Application

Beginning builders sometimes find themselves in a difficult situation.

The drills are new, of a good brand, the drill is in working order, but the resulting hole is not at all as planned, or does not work out at all. Often the reason for failure does not lie in poor work skills or a low-quality tool. The first thing you should pay attention to is the materials from which the drill is made and the surface where you want to make the hole. The basic rule is that the cutting tool must be harder than the thing it will cut.

Proper sharpening of the tip is also important.

If you take a high-quality metal drill and try to make a hole, for example, in concrete, the product will quickly fail. It is not intended for such purposes. Drills with Pobedit tips are suitable for processing the hardest surfaces. Their cutting part is coated with an alloy called “win”, which has increased strength.

On the contrary, such products are often not suitable if they need to be processed, for example:

- plastic;

- steel;

- tree.

Pobedit does not cut the material, but rather crumbles it, so the holes are shaggy, ugly and larger than necessary. In the case of plastic, the necessary chip rejection is not ensured. As a result, the hole quickly becomes clogged, which leads to undesirable consequences:

- the load on the drill increases;

- operating time increases and efficiency decreases.

Because of these features, many masters, especially the “old school” ones, advise using pobedit only in suitable cases. However, the classic pobedit drill gradually changed. Now on the shelves there are products with special soldering (inserts), which are used to work with various materials, including “inconvenient” ones. For example, you can find a pobedit metal drill.

What is it that will win

Pobedit, an alloy containing 90% tungsten and 10% cobalt, was developed in 1929 by Soviet specialists. The main task that the developers set themselves was to create a material capable of imparting exceptional hardness to the working part of the cutting tool. Pobedite brazing began to be made from the new alloy, which made it possible to significantly increase the efficiency of using drills, as well as to process high-strength materials with their help.

In the time since the appearance of Pobedit, the alloy has been constantly modernized. As a result of this modernization, quite a lot of varieties of tungsten-cobalt alloys have been developed, many of which are distinguished by higher strength, more affordable price and ease of production technology. Despite the fact that the ratio of components contained in such alloys may differ greatly from the composition of classic pobedit, they are still called pobedit.

Pobedite tips for drills and augers

It should be borne in mind that a drill with a Pobedit tip does not cut, but crumbles the material being processed. That is why a drill tipped from Pobedit is optimal for making holes in concrete, stone and brick, but is not suitable for processing wood, plastic and steel. When trying to drill into a wooden product, such a tool will simply tear the wood fibers. As a result, the inner surface of the hole will be “shaggy”, and its diameter will be larger than required. It is also not recommended to use a Pobedit drill for metal work: it will not be able to form a high-quality hole in such material.

Until recently, drills of different categories were used to form holes in materials of varying hardness. Today, drills with various pobedite tips are produced, which are specially designed for drilling materials that differ in structure and degree of hardness.

Drills with replaceable carbide inserts are used for industrial drilling

Properties of alloys

Properties of refractory metals and alloys

The properties of metals and alloys are completely determined by their structure (crystalline phase structure and microstructure). The macroscopic properties of alloys are determined by the microstructure and always differ from the properties of their phases, which depend only on the crystal structure. Macroscopic homogeneity of multiphase (heterogeneous) alloys is achieved due to the uniform distribution of phases in the metal matrix. Alloys exhibit metallic properties, such as electrical and thermal conductivity, reflectivity (metallic luster) and ductility. The most important characteristic of alloys is weldability.

Common notations

Mechanical and physical properties of metals and alloys

The percentage of certain substances affects the various qualities of drills, cutters or discs. There are several ways to find out these numbers, one of them is marking. It is this that they initially focus on when setting the goal of handing over hard alloy scrap. The price greatly depends on the metallic composition of the materials, as well as its contamination.

Terdoalloys are regulated by GOST 3882-74 – view / download GOST.

Currently used hard alloys are divided into:

Tungsten alloys of the VK group: VK3, VK3-M, VK4, VK6, VK6-M, VK6-OM, VK8, etc. In the symbol, the number shows the percentage of cobalt. For example, the designation VK8 indicates that it contains 8% cobalt and 92% tungsten carbides. The letters M and OM indicate fine-grained and especially fine-grained structure;

Titanium-tungsten alloys of the TK group: T5K10, T15K6, T14K8, TZOK4, T60K6, etc. In the symbol, the number after the letter T shows the percentage of titanium carbides, after the letter K - cobalt, the rest - tungsten carbides;

TK brand carbide end mills

Titanium-tantalum-tungsten alloys of the TTK group: TT7K12, TT8K6, TT20K9, etc. In the symbol, the numbers after the letter T show the percentage of titanium and tantalum carbides, after the letter K - cobalt, the rest - tungsten carbides.

