When choosing equipment for drilling holes, you need to take into account its technical characteristics. Particular attention should be paid to the diameter of the metal drill. The purpose, cost of the gimlet, and its cost depend on this indicator. The characteristics of drills are determined by state standards that manufacturers must comply with.

Drill bits

Purpose

Metal drills are used to perform various jobs:

- drilling holes of different diameters and depths;

- creating smooth blind recesses in metal blanks;

- removing debris from broken equipment;

- for thread cutting.

There are drills for drills, screwdrivers, and industrial equipment.

Wood drills

Wood drills are made from special carbon or alloy steel. The following types of drills are made for woodworking: spiral (for small and medium holes), screw or twisted (for deep holes with smooth edges), feather (for holes from 1 to 2.5 cm), ring (for diameters up to 10 cm ), Forsner drill (for soft wood and chipboard).

Design features

A drill is an axial cutting tool. For drills and screwdrivers, cylindrical rods with spiral sharpening are used. Drills consist of several parts:

- shank;

- necks;

- working part.

The cutters are fixed on the working part. The cutting part consists of two elements - two sharp incisors and auxiliary cutting edges.

Drill design (Photo: Instagram / 73instrument)

Classification

You can find different types of drills on sale. They are classified depending on color, material, type of shank, type of coating, and accuracy class.

By color

A faded yellow tint appears after a vacation at work. Thanks to additional processing, the durability and strength of the equipment increases.

The bright yellow equipment is durable and wear-resistant. It has a low friction index. The equipment has a titanium coating, which provides it with increased strength.

Black color indicates additional steam treatment. This is durable equipment with a long service life. The cost is not very high.

Drills of the lowest quality that have not been subjected to additional processing are gray in color. Such equipment has a low price, but you won’t be able to save money, since the drills break quickly.

By material

Drills are made from different types of steel:

- carbon tool;

- alloyed instrumental;

- high-speed

Additionally, plates made of hard alloys are attached to the cutting parts.

Steel drills (Photo: Instagram / linkorspb)

By shape

Kinds:

- Stepped, conical. They are also called gimlets. The working part has a conical shape. Designed for drilling holes of different diameters in metal sheets up to 2 mm thick.

- Centering. Multifunctional gimlets, which are needed for creating special holes in metal workpieces. The parts are fixed in drilling equipment.

- Elongated. Used to create blind, through holes.

- The first ones. Tool with replaceable inserts. With its help you can make large diameter holes with smooth walls.

- Crowned. Hollow crowns that have many sharp teeth along the edges. Suitable for drilling holes in thin metal sheets up to 30 mm in diameter.

- Threaded. Used for cutting threads in pre-prepared holes.

- Highly accurate. With their help, you can perform precise technological operations.

- Left-handed. Equipment for highly specialized purposes, which is needed for drilling damaged equipment out of holes.

The most common type of metal drills is twist drills. Designed for drilling holes of different depths and diameters.

Conical drills (Photo: Instagram / dismart_kh)

By shank type

Types of shanks:

- Conical. The equipment is designed for high-power, professional drills or industrial drilling machines.

- Cylindrical. Suitable for power tools.

- Hexagonal. Used for fastening in jaw chucks and clamps.

By type of coverage

The following can be applied to drills:

- titanium aluminum nitride;

- titanium carbonitride;

- diamond chips;

- titanium nitride ceramic coating;

- oxide film.

The last type of coating is the most affordable and reliable.

Cobalt drills (Photo: Instagram / vmiha80)

By accuracy class

Accuracy class:

- Normal accuracy marked B. Designed for drilling holes with an accuracy of up to 15 grade.

- Normal accuracy marked B Designed for drilling holes up to accuracy class 14.

- High precision equipment marked A1. Suitable for creating holes with accuracy from 10 to 13 classes.

Features of materials processing by cutting

In metal technology, it is customary to consider the process of cutting a material by introducing a wedge into it.

Cutting by introducing a wedge into the thickness of the material: α – angle of sharpening of the wedge (angle at the apex); h – cutting depth; l – chip separation length; l₁ – length of chip twisting; d – width of the blasting surface

- It is assumed that the wedge itself is made of a hard substance that is stronger than the body being penetrated. Therefore, only the processed object is destroyed.

- The movement of the wedge is carried out due to the applied force P. It is sufficient to have a destructive effect in the contact zone.

- The sharpening angle α is less than 90⁰, so cutting into the material is possible.

