Dowels for aerated concrete - what are their features

The dowel for aerated concrete is designed for fastening weights on walls made of loose and soft material. Standard screws and self-tapping screws are not suitable here, since the wall material crumbles and the fasteners fall out.

For load-bearing structures made of aerated concrete, self-tapping screws of a special design are used. Fasteners for foam blocks and gas blocks look like spiral bushings made of metal or plastic. During screwing, the ribs of the sleeve become wider and are firmly attached to the loose surface of the foam block. This mount can withstand a load of up to 20 kg.

How to use an aerated concrete anchor

We understand that installation technology is not a very difficult task, but we must fully cover the topic so that the reader does not have any questions after reading the article. Let's divide the work into three stages.

Drilling holes

The best tool for the job is a hammer drill set to hammer drilling mode. We select a drill of the required diameter and insert it into the chuck until it clicks.

Expert opinion Vitaly Kudryashov builder, aspiring author

Ask a Question

Be careful not to accidentally release the trigger and activate the tool. It is not difficult to guess that this can lead to injury, so it is better for inexperienced craftsmen to remove the plug from the socket during such manipulations.

- The tool is installed in the working position - make sure that the angle between the drill and the wall is straight, without significant deviations.

- Try not to drill in the seam areas, as voids may appear here and the fasteners will not hold securely.

- Press the trigger lightly, causing the drill to rotate. As soon as its tip begins to sink into the body of the aerated concrete wall, spin the power tool harder and reach the desired depth.

Expert opinion Vitaly Kudryashov builder, aspiring author

Ask a Question

If we are talking about installing an anchor in a house where the interior decoration has already been completed, then before starting drilling you need to make sure that there is no electrical wiring running under the layers of plaster at the intended point. For this, special detectors, indicator screwdrivers, multimeters and other traditional methods are used. Remember that in the event of an accident, a short circuit will occur, which can result in a power outage. Sometimes the carelessness of the master can lead to an accident, so it is always necessary to exercise caution.

If you don’t have any tools to check, then you can navigate by the position of sockets and switches. It is known that electricians never pull wiring obliquely, laying it only horizontally or vertically. That is, from any electrical point, the wire first stretches upward, reaching the level of the junction box, and then turns in the desired direction.

To avoid making the hole too deep, you must use a mark on the drill bit or a special stopper attached to the handle of the hammer drill. You can mark the drill with any marker or with a piece of electrical tape wound on top.

Installation of fasteners

The next step is to place a dowel in the hole. In most cases, this part of the fastener is simply hammered into the hole until the outer collar rests against the wall. This stopper prevents the dowel from falling into the hole.

- If the sleeve has a thread cut on top, it must be screwed into the hole. Typically, a 4 or 6 mm hexagon is used for this, which is inserted into the center of the dowel, after which it is placed with the opposite end into the hole, and clockwise rotation begins.

- The easiest way is to screw metal fasteners into the wall, since they have high rigidity, while nylon will desperately resist insertion, which will cause some inconvenience for the installer.

- If a galvanized steel wedge anchor is being installed, it must also be driven into the hole. But be careful not to hit the spacer with a hammer - otherwise early opening will occur, which will break the walls of the inlet hole and significantly weaken the attachment point. The blows must be delivered weakly, on a special platform on the side of the wedge.

A frame-type metal dowel for aerated concrete is also driven into the hole. In this case, it is impossible to allow its premature opening, since it is carried out only by rotating the central screw in the product.

Installation of spacer element

The last step in installing any anchor is wedging the dowel - depending on the design, nails or screws may be used for this. Accordingly, we need to either hammer in the spacer element or screw it all the way.

This procedure is very simple, so we see no point in going into details. The only thing that stands out from the total mass is the chemical anchor, in which the pin is pushed by hand until it reaches the desired position.

The main types of dowels, which fasteners are best to use

Commercially available dowels are divided into:

- metal;

- plastic or nylon;

- chemical;

- nails;

- frame;

- thermal insulation;

- universal.

Metal

The material for the manufacture of metal anchors is galvanized steel. Dowels for metal foam blocks are fire-resistant and durable, but are much more expensive than their non-metallic counterparts. It is not recommended to use metal dowels in places of high humidity and for outdoor work. The fastener is equipped with a cuff or retaining flange that prevents it from falling into the wall.

