Types of hand tools by purpose

During the repair process, a craftsman may need various metal work: bending, chopping, drilling, filing, threading.

Solving the listed problems is possible using specialized plumbing tools, which are always at hand. Based on its purpose, it can be divided into several main groups. Below we will look at where each device is used. Impact and marking tools:

- Machinist's hammers and blacksmith's sledgehammers are used in many technological operations: chopping, bending, straightening.

- Punch punches are used to mark metallic as well as non-metallic materials.

- Chisels are used to cut metal.

- Crosspieces allow you to cut out keyways and grooves. They differ from chisels in having a narrower cutting edge.

- Using scribers and compasses, precise marking work is carried out.

- The bits are designed for punching holes in sheet metal.

In the process of performing plumbing and assembly operations, various pliers are used. This includes pliers, pliers, round nose pliers, tongs, and pliers. A bench vice is used to fix parts for subsequent processing.

Thread cutting tool:

External threads are cut with dies, internal threads with taps. Die holders and wrenches are devices for rotating hand-held thread-cutting tools.

Devices for cutting and machining metal:

Files and needle files are used for filing parts and workpieces. Hacksaws are used to cut sheet and profile metal, and also perform other types of work. Hand shears are designed for cutting sheet metal. Thin layers of material are removed from parts using scrapers. As a result of scraping the mating surfaces, their tight fit and tightness are ensured.

Hole making tool:

- Holes in the workpieces are made using drills. They are made from alloyed carbon steels.

- Reamers allow high-precision machining of cylindrical and conical holes.

- Countersinks are used to process recesses and chamfers of drilled holes for the heads of screws, bolts, and rivets. Using counterbores, the end surfaces are cleaned.

- Countersinks are used to increase the diameters of drilled holes, improve their accuracy and quality.

Tool for assembling threaded connections:

- Spanners. By design, they can be horn or cap, end, hinged, adjustable, ratchet. Choosing the right version ensures ease of work in hard-to-reach places.

- Torque wrenches allow you to adjust the tightening force of fasteners.

- Plumber's screwdrivers for screws and screws with straight or Phillips slots are indispensable in production, construction, and repair.

Measuring devices include:

- Rulers, roulettes.

- Vernier tool. This includes calipers, height gauges and depth gauges.

- Micrometric instruments, bore gauges.

- Length measures: plane-parallel end, angular prismatic, line.

- Test plates, probes, straight edges, squares.

- Radius and thread templates.

- Instruments for measuring angles: protractors, levels, sine rulers.

- Indicating devices.

Thus, hand tools allow you to solve most problems when working with metal.

What are the types of metalworking tools?

Metalworking tools come in the following types:

- Cutting machines designed to separate metal sheets or any other workpieces into parts. They are made of hardened or alloyed steel, as well as alloys based on them, the hardness of which exceeds the strength of the material being processed.

- Abrasive, used for roughing or finishing workpieces: polishing, grinding, stripping in order to achieve the desired level of roughness. Unlike cutting tools, they can be flexible and ductile. They are made from various materials that are resistant to friction and have high strength.

Cutting tools are only metal, hard, retaining their shape and geometric dimensions during processing and after its completion. The cutting part has a wedge-shaped shape, which allows it to easily penetrate layers of material and remove part of the metal under mechanical influence.

Abrasive equipment can be rigid (circles) or flexible (belts, sandpapers, fabrics). The general similarity is the presence of an abrasive layer on their working surface, which can process the outer layers of the material depending on the force applied. Flexible abrasives allow you to clean non-linear surfaces.

Read also: DIY converter 12 220 1000W

According to the method of mechanization, tools are of the following types:

- Mechanical ones are intended for manual processing. They are used for one-time or permanent private or industrial use. They are characterized by simplicity of design, low productivity and cost of processing.

