

Mechanical option

Open overflow neck and drain hole, which is closed with a lid. Here are the main features of the equipment. The upper part can be covered with a decorative element. This does not make the throughput any worse. All functions work perfectly.

To close the bottom drain, the kit includes a special cover, which is made of plastic or metal, but has a rubberized part that ensures a tight fit. For greater convenience, some manufacturers equip the element with a chain; it allows you to quickly find the plug under water.

In many bathrooms, the mechanical product is in high demand. Because the bath itself has a long service life and is rarely changed. Of course, the product cannot provide any special features, and all actions are reduced to manual control, but its reliability has been proven over the years.

Advantages:

- Low price of equipment;

- Easy installation;

- Good durability indicator;

- Reliability.

There are disadvantages, not many of them, so most of them are conditional:

- An outdated option that is not suitable for lovers of modern solutions;

- Sometimes the plug can get lost, especially if there is a child in the apartment.

Semi-automatic devices

A modern option that features additional functionality and an affordable price. The equipment is equipped with special elements that increase operating comfort. The design of this device is much more complex, so installation work is recommended to be carried out by plumbers.

Advantages of execution:

- Convenient adjustment of the water level; a person does not need to come into contact with the water to find the plug; just turn the lever or press the button located on the overflow neck.

- Beautiful external design that stands out from the general background.

Flaws:

- If the user uses the drain hole control device several times a day, the cable will quickly become unusable and begin to work incorrectly.

- It is not recommended to install the structure in apartments where hard water flows through the water supply, because plaque will begin to form on the main elements. This will cause the equipment to break down after a couple of years of use.

Due to the fact that the system is equipped with a rotating element, this is its weak point. Therefore, the following problems occur:

- Cable breakage due to severe wear;

- Damage to the drain element;

- Flywheel failure.

There are many options for the formation of problems, so when choosing this product, attention is paid to the manufacturer and material. Everything must be manufactured at the highest level so that unexpected malfunctions do not occur. It is advisable to provide a long warranty. We also must not forget about proper operation; compliance with these rules often extends the service life by 2 times.

Automatic equipment

Of course, there is no complete automation in this product; all actions are performed using mechanical forces, as in the previous version. There are also differences, for example, to open or close, an intermediate element, for example, a cable, is not used, all actions are performed directly. This mechanism is located in the drain neck.

Advantages of the system:

- Ease of use;

- Beautiful appearance;

- There are practically no breakdowns, since there are no transmission mechanisms.

Despite the positive aspects, such equipment also has disadvantages:

- To descend from a bathtub where there is a large amount of water, you will have to dip your hand in the liquid and press the corresponding button;

- If the valve fails, a person will have to buy a new model, since the product cannot be repaired;

- Sometimes there are breakdowns of the latch where a spring is used. However, this element can be replaced, the main thing is to use the same model.

- Low bandwidth.

Disadvantages and advantages of the automatic system

An automatic drain and overflow system for a bathtub is one of the most complex designs. In its structure, it is not much different from any other. The main feature of such a piping is that its drain part is equipped with a “click-clack” valve.

The system is very easy to use and does not require the use of any additional devices: rotary levers or locking plugs. With a light press, the user closes the drain hole, and repeated action will allow the water to flow into the sewer pipe. It is very convenient to control the valve with your foot while directly in the bath. You just need to step on it while standing in the shower.

Diagram: automatic drain system device

However, this system also has a number of disadvantages; it should be noted that the automatic siphon is:

- Expensive pleasure. A good quality automatic system will cost several times more than a conventional mechanical siphon with a bathtub stopper. That is why the choice often falls on cheaper models.

- Frequent breakdowns. A system with automatic shut-off of the drain hole, made of insufficiently high-quality materials, can quickly fail. When purchasing such a design, you should pay special attention to the company and country of the manufacturer. German manufacturers have proven themselves best: they carefully monitor the quality of the product in order to maintain the brand.

To fill the bath, the automatic drain system will also need to be closed manually - Bend over again. This applies to those people who like to rationalize their every action. If you need to fill the bath in advance or use it for other purposes, then in order to block the drain hole you will need to bend over and do it manually.

Important!

The quality of any product determines its cost. The lower the price, the shorter the service life of the structure. You should also know that if the spring that holds the valve and operates it (the most vulnerable part of the automatic system) fails, the entire structure must be replaced.

Installation

You can install the drain and overflow yourself, but it is important not to forget that the tightness of the bathtub in the future depends on the quality of the work. However, despite all the responsibility, installation of the system can be carried out by a non-professional; you just need to listen to the advice of specialists.

General recommendations:

- Follow a certain sequence in your work;

- Use special sealants to process connections;

- When tightening parts, be careful not to strip the threads;

- All elements must be tightened one quarter of a full turn after hand tightening;

- If you cannot tighten the connection, you need to check whether the nut is level.