Plastic

A plastic dowel is cheaper, but is used one time. These hardware are lightweight, corrosion resistant, and have a spiral cut. A type of plastic dowel is a nylon fastener. It is stronger than a standard non-metallic anchor, so it is used for installation of systems with variable loads.

Chemical

This type of fastening is used almost everywhere. Externally, the anchor looks like a tube containing chemical components. Such anchors provide reliable fastening due to adhesion forces. Connections made using chemical anchors are much more reliable than standard fastenings.

Nail dowels

A nail anchor is used to fasten aerated concrete blocks. The anchor is held by spreading the lamellas when driving the element into the supporting structure. The thread of the spacer element is asymmetrical. The material for making the sleeve is plastic (nylon or polyamide). The helical screw is made of high carbon steel. Basically, dowels and nails for aerated concrete are used for domestic needs and outdoor work. It is chosen because:

- the cost is 15-20% lower than the price of other types of fasteners;

- ease of use;

- reliability within the stated characteristics.

Frame dowels

A metal frame anchor is a good fastener for door and window frames made of aluminum or plastic. This fastener is used when installing and connecting wooden elements to a load-bearing surface. The frame dowel for gas silicate blocks is entirely made of galvanized steel. Some of the hardware has a galvanic coating, which reliably protects the anchor from corrosion.

Frame screws for aerated concrete are used due to:

- ability to withstand high lateral loads;

- Possibility of application during installation of multi-profile structures;

Thermal insulation fasteners

Designed for installation of loose thermal insulation materials. It is made from copolymer materials and looks like a long hollow tube with a wide cap at the end, which is why this fastener is also called a mushroom dowel. The rod is plastic or metal. The perforated surface of the cap facilitates final finishing and reliably hides the thermal insulation under a layer of plaster.

Thermal insulating hardware is also used when installing roofs. In this case, one should count on their continuous operation for several years under the influence of atmospheric conditions. An incorrect choice of material or length of the product can trigger the start of corrosion processes with further destruction of the fasteners for the gas block and the collapse of the structure.

Chemical anchor

Chemical fasteners in aerated concrete are used:

- during the construction of multi-storey buildings;

- when working with the foundation in conditions of high humidity;

- for the construction of bridges;

- when laying concrete floors;

- for the construction of reinforcement outlets.

Chemical anchors are absolutely safe for humans. Their widespread use is hampered by the high cost and relatively long curing time of the adhesive composition - from several hours to a day.

Universal anchors

Universal hardware can serve as an anchor for standard load-bearing structures made of brick or concrete. It is also used as fasteners for aerated concrete blocks. The secret of its strength is in the special cutting of the sleeve, which reacts differently to contact with different materials. Thanks to its specific shape, such an anchor can be screwed into various load-bearing surfaces:

- In dense concrete or brick, the anchor is held in place by frictional forces.

- In a hollow material, hardware does not encounter resistance, therefore, depending on the shape, it behaves differently. In the first case, the dowel is screwed onto a self-tapping screw. This forms a tight knot, ensuring reliable fastening. In the second case, when the rod is screwed in, the sleeve changes its shape, turning into a persistent bolt.

Types and features

The dowel fastening device is a sleeve with four “petals” and a rough surface. When twisted or hammered, they begin to expand in the porous structure of aerated concrete. The teeth and incisors in such a device contribute to reliable fixation. They can be secured especially firmly when the teeth move in a spiral and the tip of the screw does not extend beyond the dowel.

Depending on the material used, fastening elements can be:

- metal - stainless steel, galvanized, brass, aluminum, with the addition of an anti-corrosion compound;

- plastic (polyethylene, polypropylene, nylon).

The first type is considered the most reliable in operation.

They are excellent for through-and-through and complex installations. However, such fasteners have a significant drawback - they begin to oxidize under prolonged exposure to moisture. They are equipped with supporting elements to minimize the risk of heavy hardware turning or falling inside the aerated concrete blocks. READ What is the best cement to choose for the foundation of a private house? Plastic fasteners are valued for their lightness, versatility and resistance to corrosion processes. Among all varieties, nylon dowels are considered the best

All these fasteners are divided into driven-in and screw-in, depending on the installation method. They are suitable for installation without pre-drilling the blocks, and they are also fixed using threads in a pre-prepared hole.