- Automatic ones are used for mass production of parts. They provide high processing productivity, functionality, cutting accuracy, and minimize labor costs. They have a complex design, require periodic maintenance, and differ from manual ones in the low probability of producing defective parts.

The process of removing chips by all methods has the same principle. The cutting part, under the influence of the applied force, acts on the surface being processed, cuts into it, deepens and chips or chips are removed.

Chip shear typically occurs at an angle of 135 to 155 degrees. Tool wear and cutting quality depend on the cutting angle and turning of the cutting edge. When processing metal, heating occurs, so it is necessary to choose the optimal speed of action to prevent dulling of the cutting edge.

Locksmith work

Preparatory

- Marking

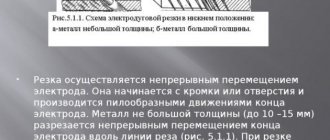

- Metal cutting

- Editing and straightening

- Bending

- cutting

Dimensional processing

- Metal filing

- Hole machining

- Processing of threaded surfaces

Fit

- Scraping

- Sawing

- Fit

- Fitting

- Lapping

- Finishing

- Polishing

First, a rough blank is created and markings are applied according to the drawing. Next, depending on the need, the workpiece is processed by chopping, cutting, bending, and straightening. Then dimensional processing is done, the part is precisely processed to size. And finally, the final finishing of the processed product.

We’ve sorted out the types of work, now let’s look at the plumbing tools themselves.

Tips for choosing metal cutting tools

When choosing metal cutting tools, consider the following recommendations.

- The best choice will always be a tool that is designed for specific operations on workpieces made of certain materials. Lists of suitable devices can be found in the process descriptions.

- Also note that many operations are performed using multiple tools - for roughing, semi-finishing and finishing. A great example is cutting external and internal threads.

- The second factor, which also has a strong influence on the choice of metal cutting tools, is the type of equipment used. Purchase devices with suitable fastenings. Such tools are fixed as securely as possible. Runout is reduced to a minimum. At the same time, the quality of processing of blanks and products is significantly improved.

- Study technological maps, which indicate the main cutting parameters. This will help you select tools whose working and main parts are made of suitable alloys. For example, for operations on workpieces made of difficult-to-cut materials, carbide metal cutting tools are used.

- Consider performance. It is greatly influenced by the wear resistance and quality of the tools. For processing workpieces and products at home, devices in the low price segment are best suited. At enterprises specializing in serial and mass production, they usually do not skimp on the quality of cutting tools for metalworking. This is especially important in the manufacture of complex and high-precision parts and products.

- Purchase devices of suitable design. Maximum productivity and savings are achieved by using prefabricated cutting tools. The parameters of their working parts can be quickly changed.

- Achieve high efficiency. Tools and equipment must use the maximum amount of available power without compromising the quality of metalworking and productivity.

Types of plumbing tools

Measuring

- Rulers, tape measures - length measurement, quality and accuracy of metal rulers justifies their price

- Feeler gauges are a set of steel plates used to determine the thickness of the gap

- Vernier calipers - allows you to measure the internal size, external size and depth, like a ruler, a very accurate and high-quality tool

- Micrometer - allows you to measure distances with an accuracy of hundredths of a millimeter

- Protractor - measuring angles

Marking

- Scribbler - a steel rod with sharp, hardened ends

- Marking compass - for drawing circles and roundings on the marked workpiece

- Punch punch - for making small indentations on the workpiece marking lines

- Articulated pliers tools - pliers, forceps, pliers and their varieties

- Vice - for clamping and further processing of workpieces

- Clamps - allow you to tightly press parts together, for example when gluing

- Hammer - a device for bending, straightening and hammering

- A sledgehammer is the same as a hammer, only 10 times heavier

For cutting metal

- Side cutters - cutting through thin materials

- Hacksaw for metal - cutting metal, sawing

- Scissors - cutting metal sheets

- Chisel - cutting metal

- Kreitsmeiseli - for cutting keyways and grooves

For metal processing

- Files and needle files - removing a layer of metal by filing

- A scraper removes thin layers of metal from a part.

