Selection of hydraulic cylinders

The force developed by one hydraulic cylinder is determined by the load and the coefficient of friction.

For example, the mass of the moved cage is m=51t.

Friction coefficient, taking into account the impossibility of assessing the condition of contacting surfaces

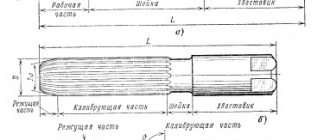

The piston diameter is selected based on the standard range of Duplomatic HC3 hydraulic cylinders and a pressure of 130 bar - D = 200 mm. Based on the force developed by one hydraulic cylinder, its mounting scheme, and reference length, we select the diameter of the hydraulic cylinder rod

where L is the stroke of the hydraulic cylinder,

i – stroke index.

The design point lies between the 56 mm and 70 mm rods.

We take the rod diameter to be d = 125 mm based on the piston diameter of the HC3 cylinder.

Calculation of the hydraulic cylinder for lifting loads

Forklift mechanisms Read more: Calculation of a hydraulic cylinder for tilting a forklift

2.1.2 Calculation of the hydraulic cylinder for lifting loads

The diameter of the plunger is determined by the formula:

(20)

where is the number of hydraulic cylinders operating simultaneously; (=1)

operating pressure in the system, MPa; (in accordance with the analogue, we accept 16 MPa)

– pressure loss (total resistance) in the pressure line from the pump to the cylinder, kgf/cm²; ;(in accordance with the recommendation [2], we accept = 0.5 MPa)

– mechanical efficiency of the hydraulic cylinder; (in accordance with the recommendation [1], we take =0.96 MPa)

Efficiency of a pair of grease-lubricated plain bearings; (in accordance with the recommendation [2], we take =0.94 MPa)

In accordance with the recommendations [3], we accept a hydraulic cylinder with the following parameters:

According to recommendation [1], we take the plunger stroke equal to half the maximum lifting height of the load:

2.1.3 Calculation of the cross-section of the forks

Load forks are designed to withstand complex bending and tensile strength. Section A – A.-Figure 2 is considered dangerous; in this section the forks are stretched by force:

21)

where is the nominal lifting force;

dynamic coefficient, (in accordance with recommendations [1], we accept 1.2)

In section A – A the forks bend at the moment:

(22)

Voltage arising in the dangerous section of the forks:

(23)

where and are the section and moment of resistance of the forks.

According to the recommendations [2], we accept the following parameters of cargo forks: Width = 150mm, thickness = 60mm.

Then the moment of resistance will be equal to:

(24)

(25)

We assume that the forks are made of 45 Steel with a yield strength

Examination:

The permissible stress is determined by the formula:

(26)

The condition is met.

2.2 Calculation of the tilting mechanism of the forklift

The greatest force on the rod of the forklift tilt cylinders occurs when the forklift with a load is tilted forward at the maximum angle α.

For the calculation, we assume the following positions: the center of gravity of the load in height is in the middle of the rollers at the lifting carriage, and horizontally - at a distance l (Fig. 3) from the front back of the forks; the center of gravity of the carriage with forks is in the middle of the thickness of the fork back; the center of gravity of the forklift frames together with the lifting cylinder is in the middle of the frames.

Let us accept the following notation and assign the necessary data

= — cargo weight (as specified); (61740N)

— weights, respectively, of the lifting carriage with the forks of the retractable frame with the plunger of the lifting cylinder and the traverse with rollers and the outer frame;

=6468N, =3175.2N, =3492.764N

— height from the axis of rotation of the forklift, respectively, to the center of gravity of the load and the lifting carriage with forks, retractable and outer frames, and to the axis of attachment of the tilt cylinder rod to the outer frame; =2.89m,

, ,

where k is the scale factor equal to 32.2

-length of the lower frame

— the distance of the center of gravity of the load from the axis of the frames, equal to ;

— the distance of the center of gravity of the lifting carriage from the axis of the frames, equal to

;

— the distance between the hinges of the lifting axis of rotation and the cylinder rod and the tilt cylinder rod on the outer frame;

,

a – horizontal distance from the middle of the frames to the center of rotation of the lift;

— force on the cylinder rods;

φ — angle of inclination of the cylinder, taking into account the angle of inclination of the forklift forward at an angle α=20, φ=350

Let's create an equation of moments around hinge A (Fig. 3)

(27)

Figure 3. Diagram of the action of forces in the tilt mechanism of the forklift

Solving this equation for , we obtain the total force on the tilt cylinder rods.