According to the type of thread and fixation of elements, bushings can be standard with the same cross-sectional length and helical spiral. There are cone-shaped hardware that spread out to the sides with blades when twisted. Some begin to expand when the structure expands.

A separate group includes chemical anchors. Their fixation occurs due to the polymerization of a special composition. They are very convenient to use, since you just need to place the capsule in the prepared place.

Metal dowels

These fasteners are fire resistant and are therefore often used in areas where there is a risk of fire. Metal dowels have a locking collar , which is also called a “cuff.” At the moment of twisting, it prevents the bushing from rotating around its axis and prevents it from falling into the wall. Most often they are made from galvanized steel.

Metal dowels for aerated concrete are used when performing the following work:

- for installing equipment and furniture with impressive weight;

- fixation of pipelines, including the most complex ones;

- fastening guides designed for installation of gypsum board sheets.

However, such metal fasteners have their drawbacks. Over time, they develop destructive rust. Fasteners made of galvanized steel are considered the best and for this reason are expensive. Due to their positive qualities, they are often reused.

Plastic and nylon fasteners

Such fasteners are good because they are not affected by corrosion processes.

The plastic dowel for aerated concrete has special spiral-shaped ribs. This part of the part is responsible for maximum adhesion to the cellular structure of the material. The main advantage of plastic fasteners is environmental friendliness. The advantages also include resistance to aggressive environmental influences. READ What different brands of cement are made of, their chemical composition

They are characterized by their low cost, which makes them indispensable and always in demand when working with aerated concrete. Despite all the positive characteristics, they are not suitable for use on facade surfaces. Their significant disadvantage is poor resistance to sub-zero temperatures. In winter, during frosts, such a fastening can easily burst.

Nylon options are also corrosion-resistant. However, they are more wear-resistant than their plastic counterparts. They are often used for outdoor work. Nylon dowels for aerated concrete are considered much stronger and more durable. They are much more expensive in cost, so they are not often purchased by consumers.

The high price is fully justified, since the characteristics of the clamps allow them to be used for many jobs. For example, they are used to install window and door openings. This is an excellent option for attaching mirrors and installing lighting fixtures if you use fasteners with a diameter of no more than 12 mm.

Chemical anchor

Often it is necessary to mount massive objects on aerated concrete surfaces. In this case, chemical anchors are used. Metal dowels, compared to anchor bolts, will not be able to withstand very heavy weight. They are sent to the prepared place using a special adhesive composition.

This method of fastening gives a 100% guarantee that a large object will be securely fixed and will last for a long period.

Varieties by method of application

A variety of fastening features allows you to use plastic and metal dowels for aerated concrete for specific tasks. Which ones make different anchor designs and how to use them?

Frame fasteners

The use of frame dowels for sibit, foam concrete and other non-solid surfaces is necessary during the construction of buildings in the period preceding the stage of finishing work. Before installation, the surface is cleaned of dirt and dust and holes are drilled that are comparable to the length and thickness of the dowel itself. The holes are chamfered so that the anchor head does not protrude above the surface. The dowel is inserted into the hole using a hammer. The fastener is driven in until it stops and then tightened.

The frame dowel can be used to install swivel consoles, wall cabinets, heating radiators, sinks and more.

When installing, do not overtighten the screw: the maximum load should not exceed 5 Nm.

Thermal insulation fasteners

There are two types of thermal insulation hardware available for sale:

- A dowel with a plastic rod is used for attaching thermal insulation (foam plastic, etc.) to enclosing structures and facades. The material for the fastening base is class B25 concrete, hollow brick or natural stone.

- The thermal insulation dowel for gas silicate is equipped with a galvanized steel screw. Unlike its universal analogues, such an anchor does not destroy the load-bearing surface, but reliably fastens the thermal insulation.

Instructions for using thermal insulation fasteners look like this:

- marking places for installing fasteners;

- drill holes with a diameter of 10 mm with a depth margin of 5-10 mm;

- We position the dowel and press it all the way (so that the perforated cap is pressed tightly against the load-bearing surface;

- insert a metal rod and hammer it in until the insulating material is completely fixed.

When installing the thermal plug, using a hammer is strictly prohibited!

