Numerous industrial devices, as well as many household items, have threaded connections, which have been used since ancient times.

The main equipment used to produce elements of such connections is a tap. Its use makes it possible to quickly and without much difficulty cut precise threads on the inner surface of holes. To cut a thread with a tap, you need a table to determine the dimensions of the device.

Design features

The first devices for cutting threads were distinguished by a simple system, and consisted of a tetrahedral rod, on the working end of which, sharpened to an even cone, teeth were cut out. When using such a device, the thread was cut by screwing it into the inside of the nut, or into a pre-prepared hole in the product being processed.

Of course, this kind of mechanism had a large number of shortcomings. The most significant disadvantages include the absence of a rear plane on the cutting part, as well as a negative rake angle. Over time, the tap system has become more thoughtful, and today, they make it possible to create clear and high-quality internal threads.

Each tap for cutting on internal surfaces contains the following elements:

- grooves (from 2 to 6);

- fence part;

- calibrating part, which has a tubular configuration.

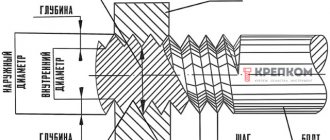

The grooves, located on the frontal plane of the device along the entire length, simultaneously perform two functions: ensuring the removal of chips from the processing area, and simplifying the supply of lubricating-cooling fluid (coolant) to this area. The configuration that the groove has in cross section is determined by its two planes, one of which is considered the front edge of the cutting tooth of the device, and the second is its back.

Depending on the type of profile, chip flutes are of the following types:

- single-radius (with grooves of this shape, mostly calibration type taps are made);

- with straight surfaces (devices with grooves of this shape are used for cutting inside nuts);

- with straight and radius surfaces (most taps are produced with chip flutes of this type).

Grooves can be placed in different ways; there are straight grooves and spiral grooves. Multi-purpose taps of general direction are produced with rectilinear grooves. Devices used for cutting threads into passages are made with spiral left-handed grooves. The chips created by the device move ahead of it along the hole being processed, thereby eliminating the threat of deterioration of the already cut thread. When using taps with the right direction of twist of the grooves, the chips are removed from the processing area to the shank of the device. Right-handed ones are optimal for cutting in blind holes.

The intake portion of the tap, as described earlier, has a conical configuration, which simplifies the process of inserting the tool into the hole. A certain value of the part of the inclination angle, which can be in the range of 3−20°, is selected taking into account the type of processing the mechanism will be used for: roughing, intermediate or finishing.

The cylindrical calibration part is produced with a return reduction of up to 0.1 millimeters, which is necessary in order to reduce the friction forces that arise during cutting. Reducing the friction force between the working part of the tap and the surface being processed is also made possible by backing the rear plane of the cutting teeth, performed from their top to 1/3 of their width. In a similar way, an underestimation of the rear plane of the cutting teeth is formed, the size of which for a tool with a diameter of 12-30 mm is about 0.1 mm.

Do you need an internal thread? Then you need a tap.

To cut internal threads you will need a tap. They come in 2 types - metric and pipe. The first ones are for ordinary metric threads (the kind that goes on bolts and nuts), the pipe ones - respectively, for threads on pipes. Metric ones have the letter M in their designation, pipe ones - G, K or RC.

Metric machine-manual

The marking is the letter M, followed by the thread diameter and pitch. For each thread diameter there are several steps (fine, medium, standard), of course the steps begin to increase with increasing diameter. For example, a standard M5 thread has a pitch of 0.8; there are no more steps per diameter of 5. However, already at 6 mm there are standard threads of 1 mm, as well as small threads of 0.75 mm (rare and unclaimed). A 10 mm thread has a standard pitch of 1.5; it also comes in 10*1 and 10*1.25.

Most often, taps are sold in sets of 2 pieces - rough (for initial cutting) and finishing (for cleaning threads). The first number has a sharper approach, the second - more blunt. Often, dashes are used to indicate the first and second, 1 stripe on the rough, 2 stripes on the finishing.

For taps with standard threads, the thread pitch is not written; it is simply designated M10 (standard pitch 1.5) or M8 (standard pitch 1.25). Related article - table of standard pitches for thread diameters. There you can also find out which drill is suitable for which thread - the information is more than useful. You can find out the thread pitch using a thread gauge - a set of pitch templates. For metric threads - one thread gauge, for pipe threads - another (at 55 degrees).