Carbide scrap

Using alphabetic and numerical expressions, they understand what kind of metal they are dealing with. As a rule, in the Russian version this is the first letter of the name of the element, the number next to it indicates the percentage of each of the components, sometimes there are two or three. Additional letters M indicate the grain size of the impurities. For example, the marking VK10ХОМ indicates that the fine-grained alloy contains 10% cobalt, the rest is tungsten, but part of the carbide of this element is replaced by chromium carbide.

However, these materials are known for their ability to work under harsh operating conditions: at high temperatures, while maintaining appropriate speeds. Therefore, you can also see type markings: HRA 80-92 (HRC 73-76), indicating the hardness of the materials. It is especially often displayed on imported pieces of equipment.

But on the territory of Russia, at scrap metal collection points, the most popular scrap of hard alloys is VK, TK, TTK. Their composition a priori includes tungsten, then the content of titanium and tantalum is read by numbers. A separate category of tungsten-free vehicles is labeled as TN or TNM.

Reviews

| Igor, Yaroslavl |

| I was going to build a bathhouse from willow tree trunks, but they were hard and dry, like bone. They lay in the yard for several years, nothing could take them - not a chainsaw, not a hand chain. I had to buy Shtilevskaya from Pobedit. It is very easy to saw, small sawdust began to appear only towards the end of summer - after two months of active use. The teeth did not have time to become dull or crushed. I think this chain will survive more than one saw. |

| Dmitry, Rostov |

| I was buying a chainsaw and they offered to take the coolest chain right away, but I just had a lot of firewood. I sawed all summer - the teeth were like new. I sharpened it once with a diamond wheel. The teeth are hard, and the chain itself is no different from the usual one - it quickly stretched. I had to knock out the bushing and shorten it by a couple of links. It’s working for now, but if I shorten it further, it will either stop hitting the sprocket or erase it altogether. For the same amount you could buy 3-4 regular chains and not fool your head. |

| Andrey, Tula |

| I have long dreamed of a powerful victorious chain and bought it at a big discount on the Internet. As it turned out, they sold me a Chinese fake - the first time I cut the frostbite, the cutting edge simply jammed. Although the teeth looked like they were made of real hard alloy. |

Thus, pobedit chains cannot be called economical. In cost they are equal to 3-4 chains and one carbide chain lasts about the same number of times longer. Their undoubted advantage is that they can cut things that ordinary chains cannot and do not require frequent sharpening.

How to obtain hard alloys

Metal compounds are a mixture of powders that are pressed and baked. It contains carbides and cobalt. The powders are mixed in baking dishes and pressed under a pressure of 200 kgf/cm2. After pressure treatment, the molds are heated to a temperature of 1500 degrees. Ready-made compounds are used in the production of difficult-to-process materials.

Properties of hard alloys

To understand which metal or mixture is the strongest in the world, you need to know their properties. The main characteristics will help you understand certain types of materials and use them wisely in production. Properties of hard alloys:

- High mechanical and thermal shock strength.

- Wear resistance.

- Red fastness. This indicator appears at temperatures from 900 to 1000 degrees.

Properties of hard alloys such as impact resistance, ductility, compressive or bending strength and hardness directly depend on the amount of cobalt contained in the compounds. The grain size of the tungsten carbide is also important.

Characteristics of hard alloys

To determine the hardest alloy, you need to understand the characteristics. These include the chemical composition of the metal compound, its mechanical and physical properties, and the process of obtaining finished alloys.

Mechanical and physical characteristics:

- Heat resistance.

- Density (14.9g/cm3–15.2g/cm3).

- Hardness (89.5HRA-91 HRA).

- Thermal conductivity - 51 W.

- Permissible strength - 2150 MPa.

These characteristics also include the resistance of the compounds to the effects of corrosive processes. The hardest alloy has inflated physical and mechanical characteristics.

Heat-resistant metal

Stamps

According to state GOSTs, special markings are established that mark all compounds of hard metals. It consists of capital letters and numbers:

- VK6M - tungsten-cobalt mixture. The number 6 indicates the amount of cobalt in the composition. The letter “B” indicates tungsten, respectively, the letter “K” indicates cobalt. The letter “M” indicates the area in which this alloy is used. Tools for metal processing are made from it.

- VK2 - in this case the mixture contains 2% cobalt and 98% tungsten.

- BK8 - this mixture of cobalt contains up to 8%.

- T14K8 - such compounds contain a third element - titanium. It contains 14% of it. Cobalt 8%. Everything else is tungsten.

- T5K10 - similar to the previous mixture, in which 5% titanium, 10% cobalt and 85% tungsten.

- TT7K12 - tantalum is added to the above elements. Its percentage is the same as that of titanium.

Alloy grades are indicated on finished parts and blanks.

Areas of use

There are many applications for hard alloys. These include:

- Production of tools for metal processing.

- Manufacturing of parts for industrial equipment.

- Equipment for working with metal workpieces.

Often hard alloys are used as a coating on softer ones. The scope of application extends to the construction of large transport vehicles.

lekalschik' — blog

I decided to make myself carbide, anti-vibration holders for a lathe for internal boring. I have 3 pieces. They have proven themselves to be excellent. But they are bourgeois, expensive, from eBay.