Installation begins after the bowl is secured to the support. The bathtub must be leveled and fixed. It is also necessary to leave a height gap between the floor and the tank (from 150 mm or more).

Correct sequence:

- The bottom hole of the bathtub is connected to a tee. In this case, you need to process the connection using a sealant and secure the elements with a screw;

- Next, attach the siphon and secure it with the tee outlet with a nut. A rubber cuff can be used as a seal here;

- The overflow neck is connected to a side curved tube (siphon);

- The process is completed by connecting the siphon to the sewer pipe. For this purpose, a special spout pipe is used;

- During each connection, you should remember to lay the seal.

After installation is complete, you need to check the bathtub for leaks. The bowl is filled with water, then you need to carefully examine all the joints and connections. If drops appear on the surface, tighten the elements more tightly and re-treat with sealant.

Siphon installation video:

Semi-automatic siphon and its best aspects

The semi-automatic drain-overflow system, despite its ease of use, is a rather complex design. In addition to the standard hermetically connected pipes for draining waste water and an overflow system, models of this type are equipped with a shut-off valve, which is actuated using a lever mounted on the overflow hole. It is made in the form of a decorative handle or valve.

Operating such a drainage system is quite simple. The user turns the control lever 90° and the shut-off rod rises, opening the drain hole, and if you turn the handle in the opposite direction, the rod lowers, making it possible to fill the bath with water.

Diagram: semi-automatic drain device for bathtubs

The system works thanks to an auxiliary cable, the tension of which allows the plug to rise and fall. The design of the valve control handle can be varied. The most popular models are designed as:

- buttons;

- rotary ring;

- handles;

- decorative valve.

The overflow device in such systems is hidden under the control handle of the drain structure. This gives the harness a more aesthetic and stylish look. Also, one of the advantages of such a system is ease of use. By turning the handle located at the top of the bathtub, the user does not have to wet his hands or once again bend down to the bottom of the bathtub.

Semi-automatic drain with decorative valve

And if we talk about the disadvantages of such a system, it should be pointed out that the design is quite complex and has a lot of connecting and moving parts, and therefore attention should be paid only to models from responsible and conscientious manufacturers who have already proven themselves in the plumbing fittings market.

There is a type of semi-automatic drain-overflow system that allows you to fill the bathtub. This is the most complex of all automatic and semi-automatic harnesses. To install such a structure, it is necessary to supply water pipes to it. Using this type of piping, you can eliminate the installation of a mixer for filling the bathtub.

The best manufacturers

The name of the manufacturer is a guarantee of quality, and when it comes to such important plumbing equipment, it is better not to skimp on quality and trust only trusted companies. It is difficult to list all the worthy ones - we will mention only the largest and most trusted manufacturers of drains and overflows:

- GROHE is a famous German company that offers automatic and semi-automatic siphons. The quality, design, assortment are at their best, but the prices are appropriate;

- HANSGROHE is German quality. The company produces piping from sanitary plastic, the external elements imitate a metal coating. The range includes automatic and semi-automatic systems. The drain and overflow from this company is traditionally of high quality, but if something happens, components for repairs are not difficult to find;

- GEBERIT is a Swiss company that produces automatic and semi-automatic systems, which are distinguished by a special siphon shape, which accelerates the outflow of water;

- Cersanit is Polish sanitary ware of very good quality. Prices are affordable, there is enough choice, which determines the popularity of the brand in the domestic market;

- Ideal Standard is a brand of reliable German plumbing products. The harnesses are made mainly of plastic, the external elements are chrome plated. The price-quality ratio is excellent;

- Kludi is a German company that specializes in the production of semi-automatic siphons. The quality is at a high level, but prices are sometimes high;

- RAVAK is a relatively inexpensive Czech plumbing product. The assortment, although inferior to market leaders, is still sufficient. There are automatic and semi-automatic systems. The quality is excellent and the price is reasonable;

- JACOB DELAFON is a French manufacturer that makes plastic products with chrome-plated external elements. The products are very popular in Russia, as they have an excellent appearance and excellent performance;

- KAISER is a German manufacturer whose product range includes strappings made of non-ferrous metals. The products combine high quality and relatively low price;

- ALCAPLAST is a Czech company that produces mechanical, semi-automatic and automatic drains;

- Triton is a domestic company that focuses mainly on semi-automatic systems made of chrome-plated plastic. The products are of good quality and reasonable price.

Economical system. Cheap and easy.

The simplest design of a bathroom drainage system is a mechanical drain-overflow system. There are no moving parts or levers and therefore it is the most reliable of all other types of harness.