For machining holes

- Reamers - precision hole machining

- Countersinks - they are used to make chamfers and recesses for the heads of bolts, screws, rivets

- Countersinks - they are used to increase the diameters of holes

For thread cutting

- Dies - for cutting external threads

- Taps - for cutting internal threads

Assembly tool

- Screwdrivers - Phillips, slotted, hex, torx

- Wrenches - open-end, box, socket, hinge, adjustable, ratchet

- Torque wrenches - have adjustable torque

As you can see, locksmith tools have a very wide variety.

Types of metal processing

The following types of metal processing are available:

- Turning of surface layers of material on lathes. The rotating workpiece is affected by a cutter that can move along the entire length of the workpiece.

- Planing on transverse or longitudinal type machines. When the part moves back and forth relative to the cutter or vice versa, layers of metal are removed in a given plane. The movement of the cutter along the surface is intermittent.

- Chiseling of workpieces on slotting machines or manually. The equipment moves relative to the part along a reciprocating path along the selected axis. Allows you to simultaneously remove large pieces of material from the end part.

- Drilling on machines or manually. When the drill rotates around its axis, metal layers are removed and a cylindrical hole is formed. The translational movement of the drill is performed along the selected centerline.

- Milling on machines. A reciprocating movement of the cutter is carried out, rotating around an axis parallel to the surface of the workpiece and a layer of metal of a certain thickness is removed. Some machines implement movement of the workpiece relative to a rotating cutter.

- Grinding on machines. It is performed by direct contact of a rotating grinding wheel or sanding belt with the workpiece. It is permissible for the workpiece to move relative to the abrasive part of the equipment, or vice versa.

Household or professional

Also, hand tools should be divided into household and professional. What are the differences? What are the advantages and disadvantages?

Professional plumbing tools are significantly more expensive than household ones. Its price is justified by ergonomics, wear resistance, durability, and weight. Buy this tool for daily use. Any mechanic will confirm the advantages of professional hand tools.

Household hand tools are inferior to professional ones primarily in quality. Both in terms of materials used for manufacturing (lower quality steel, powder metals) and in execution (burrs, inconsistencies). But the price, in turn, is minimal.

Well, we’ve sorted out the main aspects of a mechanic’s tool, let’s summarize. Of course, all of the above assortment is not needed for the home. First of all, you need to decide what locksmith operations you will perform. Based on these considerations, select the devices you need. Well, for the home you need some kind of universal set. In my opinion, it will be quite enough to assemble the following plumbing tools and accessories at home:

- ruler;

- roulette;

- center punch;

- pliers;

- needle nose pliers;

- 300 gram hammer;

- side cutters;

- hacksaw for metal;

- screwdriver with a set of bits;

- adjustable wrench;

- set of wrenches.

When purchasing, pay attention to quality. It’s not worth taking the cheapest tool, but there’s no need to take the most expensive one for household needs either.

How to Choose the Right Tool for Metalworking

Criteria for choosing a tool for metal processing:

- type of metal being processed - mechanical or chemical properties;

- cutting conditions - the ability to use a power tool or a manual one;

- cutting method - manual, automated;

- type of work performed - cutting, chiseling, drilling, planing, grinding, threading;

- processing accuracy - coarse or fine;

- surface relief - flat, cylindrical, conical;

- metal strength;

- work performance requirements;

- ease of processing workpieces;

- cutting depth, cutting tool feed speed;

- resistance of the metal to elevated temperatures that can occur as a result of rapid processing.

When the cutting part is heated during processing, the tool partially loses its hardness and is therefore susceptible to irreversible changes in properties and damage. This property is called red fastness.

The red resistance is also affected by the sharpening angle of the cutting edge, since the area of contact with the surface of the workpiece depends on it. A smaller angle reduces friction, increases wear and reduces the need for significant machining forces.