Pipe

There are 3 types:

1. Pipe cylindrical - designation G 2. Pipe conical - marking K 3. Conical inch - designation RC

You don’t have to worry too much, the standard thread for pipes is a cylindrical pipe thread (designated G, G1/2″ is half an inch, G1″ is an inch thread, and so on by analogy).

The most commonly used on the farm are G 1/2″, G 3/4″, G1″, G 1 1/4″ (an inch and a quarter) and 1 1/2″ (one and a half inches).

Price and quality of the tool.

We will talk about the quality of the metal. By and large, there are only two types of steel: carbon steel (U7) and high-speed steel (r6m5, r18, HSS).

Also note: Photo review of a manual compact pipe cutter

If you need threads in soft metal, you can easily get by with carbon threads. They are much cheaper than a quick cutter, 2-3 times cheaper. For example, M6 carbon costs 60 rubles, and high-speed cut costs 170 rubles. The difference is obvious.

High-quality high-speed cutters are needed primarily for hard metal (they often buy from us for cutting threads in alloy steel). Carbon steel can break under heavy load, so if you are doing important work, don’t skimp, buy from a quick cutter.

An excellent manufacturer is the Lviv plant, also look for any taps made in the USSR either with a quality mark or made of P18 steel - it will be very difficult to find them, but their quality is simply excellent. They still knew how to make instruments in the USSR, not like now - it’s all China, you don’t even know what and how to choose. But on this site you will find only truthful information, so follow the advice - you won’t go wrong. You can read about normal metal drills here.

Not bad carbon U7 - you can easily cut threads with them in a regular corner, copper, galvanized iron. The ones in the photo above are quite possible to get by with for your home, fortunately their quality is more or less and their price is low.

Nut

Sold individually, as opposed to machine-manual. It is much longer than the machine-manual one, its entry is very sharp (so it is not suitable for cutting threads in a blind hole). They also come with standard threads, and with fine and medium threads. There's nothing special about him anymore, he laughs just like anyone else. Therefore, if you need to cut a couple of holes on hard metal, but cannot fork out for a set, then buy a single one and save 40 percent.

To cut threads, you will also need a tap holder and oil (household, machine). It is better to take a domestic holder, otherwise all imported ones are made of silumin (powdered metal), are weak and often break.

The cutting technology is simple - drill a hole (each diameter and pitch has its own), then secure the tap (first rough) in the holder, drop a couple of drops of oil on the tap and insert it vertically into the hole. It is advisable to clamp the workpiece in a vice so that the thread does not go askew. Slowly turn clockwise (if right-hand thread). So twist it, a little forward, then back and forward again. The lesson is difficult only for the first time.

Another note: What is a die and how to use it to cut a thread.

Left

For left-handed threads there are special taps marked LH. The price for them is a little higher, and sometimes it can be quite difficult to find them on sale. When cutting, do not forget to twist counterclockwise.

Sets of taps and dies

Nowadays you can find anything on store shelves. Many people want to buy a set of taps and dies for their home at once. And they are available for sale and the price is low. The question arises - is it worth buying sets, how is the quality? My answer is that in my opinion, such sets are worth buying only for home use. The sets are Chinese (no one produces these anymore) and the quality of the metal of the instrument is not very good. Of course, if you need such a set for your home, you can buy it, since thread cutting is not a common task. Of the more or less decent ones. Although, in my opinion, if you really want to have a high-quality instrument, then take it separately. How much do you need for your home - sizes M4, M5, M6, M8, M10, M12 and the same dies. Of course, this will cost you 1000 rubles, and for the dies another 400 rubles. But you will have a really high-quality tool and you can work with it on any metal. It's up to you to decide, of course. Yes, by the way, buy dies only from old stocks, I checked it personally - they are many times stronger than modern ones.

Types of taps by purpose

Modern industry produces various types of taps, differing in design and multifunctional capabilities. Thus, according to their intended purpose, taps can belong to one of these types.

Locksmith's tools

These devices are most often considered hand-held and are used in conjunction with a crank, through which rotation is imparted. As a rule, they are published and used in sets consisting of 2-3 devices, each of which removes only part of the allowance from the cultivated plane. The scales of the taps included in such a set (working diameters) are different.