Mechanical bathtub drain and overflow system

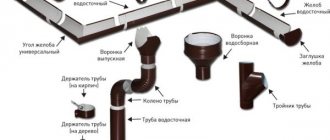

The system consists of several main parts:

- Drain neck. Placed at the bottom of the bathtub, connected to the siphon.

- Overflow pipe. Mounted on the overflow hole.

- Corrugated tube. With its help, the overflow pipe and the main part of the system are connected.

- Siphon. A U-shaped pipe that acts as a shutter. Prevents the spread of odors from the sewer.

- Spout pipe. Ensures the passage of wastewater into the sewerage system. Such a pipe can be a corrugated hose or a straight pipe, depending on the location of the sewer outlet.

- A plug blocking the drain hole. Most often it is connected by a chain to a grille installed on the overflow.

Connecting the plug

This system is very easy to assemble and install; anyone can handle it, even without in-depth knowledge in the plumbing industry. As a rule, failure of such a siphon is caused by wear of the sealing joints.

Advice! To increase the service life of sealing cuffs and gaskets, they can be pre-lubricated with silicone grease.

Classification of types of drain mechanism

Three types of devices are considered and each has its own design features.

Standard type device

This simplest design is represented by components:

- a siphon is represented by a pipe. It stops the penetration of unpleasant odors into the room;

- drain hole for overflow;

- liquid outlet hole at the bottom of the bowl;

- connecting tube for siphon and sewer pipe;

- The liquid is poured through a corrugated pipe into the siphon.

The mechanism is called traditional. When the drain neck is closed with a stopper, water is drawn into the tank.

Operational problems may arise with rubber gaskets. They change periodically. The price of a standard mechanism is 10-25 dollars.

It is classified as a reliable mechanism, since there are no moving elements in its design. The simple drain design is easy to assemble and install yourself.

Differences between automatic and semi-automatic mechanisms

Structurally, the drainage mechanism for the bathtub is designed in two types:

- automatic bath drain;

- semi-automatic in the bathroom.

Automatic bath drain

The device is also called “click-click”. The system works very simply. At the bottom of the bowl there is a button that starts the automatic siphon. The first press of the button opens the drain, the second press closes it. The operation of the mechanism depends on the spring that is attached to the system plug.

Plastic or metal?

Very often, buyers ask the question: “What material should the drain-overflow system be made of?” Currently, manufacturers use several basic materials for the manufacture of strapping:

- plastic;

- black metal with chrome plated;

- non-ferrous metal;

- stainless steel.

Plastic siphon

Plastic siphons have the most favorable cost and a relatively long service life. But their aesthetic appearance leaves much to be desired. The same can be said about ferrous metal systems. Manufacturing companies are currently increasingly resorting to the use of such raw materials.

Non-ferrous metal and stainless steel are the most expensive materials, but they are practically not subject to corrosion. Products made from such raw materials have a special style and can complement the overall look of the bathroom decor. For example, if the design idea was for a retro-style bathroom, then a siphon made of processed brass in an open bathroom (without using a decorative screen) will look very organic and stylish.

Brass bathtub overflow

When purchasing a bathroom fixture, always pay attention to the quality and brand of the manufacturer. These are the determining factors in choosing a drainage system. This is especially true for bathtubs covered with decorative panels and screens. The user’s desire is to look under the bathtub as little as possible, so it is better to install a structure of the highest quality, and thus insure yourself against leaks for a long time.

What are the devices made of?

In previous years, when the plumbing equipment market was not particularly diverse, the main elements of the system were made of ferrous metal.

In principle, such structures can properly serve for decades; their only drawback can be considered their unsightly appearance

The materials for the manufacture of the main elements of modern systems are most often:

- sanitary plastic;

- non-ferrous metals.

Polypropylene is affordable. It is famous for the fact that it does not rust and is resistant to water, “rich” in salt content. But in comparison with metal, when arranging a bathroom, plumbing plastic looks very budget-friendly.

And in bathrooms decorated in exquisite design - it’s completely ridiculous. You should choose plastic piping if you plan to install a screen under the bathtub.

In terms of design and excellent performance parameters, metal bindings are the leaders: although they are more expensive, they allow you to maintain the desired style

Among non-ferrous metals with high corrosion resistance, the most common are copper, bronze and brass. As a rule, they are not used in their pure form.

Opening mechanisms, drain grates and other visible parts are coated with nickel or chromium using electroplating technology.

Metal strapping is advantageous in that it practically does not deteriorate over time; the service life of such products is more than 10 years. They need timely cleaning, which is not difficult to do by disassembling the washer connection.

Chrome parts are “vulnerable” to mechanical stress. The slightest scratch can ruin the protective nickel-plated film; over time, the coating will simply “wash off”.

