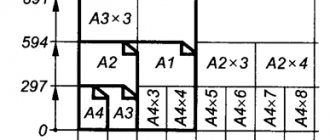

According to SNiP1.02.01-85

detail drawings of metal structures (DMD) are developed at manufacturing plants. KMD drawings are carried out in accordance with the provisions of the “Temporary Instructions for the composition and design of working drawings of buildings and structures. Metal structures. KMD drawings" dated 1979 (hereinafter referred to as the "Instructions").

The drawings included in the KMD documentation are a single document for the manufacture and installation of metal building structures. They must contain all the information necessary for the manufacture of all structural elements, their relative position, and methods of connection.

A set of KMD drawings consists of:

- title page (general data);

- drawings of installation diagrams and assembly units;

- drawings of dispatch elements;

- additional drawings (if necessary).

All instructions in the instructions also apply to the drawings of small metal structures included in the working drawings of AR, KZh and others, according to which they are manufactured.

Marking and designation of channel in accordance with GOST 8240

The height of the channel profile is approximately 1.5-3.5 times greater than the width.

The shape of its cross-section provides it with high levels of rigidity. This allows this type of rolled steel to be used in heavy engineering and construction, mainly for the manufacture of critical metal structures, as load-bearing elements of floors, frames of buildings and structures. In addition, many brands of channels are used in the automotive industry, carriage building, for the manufacture of supports, fences, gates, and for decorative purposes. The geometric parameters and dimensions of the channels of the P series (with parallel edges) and the U series (with a slope of internal edges) are the same, the main difference is only in the radii of curvature of the shelves.

The key parameter in marking and designation is height. Channel number = Height in mm / 10, or, in other words, equal to the height of the channel in cm.

| Channel number | Channel height | Shelf width | Wall thickness | Shelf thickness |

| 5P, 5U | 50 | 32 | 4,4 | 7,0 |

| 6.5P, 6.5U | 65 | 36 | 4,4 | 7,2 |

| 8P, 8U | 80 | 40 | 4,5 | 7,4 |

| 10P, 10U | 100 | 46 | 4,5 | 7,6 |

| 12P, 12U | 120 | 52 | 4,8 | 7,8 |

| 14P, 14U | 140 | 58 | 4,9 | 8,1 |

| 16P, 16U | 160 | 64 | 5,0 | 8,4 |

| 18P, 18U | 180 | 70 | 5,1 | 8,7 |

| 20P, 20U | 200 | 76 | 5,2 | 9,0 |

| 22P, 22U | 220 | 82 | 5,4 | 9,5 |

| 24P, 24U | 240 | 90 | 5,6 | 10,0 |

| 27P, 27U | 270 | 95 | 6,0 | 10,5 |

| 30P, 30U | 300 | 100 | 6,5 | 11,0 |

| 40P, 40U | 400 | 115 | 8,0 | 13,5 |

Marking

If you look at the range of channels, you can see that it includes metal profiles with a wide range of sizes. With such a variety of options offered, it is very difficult to choose exactly the brand of channel that will be optimally suited for solving a particular problem. Naturally, the manufacturers took this point into account. To designate their products, they use markings, which can be used to get a fairly complete picture of the characteristics and dimensions of the U-shaped profile.

Parameters of a channel with parallel flange edges

Markings that comply with GOST 8240-97 include both digital and alphabetic designations. The first number in the designation is the main characteristic; it corresponds to the size of the channel, that is, the distance between its flanges. By the letter in the marking you can determine what type the channel is. These can be products in which the internal edges of the shelves are made with a slope or are parallel to each other (“U” and “P”, respectively), metal profiles of economical (“E”) or light (“L”) type, special purpose (“S” ).

If you need to know all the other dimensions of a channel of a certain brand from the assortment, then for this there is a special table in which they are indicated. The choice of a product of a certain brand is made depending on what kind of loads the structure for which it is planned to be used will be subjected to.

With slanted shelf edges

Size chart for channels with inclined internal edges of shelves (click to enlarge)

Explanation of the additional parameters shown in the table:

- I—moment of inertia;

- W is the moment of resistance;

- i is the radius of gyration.

With parallel edges of shelves

Size chart for channels with parallel flange edges (click to enlarge)

Economical with parallel shelf edges

Size chart for economical channels with parallel flange edges (click to enlarge)

Light series with parallel edges of shelves

Size chart for light series channels with parallel flange edges (click to enlarge)

Special

Size chart for special channels (click to enlarge)

Types of channels - classification, standards

According to the production method, the channel is divided into bent and hot-rolled profiles. A bent profile is obtained by cold profiling from a steel sheet blank (strip). In turn, a bent channel can be equal-flanged or unequal-flanged.

GOST 8278-83 regulates the range and maximum deviations of bent steel equal-flange channel. According to the requirements of this document, channel dimensions can be in the range from 25x26 to 410x65 with a thickness of 2 to 20 mm. The length of the bent profile, which is made from carbon, low-alloy steels, can range from 3 to 12 m.

GOST 8281-80 contains the range and value of maximum deviations of bent steel unequal-flange channel, which is made from ordinary quality grades and high-quality carbon steels, as well as low-alloy grades. Profile dimensions according to this document range from 32x22x12 to 300x80x40, thickness from 2 to 10 mm. The measured length of this profile is 4-11.8 meters.