The first tool, in the shank of which a designation with 1 line is entered, is used for roughing, the 2nd (with 2 lines on the shank) - for intermediate, and the 3rd (respectively, with 3 lines) - for finishing thread processing .

Machine or machine-manual

These are devices with which carving can be done manually and on various types of machines (lathes, drills, aggregates, etc.). Such devices differ from locksmith devices only in their shortened fence component and higher resistance to mechanical loads.

Nut tools

With the help of such devices, as their name suggests, cutting is carried out in nuts. Nuts, in which threads have already been cut with a similar tap, are not twisted from the device, but are moved to its elongated tail part. The shanks of the devices used to cut threads in drilling machines have a straight-line configuration.

Nuts with already cut threads, moved to such a shank, are simply shaken off it after removing the device from the machine chuck. To cut nuts in automatic threading machines, devices are used whose shanks have a curved configuration. When threading using this method, the nuts, under pressure from each other, are pushed along the shank of the device, reach its final part and fall into the prepared container.

Types of taps by design

Based on their design, devices are also divided into various types. So, depending on this parameter, the following tools are distinguished:

- with chip grooves of shortened length , which are called grooveless (a system of such taps is specially invented in order to cut parts made of low-carbon tough steels, aluminum alloys, as well as strong alloy steels);

- with grooves placed along a helical line (such devices are installed on machining centers and used for cutting blind threads);

- with cutting teeth made in a checkerboard pattern (due to the fact that the cutting teeth in the calibration part of such a device are cut one after another, it is possible to achieve a reduction in the friction force during processing);

- stepped type with a working part divided into 2 places , each of which performs its own function (for example, there are stepped taps, where the first section functions according to a generator circuit, and the 2nd - according to a profile; for stepped devices of other types, the first section carries out cutting function, and the 2nd - smoothing);

- combined (this is essentially 2 in 1: their cutting part, made in one design, starts with a drill and ends with a tap);

- broach taps used in a hole of any diameter (with their support, the thread is cut on a lathe, in the chuck of which the workpiece is mounted, and in the tool holder - the shank of the device used. The movement of the tap during thread cutting is supported by the mechanical feed of the caliper, and the rotation of the workpiece is supported spindle rotation);

- with an internal cavity , as a result of which the device is cooled during processing (the use of such taps, specified in special or multi-operational equipment, makes it possible to significantly increase the efficiency of thread cutting);

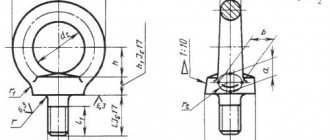

- bell (similar devices are used for significant diameters (50-400 millimeters) and have a prefabricated system consisting of single cutting components).

Structurally, all the above devices are so different from each other that it is possible to distinguish them from each other even from a photo.

How to choose good taps

Most experienced home craftsmen are armed with a wide arsenal of specialized tools that are indispensable in the process of eliminating numerous household breakdowns. Professionals generally cannot do without taps and dies, which greatly simplify the performance of a number of rather complex tasks.

What do you need to know before buying a tap?

There are a number of important features, knowledge of which will greatly facilitate the process of choosing a truly high-quality and reliable tool.

At the very beginning, experts recommend determining the type of dies and taps that will be most useful in your case. Of the two generally accepted thread standards (metric and inch), the choice most often falls on the metric version. The cutting edges of metric dies have conical blades. This type of tool is more widespread, so it is recommended to purchase first.

When choosing a die, pay attention to the thread - it is desirable that its profile has a triangular shape on the last threads of the blade. Using this type of tool allows you to screw the nut onto the restored thread.

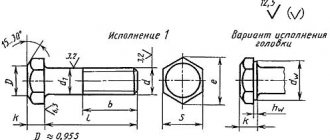

Hand tap GOST 3266-81 is used primarily for plumbing work. Thread cutting is done manually. If you plan to work with materials of high viscosity (for example, titanium alloys), professionals recommend choosing sets of several taps. If it is necessary to speed up the thread cutting process, it is recommended to use machine taps that work through the use of a machine.

Among the dies, the most widely used are sliding, split and solid products. Solid dies have the highest level of rigidity, so they are used for cutting the highest quality threads.

Using split dies produces less precise threads. Sliding-type instruments are placed on clamps with special guides. To solve a wide range of problems, it is recommended to purchase a set of several of the most popular dies.