Nickel parts are renowned for their durability. But they are significantly inferior to plastic in terms of resistance to mechanical stress. Bronze products are much harder and more durable.

The easiest way to visually determine what metal the system elements are made of is by the color of the metal:

- copper is a rather soft and ductile metal with a reddish tint;

- bronze is a durable alloy of copper and tin, which is closer to dark brown in color;

- brass - is a harder alloy of zinc and copper, colored yellowish.

In interiors decorated in classic and retro styles, trims made of brass or bronze will look good

For modern styles, nickel-plated models with a shiny surface are more suitable.

Bathtub drain and overflow system: photo

Main selection criteria

The main selection criteria include:

- price;

- completeness of the system (presence of main and control elements, seals, etc.);

- material of manufacture;

- distance from the drain hole to the floor;

- diameter of siphon and sewer outlet;

- bathroom design, the presence of a decorative screen;

- system manufacturer;

- the presence of additional functions (water supply, branches for a dishwasher and washing machine).

If you have a small budget and do the repairs yourself, you need to choose a mechanical drain and overflow. In addition to the type of system, it is worth considering the configuration of the siphon. The water seal (glass) of the pipeline must have a volume of at least 300 ml.

Installing a drain siphon

Of course, you should also study all the features of the installation process. In the kit for the drain and overflow, the manufacturer usually provides small installation instructions, and if everything is done according to it, you will be able to install the device. But problems may arise in the process. The installation principle for semi-automatic and conventional devices is almost the same. Everything is done in several stages.

- If we are talking about replacing an old siphon with a new model, then you should dismantle the device and carefully clean the fastening elements (so that nothing interferes with the elements performing their functions).

- It is necessary to take the bottom overflow, install a rubber gasket in it and attach it to the drain hole. At the same time, with your free hand you need to place the upper element on the hole, insert the screw and tighten it. But it’s worth considering that you don’t need to screw it in too tightly, because the body of the part is quite fragile.

- The upper part, the overflow, is installed in the same way. It is better to install the pipe, which is designed to drain excess liquid, not vertically, but slightly to the side, this will make it more convenient to install.

- At the next stage, the drain and overflow must be connected to each other; a corrugated hose is used for this purpose. But in no case should you cut it to shorten the element; you can bend it a little. First you need to put the nut on the corrugation and only then install the gasket.

- A water seal is attached to the drain pipe under the bathtub bowl. Here you should take into account such a nuance that before connecting the elements you need to carefully inspect the fasteners and find out if there is any damage or other problems. All burrs and casting defects must be cut off to ensure high-quality sealing.

- After this, you need to attach the pipe to the water seal. This is necessary in order to connect the device to the sewer. Everything is done in the same way as connecting the pipe and the valve.

- Connecting the siphon to the sewer. Here it is necessary to take into account that in some variants of drains and overflows the connection is made directly into the socket of plastic structures, in other variants a sealing collar is used.

- After that, all that remains is to check the build quality. This is very simple to do, you just need to open the tap and fill the bath bowl with water. If there are no leaks when the drain is closed, then everything is installed correctly.

Types and features of materials

The main condition when choosing a material is corrosion resistance. These options include:

- Bronze, brass or copper. Often these non-ferrous metals are not used without a protective layer. Parts located in the visible area can be coated with nickel or chromium (using the electroplating method). The use of nickel is preferable; this material is characterized by long-term operation. The visual difference of nickel is the blue tint of the parts;

In order to determine the type of metal, you should pay attention to the holes in the top and bottom of the bath. The color of copper is red; the strength characteristics of copper are inferior to other materials. Brass is stronger than copper and has a light yellow tint. The bronze base is the most durable in this category, comparable in stability to ferrous metal. Bronze is characterized by a dark brown tone; the main components of the alloy are zinc and copper. Non-ferrous metals are an excellent option for the production of plumbing fixtures. Due to the resistance to corrosion, the parts are easily connected by thread.

Tips for care and use

To extend the life of the overflow system, you need to follow a number of rules:

- during repairs, provide a technological hole or door in the decorative screen;

- regularly inspect connections and pipes for damage and leaks (you need to be most careful with plastic parts);

- wash the siphon with hot water and soda, vinegar or citric acid at least once every 1-2 months;

- 1-2 times a year check the tightness of the pipeline and replace worn gaskets;

- when draining water slowly, unscrew the water seal glass and clean it of debris;

- If a blockage occurs, pour alkali solutions into the drain hole to clear the sewer;

- promptly replace rusted parts (screws, metal grilles, etc.).

Damage to the corrugations, chips and microcracks on the siphon are reasons to replace the system. If the automatic device button or control lever stops working, you can disassemble them and put them in a weak acid solution. This will remove the layer of salt deposits and restore the mobility of the elements.