I bought 330 mm carbide rods from a flea market that had passed away. These are high quality rods, polished. 8,12,16,20mm. They probably served as blanks in the manufacture of cutters and drills, but they didn’t tell me the mark.

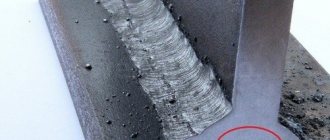

The holders are made simply by soldering a steel head with refractory solders, with a fit under the cutting plate. There is one “secret” here. To increase the fracture resistance of the holder, soldering is carried out not on the flat end of the rod, but on the conical surface. Which increases the solder joint area.

I decided to taper the ends of the rods in a lathe using CBN cutters. (Machine IZH250ITPM) And during the turning process I came across an unexpected obstacle in the form of a “pobedit” of extreme hardness and fragility. I will say that I have had to grind hard alloys more than once and never had any problems. I was always able to select the sharpening of the cutting edge and finish the job. But not this time... This “will win” defeated me. That's it. photo

No matter how much I was exiled, I couldn’t. Well, it doesn’t sharpen! It breaks like glass. Although the glass would break

Now I'll probably have to solder the head onto an oblique cut. Stupidly grinding on a diamond wheel. Diamond, thank God, gives in.

Would you like to find out what kind of alloy this is???

One cutter is completed and, at the request of the worker, I will describe the process of its manufacture. Although initially I only wanted to draw attention to the properties of hard alloys, which surprised me.

So, the boring bar blank is chosen with a diameter of 12 mm. under it we sharpen the tip, with a corresponding recess.

It should be noted that the adjustment should be performed as accurately as possible. Because, in soldering, as in gluing, the thinner the seam, the stronger the connection.

Here, in the photo, almost all the materials used for soldering. Burner, gas, silver solder and flux.

Flux can be found at the market, in refrigeration goods. Well, or buy it over the hill.

The flux is moistened to a paste-like state and applied to the products being soldered. How is it better than borax? Well, the melting point is lower, it does not foam and is not blown away by a flame, and it can also be removed from parts with water.

I bit off a couple of pieces of solder and threw it into the recess of the tip, where it melted. After cooling we have this look.

Then we grind the tip in a lathe to a diameter of 12.5 mm. Please note that the seam is almost invisible.

Further, if you wish, you can use your capabilities to process the seat for the cutting blade. Mill it in a vice or on a CNC machine. I followed the latter method, using the miniature size CCMT060204 plates available in the assortment.

Hello! Conducted tests. Blank made of steel 45 with a hole of 14 mm. Bored with this cutter on an IZh250ITPM machine. Boom reach 100 mm. Depth of cut 0.25 mm feed 0.05-0.075 mm per revolution. The speed was varied by a frequency control, about 1000 rpm. Sharpens without squealing. Steel plate.

Design features and operation

Unlike some other drills, Pobedit drills do not require sharpening. They initially have the required tip structure (angles) for proper operation.

The cutting part is represented by two “shoulders” of approximately the same width. Where they intersect is the future center of the hole. If their widths are different:

- the diameter of the hole will determine the larger “shoulder”;

- as the craftsmen put it, the drill will “break” the hole: it will turn out larger than necessary;

- physical activity will increase;

- the intensity of the drill will increase;

- drills break more often.

If the tip becomes dull, it can be sharpened. In this case, you need to keep in mind:

- The angle depends on the hardness of the material to be processed. The stronger the surface, the smaller it is.

- Pobedit does not tolerate too much heat. At high values, the tip may crack or even separate from the drill. Therefore, you need to prevent overheating and cool it more often when sharpening. For example, plain water will do.

- If overheating does occur, do not cool it suddenly. Otherwise, cracks will appear. It is best to allow it to cool naturally, that is, on its own.

If the diameter of the product is small, then it will most likely fail earlier. This rule applies even to experienced craftsmen. Therefore, it is better to stock up on a certain supply of drills to save time and nerves. Some masters argue that sometimes “courage” is also important. The work spirit can also be lost after going to the store. The extra ones will still come in handy later.

Who invented the wheel?

Ah, the wheel. The tool that underlies modern transport, and much more. The invention of the wheel has become a cultural stereotype dating back to prehistoric times, but did the wheel really have an inventor?

We do have a definite "oldest wheel", but what it was used for may surprise you... The first wheel we have archaeological evidence of was discovered in Mesopotamia and dates back to approximately 5,500 years. However, it was not used for transport, which dates back 5,500 years, but rather was used to make pottery.

Early wheels and their innovations

It is believed that Mesopotamian cultures were the first to invent the wheel, although this assumption is based solely on existing archaeological evidence. The Mesopotamian civilization used these early wheels to create pottery. It took another 2,000 years or so before the ancient Greeks developed the idea of wheels sufficiently to use them for transporting goods.