- The wedge has two surfaces: one faces the material being cut, which is why it was called the front; the other is adjacent to the workpiece, it is called the back.

- During the destructive action, chips are formed. Depending on the plastic properties of the workpiece, it can: break into separate fragments; chip away while maintaining a single body; to be twisted, twisted.

The cutting process is characterized by the following parameters:

- h – cutting depth, mm (for different types of tools this value is determined in different ways);

- v – cutting speed, m/s (it is customary to consider linear movement inside the cut chip per unit of time);

- s – feed, mm/rev (a criterion characterizing the productivity of the cutting edge penetration into the workpiece).

When developing a technological process for processing materials by cutting, the main parameters are calculated. From these they are further determined:

toper – the duration of the actual time required to remove the layer by cutting, min;

tpiece – piece time is calculated to determine the actual costs of a technological operation, min.

Elements of a metal drill

For metal, drills made of high-speed steel are used, as well as with overlay plates made of hard alloys. They are marked:

- R6M5, R9, R18 - different versions of high-speed steel. Its main feature is the possibility of self-hardening during cooling after completion of work;

- T5K6, T15K8 – carbide surfacing for drills on hardened steel. They are used to make holes in metal having a hardness of HRC 45...50;

- VK6, VK8, VK12 – drills with carbide tips for cast iron. They can be used to drill holes in the presence of shock loads.

Cutting edges of a twist drill for metal

A distinctive feature of a tool designed to make holes in metal parts is the presence of several cutting edges. It's easy to identify them:

- jumper. It is located between the main blades;

- two main blades. For different types of metals, they create their own sharpening angle;

- the ribbons are two spiral edges. Their task is to form the inner surface of the hole.

When sharpening, an angle is formed between the two main blades in a special way.

Drill sharpening angle

Wood drill cutting edges

For wood, a different type of drill is used. The most widespread are perks (feather drills). The main difference is this:

- there is a special cone that defines the center (in some designs a conical spiral is created here);

- sharp triangles along the periphery specify the drilling diameter;

- the two main cutting edges are perpendicular to the axis of rotation.

Wood drill bit

When the hole depth is shallow, there is no need for surfaces to remove chips from the holes. Due to centrifugal force, waste flies out.

Drilling and reaming

The drilling process has certain differences from other operations. This is where the tool itself rotates. At the same time, it is embedded inside the part.

Drilling and hole reaming

Possible options:

- drilling, this process is characterized by the creation of a new hole;

- reaming is an operation to increase the diameter of a hole.

When metal is processed, the heat generated is distributed:

- on the cutting edge of the drill;

- for heating the chips;

- to heat the entire workpiece.

Quite a large amount of heat is released. It usually accounts for up to 50...60% of the total energy spent on the operation. Therefore, when working with steel and other alloys, they try to remove heat. Lubricants and coolants are used.

It is customary to distinguish processes by depth. If the hole is drilled to 4...6 diameters, then it is assumed that normal drilling is being performed. If you need to get a hole in which the depth is more than 6 diameters, then such an operation is called deep drilling. Here it is necessary to supply coolant to the cutting zone.

Drilling wood

When doing woodwork, note:

- the chips practically do not heat up;

- the body of the part itself has local heating only in the place where the cutting edge comes into contact with the material being processed;

- The edge gets very hot, there is practically no heat dissipation.

Drilling wood. The resulting chips do not heat up

When working with wood, coolant is used extremely rarely. Only wood boards impregnated with polymer resins can be treated with lubricants and cooling. Delta wood, which was previously used to make aircraft, was drilled using coolant. In those processes, the need was determined by the high productivity of labor at aircraft factories.

Main types of wood frames

Considering the design of the tool, you can note the difference:

- the twist drill does not have a pronounced ribbon, but has a sharp cone for penetration in a given direction;

- For deep holes I use the Lewis spiral design. It only has one main edge. She crashes into the part. During operation, the spiral itself is pressed tightly against the walls, so moving to the side is impossible;

- Forstner drill is used to make shallow holes. A similar tool is used on filler machines, where recesses for fittings are made.

Dimensions

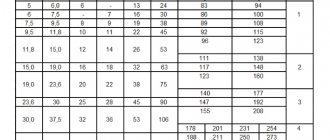

The dimensions of metal drills are indicated in government documents, which manufacturers of certified products must follow. The requirements are regulated by GOST 886–77, GOST 4010-77, GOST 10902–77. Depending on the size, accessories for power tools are divided into 3 groups:

- Short - self-tapping screws with a length from 20 to 131 mm. Outer diameter - up to 20 mm.