Most sets consisting of dies and taps are sold in durable and convenient cases made of plastic, less often made of wood. Transporting and storing the tool in this form is much more convenient and greatly simplifies the search for the right product. It is better not to save on purchasing a set - it is more profitable to purchase products made of high-quality steel once than to try to save on buying a bad tool that will fall apart in your hands at the most inopportune moment.

Thread types

By using taps of various categories, as well as various types of dies, you can create different types of threads on the surfaces of the part. Depending on the type of thread, taps are divided into the following categories:

- metric _ These are devices used to cut metric threads. The cut component of the thread in such variants has the configuration of an isosceles triangle, and all its characteristics are measured in millimeters. The markings of such taps contain the letter “M”. To select metric taps and pre-hole diameters, a special reference table is used;

- inch . The working portion of such taps has a conical configuration. The diameter of inch devices is measured in inches, and the pitch is measured in the number of threads per inch (25.4 mm). The slope of the average plane of taps of this type is 1°47'24″;

- pipe _ This includes tubular and conical devices used in pipe connections.

Taps can be used for holes with different threads. For left-handed threads they differ from right-handed devices only in the direction of the rise of the line of the cutting part. There are various taps for thread cutting, the size chart includes the types you need.

Metal Cutting Tools – Taps and Dies

A long metal drill is used to make through and dead-end passages in massive objects. Due to difficult working conditions, the speed and productivity of these drills is relatively low. This type of tool is produced in accordance with GOST 886-77, GOST 2092-77 and GOST 22094-76. This drill has significant resistance to fracture and overheating. Works with cast iron, non-ferrous metals and alloys. I produce the most common drills of this type in the range: diameter - 1-20 mm, length 56-254 mm. They are characterized by a long working distance. The tip angle of the working edge is usually 118-135. This improves drill performance characteristics and extends service life. An elongated metal drill is used when making deep holes, where chip removal and tool cooling are difficult. During the production of this tool, the requirements for alignment and surface grinding are more stringent, and all errors of the device must be minimal. The drill material must be sufficiently hard, but at the same time resistant to fracture. Sharpening a drill for metal. It makes more economic sense to sharpen drills with worn edges rather than throw them away, as is sometimes done. There are different methods for this operation, according to the type of drill and the required cutting edge angle. There is a universal angle - 118-120 degrees, suitable for many types of drills, but applicable only for diameters up to 12 mm. The method of rehabilitating the tool depends on the type of diameter and purpose of the drill; to accurately determine it, there is a document “drill sharpening angle for metal table”.

Taps and dies are used for cutting or restoring threads in holes and workpieces

Taps

A device for making internal threads, calibrating them or restoring them.

There are the following types of this tool: • Manual, machine and machine-manual • For driving through and blind holes • Roughing and finishing It has a passage and a calibrating part, the first guide, the second performs the final formation of thread grooves. Dies

- A toroidal-shaped device (reminiscent of a nut) used for cutting external threads and restoring their damage. The die can be whole or sliding; in the latter case, using a special screw, you can change the cutting diameter within the limits determined by the resolution of the tool.

Types of metal-cutting taps

The machine tap has helical, shortened grooves and a shank adapted exclusively to the machine chuck. Unlike manual ones, it can produce high-quality threads in one pass. The hand tap is adapted for a hand crank. Used for manual cutting of various types of threads. They are produced in a set of 2-3 pieces, the rough tap provides a guide penetration, the finishing tap performs the final calibration. Most often, a set of 2 tools is used. Machine tap - manual tap. Universal option for hand crank and machine chuck. The tap used in cutting through threads has 6 turns of the threaded spiral. To drill blind holes, use a tool with three turns on the working part. An inch tap is used in working with threads according to the Western system, which is still accepted in the standardization of the USA, England, Australia and countries that support this calibration. They have from 2 to 3 devices included and three points for determining accuracy. The parameters are determined by special regulations and a table.