These first wheels and axle carts, developed by the ancient Greeks, were very simple in design. Essentially, they consisted of just two rods with a wheel and axle at the end. They could be used to transport large loads across fields. When were wheels invented? As we mentioned above, wheels were first invented around 3500 BC. E.

This means that their invention came after the invention of agriculture, boats and woven fabrics. From the perspective of the time, this places the invention of the wheel somewhere between the Neolithic and Bronze Ages.

Why the wheel is such an important invention

One of the reasons it may have taken so long to invent the wheel is that wheels and axles do not occur in nature. Tools such as levers or forks are based on natural things, such as forked sticks. Although tumbleweeds and dung beetles use rolling, rolling without an axle is virtually useless.

The difficulty with the wheel is that it does not represent a cylinder rolling along the edge. He figures out how to connect a stable stationary platform to this cylinder without interfering with the movement of the cylinder.

A closer look at the invention of the wheel and axle

Around 1975, archaeologists discovered the Bronoczyce pot, a ceramic vase discovered in a Neolithic village in Poland. It is thought to date from 3635 to 3370 BC and contains the earliest known depiction of what is likely is a wheeled vehicle. To be precise, this means that the use of the wheel and axle may have first appeared somewhere on the Eurasian steppes. In fact, many words associated with wheels and carts come from the language of the Trypillians, who lived in what is now Ukraine.

RELATED: HISTORY AND EVOLUTION OF THE WHEEL

The first wheel and axle carts had a fixed wheel and axle design in which the wheel and axle rotated together. Essentially, pegs were used to hold the wheel and axle in place, and all movements were performed by this axle-wheel combination. It was only later in the history of wheels that bogies were developed that used holes rather than pegs to hold the axles in place.

Source: Pxhere / Public Domain

This is more difficult because to create a fixed axle with rotating wheels, the ends of the axle and the holes in the center of the wheels must be almost perfectly smooth and round. Otherwise, friction will prevent the wheels from turning.

The axles also had to fit snugly into the holes in the wheels, but remain loose enough to allow them to spin freely. This is why the development of the axis probably did not occur until after 3500 BC. E. when the first copper chisels and gauges were created so that precision-fitted holes and axles could be bored.

At this point, the wheel had essentially evolved into what it is today, except these wheels were made of wood instead of rubber and metal.

Modern wheel

Today's wheels have virtually nothing in common with early wheel designs. While they are notably still round, they are fundamentally different in every other way. All this is due to innovations in materials science and the development of mechanical engineering, which makes it possible to create more complex but effective wheel assemblies.

The invention of the wheel opened up access to a variety of other tools, including chariots, wheelbarrows, mills; as well as gears and a range of devices, from steamships to bicycles to watches, that use gears.

Wheels were one of the most important discoveries in human history. It was also one of the most complex, requiring a number of different developments to be carried out simultaneously. In fact, the invention of the wheel was such a difficult task that some archaeologists have hypothesized that it probably only happened once in one place. From here it spread so quickly that today it is almost impossible to determine exactly where it originated.

.

Team compositions

Rostov

It is important for the club from Rostov-on-Don that it was able to retain the team leaders. Neither Eldor Shomurodov nor Mathias Normann have left anywhere yet

But despite this, Rostov also strengthened its squad. In the summer, the Japanese Kento Hashimoto joined the team. He has already played the first match as a substitute, but as time goes on he will probably start playing more and will be useful. The 26-year-old football player can become Rostov's wild card in the match with Zenit. In any case, Valery Karpin loves to surprise.

Kento Hashimoto (Rostov)

Zenith

During the summer transfer window, Liverpool defender Dejan Lovren joined the St. Petersburg team. Sergei Semak did not delay his debut, so the Croatian played from the first minutes in the Super Cup against Lokomotiv. And Lovren performed well. As it turned out, Zenit with a new defender can position the defensive line higher than usual. In addition, Lovren plays excellently with both feet and is generally much more confident than Branislav Ivanovic, who occupied his position previously. Lovren will certainly play a big role in the match with Rostov and in general during the current season.

Dejan Lovren (Zenit)

How to choose the right grade of carbide

When choosing an alloy grade, you need to pay attention to their separation. These can be titanium-tungsten and tungsten mixtures

Steel is processed first, cast iron second.

Physical and mechanical characteristics also need to be taken into account. The power of the equipment with which the processing will be carried out plays an important role.

Advantages and disadvantages

Solid metal compounds have both advantages and disadvantages. Strengths include:

- High mechanical and thermal shock strength.

- Uniformity of structure.

- The sharpening on the instrument lasts much longer.

- High temperature resistance.

Disadvantages include the high price of tools and equipment made from solid compounds.

Hard alloy products

In hardware stores and markets you can find various products made from mixtures of hard metals. These can be various tools, parts for machines, machine tools, power tools, construction plates and other products.

Review of the best options

There are not many manufacturers producing carbide chains yet. The most common ones are from Stihl and Oregon.