- Extended - equipment up to 205 mm long. The diameter is similar to short drills.

- Long - length up to 254 mm. Outer diameter - up to 20 mm.

Sometimes you need to make a hole for the self-tapping screw before screwing it in. There is no point in selecting equipment of the same diameter as the fastening element, since the fastening will not hold. To select the diameter, it is recommended to use ready-made calculation tables.

Drills of different lengths (Photo: Instagram / promoborydivanie)

What common?

- Manufacturers produce twist drills for metal and wood of the same diameters, because identical holes may need to be drilled in both materials. Their diameter varies from 0.1 mm to 8 cm. There are, of course, unique ones, but they cannot be found in a simple household or hardware store.

- They can have the same dimensions and reach 600 mm .

- Metal drill bits can be used to drill small holes in wood. However, you cannot use wood drills for metal. But it is important to remember that if a metal drill is used for woodworking, you need to constantly monitor its condition. The edges of the hole will not be smooth, because such a drill will tear the fibers, also wood shavings can clog the grooves, and the drill will begin to overheat, which will have a very bad effect on its condition. It is very important to clarify that analogues for concrete are not suitable for working on wood. Although many builders save money in this way, it is possible not only to ruin the entire structure, but even cause a fire, since the heavy-duty material will not drill, but will simply scorch the wood.

- Some types of drills are used for metal and wood, for example, screw or spiral, they are simply made from different materials so that you can drill both dense materials and more pliable ones like chipboard.

- There are universal drills that can be used to drill anything. And not only metal or wood, but even plastic, ceramics and concrete. It has a unique sharpening, thanks to which you can drill anything. True, if you had to buy it, it is better to choose expensive rather than cheap models. Counterfeits and models with poor alloy will not last long; some of them break after the first use. Quality ones, on the contrary, can last for many years.

- Carrying out work on drilling holes in different materials is identical. The technology is exactly the same, as are the recommendations given for the job.

- The markings of similar products are the same . Letters and numbers indicate the manufacturer, type of steel, tungsten content, and particles of other elements in the alloy. It is believed that the more elements in the alloy, the better the drill will be. It can withstand heavy loads and temperatures.

Marking

If you know how to understand the equipment markings, you can find out the technical characteristics and purpose of the drills. Designations:

- The alloy of the material, the amount of alloying additives is indicated in Latin letters with numbers. For example, K3, the alloy from which the drill is made, contains 3 parts of cobalt.

- High speed steel is designated by the letter P.

Foreign manufacturers use the HSS marking. It is applied to high quality equipment.

Selection principles

When choosing, you need to consider:

- product color;

- purpose of equipment;

- quality of sharpening;

- symmetry of incisors;

- equipment material, type of protective coating.

Drills of different types (Photo: Instagram / koleso_ast)

Advantages and disadvantages

Advantages:

- the ability to perform various technological operations;

- strength, reliability, durability;

- low price.

Only cheap gimlets have disadvantages, which are made from low-quality materials and do not have a protective coating.

Manufacturers and prices

Manufacturers:

- Bosch;

- Haisser;

- Ruko.

Gimlets with the USSR designation are considered the most reliable and durable. The price of a classic drill marked HSS is 500 rubles.

Bosch brand drill (Photo: Instagram / sergei.wood_man)

Sharpening rules

To sharpen a drill yourself, you can use a sharpening machine, hand tools, or special mechanical sharpeners. It is important to take into account some features:

- During sharpening, the cutting edges should be positioned parallel to the abrasive surface of the whetstone.

- When sharpening a drill, do not press hard on it. This especially applies to sharpening equipment on sharpening machines.

- It is important to control the length of the cutting edges. They must be the same length.

Regrinding can be considered completed when the metal surfaces being processed stop reflecting.

Difference from wood drills

Gimlets for metal differ from equipment for drilling wood:

- The strength of the alloy. For the manufacture of metal drills, more wear-resistant material is used.

- Angle between incisors.

- Sharpening. Metal gimlets do not have a centering point.

It is difficult to choose equipment without practical skills or knowledge of theory. The choice is complicated by a large assortment of drills and differences in technical characteristics. It is enough to study the features of different types of equipment in theory in order to choose drills for power tools.

How to distinguish a drill for metal from wood | What are the differences between drills?

What is the difference between drills for metal, wood and concrete?