Metric thread on taps and dies

Taps M

with metric threads fixed in the Russian Federation and the international system, classified according to GOST systems from 24705-2004 (ISO 724:1993) to GOST 8724-2002, Mainly used in the diameter range 1-600 mm, thread pitch 0.25-6 mm . The main type of fastening threads, its properties are determined by GOST 9150–81, is a profile protrusion of triangular geometry, the angle between the sides is 60. The shape of the profile spaces is unlimited and can be made round or flat. The profiles of the external and internal threads should differ in the ratio of tips and valleys for better adhesion. GOST 8724–81 establishes the values of diameters and thread pitches; the systematization is given in detail in the corresponding tables.

Trapezoidal thread taps Tr.

— Trapezoidal thread with an angle of 30 degrees, Н=1.866Р. Use is determined by GOST 9484-81. Used in transmission units: screws in calipers, running units, ship mechanics.

American and British inch thread

Inch (pipe) thread

– Its main properties: diameter, measured in inches, and the number of threads. The specificity of this type of thread is in a special unit of measurement - the pipe inch (33, 249 mm). In addition to the traditional size, it takes into account the thickness of the pipe profile; they also use the unit of measurement for a half-inch pipe of 21.25 mm. Unlike metric ones, the protrusions of the external thread are more pointed, and the internal threads are rounded. It is used in various pipelines, units with such systems, and sometimes in everyday life.

BSW (British Standard Whitworth) taps

— British inch thread, Whitworth thread.

A native English standard developed in the mid-19th century. engineer D. Whitworth. There are two such standards, large, above (BSW) and with finer cuts BSF (British Standard Fine)

- British inch thread, Whitworth thread. They are classified by generally accepted tables: “Whitworth Coarse Thread BS 84 BSW”, Whitworth Fine Thread BS 84, etc. There are other types of Whitworth threads, for example BSW (British Standard Whitworth) - British inch thread, Whitworth thread - British pipe non-self-sealing thread. These classes are mainly used in various pipe connections.

Pipe taps G

— Pipe cylindrical thread. Similar to Whitworth cutting, has a profile close to triangular geometry, angle 55. The peaks and grooves are rounded. Compatibility and use are regulated by GOST 6357-81. G is the index of the threading passage on the pipe. Often there is no G designation on the dieheads, then any marking in fractions should be attributed to the above parameter.

NPT (National Pipe Thread) Tapered Inch Taps

— American conical (pipe) thread. This is a standard for pipe connections, measured in inches, introduced in the USA and some other countries. Tops and sinks 60. In the Russian Federation, the use is regulated by GOST 6111-52.

Taper taps R/Rc

- inch with cylindrical thread (pipe thread). Use is defined by ISO 7-1\GOST 6211-81. Now it is used less frequently and is gradually being replaced by a similar one in metrics. Such connections are often used in various pneumatics, pumps, oil pipelines, and are found in photo/video equipment. Commonly used in North America.

UNF (Unified National Fine Thread) cylindrical taps

— American inch thread. This is a unified fine thread. The exact classification for international use is in the corresponding table Unified fine thread UNF ANSI B1.1. The profile parameters of this cut are: angle 60, height H=0.866025P. This corresponds to metric options, except for inch measurements. Mainly used in hydraulics: fittings, reducers, adapters.

UNC (Unified National Coarse Thread) taps

— American inch thread, unified coarse thread. Developed in the USA, accepted as the international standard for coarse pitch threads. It is distinguished by a flat top, the depressions are flat or rounded. The most common type in the Western inch system, it is gradually replacing other inches.

Criterias of choice

First, the type of device is selected based on the type of thread and its purpose. Accuracy conditions determine whether a single stamper should be used or a set is required. In addition, taps are produced with different finishes of their cutting element, which has a great impact on the reliability of thread cutting.

The material in which the threads need to be cut influences the choice of device. Thus, it is necessary to take into account the leading angle of sharpening the teeth. It will be 5-10 degrees for steel, 0-5 degrees for copper alloys, 25-30 degrees for aluminum and alloys. Devices can be made from simple steels, durable steels or strong soldering, which should be taken into account when considering what material is being processed.

The main selection is made according to the diameter of the hole made in which the thread is cut. The diameter of the working device should be slightly smaller than the diameter of the hole. Thus, for a metric M20 thread (working tap diameter 20 mm), the diameter of the hole made will be 19 millimeters. With metric, if there are no special conditions, then a standard step is taken. For example, M4 thread - pitch 0.7 mm, M5 - 0.8 mm, M10 - 1.5 mm, M12 - 1.75 mm, etc.