Picco Duro 3 Stihl

Low profile pobedite chain made in Switzerland. The teeth are made entirely of hard alloy, without soldering with copper.

With a link thickness of 1.3 mm, the blade is designed for medium power tools. Used in semi-professional and household saws. According to reviews, it can work without sharpening 4-5 times longer than a regular one.

Number of links – up to 55.

Cost – 1600-2000 rubles.

Stihl 325″ Rapid Duro 3 (RD3) 1.5 mm

Pobedite chain with a link thickness of 1.5 mm. Professional tools usually work with this thickness. The teeth are coated with an alloy by electrolytic chrome plating, which ensures high strength of the connection between the base and the solder.

If you replace the bar and drive sprocket, you can use this blade on a regular saw.

The number of links is from 60 to 72.

Cost – 2250-2600 rubles.

Stihl 3/8″ Rapid Duro 3 (RD3) 1.6 mm

Carbide blade with links 1.6 mm thick. This thickness makes the chain more durable and resistant to stretching. With a 3/8-inch pitch, the blade is great for saws where the drive sprocket is a single structure with a clutch.

Number of links – 60 or 66.

Cost – 2500-3000 rubles.

Stihl 3/8″ Rapid Duro Rescue (RDR) 1.6 mm

Durable chain for working in difficult conditions. Tungsten carbide is soldered onto the entire surface of the cutting blade. This type of canvas is used by rescuers and firefighters. Easily saws through wood, small metal elements, armored glass and some composite materials.

The connecting teeth are equipped with three projections, with the help of which the working part of the links falls directly into the cutting groove. This reduces the risk of damaging the carbide tip.

Number of links – 72.

Cost – 9300-11000 rubles.

Carbide chains from Stihl can also be used for saws of other brands - Makita, Husqarna, etc.

The manufacturer claims that the chain continues to operate efficiently even at low air temperatures.

Oregon M91VXL057CR 3/8″ 1.3 mm

Pobedite chain with chrome plates. Link thickness – 1.3 mm. American made chains. In addition, the manufacturer provides a large selection of blades with any thickness of links, for any sizes of tires and sprockets.

The steel base of this blade is somewhat softer than that of Stihl chains. Because of this, they dull and stretch faster, but can be sharpened by hand.

According to reviews, such chains are somewhat weak for professional use, but are ideal for domestic needs.

The number of links is from 50 to 57.

Cost – 950-1300 rubles.

Oregon M75LPX072CR 3/8″ 1.6 mm

Carbide chain with chrome plates. Thickness – 1.6 mm. The increased number and thickness of links allows the blade to be used with powerful engines. Widely used for working with charred wood, which becomes harder when exposed to fire.

It dulls somewhat faster than Shtil, but you can sharpen it yourself, without the use of expensive tools.

The number of links is from 60 to 72.

Cost – 2500-3250 rubles.

Applications and products of hard alloys

The material is widely used in modern industry. The production technology of the alloys themselves is also developing, their quality is improving, the composition is changing, and new markings are appearing. But in addition to changing the material itself, the principles of working with it also change. New types of compounds applied to products are emerging, thanks to which they acquire new functions and roles in industry.

Today, hard alloys are used:

- In the production of cutting tools. Tools made from high-strength materials can improve the quality of production, speed it up and reduce the cost of scrap and the purchase of materials. High heat resistance and strength allow you to work at extreme speeds. Therefore, alloys are much more valuable in the production of tools than simple steel. In their production, diamond blanks are often used, which significantly improves the quality of the material and its properties. Examples of such tools include cutters, drills, etc.;

- In the manufacture of high-strength parts for mechanical products, industrial machines, automobiles and equipment, knives and blades for graders - in mechanisms that experience high overloads and forces;

- In the production of equipment intended for heavy loads. For example, mining equipment, drilling rigs. Alloys are used in supports of industrial scales and in other mechanisms designed for high forces and pressures;

- In the manufacture of small but key parts of various mechanisms. For example, bearings, terminals, various protective coatings, etc. are made from this material.

- In the production of various shapes and matrices, in the casting of steel products, both simple and complex in shape.

- For mechanical post-processing of complex materials (steel, cast iron, non-ferrous metals, heat-resistant materials, etc.).

- When stamping various products.

Before purchasing tools, parts, or simply raw materials that contain alloys, you must carefully study what class they belong to and what properties they have. This will help to understand the meaning of the markings, which indicate the composition of the product and, as a result, its ability to withstand certain loads. Each class of material is intended for use in a specific area of production and may be completely unsuitable for another, which should also be taken into account.

Rating: /5 — votes

What we are treated with: Analgin. To numb the pain or defeat the disease

Scientific review of a popular painkiller

Why is one of the most accessible and well-known painkillers in our country dangerous, against what types of pain is it effective, how do medical researchers fight for the lives of patients with pharmaceutical companies and with each other, why Sweden first banned Analgin, then allowed it, and then banned it again, read the material from Indicator.Ru from the section “How we are treated.”