Therefore, as a result of solving the equation, we obtain:

Forklift mechanisms Read more: Calculation of a hydraulic cylinder for tilting a forklift

Information about the work “Forklift mechanisms”

Section: Transport Number of characters with spaces: 33525 Number of tables: 3 Number of images: 7

Similar works

TOYOTA forklifts

21118

4

32

... dust), low-temperature models (for working in freezers). Diesel models are equipped with an in-line high-pressure fuel pump (this system is installed only on TOYOTA loaders), which ensures reliable operation on low-quality fuel; have a special 3-stage fuel purification system and an automatic gearbox, generator and battery...

Technology, organization and planning of port transshipment operations

602919

33

69

... dockers' skills. 23. SYSTEM FOR PROVIDING TRANSFERING OPERATIONS WITH TECHNOLOGICAL EQUIPMENT The system for providing equipment for technological processes of port transhipment operations includes: supply planning and production of mechanisms and devices; keeping them in good condition, i.e. registration, inspection with testing, periodic inspections, maintenance and...

Single-bucket excavators. Tower cranes. Loading and unloading machines

70804

0

11

... the functional purpose and specific application of such equipment. Based on the operating principle, a distinction is made between cyclic and continuous loaders. The former include single-bucket and forklifts, while the latter include multi-bucket loaders. According to their purpose, loading and unloading machines are divided into loaders for piece goods - forklifts and for bulk and small-piece materials - one ...

Types of forklifts

32487

0

33

… . Depending on the direction of the bucket unloaders relative to the side of the stack being developed, loaders can be front (front loaders), side (semi-swivel loaders) and rear (changeover) unloaders. Based on the type of equipment used, loaders are divided into universal and specialized; in the first case, in addition to the bucket, replaceable equipment of other types is used; in the second case, instead of...

Determination of working pressure*

The working pressure required for the hydraulic cylinder to develop the required force Fc is determined by the formula:

= 30 bar – total losses along the length of the lines and guide equipment at a viscosity of 300 cSt (at a temperature of 0°C).

Calculated (recommended) internal diameters of main pipelines

Pressure dpress = 32 mm (DN 32).

Drain ddrain = 50 mm (DN 50).

S pcs. 19144 mm2 – area of the hydraulic cylinder rod cavity;

*Working pressure is calculated based on the force developed by the hydraulic cylinder and the dimensions of its cavities (dimensions) and is selected based on the minimum cost of hydraulic system components - pumps, hydraulic cylinders, pipelines.

Driving force and speed of hydraulic cylinder piston

28. Driving force and speed of the hydraulic cylinder piston

28.1. Advance paynemt

Design driving force F

on the rod, developed by the liquid pressure

p

on the piston (the friction of the piston and rod, as well as the back pressure in the non-working cavity and the inertial force are neglected), is simplified by the formula:

, N

where S

– working (effective) area of the piston.

Working area S

The piston for a single-rod hydraulic cylinder with two working cavities (Fig. 7.1,

a

) is determined by the formulas:

- when supplying liquid to the piston cavity:

,

- when supplying liquid to the rod cavity:

, where D

and

d

are the diameters of the piston and rod.

With an equal supply of fluid to the piston and rod cavities, the movement speeds of the moving part of the cylinder will be determined (without taking into account fluid leaks) from the flow equation Q

liquid entering the cylinder according to the formulas

; , υп < υsht m/s.

28.2. Calculation of driving force taking into account inertia and friction forces

Rice. 7.2.