Reliable tools are made from the following materials:

- Tool steel (high-speed, alloyed, carbon), capable of not losing its properties at high cutting speeds and heating up to +250 0 C.

- Carbide steel has increased wear resistance and strength 4 times higher than analogues based on tool steel. When processing workpieces, the permissible heating reaches +620 0 C. It is used when cutting high-strength heat-resistant steel grades.

- Cutting inserts made of aluminum oxide alloyed with molybdenum and chromium, reinforced with metal ceramics. Resistance to heating up to +900 0 C. A special feature of the material is its fragility, so during operation it is necessary to avoid shock mechanical influences.

Read also: DIY dump trailer for walk-behind tractor

The quality of metal-cutting equipment is determined by the following parameters:

- cutting edge sharpening angle;

- properties of the material from which the working part was made;

- characteristics of cutting depth, processing speed and feed;

- during automatic processing, the presence of channels for chip removal, chip curlers, and structural elements for cooling.

It is recommended to pay attention to the products of the following manufacturers:

- CJSC "New Instrumental Solutions";

- Moscow Tool Plant LLC;

- ISCAR (Israel), whose official distributor in Russia is Intechservice LLC;

- Arno (Germany);

- Sumitomo (Japan);

- Paul Horn GmbH (Germany).

When purchasing, you need to consider the manufacturer and technical characteristics of the tool. Cheap models, especially of electrical equipment, do not always correspond to the declared parameters and are capable of operating at maximum loads. Savings can lead to frequent equipment repairs or complete replacement.

Appearance

Product design is sometimes a determining factor when purchasing. Manufacturers strive to win customers by any means and methods. As you know, the “prettier” a product is, the more attention potential buyers pay to it. And removing the weld seam will significantly increase this “attractiveness”.

If manual metal milling machines are not able to cope with their work one hundred percent (this mainly concerns non-professional tools or cheap fakes), then the reputation of the metal structure manufacturer will seriously suffer. Therefore, it is better to choose equipment from a well-known brand - it may be more expensive, but it is more reliable.

- cleaning the area from scale and slag;

- removal of reinforced seams;

- preparing the area for finishing.

These processes require a professional approach, certain knowledge and skills. A professional tool is also responsible for the appearance of the metal structure.

- removing welds with grinding wheels and cleaning the heat-affected zone from foreign formations;

- aggressive treatment of joints with fiber or flap wheels;

- cleaning seams in hard-to-reach places using a specialized tool.

- hand tool;

- machines;

- special cleaning stations.

Which equipment should you prefer?

- higher productivity due to faster processing speed;

- no additional costs for abrasives and consumables;

- “clean” and efficient work thanks to the ability to adjust the weld removal height.

- convenience and simplicity when working with the tool;

- high speed processing of metal products;

- reliability and quality;

- compactness.

Some useful recommendations for working with hand routers 1. As in any other matter, rushing when working with a router is unacceptable! Proceed to the task slowly, so as not to spoil the workpiece as a result. 2.First, double-check all the necessary settings. Pay attention to whether the stops are secured and whether there are any obstacles in the way. 3.Do not immediately set the tool to high speed: set the adjustment wheel to mark 3 or 4. Fulfilling this condition is especially important when milling to a depth of more than five millimeters. Otherwise, you risk overheating of the equipment. Hold the instrument with the front side facing you. 4. To reduce the risk of side support equipment running off the line, press it against the work with one hand and guide it with the other. 5.Always check that the cutter is securely fixed! If it suddenly takes off at high speed, it can lead to dire consequences! 6.Settings can be additionally double-checked using a ruler or square if you doubt the accuracy of the depth or distance to the edge. 7. The metal workpiece being processed must be secured as securely as possible to perform the work efficiently! 8.Before you start working with a new tool, take the time to carefully study the operating instructions! You will certainly gain a lot of useful information for yourself.