Medicines designed to combat pain, fever and inflammation are among the most sought after on the pharmaceutical market. They are in any medicine cabinet and are often sold without a prescription in Russia, but in reality, many of them can seriously threaten health, especially if you do not first weigh all the pros and cons of such treatment and do not take into account risk factors.

The hero of today’s issue of the “How We Are Treated” column is the familiar Analgin - a cheap and accessible pain reliever and antipyretic. You may be surprised, but it is prohibited for sale in Western Europe and the USA, as well as several other countries.

From what, from what

The active ingredient in Analgin is called metamizole. It was first synthesized in 1920 by Ludwig Knorr, who is also known for discovering and studying several non-steroidal anti-inflammatory drugs, such as antipyrine; He was also interested in the properties of morphine and codeine. At the beginning of the 20th century, there were not as many rules and complex approval procedures for the drug as there are now, so the drug began to be produced just two years after its discovery. In the West, a drug based on metamizole is called Dipirone.

Metamizole molecule. Sulfur atoms are indicated in yellow, carbon in gray, oxygen in red, nitrogen in blue, and hydrogen in white.

Scientists have not fully established the exact mechanism of operation of this molecule, but metamizole presumably blocks the synthesis of prostaglandins in the brain and spinal cord. We have already told the heartbreaking story that the causes of pain and inflammation lie precisely in their incorrect behavior after meeting with the cyclooxygenase sisters in the article about Nurofen. However, Metamizole is not as hardworking as our previous heroes: he does not go to suppress the uprising of dissatisfied prostaglandins personally, but sends his derivatives. It was also not found to be associated with type 1 cannabinoid receptors located in the cells of the central system, which substances from hemp, as well as paracetamol, are blamed for. Although it most likely has some influence on this system. Other authors, on the contrary, argue that, although Analgin himself did not work there, his subordinate metabolites could well act on type 1 cannabinoid receptors at his “guidance.”

The Cochrane Collaboration reviewed our review, which looked at moderate to high quality studies assessing the ability of metamizole to help with post-operative acute pain. Despite the confusion, the review confirms that this drug really works.

The Cochrane Library is a database of the Cochrane Collaboration, an international non-profit organization involved in the development of guidelines from the World Health Organization. The organization's name comes from its founder, the 20th-century Scottish medical scientist Archibald Cochrane, who championed the need for evidence-based medicine and good clinical trials and wrote the book Efficiency and Effectiveness: Random Reflections on Health Care. Medical scientists and pharmacists consider the Cochrane Database to be one of the most authoritative sources of such information: the publications included in it have been selected according to the standards of evidence-based medicine and report the results of randomized, double-blind, placebo-controlled clinical trials.

Compared to placebo, which helped only 30% of patients, a single dose of metamizole 500 mg improved the condition of 70% of study participants. True, the authors still had doubts about comparing the active substance Analgin with other painkillers: the results were too ambiguous, and the patient samples were small.

The effect of Dipiron (Analgin) against acute attacks of pain (for example, after the removal of a wisdom tooth) and in renal colic has also been proven. In the latter case, scientists also proved that intravenous injections help better than intramuscular ones.

Side effects

Analgin can be dangerous in a completely different way: our granulocytes, one of the types of leukocytes, do not like it. Associated with them is a side effect of long-term use of the drug - agranulocytosis, that is, a drop in the level of granulocytes to 5% or even lower.

Granulocytes are granular leukocytes, white blood cells, which are characterized by a clearly visible nucleus and large granules inside. In every cubic millimeter of our blood you can find about 2-6 thousand of these cells. Their goal is to fight infections, or immune protection of the borders of our body. Agranulocytosis may be associated with the effect of Analgin on type 2 cannabinoid receptors.

There is scientific evidence to support this idea. Scientists from Germany, the USA and Italy prove that substances resulting from the breakdown of metamizole are able to bind both cannabinoid receptors. They also prove that these substances react with type 1 and type 2 cyclooxygenases both in vitro and in living tissue.

When the ranks of immune defenders are so thinned out, the body becomes vulnerable to many bacterial and fungal infections. Stomatitis, ulcers of the mucous membranes, fever, pain in the throat and joints are the first unpleasant manifestations of this condition. It can cause swelling of the larynx and even suffocation. This set of clinical signs can confuse the doctor, so it is not always possible to correctly determine the cause of these manifestations.

In case of complications, an atypical form of pneumonia occurs, which is difficult to diagnose due to the absence of cough and sputum, necrotic enteropathy (damage to the intestinal walls, pain and bloating in the abdomen, loose stools), which can lead to the death of the patient if bacteria from his intestines enter the blood . Also, with severe agranulocytosis, toxic hepatitis can develop - severe damage to liver tissue.

However, scientists continue to argue about how often taking Analgin leads to this disease.

The first articles about the dangers of Analgin began to be published back in the late 1960s, and one of them caused a stir among foreign doctors: according to this article, 0.79% of patients taking Dipiron also received agranulocytosis, and a third of patients with agranulocytosis died.