– Design diagram of the hydraulic cylinder

According to the design diagram Fig. 7.2, the equilibrium condition of the hydraulic cylinder piston during acceleration with a payload to the speed of steady motion is determined by the relationship:

F

st

= F + Ff + F

tp

+ F

in

+ F

s

where F

st - design (static) load, N;

F

— payload applied to the cylinder rod H;

Ff

— the friction force of the moving parts of the hydraulic cylinder, taken into account when the latter is horizontal, N;

F

tr is the friction force that occurs in the seals of the rod and piston, H;

F

in is the inertia force of moving masses kinematically rigidly connected to the piston rod, H;

F

c is the backpressure force, N.

Design force F

st – is the driving force, an integral part of the expended energy in the hydraulic cylinder.

When the piston moves to the right: , where D

– cylinder diameter, m;

p

n

–

pressure of the working fluid in the pressure cavity of the cylinder, Pa.

As studies have shown, the optimal value of the working fluid pressure in hydraulic cylinders is a pressure of 25...30 MPa, at which the greatest economic effect is realized: the lowest metal consumption and moderate costs for the manufacture of hydraulic cylinders.

When the piston moves to the left:

where d

— rod diameter, m.

Friction force Ff

consists of the static friction force

Ff

p and the motion friction force

Ff

d, which are determined by the formulas:

and , where μ0 is the static friction coefficient μ0 = 0.15.

G

– weight of moving masses kinematically rigidly connected to the piston rod, N.

μ – motion friction coefficient; at low speeds (υ<0.05 m/s) and steady motion μ = 0.1...0.12; at high speeds (υ>0.05 m/s) and good lubrication μ =0.05...0.08.

If rubber cuffs or cuffs of reduced cross-section are used as rod and piston seals, then the friction force created by these seals is as follows:

and , where D

and

d

– sealing diameters, m;

b

– compaction width, m;

k

– specific friction;

when operating on mineral oil k

= 0.22 MPa.

If metal rings are used in the piston for sealing, then the friction force is determined by the formula:

, where b

– ring width, m;

p

k = 0.09…0.1 MPa – ring pressure on the inner surface of the cylinder;

f

1 – friction coefficient: during steady motion

f

1 = 0.07, during acceleration

f

1 = 0.15).

Inertia force F

in is determined by the formula:

where m

– mass of moving parts, kg;

a

–

acceleration m/s2;

υcp – average speed at the moment of acceleration, m/s;

l

p is the path traveled by the piston during the acceleration period, m;

Given the total travel time of the hydraulic cylinder piston t

and the distance (stroke)

l

determines the average speed:

, where kt

= 1.25 – coefficient of time loss for acceleration and braking.

Total time for moving the piston t

will amount to

t

=

t

p +

t

y +

t

t, where

t

p,

t

y,

t

t – time spent on acceleration, steady motion and braking, are determined by the formulas

, ,

where l

y,

l

t – the path traveled by the piston during the period of steady motion and braking.

Backpressure force of the working fluid F

c is determined by the pressure of the working fluid in the drain cavity

p

c.

When the piston moves to the right: .

When the piston moves to the left: .

28.3. Hydraulic cylinder efficiency

The starting efficiency of a hydraulic cylinder is the ratio of the payload to the design F

st:

.

The value of the starting efficiency ηп evaluates the power consumption during startup and acceleration of the moving masses of the hydraulic cylinder.

The operating efficiency of hydraulic cylinders can be assessed by the value of its total efficiency:

, where N

floor and

N

cost – power removed from the power cylinder and supplied to it;

– actual piston speed;

Q

t – supply of working fluid at the inlet to the hydraulic cylinder;

p

n is the pressure of the working fluid in the pressure cavity of the power cylinder.

The overall efficiency of a hydraulic cylinder can also be calculated according to the dependence:

where = 0.85...0.97 is the mechanical efficiency of the hydraulic cylinder, which takes into account power losses from friction of moving masses; its value depends on the design of the hydraulic cylinder and seals and, above all, on the quality of processing of the mating parts

– volumetric efficiency of a hydraulic cylinder, which is determined by volumetric power losses (the ratio of the actual to the theoretical design speed of the piston).