GOST 8240-97 contains the range, classification and maximum deviations of the dimensions of hot-rolled channels for general and special purposes. The profile of this group can be 50 - 400 mm high. The channel number reflects the section height expressed in centimeters. According to this standard, the cross-section of a channel can have 2 types of profile: 1) with sloped edges (U and C series), 2) with parallel edges (P, E and L series). The width of the profile corresponds to the width of the shelf and can take a value of 32-115 mm. The marking of a channel, for example 10P, reflects its height and type of profile.

There are also highly specialized types of channels. Their shape and size are regulated by relevant standards.

GOST 21026-75 standardizes rolled products with bent flanges, which are used for the production of trolleys. They have only 2 standard sizes SP-10 and SP-12. GOST 5267.1-90 contains dimensions and reference characteristics of hot-rolled channels for railcar construction. The channel number according to the requirements of this standard can take values from 8V to 30V-2. GOST 5422-73 contains the dimensions of hot-rolled profiles intended for tractors. According to the standard, profile No. 5 corresponds to a 24T channel, and profile No. 6 corresponds to 18T.

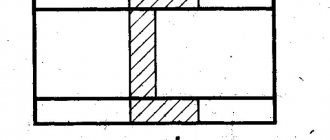

Channel drawing according to GOST (ESKD)

A channel is a standard profile of structural elements made of black rolled steel with a U-shaped section.

The channel drawing is carried out on the basis of GOST 2.109-73 - a unified system of design documentation (ESKD).

You can download this simple drawing for free to use for any purpose. For example, for placement on a nameplate or sticker.

How to draw a drawing:

You can draw a drawing either on a sheet of paper or using specialized programs. No special engineering knowledge is required to complete simple sketch drawings.

A sketch drawing is a drawing made “by hand”, observing the approximate proportions of the depicted object and containing sufficient data for the manufacture of the product.

The design drawing with all the technological data for manufacturing can only be completed by a qualified engineer.

To designate in the drawing, you must perform the following operations:

1. Draw an image; 2. Add dimensions (see example); 3. Specify the technical requirements for manufacturing (read more about the technical requirements below in the article).

It is most convenient to draw on a computer. Subsequently, the drawing can be printed on paper using a printer or plotter. There are many specialized programs for drawing on a computer. Both paid and free.

This image shows how simple and quickly drawing can be done using computer programs.

List of programs for drawing on a computer:

1. KOMPAS-3D; 2. AutoCAD; 3. NanoCAD; 4. FreeCAD; 5. QCAD.

Having studied the principles of drawing in one of the programs, it is not difficult to switch to working in another program. Drawing methods in any program are not fundamentally different from each other. We can say that they are identical and differ from each other only in convenience and the presence of additional functions.

Technical requirements:

For the drawing, it is necessary to indicate dimensions sufficient for manufacturing, maximum deviations and roughness.

The technical requirements for the drawing should indicate:

1) Manufacturing and control method, if they are the only ones that guarantee the required quality of the product; 2) Indicate a specific technological method that guarantees that certain technical requirements for the product are met.

A drawing is a projection image of a product or its element, one of the types of design documents containing data for the production and operation of the product.

A drawing is not a drawing. The drawing is made according to the dimensions and scale of the real product (structure) or part of the product. Therefore, to carry out drawing work, the work of an engineer with sufficient experience in producing drawing work is necessary (however, to beautifully display a product for booklets, it is quite possible that you will need the services of an artist who has an artistic view of the product or part of it).

A drawing is a constructive image with necessary and sufficient information about dimensions, manufacturing method and operation. You can download the drawing presented on this page for free.

A drawing is an artistic image on a plane created by means of graphics (brush, pencil or specialized program).

A drawing can be either an independent document or part of a product (structure) and technical requirements related to surfaces processed together. Instructions for joint processing are placed on all drawings involved in the joint processing of products.

For more information on drawings, technical requirements for design and indication of manufacturing methods, see GOST 2.109-73. See the list of standards for the development of design documentation here.

Information for ordering drawings:

In our design organization you can order a drawing of any product (both parts and assemblies), which will include a channel drawing as an element of the design documentation of the product as a whole. Our design engineers will develop documentation in the shortest possible time in strict accordance with your technical specifications.

How to correctly decipher the channel symbol

The type of channel symbol depends on its type (GOST) and the material from which it is made. For example, a 30P channel of normal rolling precision B, made of steel St3, fourth category, first group, has the following designation:

- Channel 30P-V GOST 8240-97/St3sp4-1 GOST 535-88

The same profile made of steel 09G2S with increased rolling precision, strength class 345 is designated:

- Channel 30P-B GOST 8240-97/345 GOST 19281-89

A bent equal-flange channel with dimensions 300x80x6 of profiling accuracy A (high), from a strip of increased rolling accuracy B, of the second category, made of St3sp steel is designated:

- Channel A 300x80x6 B GOST 8278-83/2-St3sp GOST 11474-76

Channel and material

Depending on the required characteristics of the finished product, steel of various grades can be used for its production.

With the hot-rolled method, the main raw materials are steel St3 (semi-quiet and calm), 09G2S, 17G1S, 10ХСНД and 15ХСНД. The last two are characterized by increased corrosion resistance and lower weight.

Bent rolled products are made from steel St3ps5, 09G2S, 08ps, 1ps, 2ps and others.

Since almost all of the above alloys are susceptible to corrosion, galvanizing can be done if necessary. This significantly extends their service life, especially if they are used outdoors or in high humidity conditions.