After this, Analgin-Dipirone was banned in the UK. The UK's example was followed by other countries where metamizole-based drugs disappeared from pharmacies in the seventies. At the same time, in Eastern Europe and Latin America, the same drugs were easily and freely sold, considering them to be safe analgesics. Therefore, the Europeans did not calm down and continued to look for evidence that would confirm the involvement of metamizole in the occurrence of agranulocytosis or justify the drug.

An international study was conducted, involving representatives from seven European cities and Jerusalem, but a large-scale search that lasted six years led to a rather modest figure: 1 case in 1.1 million patients per week. It looks like an excellent alibi, if you do not take into account that it included only patients in the hospital, and the controls were patients with agranulocytosis, from whom they were asked whether they drank metamizole. That being said, the case—the metric the scientists used—is quite unusual. If you recalculate the same data for a year, the figure will be completely different - 20,000.

Colleagues from Latin America saw a lot of bias in these studies: in their opinion, the risk estimates for using the drug were greatly overestimated. Thus, doctors from Sao Paulo did not find any particular dangers in the use of this medicine and stated that it, of course, increases the risk of developing agranulocytosis, but so weakly that this can be neglected without leaving people without an accessible medicine.

They also conducted another study, including Mexico and Argentina, but the results were the same. However, the author of the Russian review, Maria Avksentyeva, notes that this study was funded by a corporation that absorbed the producers of metamizole. In both studies, the risk of agranulocytosis was about half a person per million per year.

The Swedes also banned the drug. After a large-scale European project, they returned it to pharmacies again, but not just like that, but for the purpose of study. The indications became narrower: only for short-term use for renal and hepatic colic and acute pain after operations, and then doctors began to record side effects. Then the results convinced Swedish doctors that there was a danger, and in 1999 the drug was banned again.

The Dutch studied the effect of medications on agranulocytosis for 20 years, and they also considered metamizole dangerous for use. Library+will+be+unavailable+on+Saturday+01st+July+from+03.00-09.00+EDT+and+on+Sunday+2nd+July+03.00-06.00+EDT+for+essential+maintenance.++Apologies+ for+the+inconvenience), although in a small number of cases.

In a review from Barcelona doctors, metamizole took fourth place in the list of drugs that increase the risk of agranulocytosis, and for some reason no one is going to ban the winners from this “podium.” Leading the list, by the way, was methimazole, used to correct an overactive thyroid gland (that’s how important it is not to confuse the names).

In recent years, several more articles have appeared on this topic. The authors of another systematic review, examining 22 articles on the side effects of metamizole, also confirmed that the risk of agranulocytosis is increased, although its level varies greatly from one study to another. In another large study of a single dose of metamizole for post-operative pain, researchers assessed the drug's side effects in a group of 1,177 children under six years of age. The drug was administered once and intravenously, and no signs of agranulocytosis were found in patients. The same data for adults is confirmed by a review that assessed data from 79 studies.

Taking into account 77 reports from Switzerland and 1,417 international ones, the World Health Organization also summed up its conclusion: according to the conclusions of its experts, the risk is 0.46-1.63 per million person-days of use.

Thus, most of the results boil down to the fact that you should not use drugs based on metamizole for a long time, although, according to some data, a single dose may be relatively safe. Be that as it may, immigrants from Latin America to the United States continue to take metamizole illegally, swearing at local legislation, and some scientists suggest that the drug has a stronger effect on haplogroups common in Europe, so Latin Americans and Asians get much less.

Indicator.Ru recommends: can be used, but not for a long time

Scientific research data indicates the relative danger of the drug with long-term use, although not all scientists agree with this point of view. At the same time, in many developed countries the drug is either withdrawn from circulation or sold strictly according to a prescription, but in others it is freely sold, as in Russia. What to do? To be on the safe side, it is still better to heed the warnings and if you take Analgin, then do it for acute attacks of pain, but not for protracted, chronic pain. You can also make a choice in its favor if other painkillers do not help or are not suitable, but also do not get carried away with this drug and do not take it for more than a few days in a row.

Chronic use of analgesics can be dangerous: some, like many non-steroidal anti-inflammatory drugs, increase the risk of heart attack and gastrointestinal bleeding, others, like Analgin, can critically reduce the level of immune cells, a type of white blood cell, in the blood. And if this happens, you will become defenseless against a number of serious diseases, which can lead to pneumonia, hepatitis, and death at the end of this epic.

But always remember that numbing the pain does not mean defeating the disease itself. Therefore, it is better to try to find out the cause of the problem and eliminate it, if the pain does not go away after a couple of days, than to drink analgesics for weeks, turning a blind eye to a possible threat to your health not only from them, but also from the fact that while “treating” the symptoms you forget about the disease itself.

And if you still drink Analgin, listen carefully to your health: even severe stomatitis and an increase in temperature can be an alarming sign, after which it is better to go to the doctor and ask for a referral for a blood test so that these same leukocytes can be counted for you.