A drill is a type of working equipment whose purpose is to create holes in various hard surfaces. Most often used with tools such as drills and hammer drills. The equipment is clearly divided by diameter, length, and materials for which they are designed to work. In this article we will look at how to visually distinguish drills designed for processing different materials.

Let's define the common features of different types of equipment:

- Dimensions . Components intended for various tasks can have identical diameter (varies on average from 1 to 80 mm) and length (most do not exceed 600 mm).

- Labeling . Basic information about the product is indicated in the same way: brand, size, type of steel used in manufacturing, etc.

- Principle of operation . Whether you're drilling into stone, wood, or tile, the same rules and sequence of steps apply to creating holes.

- Partial interchangeability . It is necessary to drill wood, but there is no specialized attachment - it is permissible to use a more durable metal drill. You cannot use wood tools for steel or metal - you will ruin the consumable. In stores you can find universal equipment.

Main features of a wood drill

Wood is a relatively soft material, so its equipment is made from inexpensive alloys. The design provides recesses for chip removal. The way the drill looks deserves attention: on the front there is a cutting peak, with which it is convenient to create holes with high precision. Often wood attachments are gray in color.

Wood tooling comes in several varieties. To understand how to distinguish wood drills with greater accuracy, let’s take a closer look at them.

Differences between screw drills for wood

The most common type of consumables for wood. How to accurately distinguish these drills:

- There is a sharpened pin in the center.

- The design includes scorers.

- The characteristic angle of the edges is 90-100°.

Differences between feather drills for wood

In appearance it resembles a chisel with a sharp tip in the middle. Used to create large diameter holes. It is fixed in the power tool chuck with a 6-sided/round shank.

Differences of a Lewis spiral drill for wood

The species is visually different due to the wide Lewis spiral included in its name. Used to create deep and neat holes.

- Wide spiral.

- Centering point in the form of a drill.

- Small groove angle.

Differences between Forstner drills

Ideal for working with chipboard and laminate. The advantage is high accuracy of cutting the cutting line. This is achieved thanks to the sharp edge on the scorer. There is a point in the middle to make centering easier.

Main features of a metal drill

At first glance, it is visually difficult to determine how metal drills differ. More durable, if necessary, treat the wood. Another difference is in the tip: the front part of the metal bit is blunter (the angle is 130-140°).

What is the difference between screw drills for metal?

If you need to understand how to distinguish a drill for metal from wood, pay attention to the color of the consumables. Due to the low strength of the material being processed, consumables for wood are made from cheap materials and are gray in color. Tools for working with metal often have a black or gold finish.

What are the differences between milling drills for metal?

Thanks to this attachment, a drill can replace a router in simple tasks. The front part of the equipment is similar to its screw counterpart. There are notches in the middle, with the help of which milling is carried out. They can give the hole a specific shape: for example, widen it.

What are the differences between step drills for metal?

The cutting tip of this type is made in the shape of a pyramid with several segments. Thanks to this, one nozzle allows you to replace several different ones: the further you move through the material, the wider the hole will be. The result will be neat and even.

Main features of a concrete drill

The main characteristic feature of the nozzle for concrete structures is the presence of a pobedit tip. Allows you to work with dense materials. It is important to remember that due to its specific design, the concrete nozzle is incompatible with wood and metal.

Difference between drill bits for different materials

The screw attachment for concrete differs from others due to the tip made of Pobedit. Characterized by size - the diameter is larger than the base.

How to distinguish pointed drills in concrete

Unlike the screw type, the peak type does not have a spiral. Smooth, with a diamond tip in front, shaped like an arrow. Peak-shaped consumables are effective when processing stone structures. The disadvantage is the duration of work - creating a hole takes several minutes.

How to distinguish crowns from concrete

Used to create large, perfectly straight holes in materials such as concrete or masonry. They have a rod with a tip in the middle, which are used for centering. Surrounded by a large jagged bowl (crown).

Main differences between drills

All types of equipment, except screw ones, have a characteristic shape. The easiest way to learn what material is used is to remember the external signs. If you encounter a screw tip, look at the tip: the tip for wood is pointed, for metal it is blunt, for concrete it is widened relative to the base.

What else can you determine from a drill by eye?

Here is a list of signs that will help you understand how visually worn drills differ from new ones:

- After processing, it is externally noticeable that the walls of the hole are rough.

- They get hotter than new ones.

- During operation, an uncharacteristic sharp creak appears.

- Slower than new ones they enter the surface of the material.