How to use a chemical anchor

To perform fastening with a chemical anchor, you must:

- drill a hole of the required diameter and depth (information on the packaging);

- blow out the hole with air and clean it with a wire brush;

- cut off the clip from the anchor package or cartridge;

- Screw on the mixer and squeeze out a small amount of adhesive so that it fills 2/3 of the depth of the hole;

- screw the pin until it stops;

- maintain the time indicated in the instructions.

When using a chemical anchor, you should not rush and apply the load before the set time.

Installing dowels in aerated concrete: step-by-step guide

The principle of installing dowels in aerated concrete is practically no different from other surfaces. Focus on the following rules:

- It is important to make a pilot hole that matches the diameter of the dowel. It is important that the hole is smaller than the fastener. For example, for 10 mm fasteners you need to prepare a hole with a diameter of 9 mm.

- When working with a hammer drill, avoid impact mode. A drill is considered a more suitable tool.

- A screwdriver is suitable for screwing in the plastic dowel. With metal dowels, use a hammer.

- After installing the cuff all the way, proceed to screwing in the self-tapping screw.

Fastening during construction

Facade work or roof installation is necessarily accompanied by the installation of thermal and waterproofing. For such work, a thermal insulation mount in an aerated concrete wall with a wide head is suitable.

Arrangement of the foundation or construction of structures intended for operation in difficult conditions cannot be done without universal or chemical dowels. The former reduce construction costs, and the latter can be used where it is really needed.

How to drill aerated concrete

Aerated concrete blocks are known for their flexibility - for example, using a simple hacksaw you can saw a block in half without damaging the tool or requiring much effort. Accordingly, drilling holes in aerated concrete blocks does not require the use of any specialized tools. In particular, standard concrete drills with Pobedit tips are used for these purposes.

The drilling process itself can be carried out even with a screwdriver that does not have high torque. If you don’t have drills and drills for concrete, you can do the job with other types of drills - options for metal and even wood are suitable, but the further integrity of the tool will remain in question.

Types of fasteners

When deciding which fasteners to choose for aerated concrete - which is best for specific application conditions, it is necessary first of all to take into account the main characteristics by which they differ from each other, as well as their main varieties and properties. The most popular today are dowels, anchors and self-tapping screws. Let's look at their features in more detail.

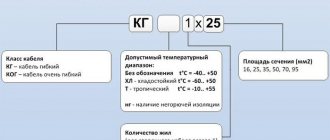

The principle of operation of the dowel and its characteristics

The dowel for the gas block has a sleeve and a self-tapping screw in its design. The first is inserted into the drilled hole. As the screw is screwed into it, it expands along the entire perimeter. Using special elements, it tightly bites into the porous mass of concrete over a large area, thereby ensuring reliable fixation.

Expanding dowel elements Source uniform-met.ru

See also: Catalog of companies that specialize in calculation, installation and repair of foundations

Dowels differ in a number of characteristics, the main ones being:

- Design and type of ribs.

Fastening elements are made in the form of a spiral or cone

- Installation method.

The product may become clogged or screwed into the wall. The first option is preferable when the sleeve is placed in a through hole in the wall.

- Material type.

The core is usually made of alloy steel with anti-corrosion coating. The collet can be made of metal, nylon, or plastic.

Good to know! Dowels and anchors provide the most reliable fastening to an aerated concrete wall. Both fastening elements operate on the principle of expansion. The anchor is an independent product, and the dowel is an insert made of synthetic material into which a self-tapping screw is screwed.

Anchor Source 1beton.info

Dowels

There are the following modifications of dowels:

- Dowel-nail for aerated concrete.

The fastening mechanism is based on the opening of the sleeve as a smooth metal core is driven into it. It is universally used for any density of porous concrete.

- Nylon expansion type.

Characterized by high resistance to rust. It has a small load-bearing capacity and is suitable for mounting light objects - lamps, non-load-bearing shelves, wiring, communication systems, mirrors, light interior items.

- For fixing frames in window and door openings.

It can have a different base - plastic, metal, nylon. Thanks to the special design, it does not overload the gas block. Used for fixing frames, guides and other elements of windows and doors.

- Steel with a protective layer of zinc.

It is characterized by maximum strength and fire resistance, but is susceptible to rusting processes. Designed for fixing heavy objects - furniture, household appliances, bathrooms. devices, guides for panel finishing, etc.

Steel dowels Source wixstatic.com