This article was published in the magazine “Idikator” on June 29, 2017.

Author: Ekaterina Mishchenko

Wins: Properties

According to its parameters, it belongs to the category of hard alloys, which, in turn, belong to the group of “superhard” materials. The composition of Pobedit, in addition to tungsten carbide, may include additional components that favorably affect the physical and chemical parameters of hardware produced from this alloy.

Belonging to these classes means that these products, namely pobedit products, the price of which is determined depending on the order, have such advantages as:

- Highest strength;

- Excellent wear resistance;

- Products can withstand very heavy loads.

All metal products are produced in accordance with established production norms and standards. Any product in this category fully meets the regulated GOST of pobedit products, which means it has the required characteristics.

To receive a free consultation on choosing the right product, contact our specialists.

Hard alloys VK, TK, and also TTK - classification and markings

Hard alloy VK based on tungsten carbide

With us you can sell hard alloys VK, TK, TTK, TN, KNT at an expensive price

- VK3b, VK3-M

- VK6, VK6-M, VK6-OM

- VK4, VK8

The marking of the VK3-M alloy makes it clear that the alloy is a combination of tungsten and cobalt. The mass fraction of the latter is 3 percent, and the mark “-M” means a fine-grained structure. “-OM” in other markings indicate particularly fine grain.

Titanium-tungsten hard alloy TK

- T5K10

- T14K8, T15K6

- T30K4, T60K6

In the markings of titanium-tungsten alloys, the number following the letter “T” indicates the percentage of titanium carbides. The letter "K" represents the percentage of cobalt. Tungsten carbide fills the rest of the alloy.

Titanium-tantalum-tungsten alloy TTK

- TT7K12

- TT8K6

- TT20K9

Using TT8K6 as an example, let’s consider the symbol - the number “8” allows you to find out the percentage of titanium carbides, as well as tantalum in the alloy, the number “6” - the percentage of cobalt. Tungsten carbide makes up the rest of the alloy.

Literal as well as numerical expressions allow you to determine the type of metal and its quality. Numbers and letters allow you to find out the percentage content of each element, and the additional letter “M” indicates the grain structure, in this case, fine-grained.

Materials of this type are ideal for use in fairly harsh conditions. They are ready to withstand high temperatures while maintaining their original characteristics. The hardness of the material is indicated by the marking HRA 80-92. Most often, such markings are found on imported components of various equipment.

Russian procurers of secondary raw materials most often accept VK TK scrap. Acceptance of VK TK hard alloy scrap is carried out after checking the quality of the material; for this purpose, markings are used to understand the percentage of components in the alloy.

We provide a full range of services for receiving hard alloys

Supervision of recycling projects

We supervise the disposal of property of public and private companies under contract. This applies to decommissioned ships, railway cars, diesel locomotives, cars, industrial equipment and much more. We have extensive knowledge and experience in this area.

Valuation of hard alloy scrap

We will send our specialist to you so that he can assess the quality of your material in advance. This will allow us to offer you the fairest conditions for receiving your raw materials. If necessary, we will conduct a chemical analysis.

High price for hard alloy scrap

We will offer you the best conditions and a really high price. Since, based on all the data you provide on the material, we carefully monitor the market and ensure optimal logistics.

Financial consulting and document management

We will help you with the competent preparation of all necessary documents for transportation and support of the transaction at all stages. We will advise you on complex issues. We guarantee confidentiality.

Dismantling

Having extensive experience in organizing complex and dangerous work. In the presence of highly specialized workers. We can dismantle anything efficiently and inexpensively. We will carry out dismantling of any degree of complexity in any conditions.

Export

We will provide you with transport for the removal and transportation of waste and scrap metal. Our database includes our own scrap trucks, manipulators, and tonars. With the help of reliable partners, we will help with the transportation of scrap by rail cars or barge.

Team position

Rostov

After a successful start last season, Valery Karpin's team was unable to pass the summer segment of the championship with the same success. Rostov suffered from coronavirus. In preparation for the resumption of the season, several players became infected a couple of days before the first match. As a result, Rostov was unable to provide adequate resistance to its opponents, so the team lost all chances of fighting for the Champions League. The Rostovites fell to the lowest possible place - fifth. Rostov will still play in the Europa League, but the main thing now for Valery Karpin’s team is to regain their previous form.

Zenith

Although Sergei Semak's team won the Russian championship two times in a row, the St. Petersburg team still plays measured football, aimed at results. Even their own fans expect spectacular and especially attacking play from the blue-white-blue team, but the head coach does not tolerate unjustified risks. In the match for the Russian Super Cup against Lokomotiv, Zenit played their usual football. And although the fans could spit at such a game, Sergei Semak won another title, leading the St. Petersburg team. So we just have to get used to the fact that Zenit most often plays in a 4-4-2 formation, where Artem Dzyuba plays a big role.